FINAL PROJECT

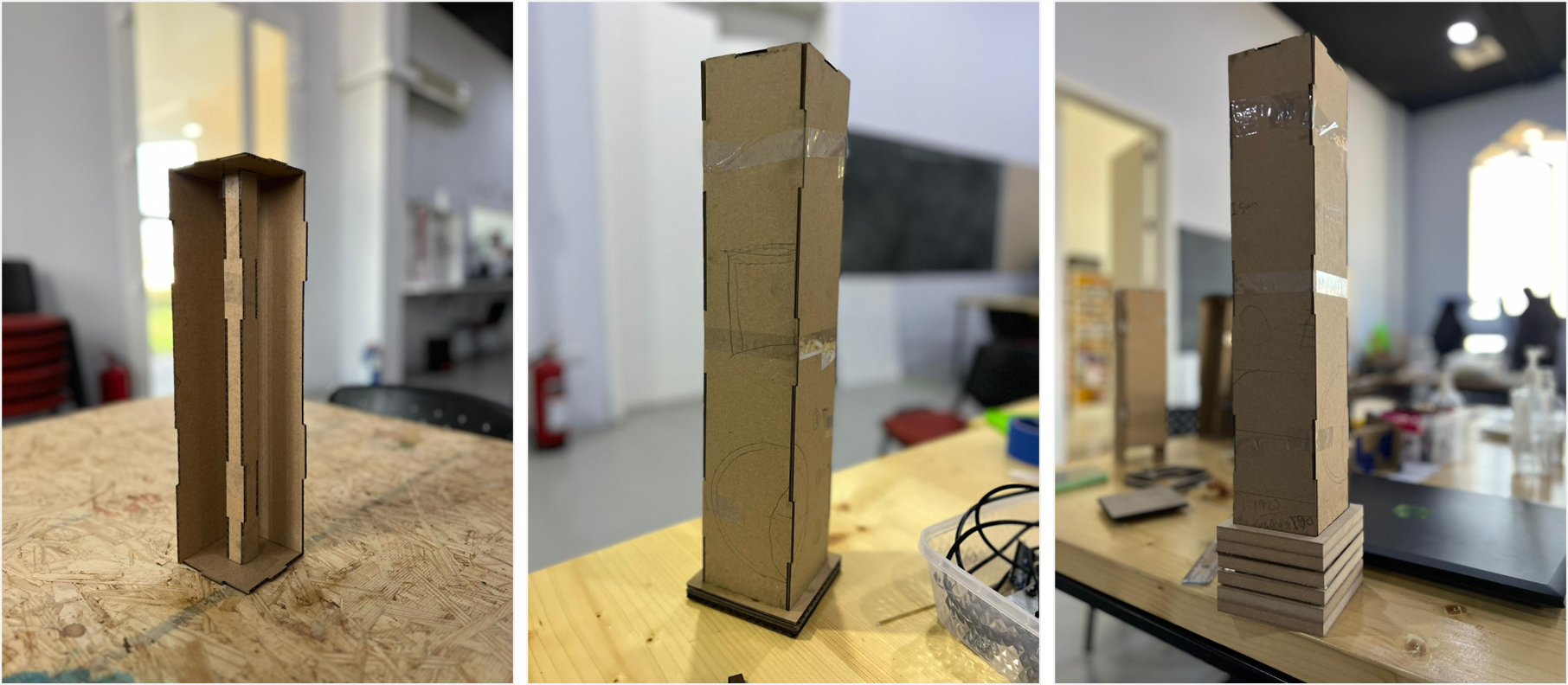

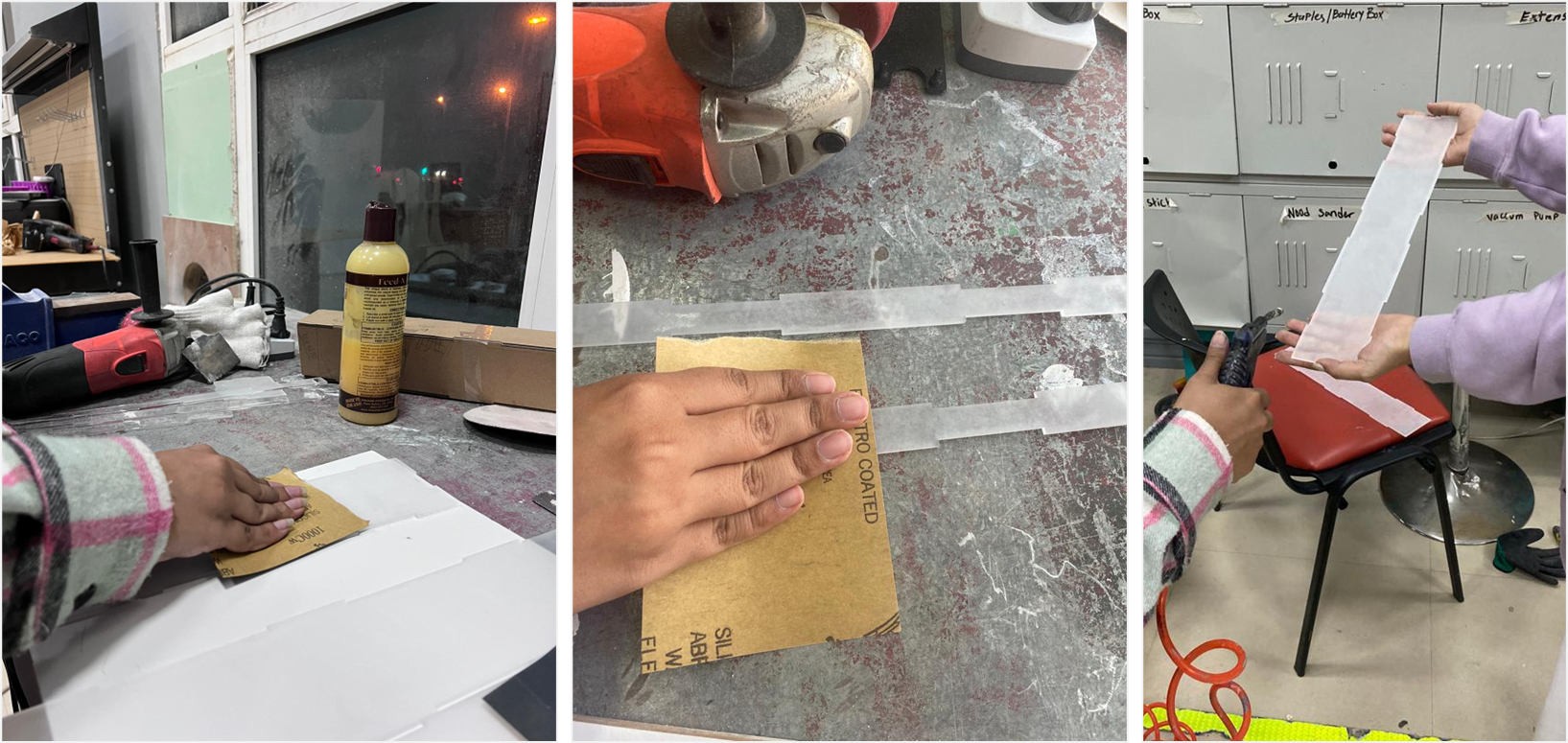

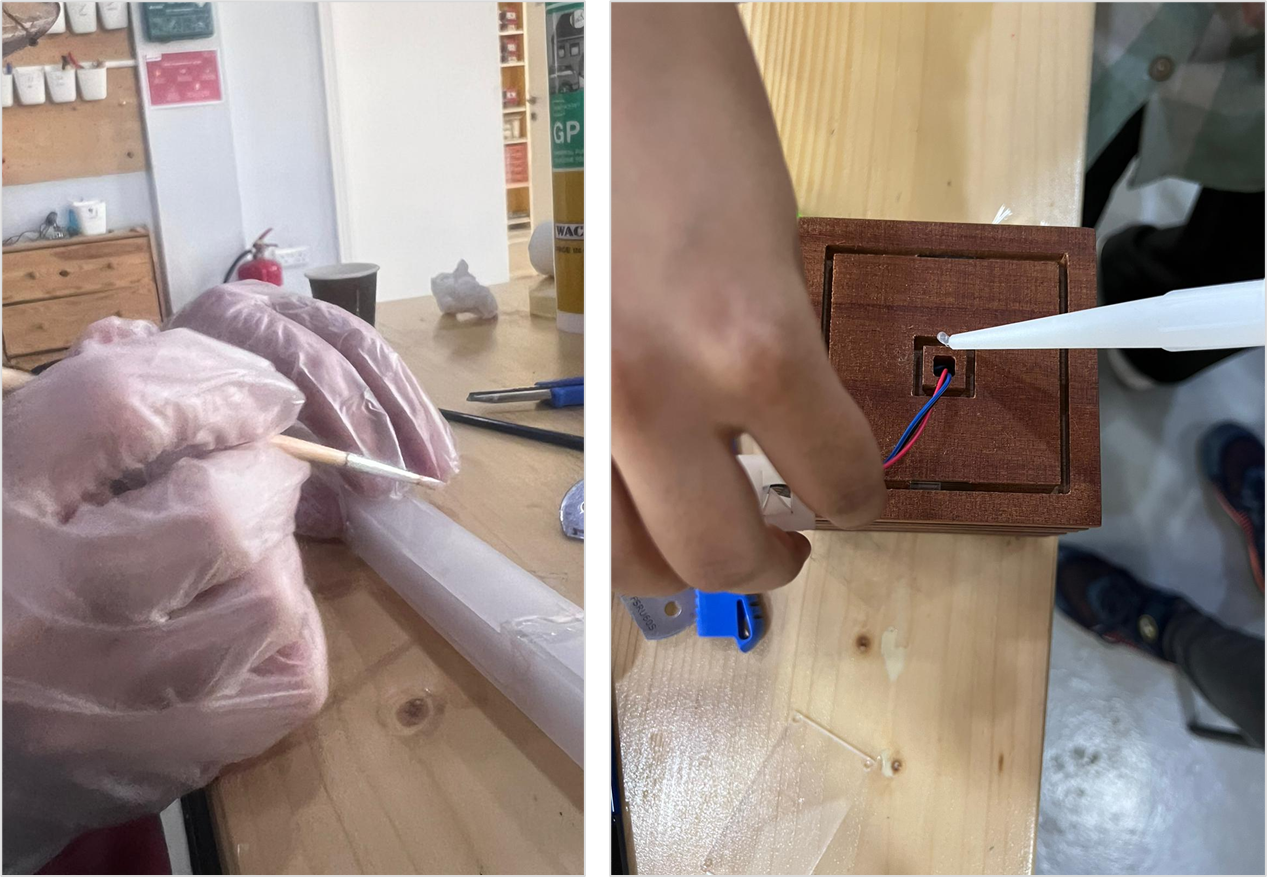

