8. Moulding and casting¶

This week we learned how to mould and cast our own designs by choosing different materials.

Introduction about the moulding and casting¶

The main difference between molding and casting is the use of the material in the process. Casting will typically involve metal, while molding focuses on plastics. In both cases, the melted material goes into a die or mold to create the final form.

Testing the materials¶

I’ve worked with jaber for collecting all the details about the dry putty and we’ve mentioned all the information here

The individual design¶

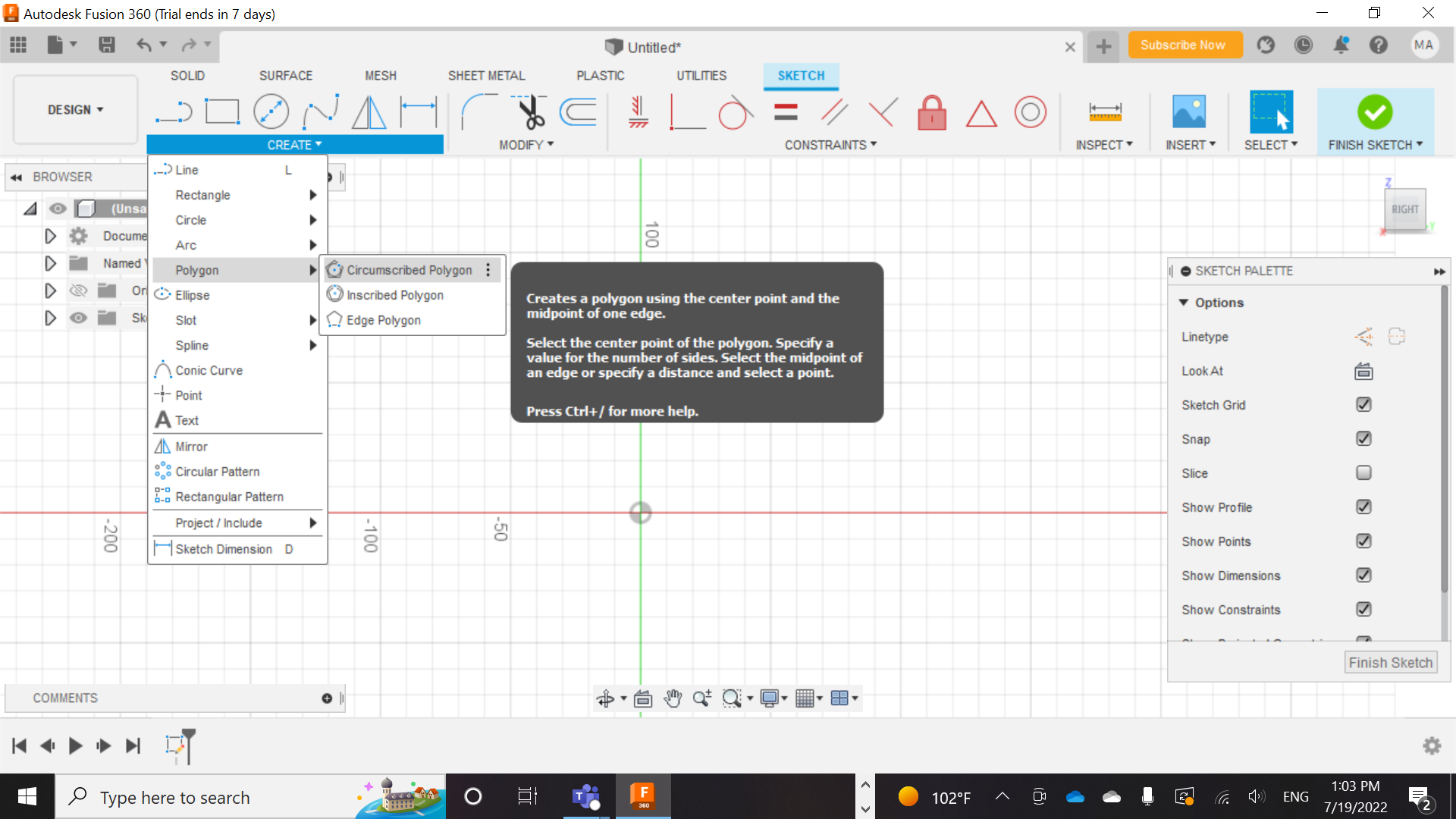

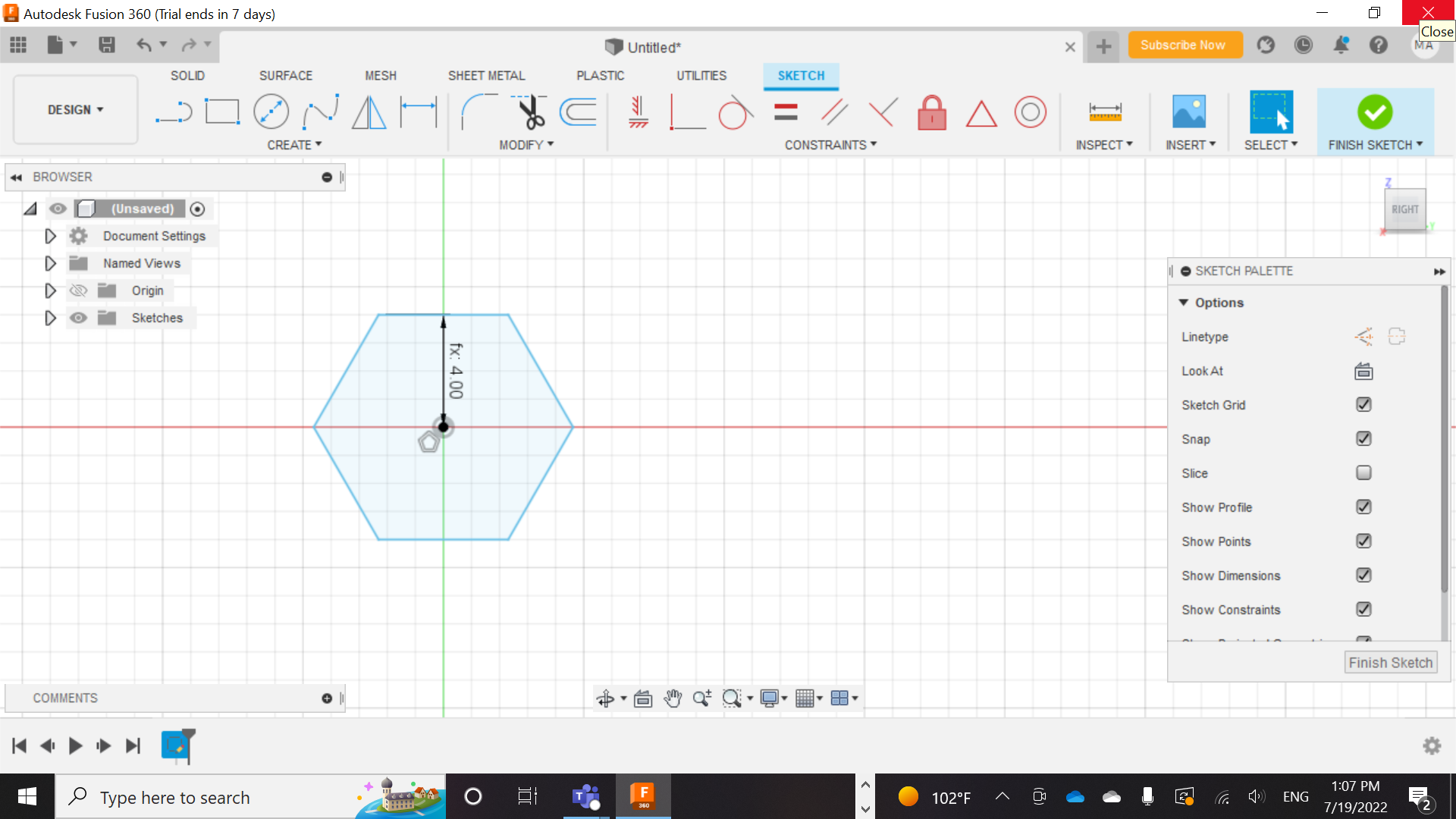

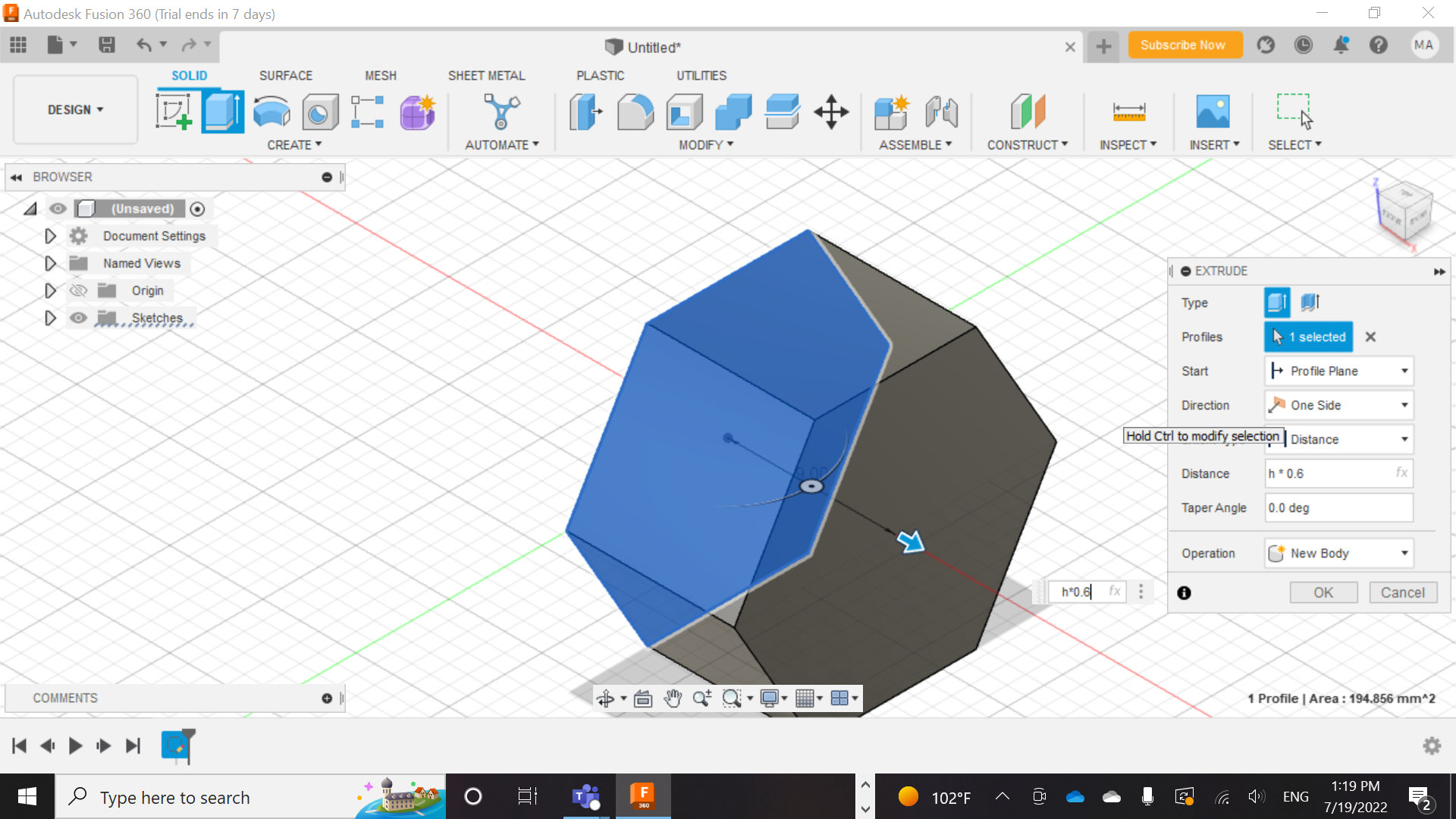

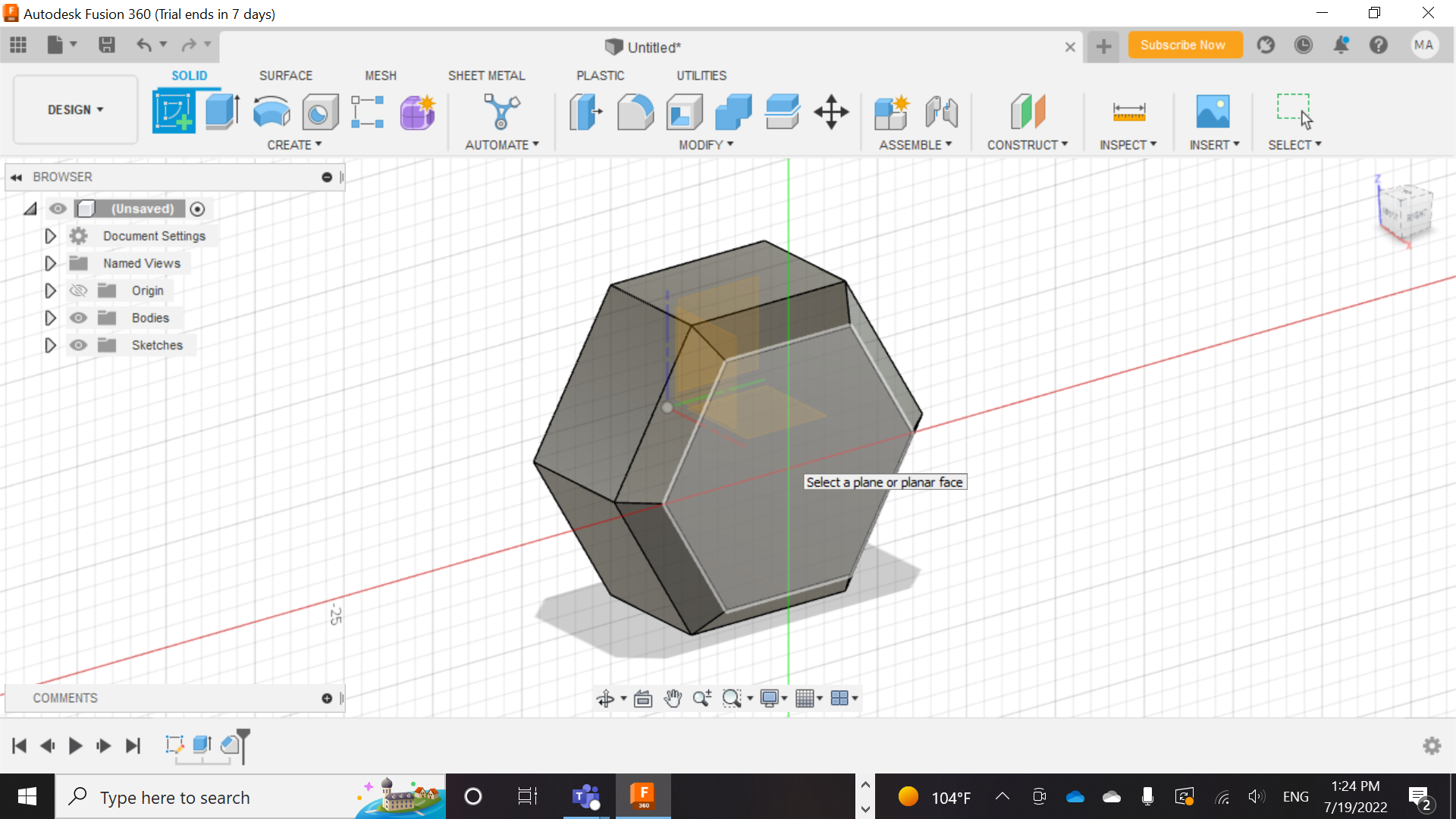

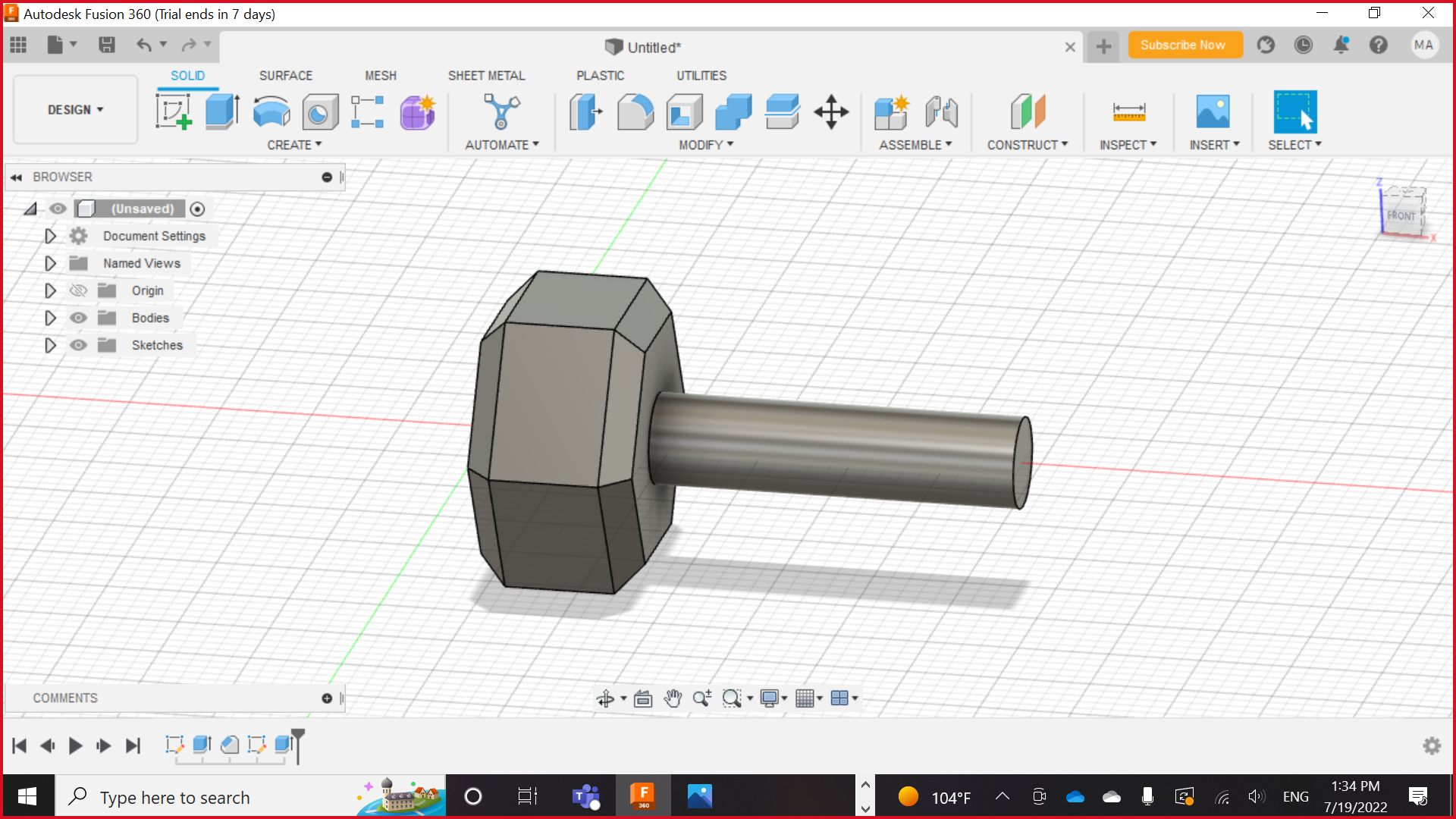

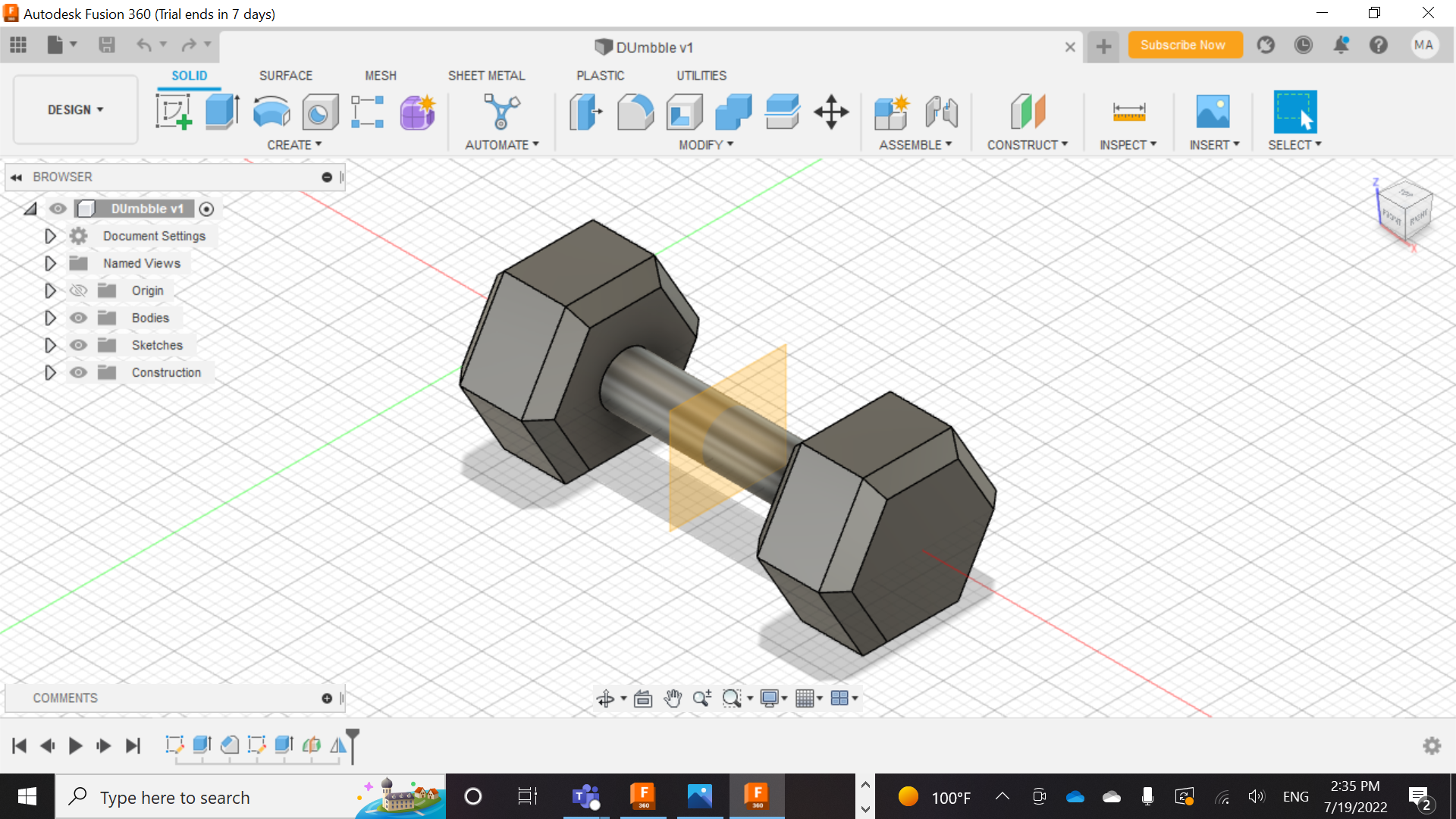

So I’ve started my own design (dumbbell)using the Fusion360 again because I found it the best place to sketch my design.

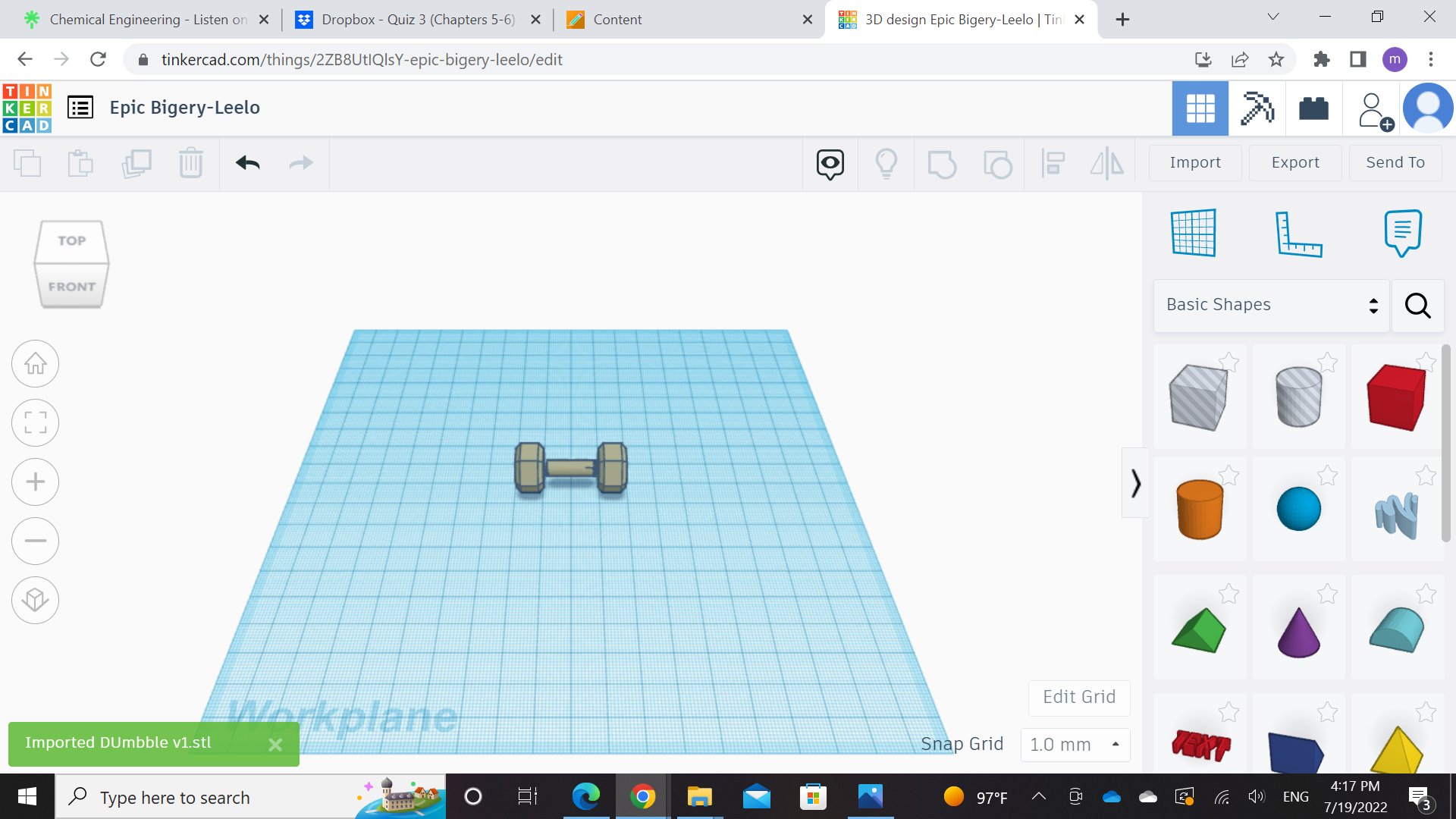

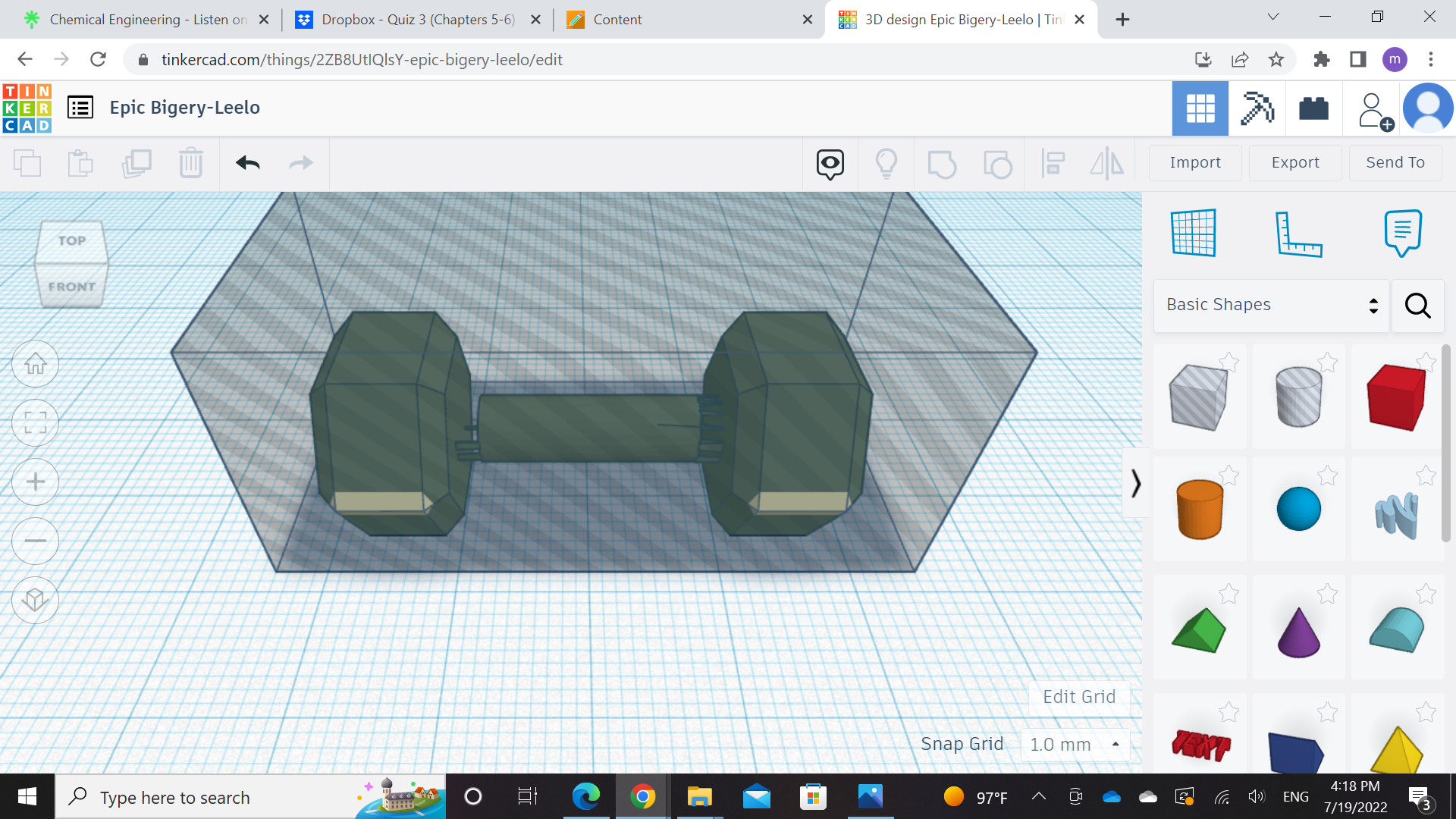

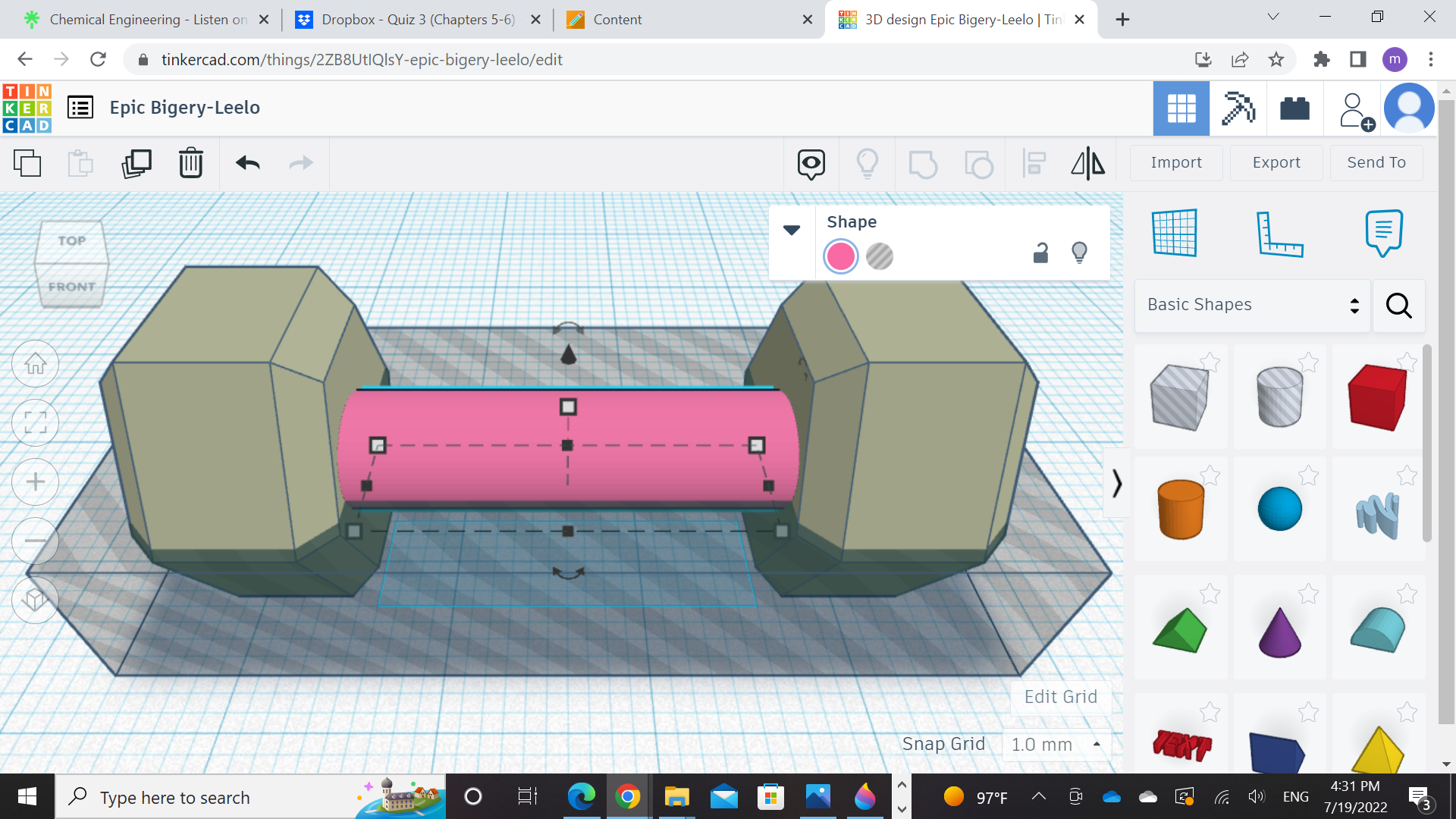

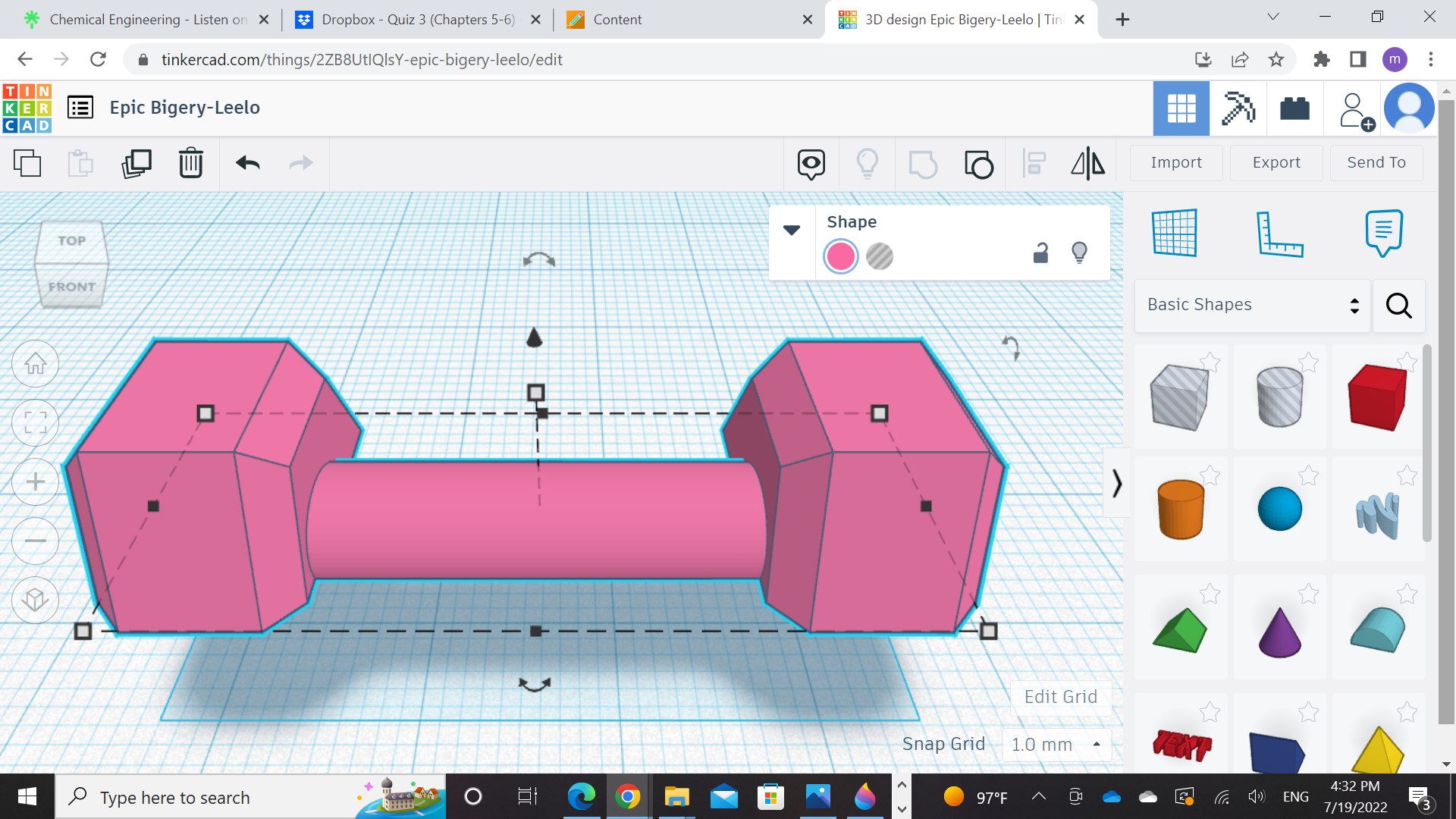

and finally I used Tinkercad to take the half of the design

the problem that I had is that I didn’t be able to upload the exact half of my design so I repeated more than once .

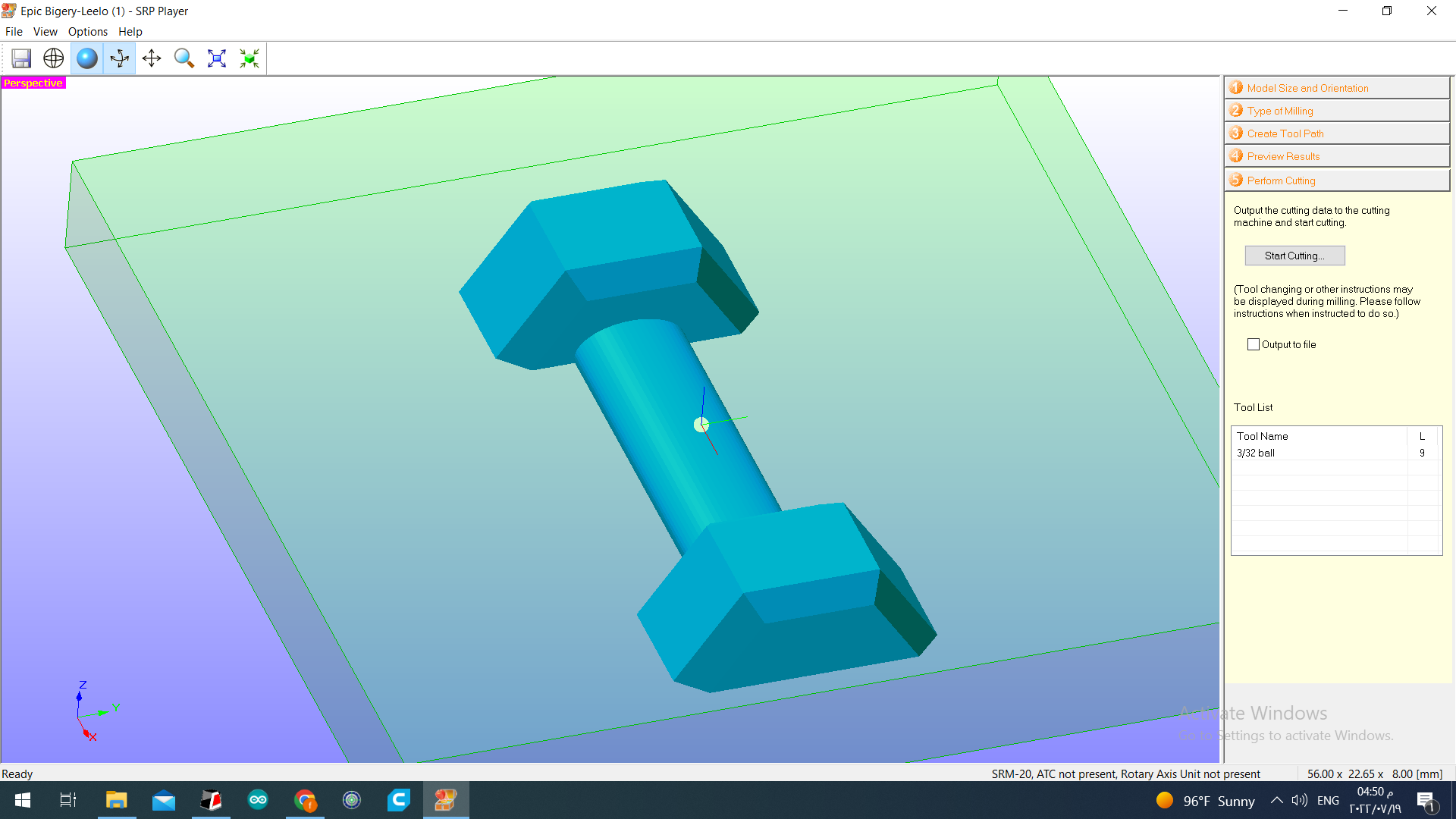

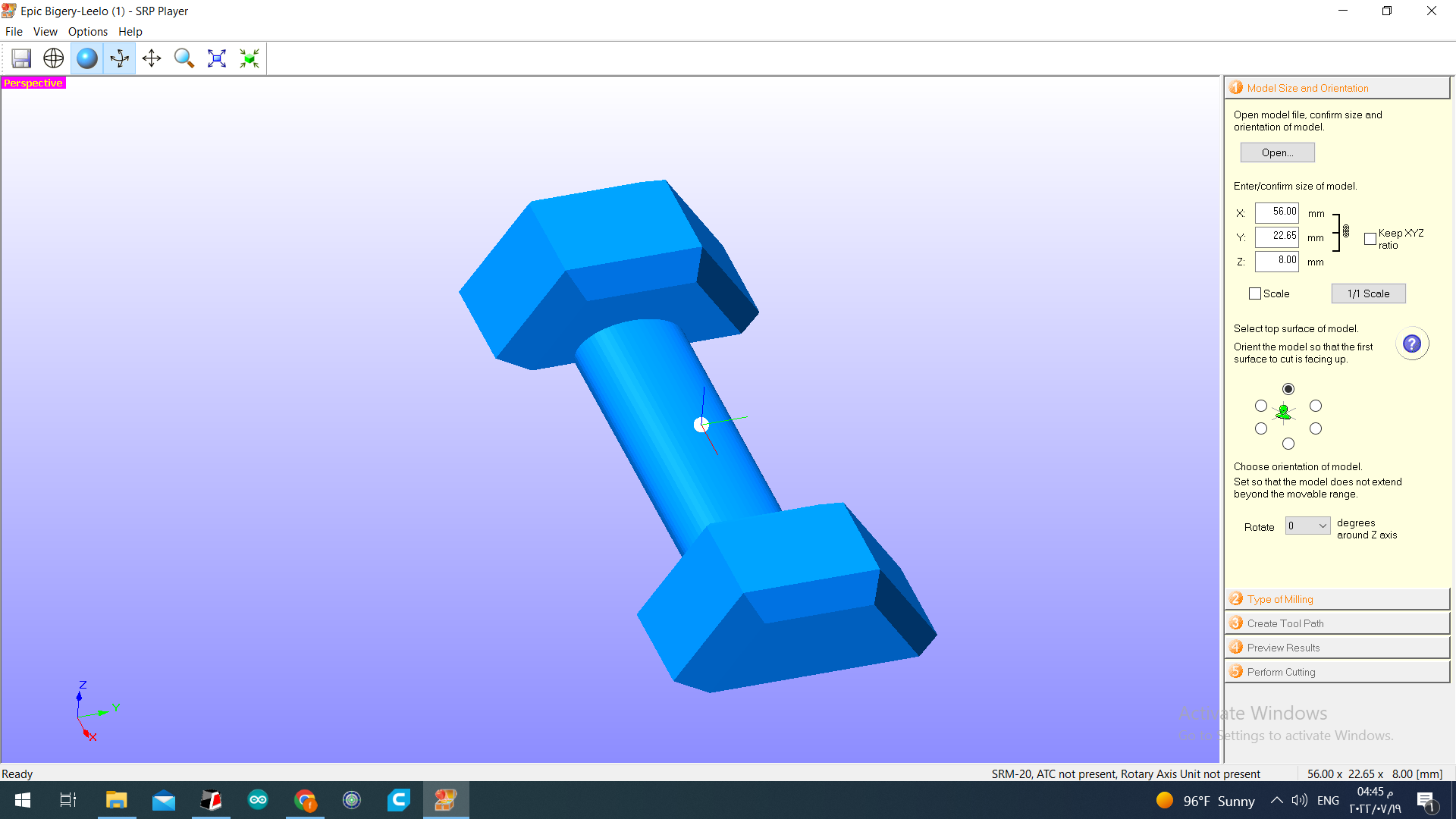

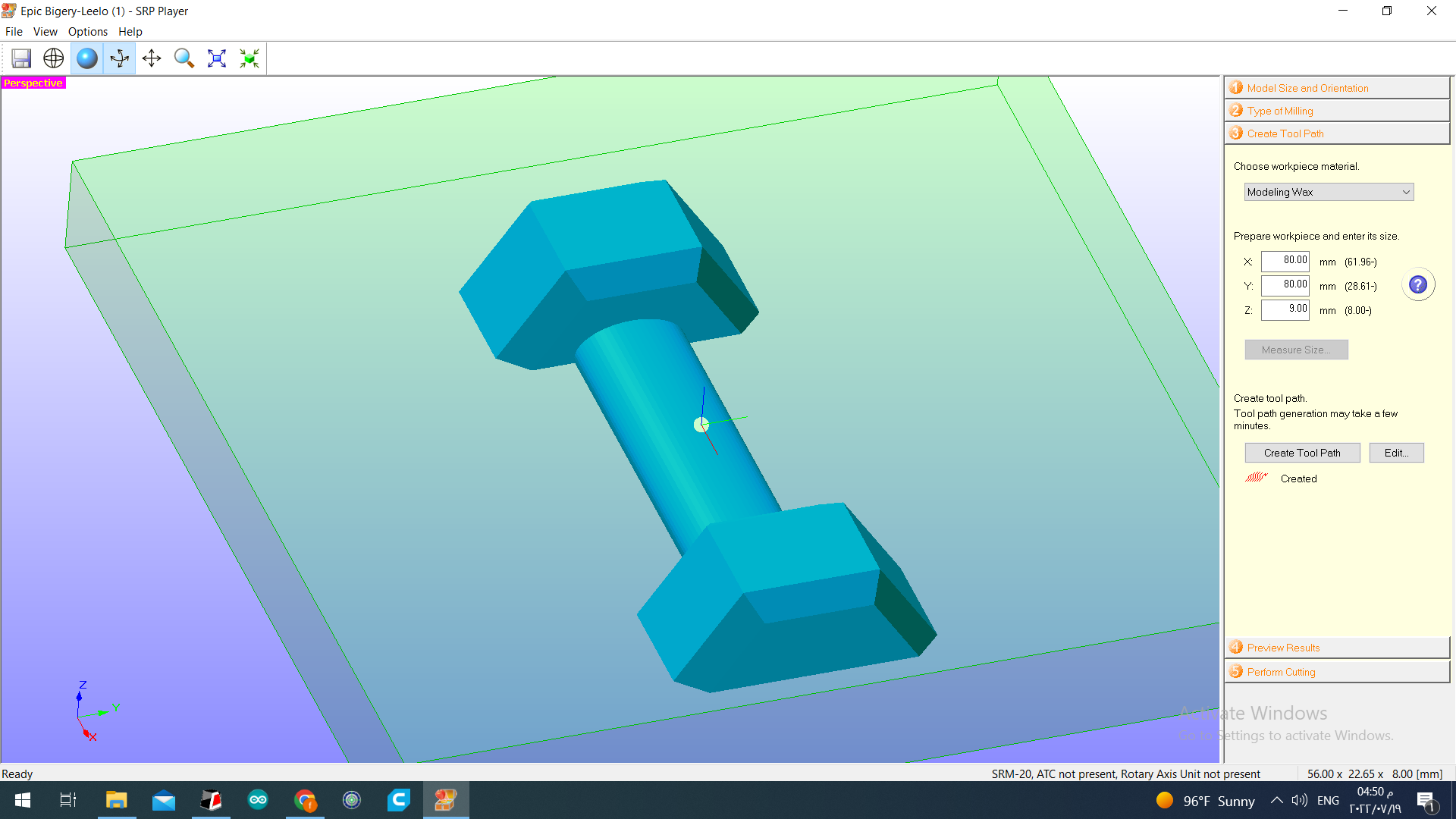

Milling¶

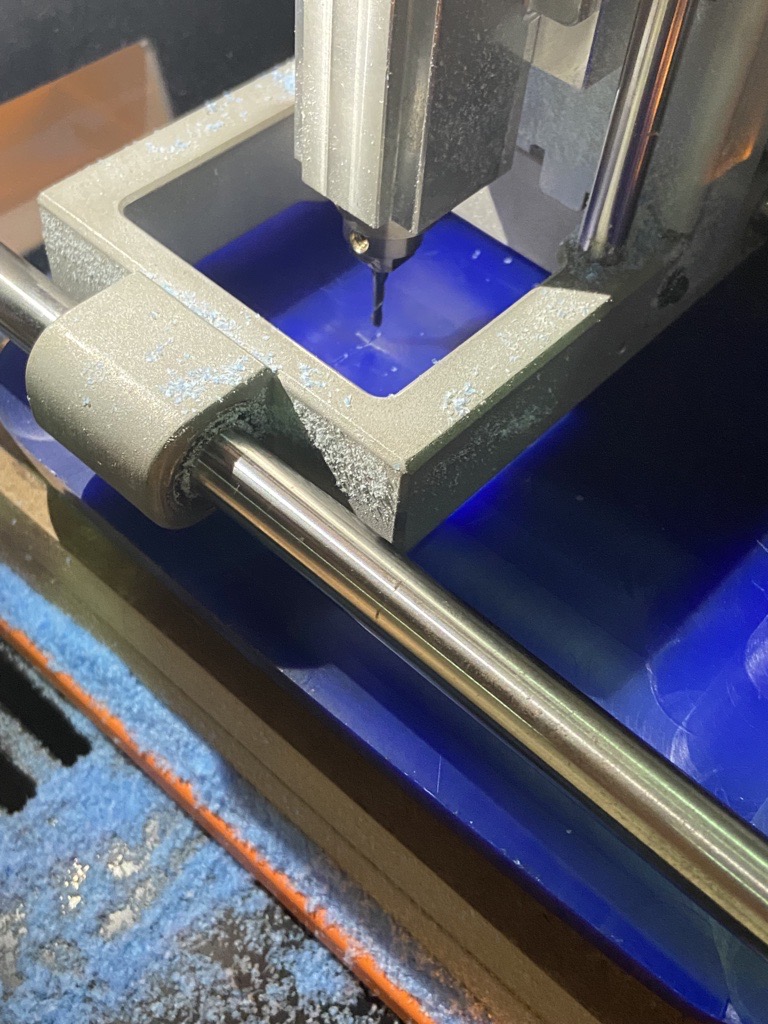

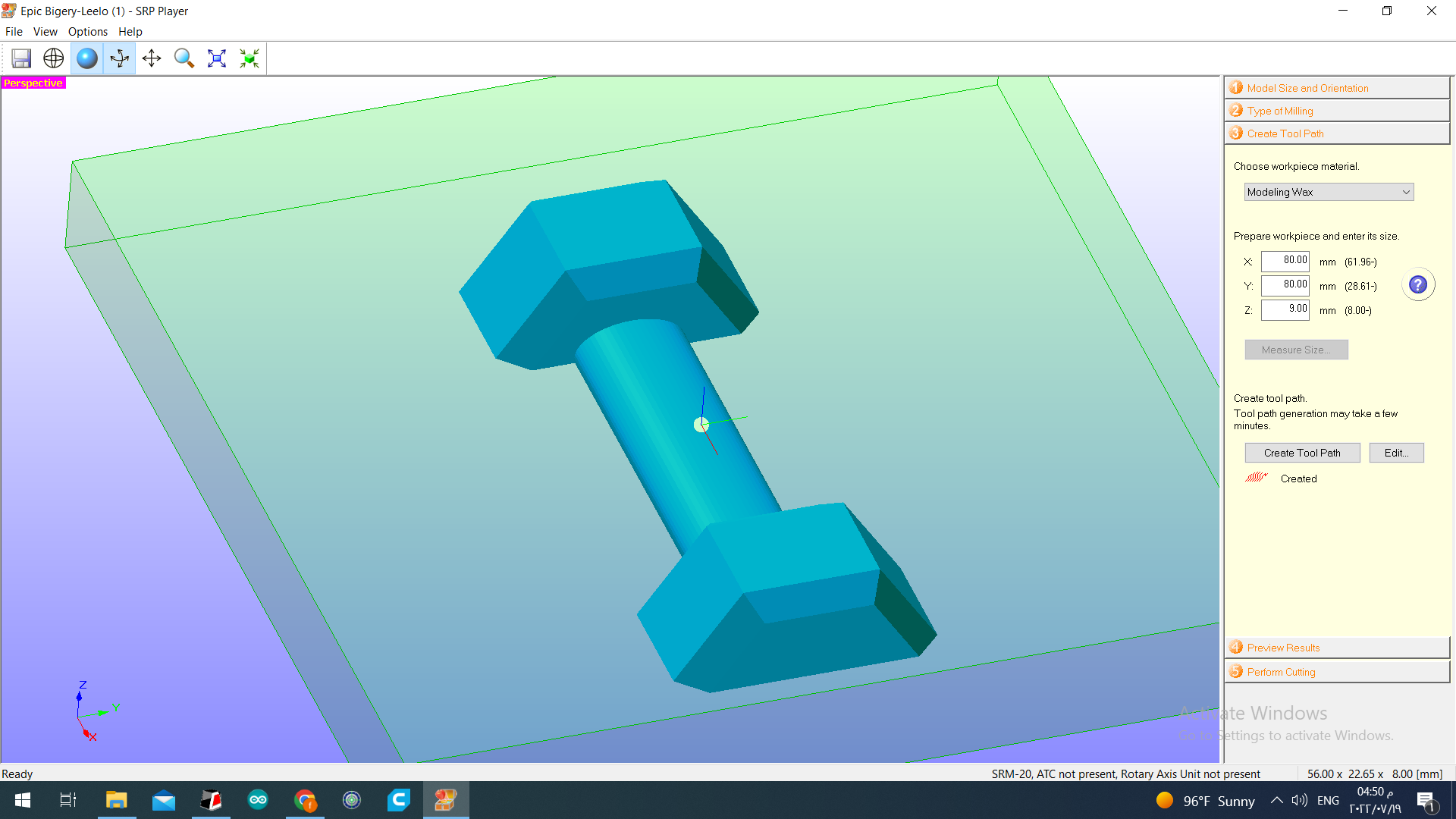

The Endmill we’re using is called 3/32 SE 2FL BN

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. Not all mills can cut axially; those designed to cut axially are known as end mills.

Editing¶

we measured the height of the wax to be typed, then we entered the size of the machinable wax ,length, width and height. and we selected the type of milling which is important . then we chose whatever suitable to our design whether we want a smooth or cruel material etc.

Moulding phase¶

The first thing we did was pouring water into the positive wax mould to measure the amount of silicon we need to create the negative silicone mould and we poured the mixture into the wax mould and left it to dry.

Second, we prepared our dry petty mixture and mixed it

After almost 24 hours, it was ready to be used

Casting phase¶

We prepared our dry petty mixture, mixed it for 5 minutes, and poured it into the negative silicon mould.

and this is the final result , I’ve broke it while removing it but still amazing