Week06

There are two assignments in this week:

Moulding vs. Casting

Moulding is the act of creating the cavity that carries a negative or reverse impression of an original model. Moulds can be made of a rigid material, such as plaster or more commonly, a flexible material such as rubber.

Casting is the act of pouring liquid material into the cavity of a mould. After a period of time, this liquid will cure via chemical reaction or cooling. The solidified part is also known as a casting.

Why casting and moulding? We have different materials to use unlike 3D printing It is good for producing large quantities of the same thing

Limitations:

We cannot do undercuts.

The precision is limited to the instrument (cutter diameter).

The depth is also limited to the instrument length.

Reference

Task 1 - The group assignment

The main goal of this assignment is to explore the material which we will need in the individual assignment later. Each two students work on one material and share the result with others in data sheet.

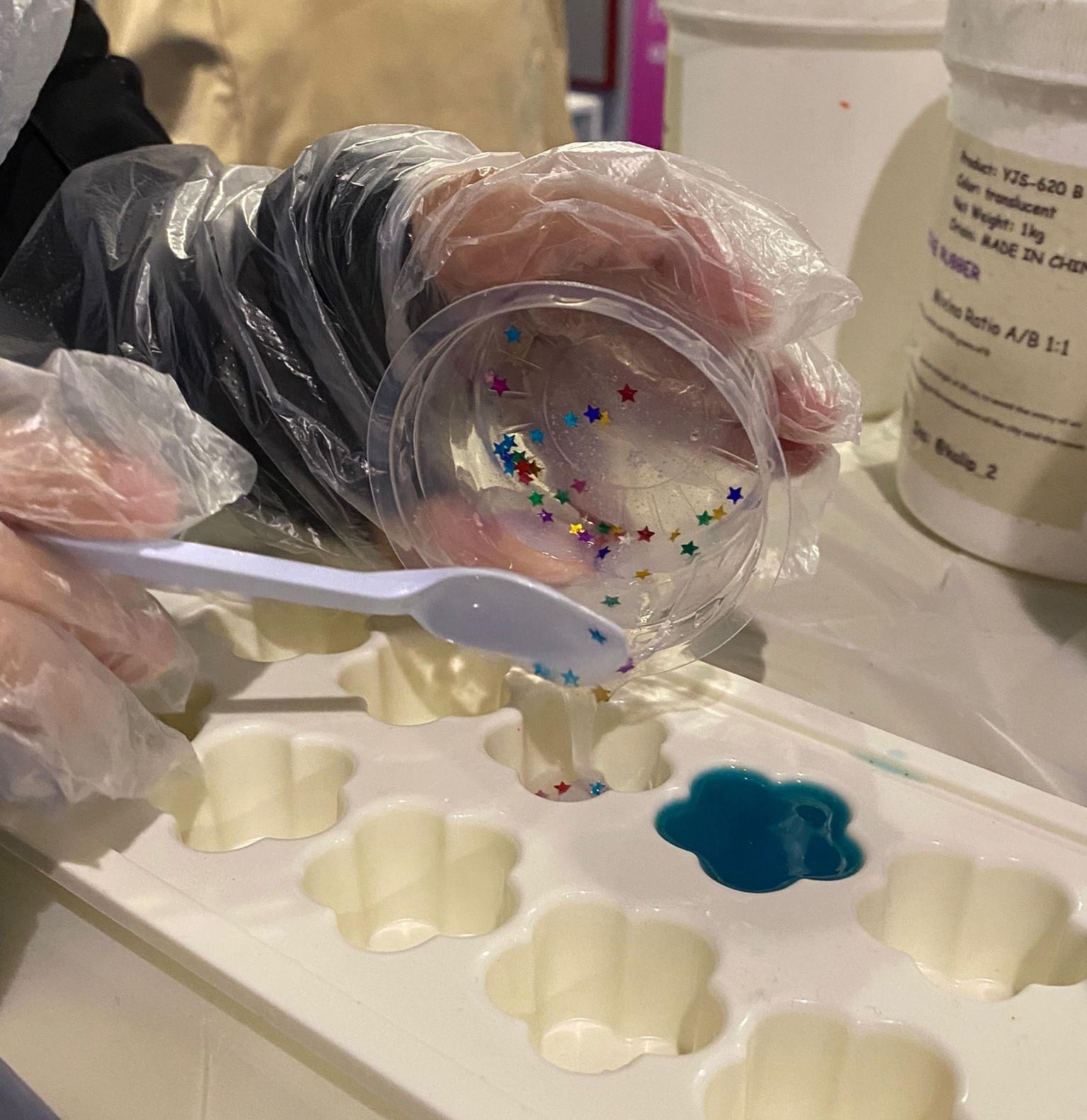

My friend Kawther and I worked on silicon, we start with searching about it then we go to work depend on the information that we found.