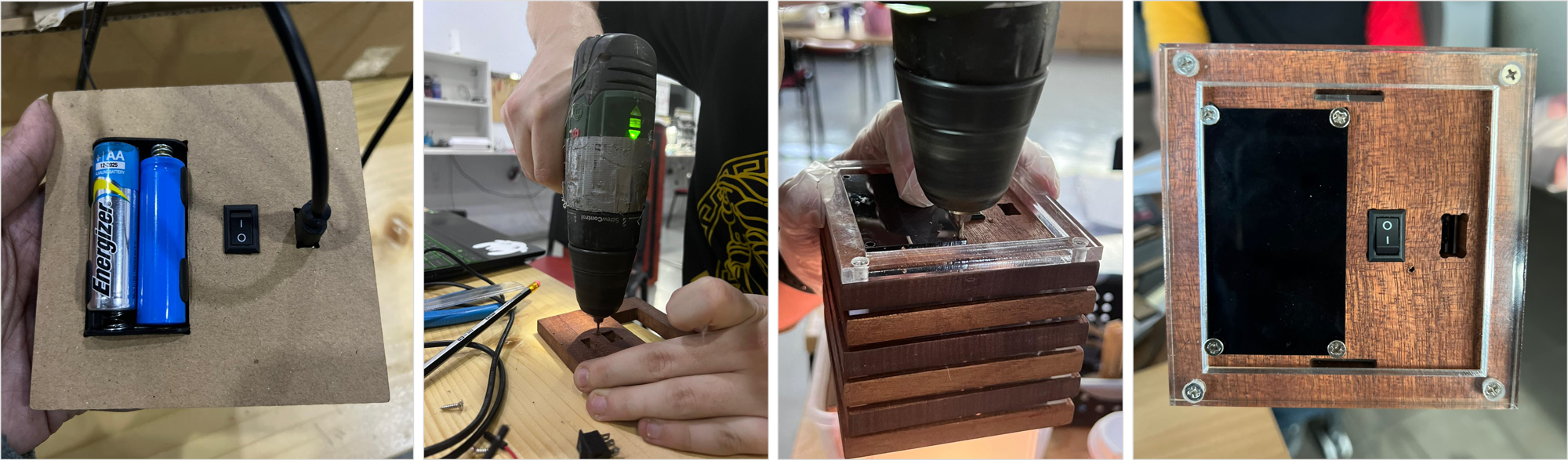

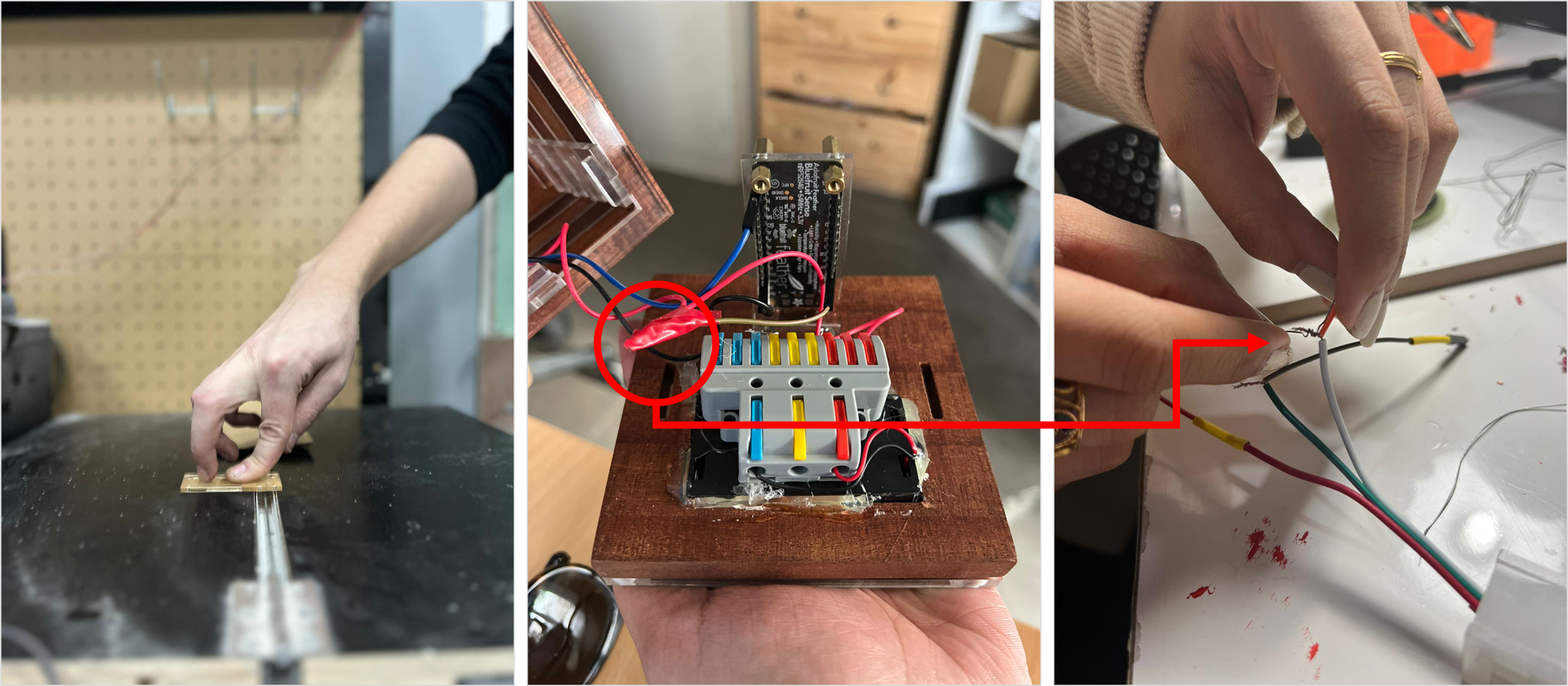

Welcome to our documentation of the final project (LENIO LIGHT). Me and my colleague Roaya worked on this project together, my documentation will be about the form of the light and hers is about the coding part.

Check out her page to see the coding process! ROAYA ALSAFFAF.

What is LENIO LIGHT?

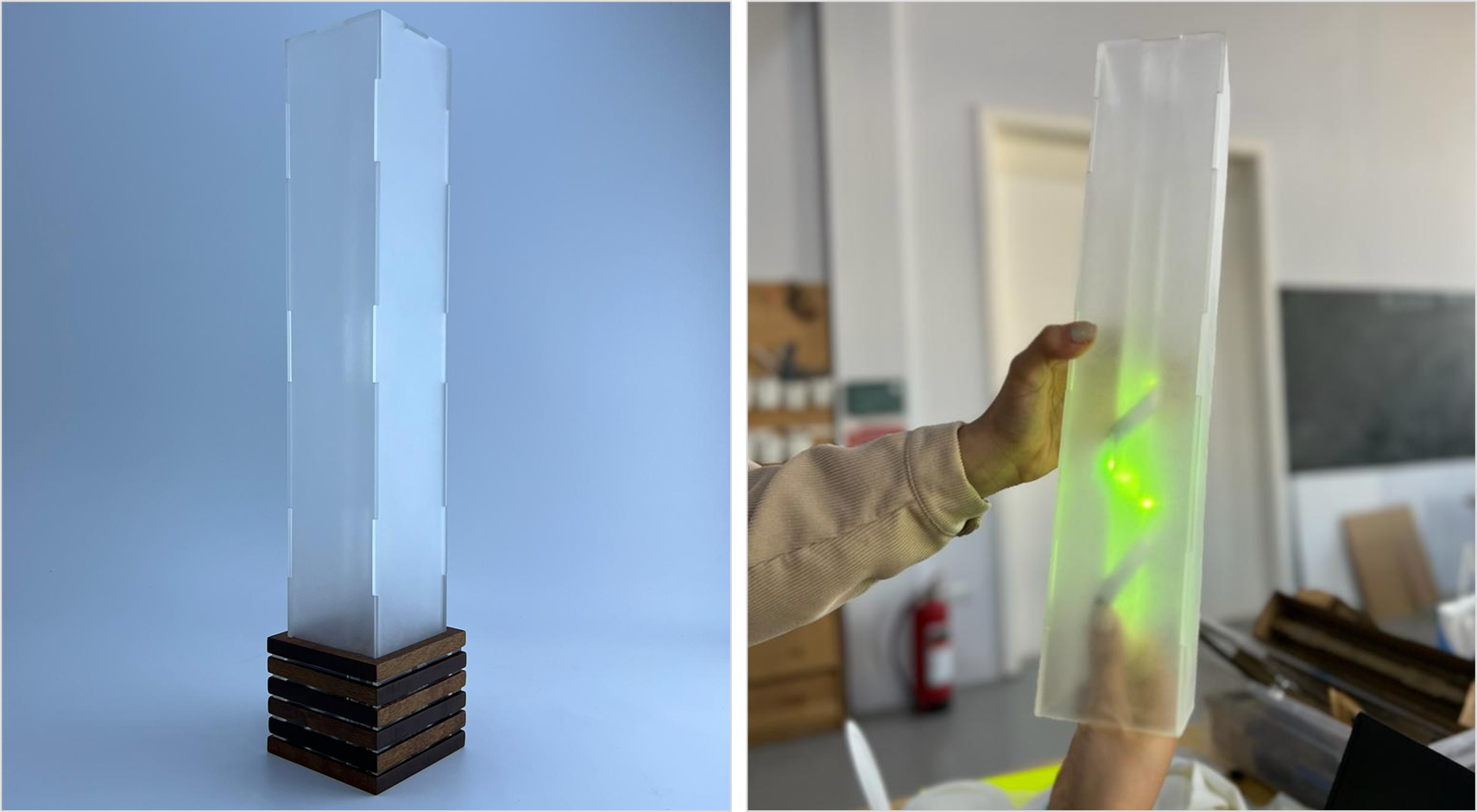

LENIO LIGHT is a smart and versatile lighting solution that combines convenience and innovation. It's a portable light that runs on batteries, making it easy to move around and use in different settings. The device is connected to an app, which allows users to access pre-programmed mood settings for activities such as sleep, relaxation, focus, screentime and migraines. Each mood setting has a specific RGB color and lighting level, which can help to improve one's mood and overall well-being. To save energy, Serenity Glow can be programmed to turn off and on at specific times, and it can even serve as an alarm clock. Its elegant design and advanced features make it a must-have for anyone looking to enhance their daily life.

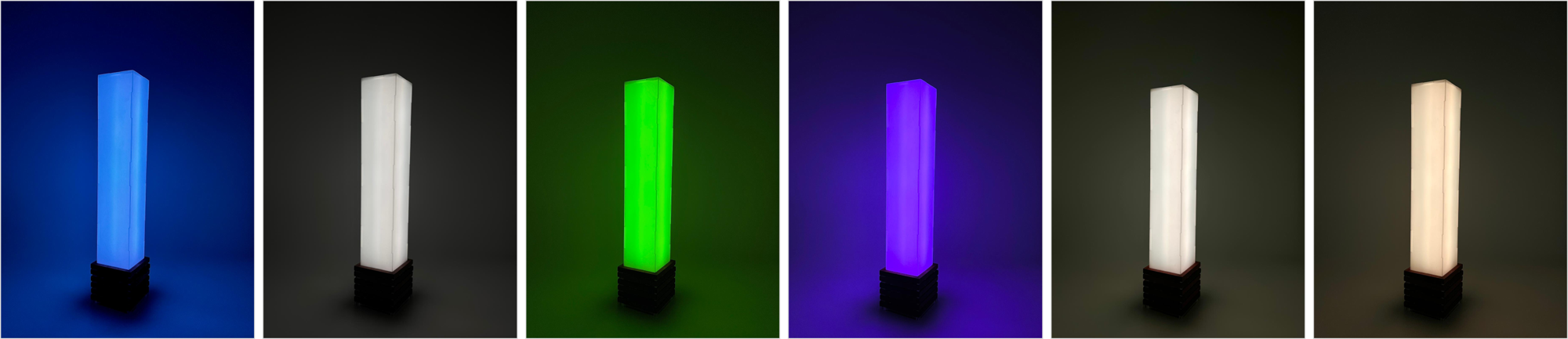

Colors and modes:

1- SLEEP MODE Blue light suppresses the body’s release of melatonin, a hormone that makes us feel drowsy and sleepy.

2- FOCUS MODE Warm white light has a yellow-orange hue thar is believed to reduce eye strain and improve focus by creating a calming and conducive environment.

3- MIGRAINE MODE Green light of a specific wavelength and intensity reduces the frequency and intensity of migraine headaches as it has zero blue light.

4- RELAX MODE Purple light can help in reducing emotional and mental stress. The nervous system and eyes are linked with this secondary colour.

5- SCREEN MODE The yellow light helps in reducing the amount of blue light exposure and can make screen time more comfortable for the eyes.

6- READING MODE Amber light is a type of warm-toned light that is often used for reading, as it is believed to be easier on the eyes compared to cool-toned white light.