COMPUTER CONTROLLED CUTTING

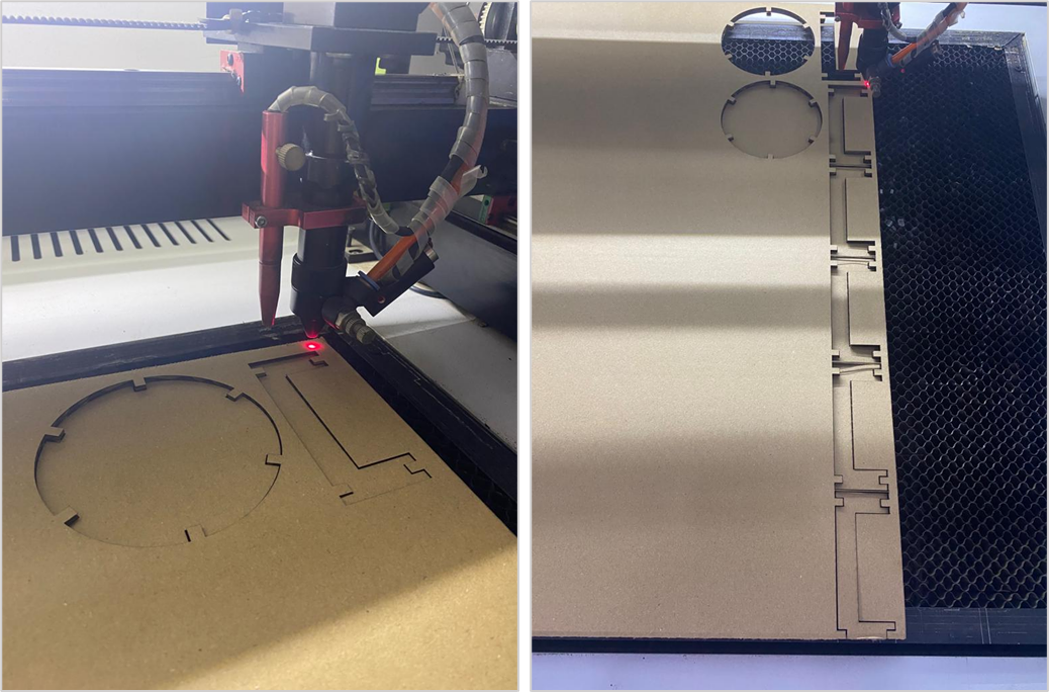

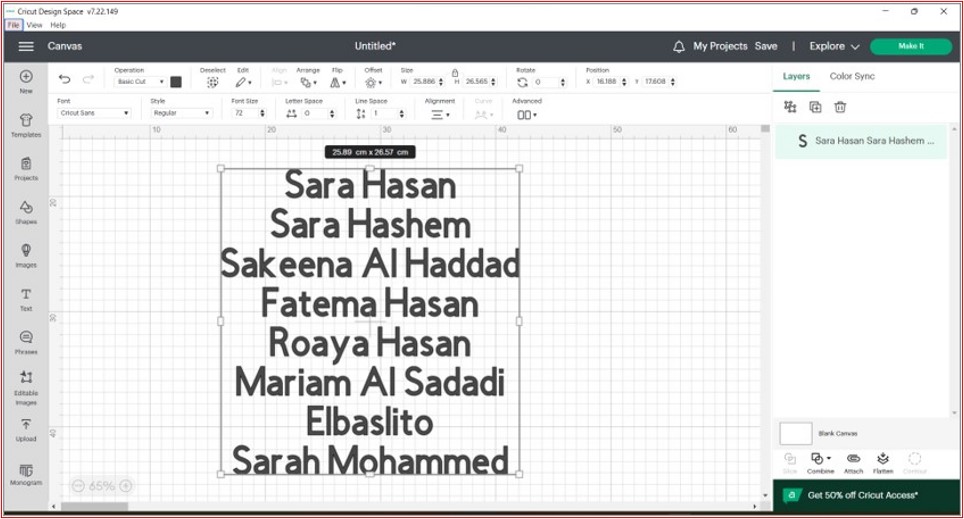

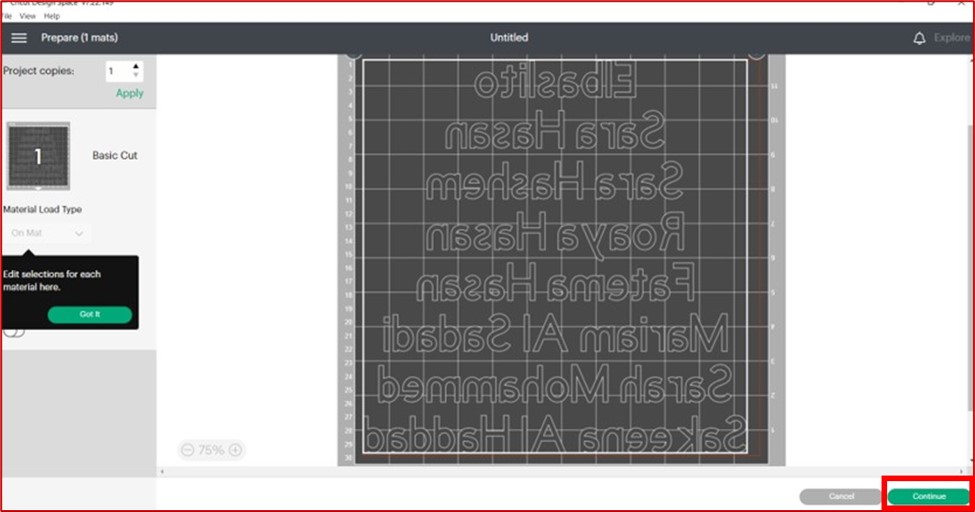

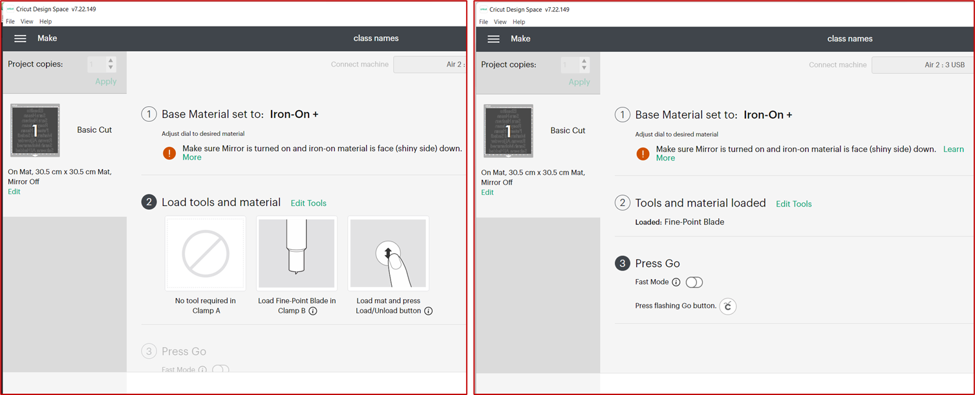

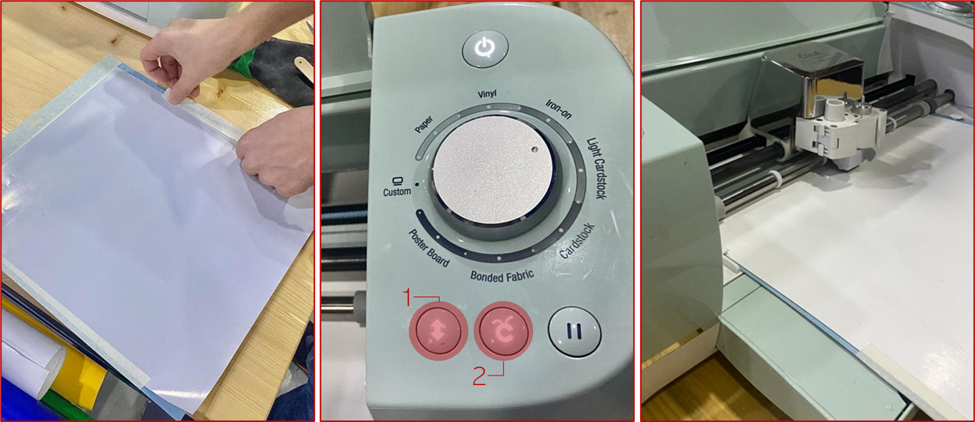

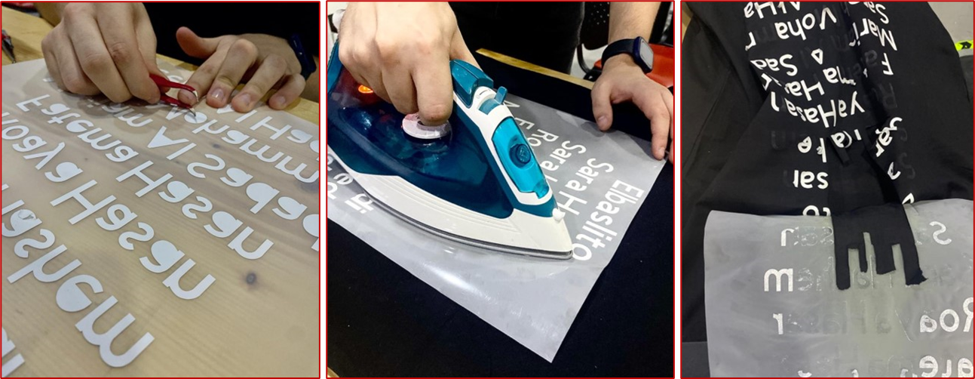

We started the practical work on the third week of the program. The team intoduced two machines to us, the first one was the lasercutting machine and the second one was the vynil machine, and we experminted with each machine, individually and in groups.

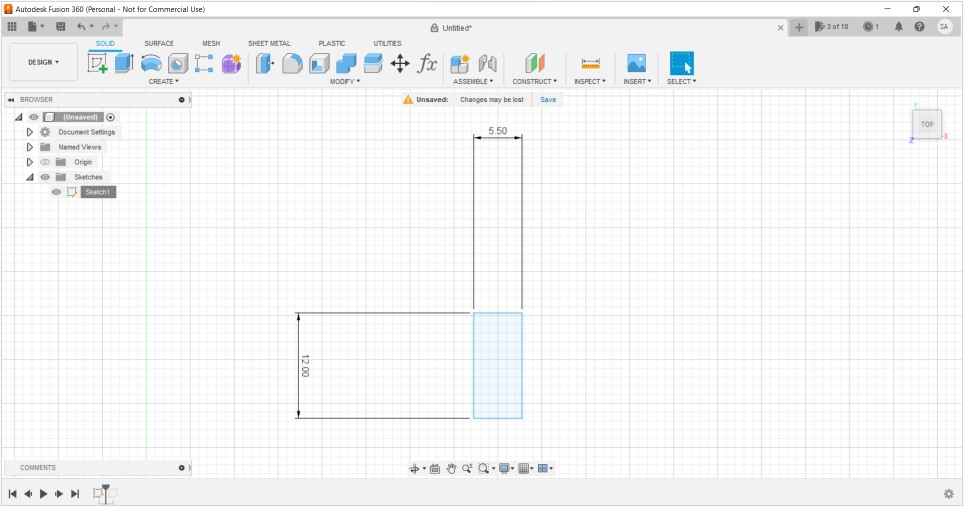

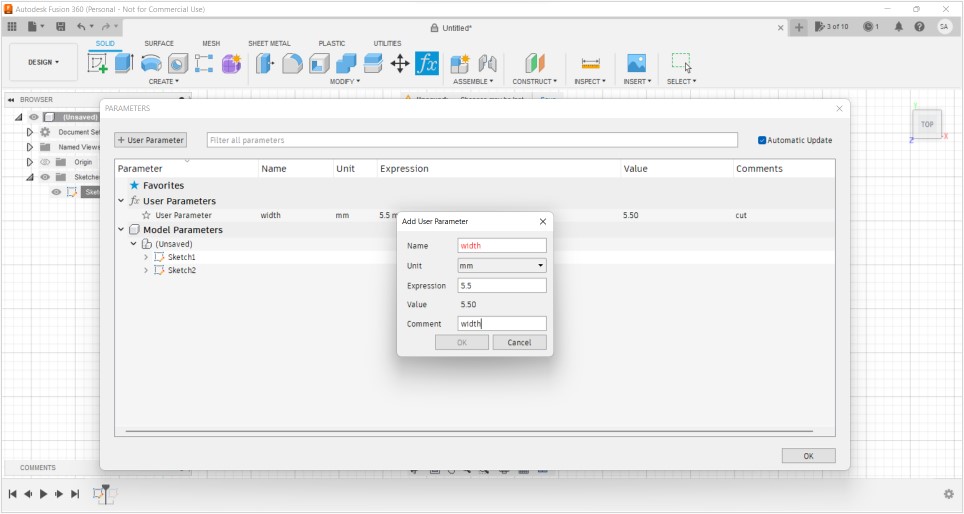

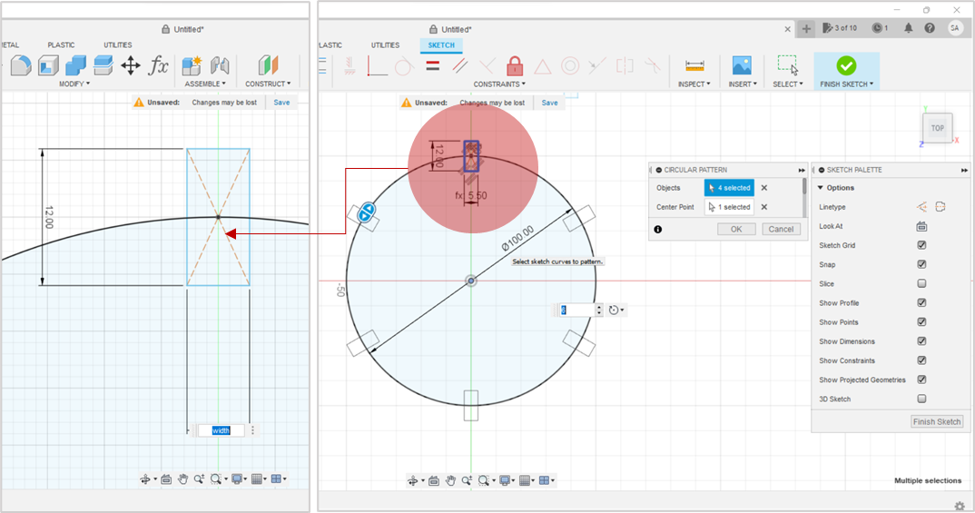

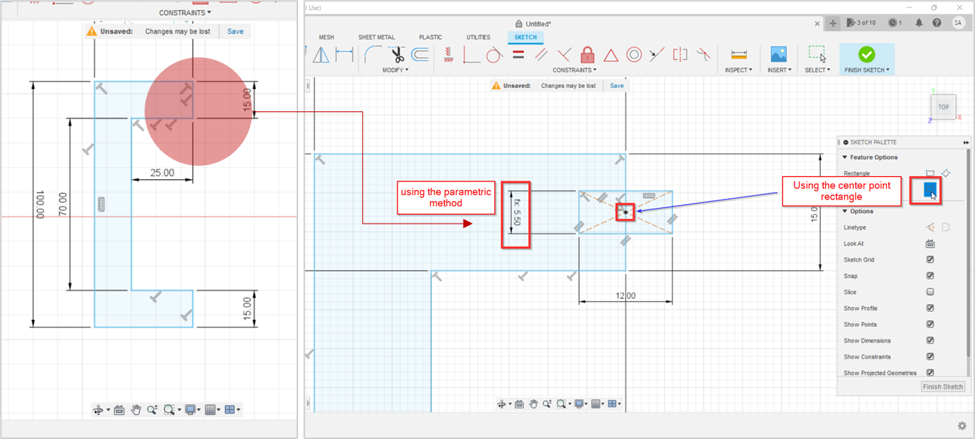

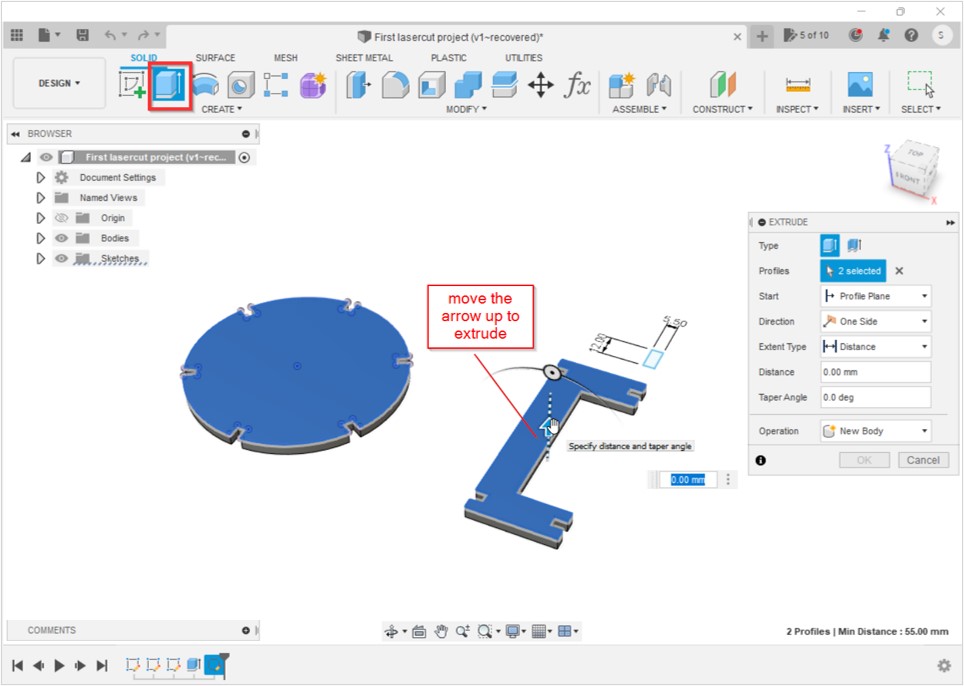

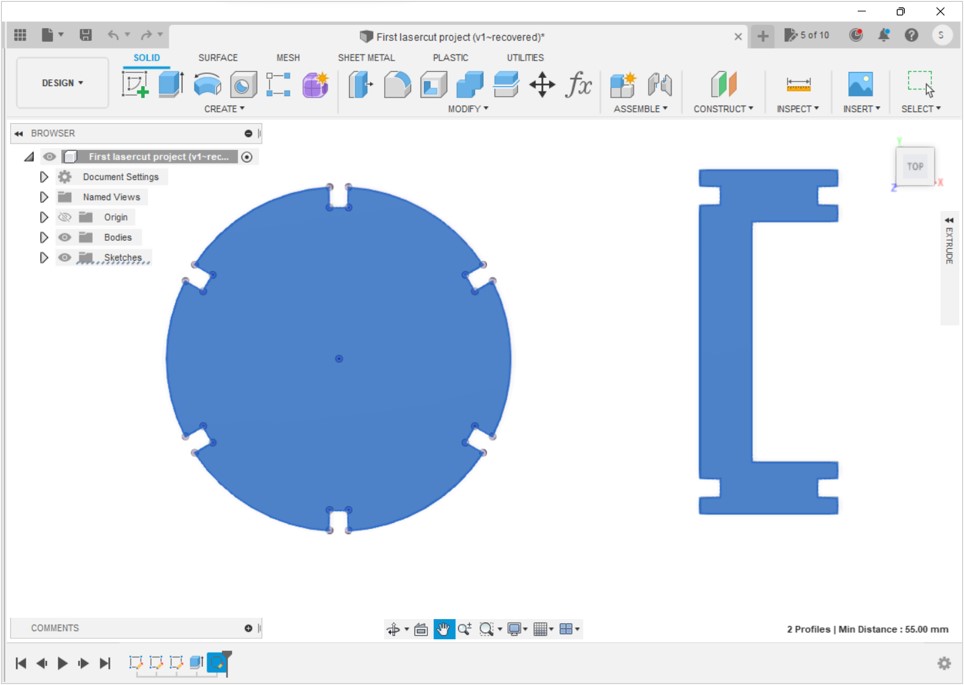

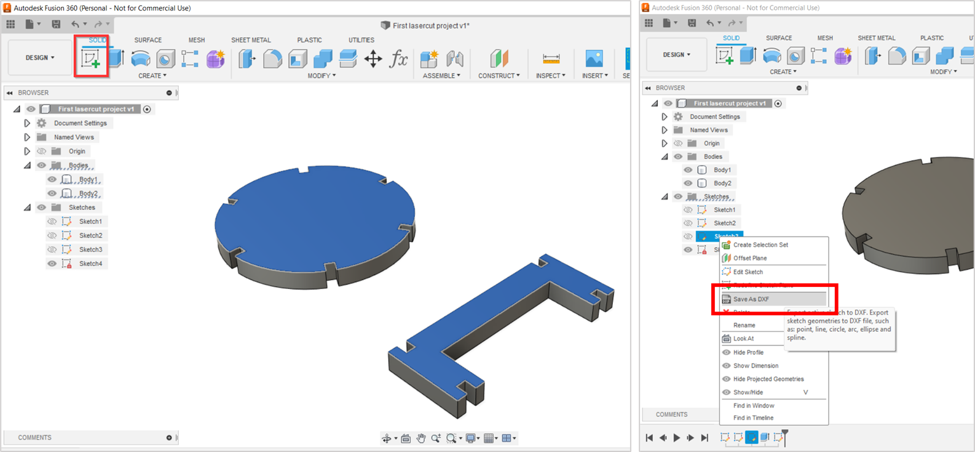

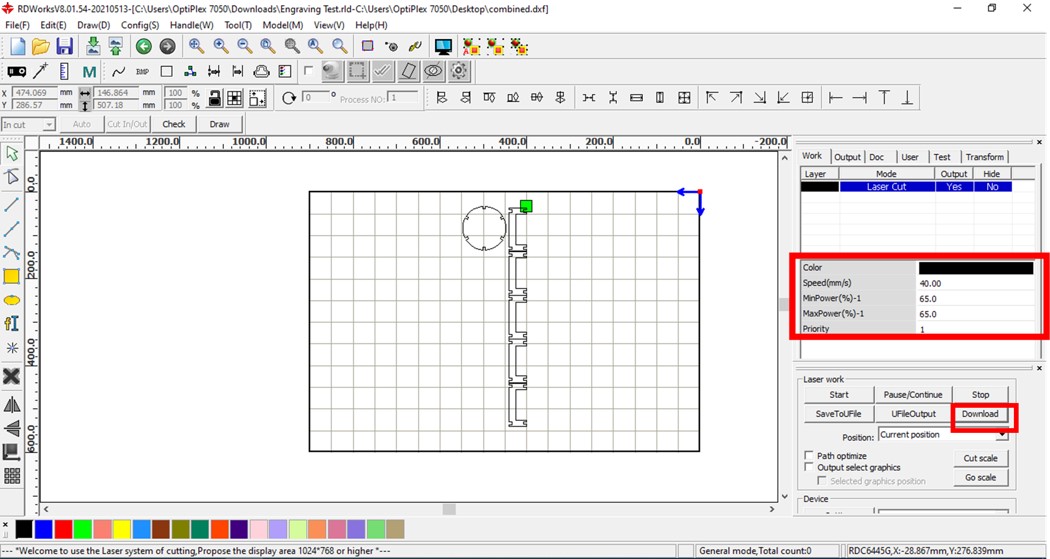

The assignments included learning how to make a parametric design in FUSION 360, which you will find the steps for it down below in the "LAZER CUTTING" section.

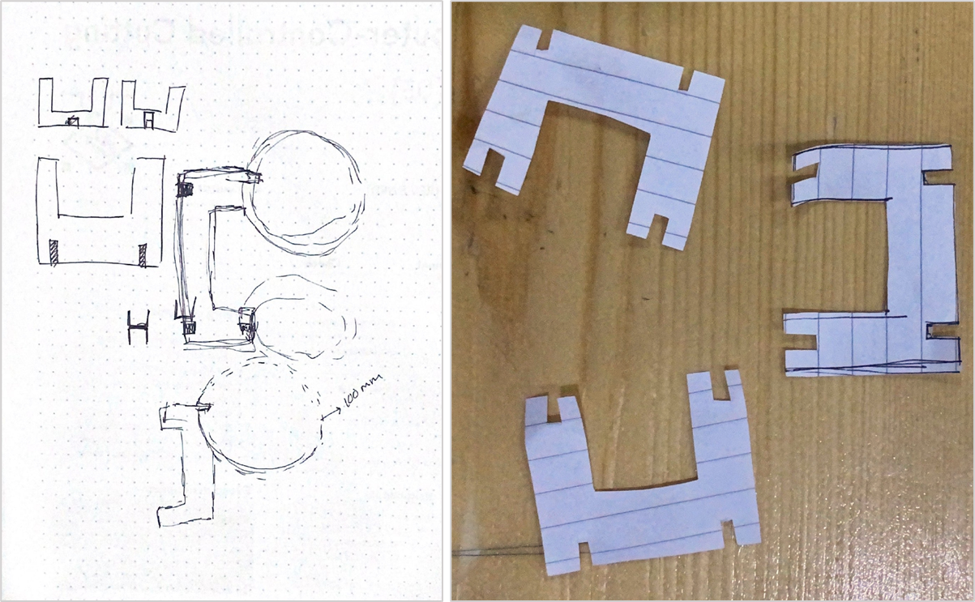

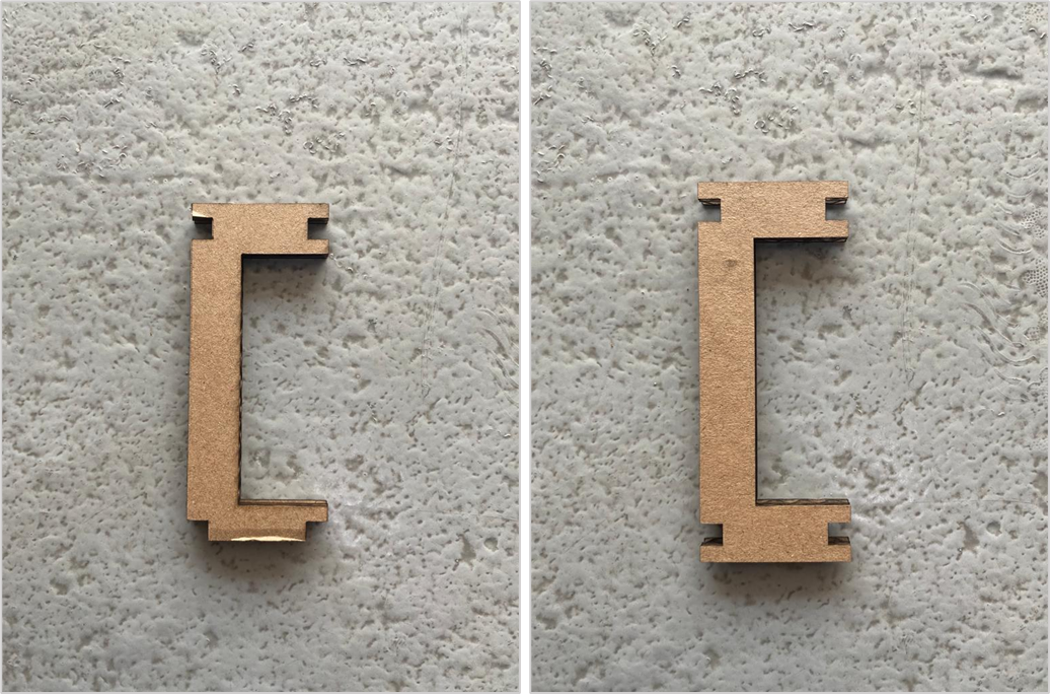

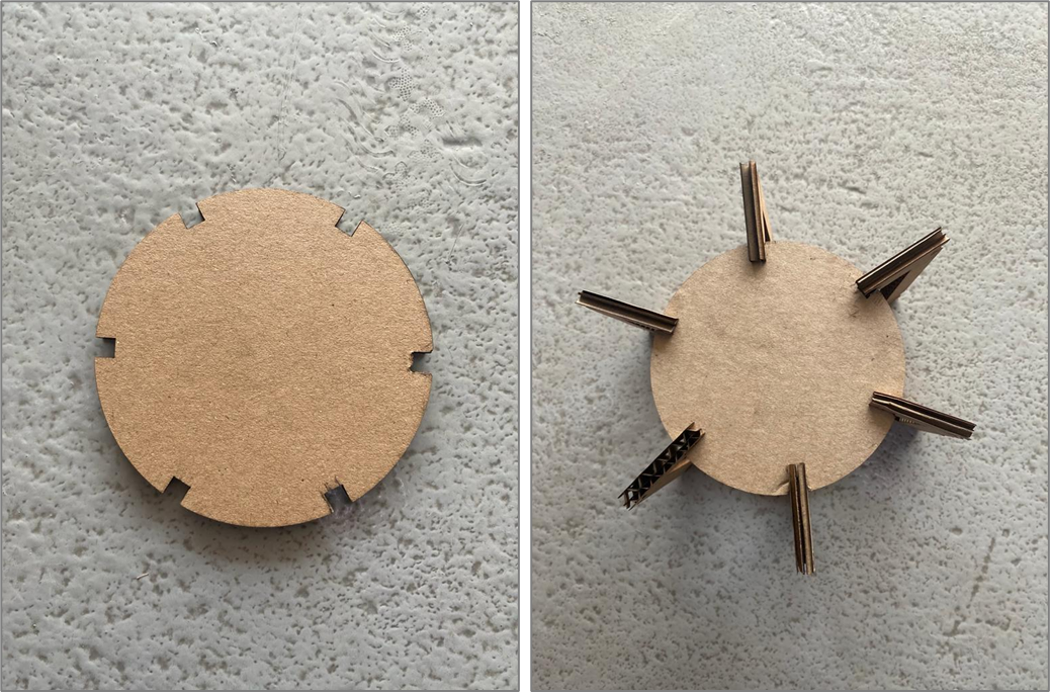

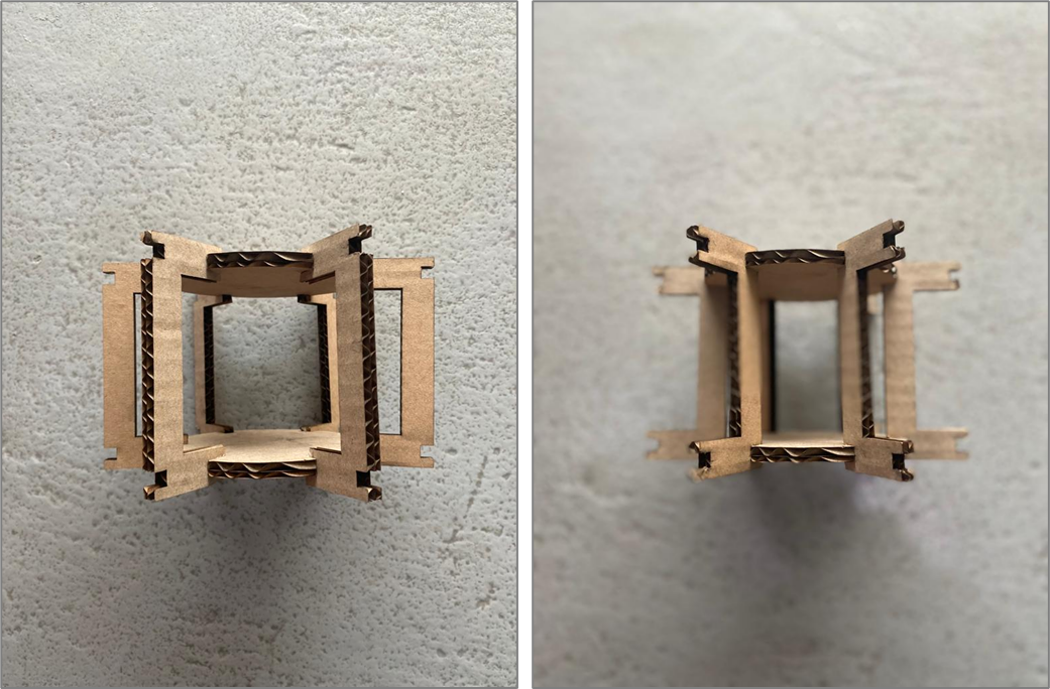

WHAT IS PRESSFIT?

The second thing we learned is PRESSFIT design, and it is the fastening of two parts or objects together through joints, without using other materials, the two parts both have a joining element that can fit through the other object.

Scroll down to learn about the two machines.