![]()

![]()

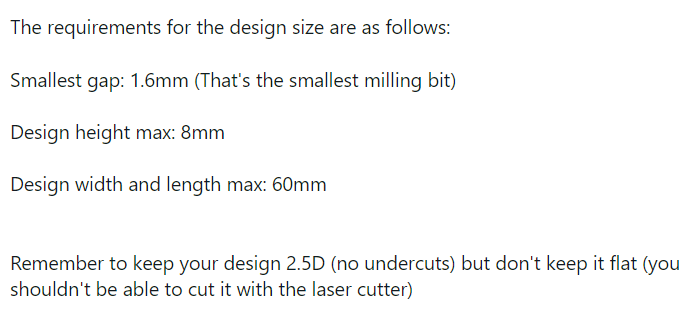

Task 2 - The individual assignment design

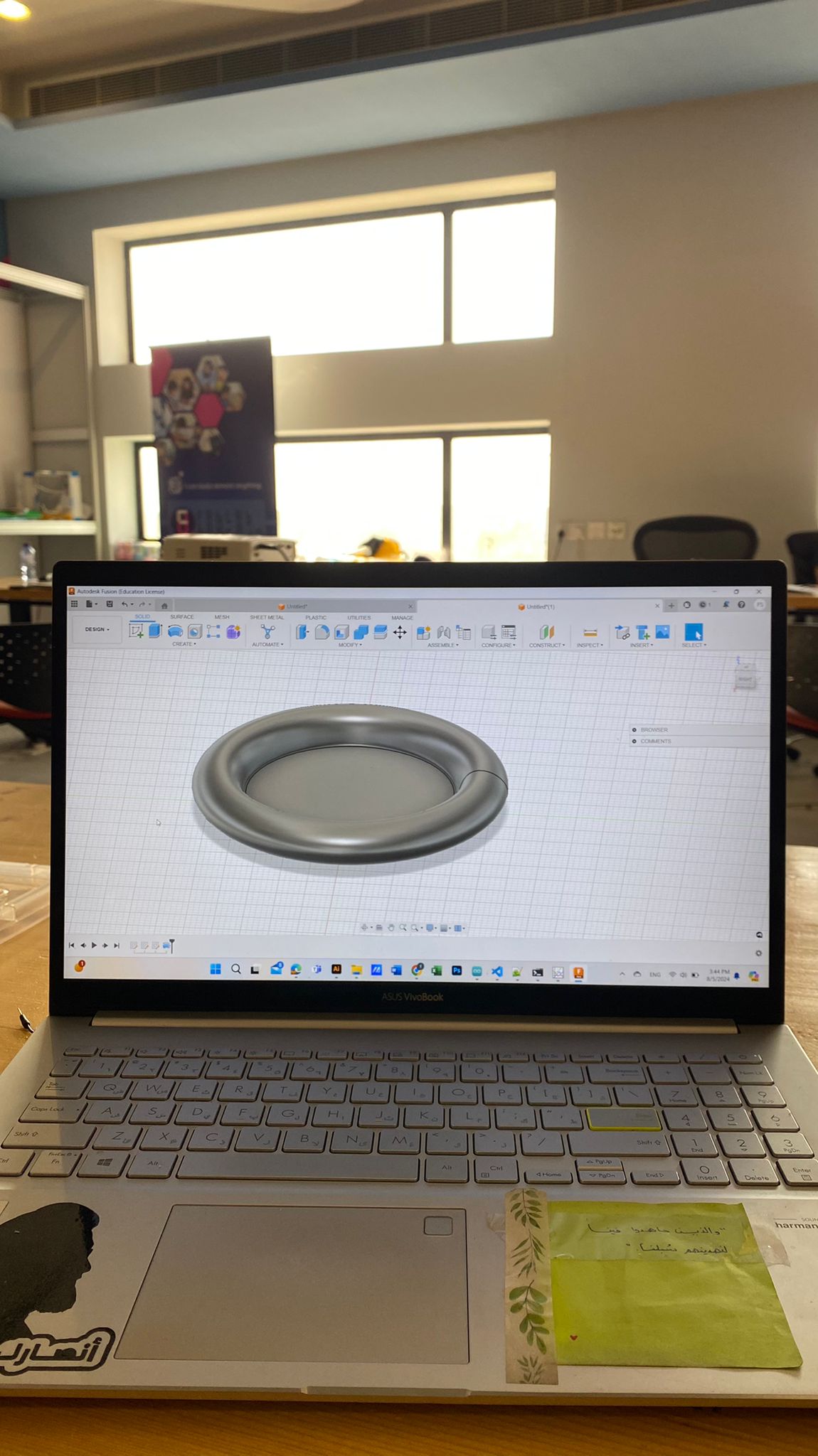

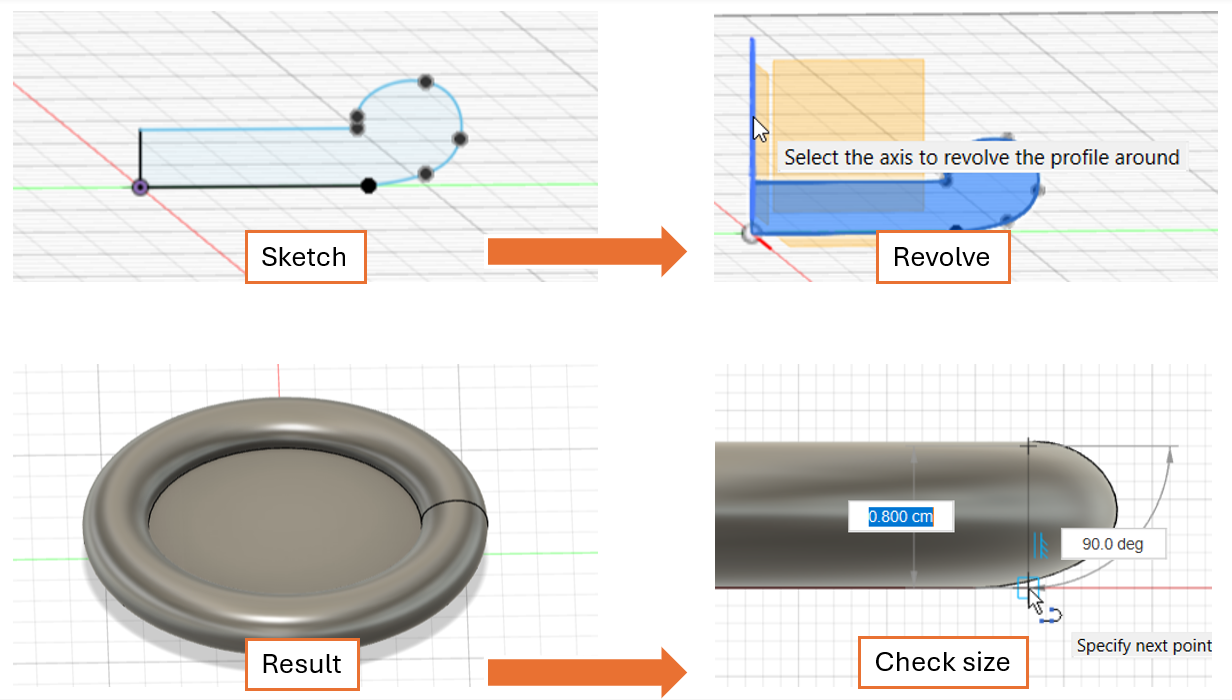

Before start design, it takes me time to think about something useful with small size and height, while there are some requirement for a design and I want some thing really useful.

I do the design by drawing a sketch then revolve it using revolve tool. I then recheck the sizes because of our limitation may some errors happen if there is a mistake.

Reference link

Task 3 - Milling

The aim of using this sensor is to know if the ball is jumping. The sensor read the acceleration in 3 dimensions, Gyro in 3 dimension and some related information.

While the sensor just take readings so we need to add something to figure out this is one jump.

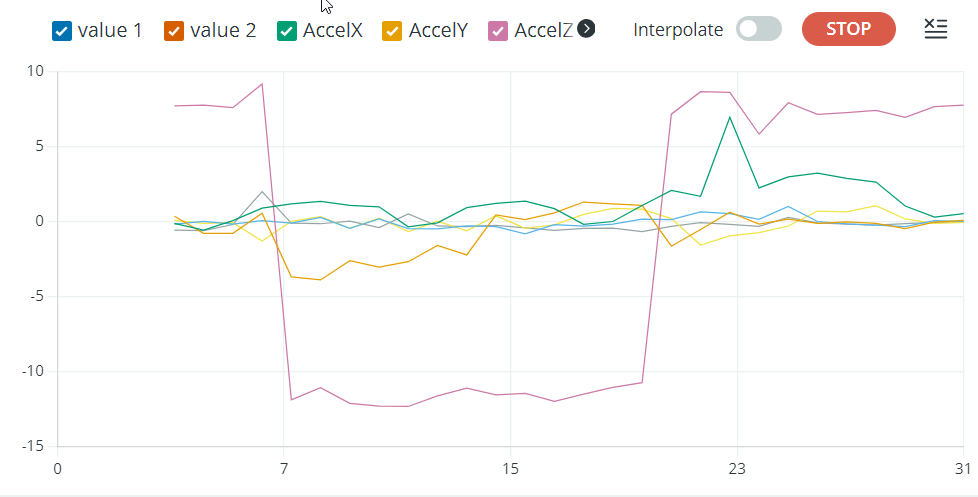

Firstly, I checked the values of multiple states for the sensor (jumping, moving, elc..) and I think that will work if we just ignore the small values and see where is the big value which show there is a real change, but I notice that the main change when the sensor jump is in the acceleration in Z direction, and we also know that the acceleration will be zero at the end of going up and down so this idea will not work good.

I then think about going with delta of Z acceleration because the main change is there as you can see in the graph below.

To get delta of Z acceleration I need to save the past Z acceleration then take a delta after reading the new value. But while I don't need all of this values so I add If statement to remove any value of delta Z-acceleration less that 3.

This is the code after editing: