Laser Cutting

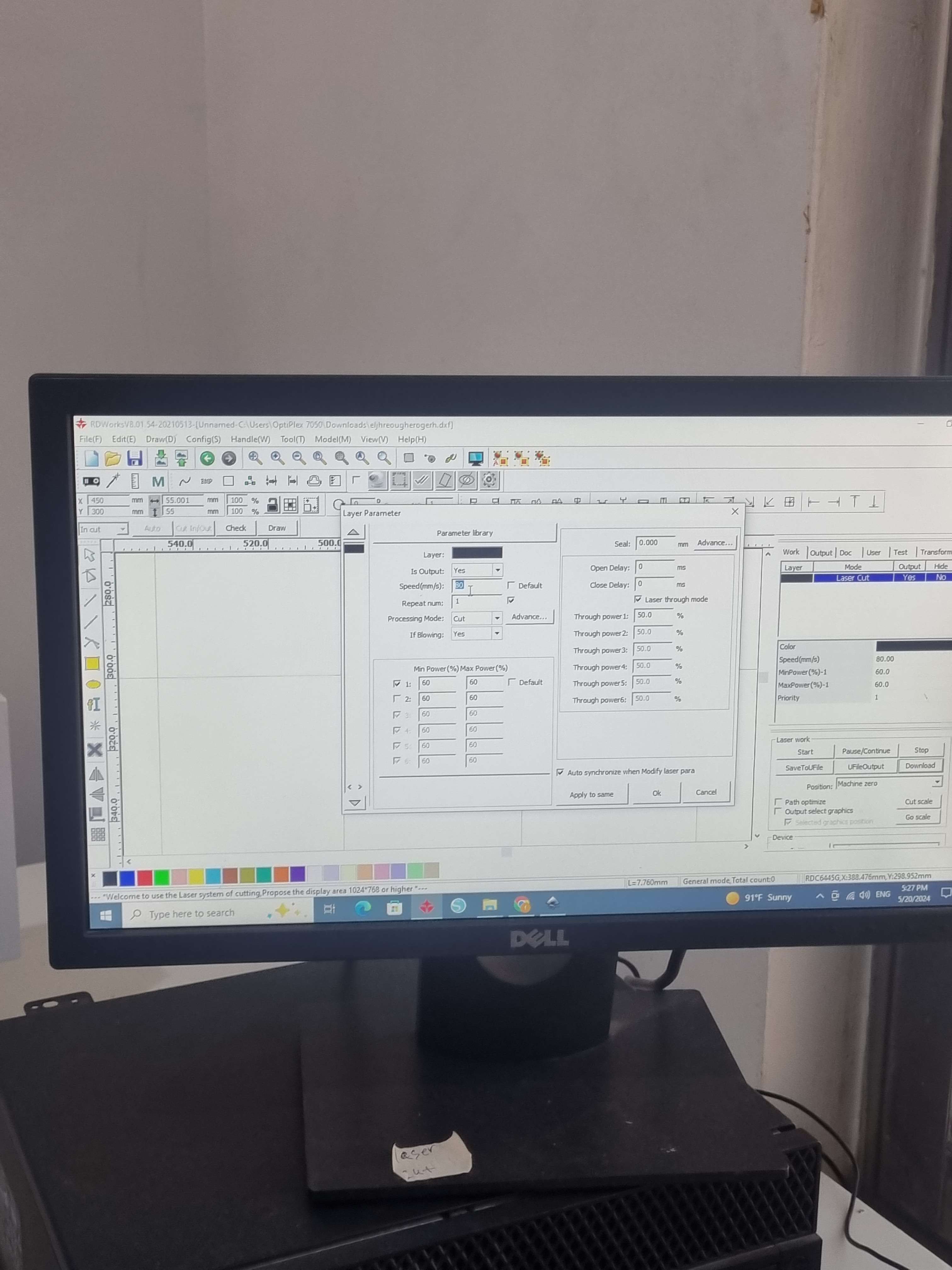

For the laser cutting week the aim was to cut a parametric shape that can be used recursivley to create different shapes, the joint was made based on the thickness of the carboard we were using while giving it extra tolerance space, the file was exported to dxf, imported into the laser cutter, and cut using the proper settings for the material.

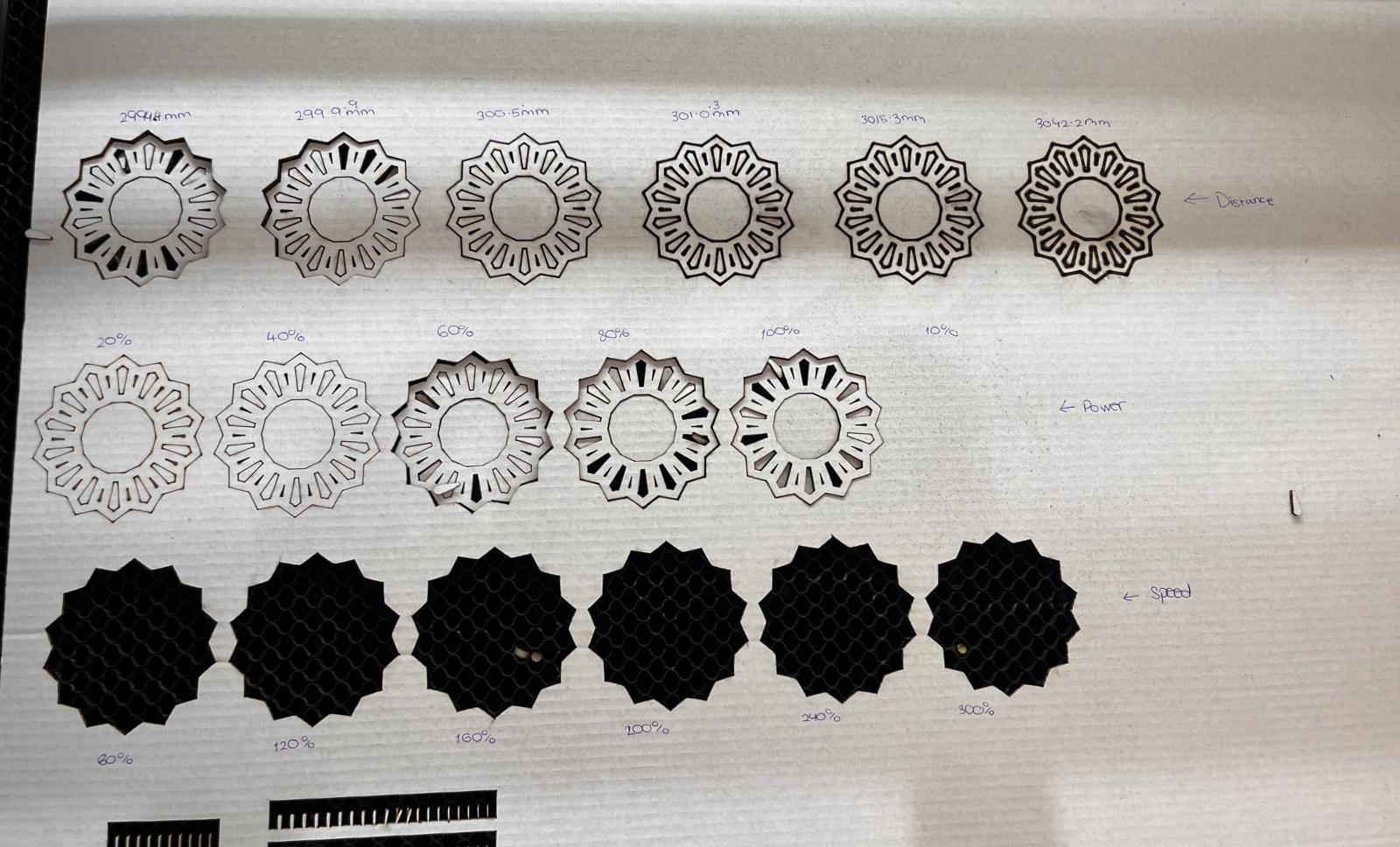

A test was also done for different settings of the laser cutter, changing it's:

ೃ⁀➷Distance

ೃ⁀➷Power

ೃ⁀➷Speed

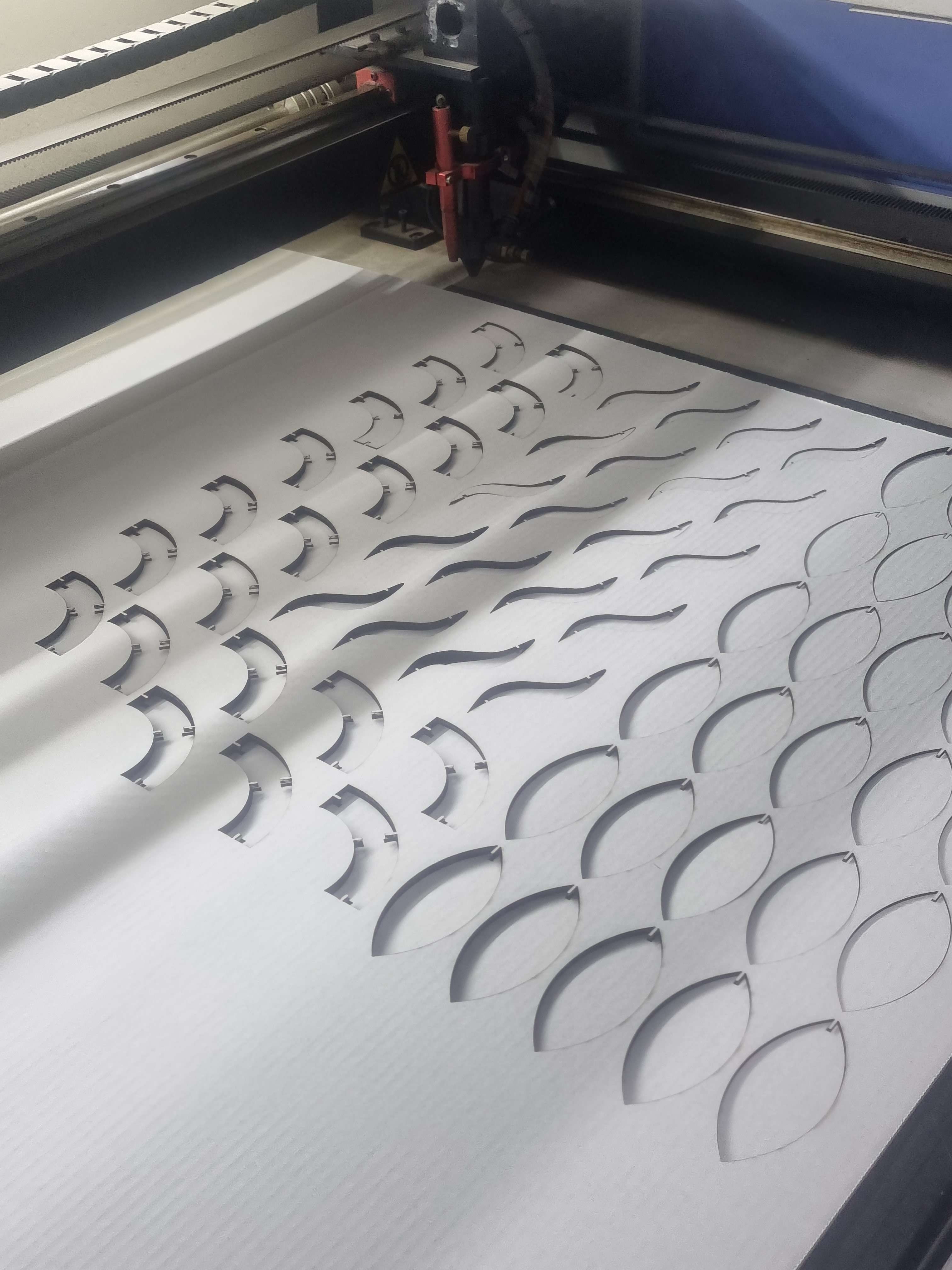

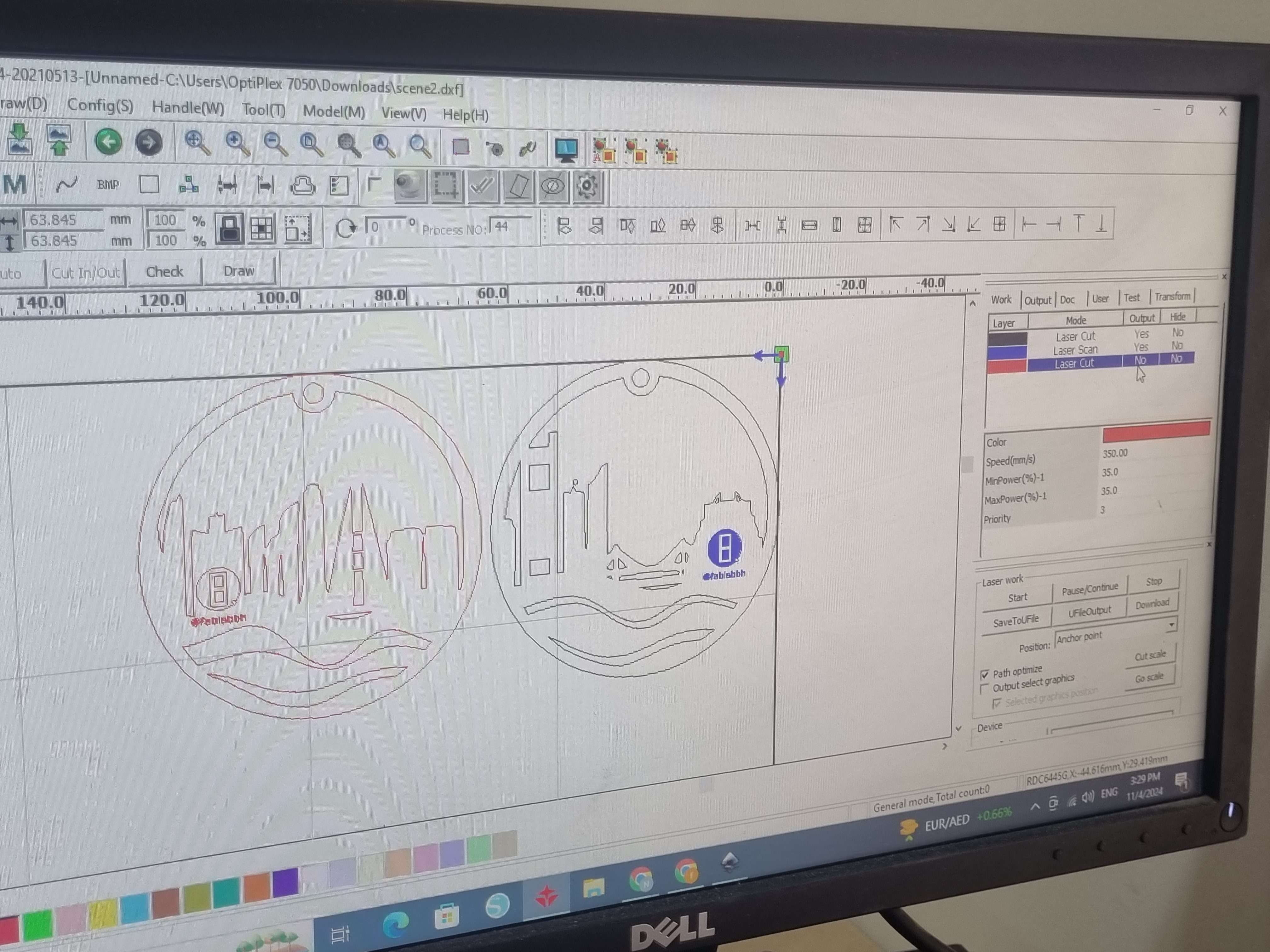

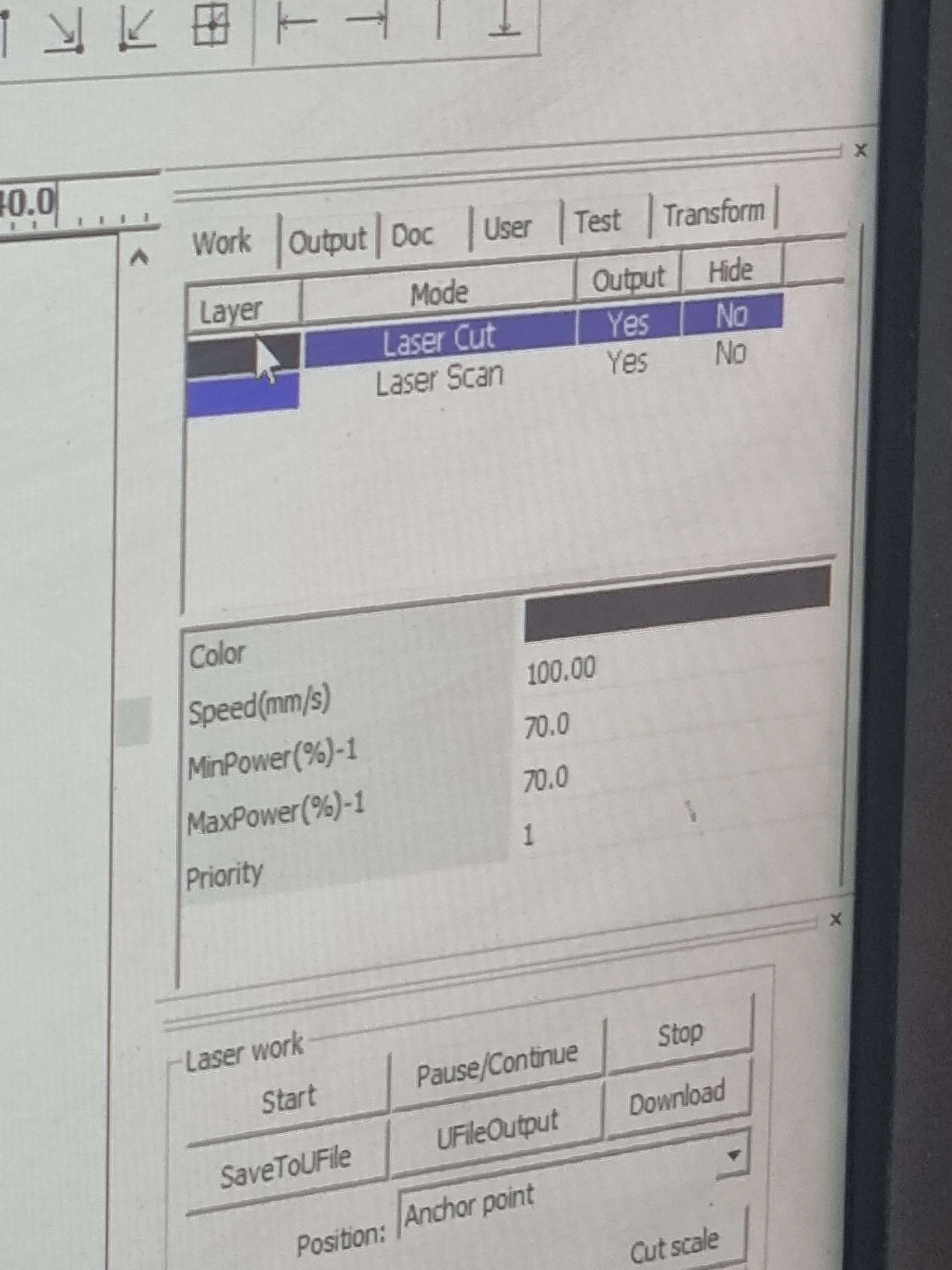

This keychain was being made for and event with the intention of having some parts engraved/scanned instead of fully cut through, different settings were used for the scanning/engraving in the laser cutter.

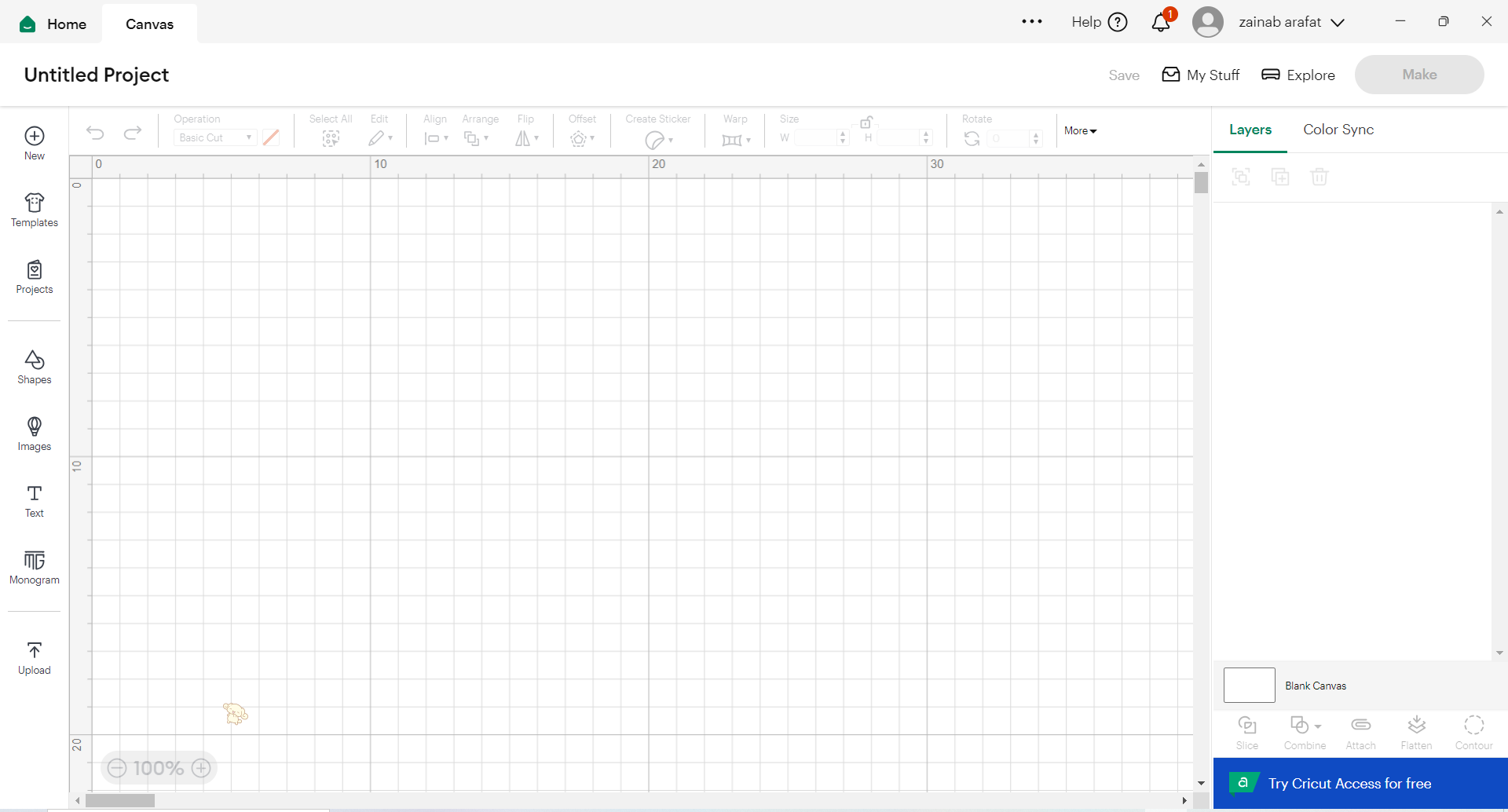

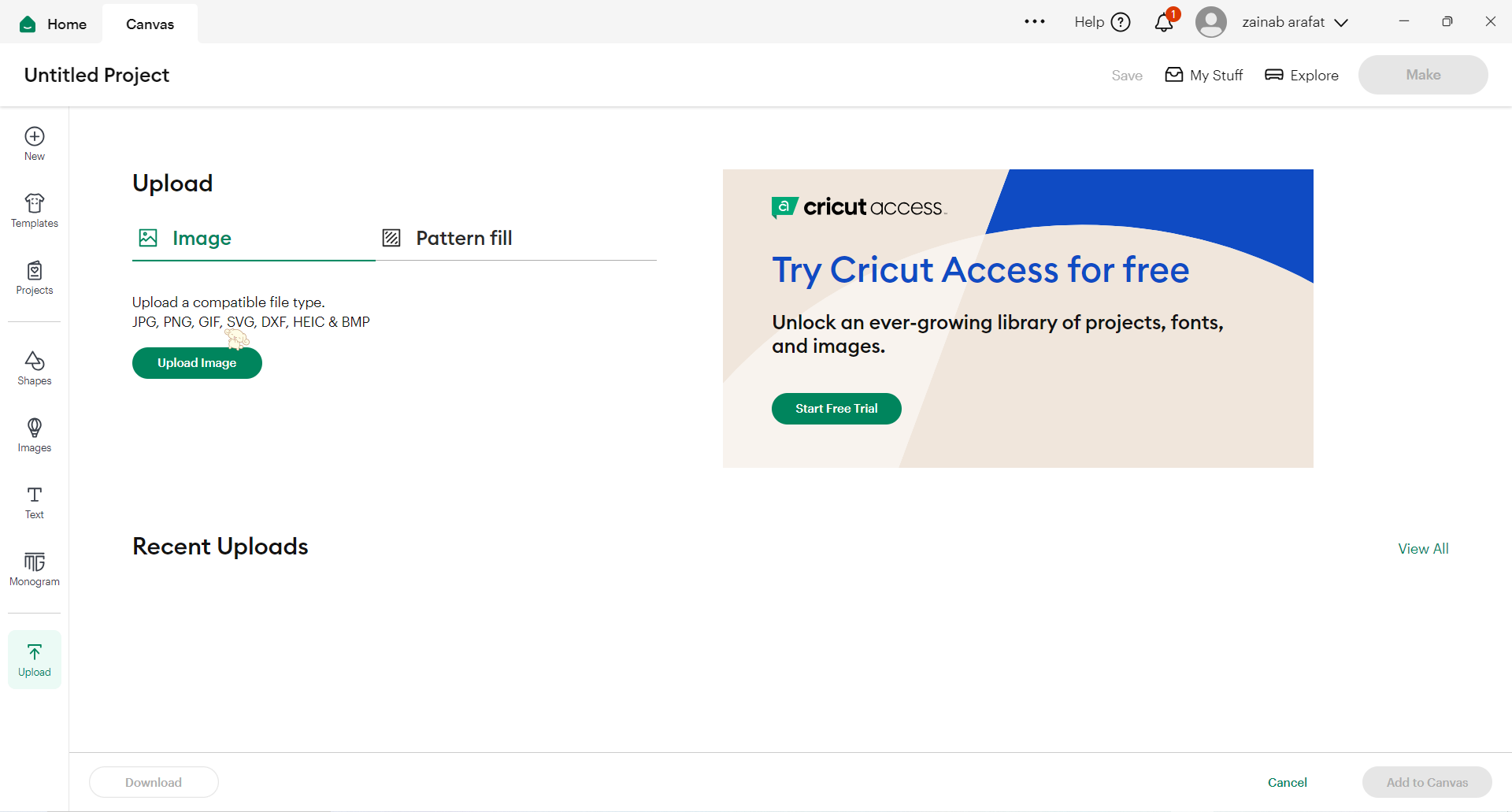

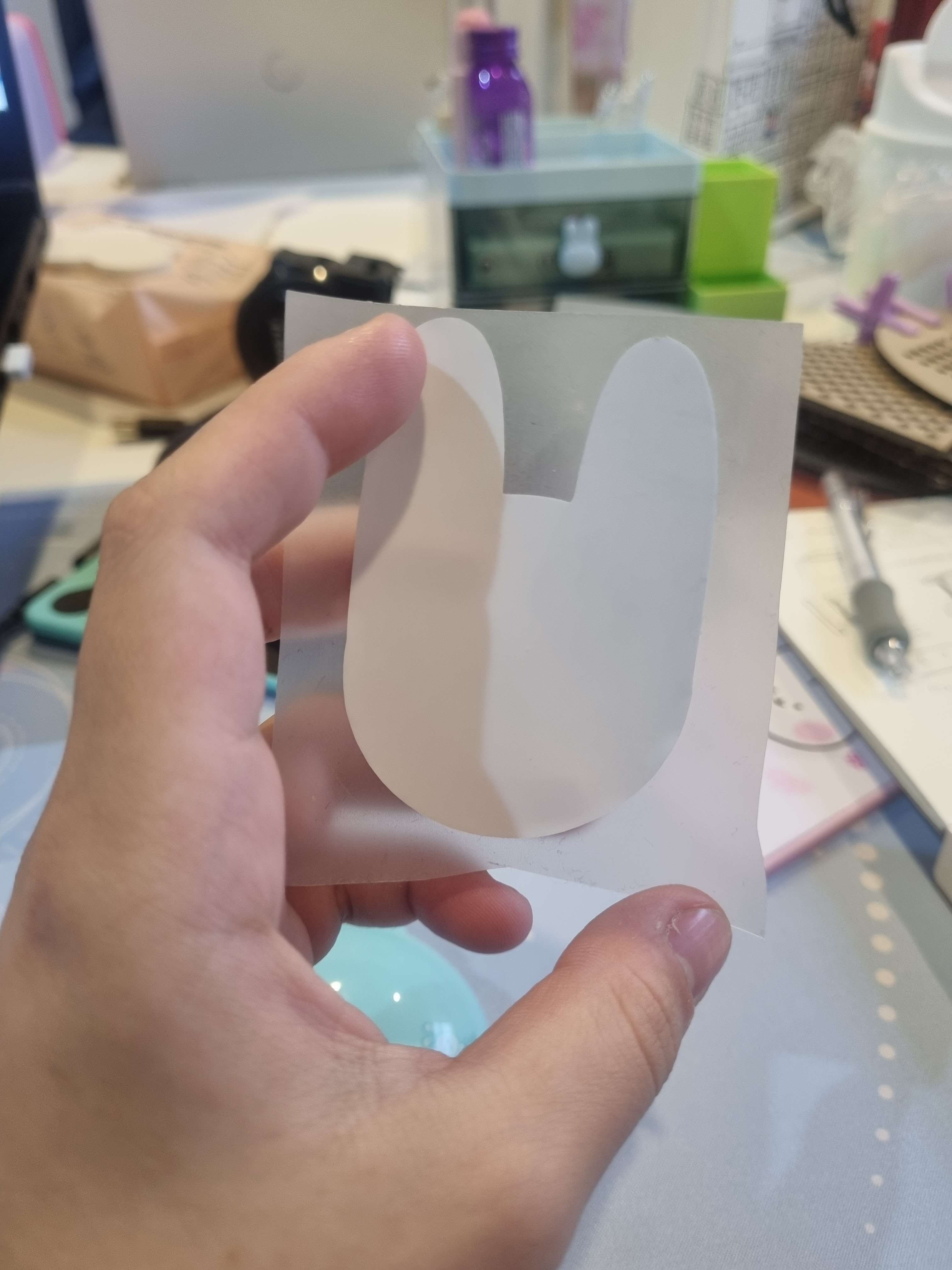

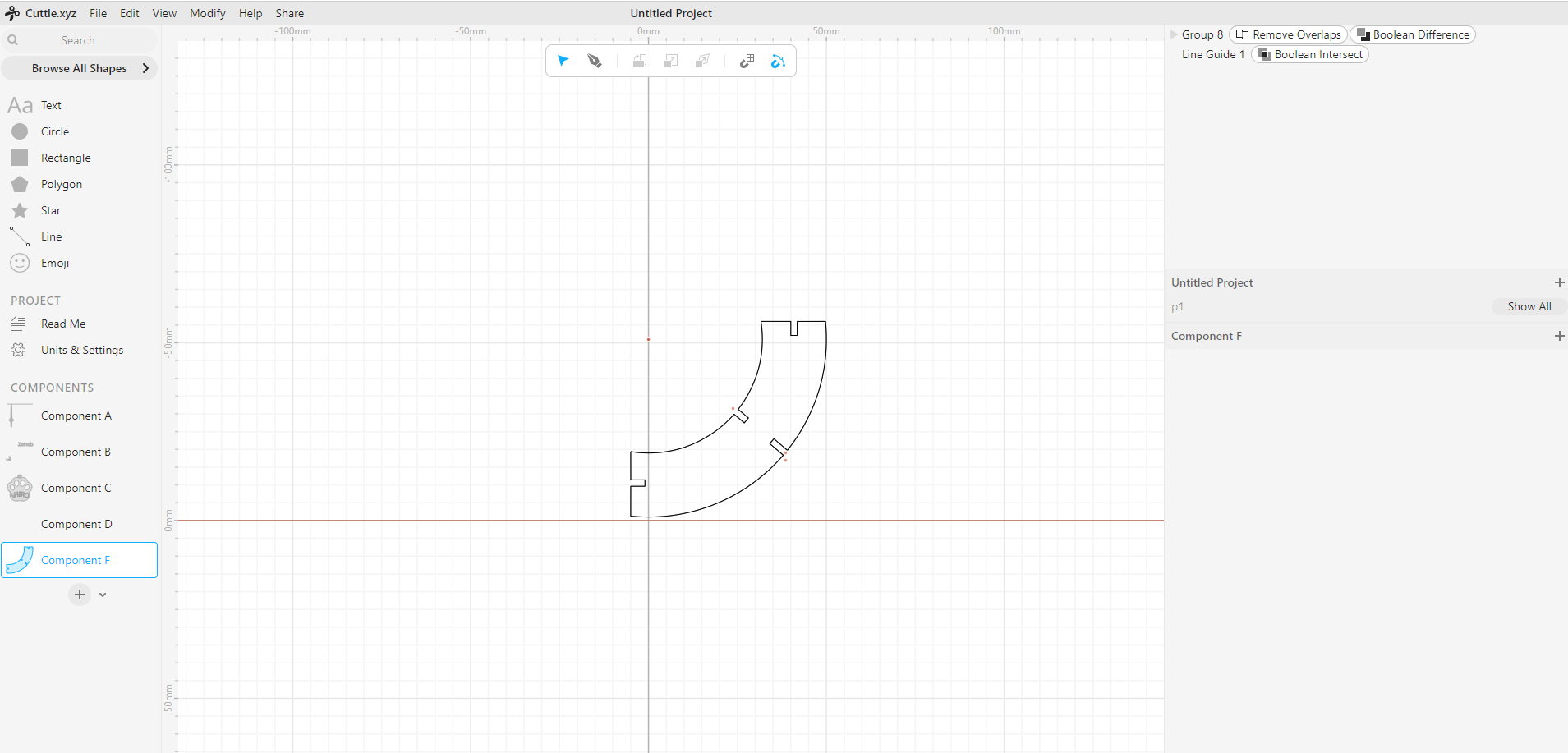

Vynl Cutting

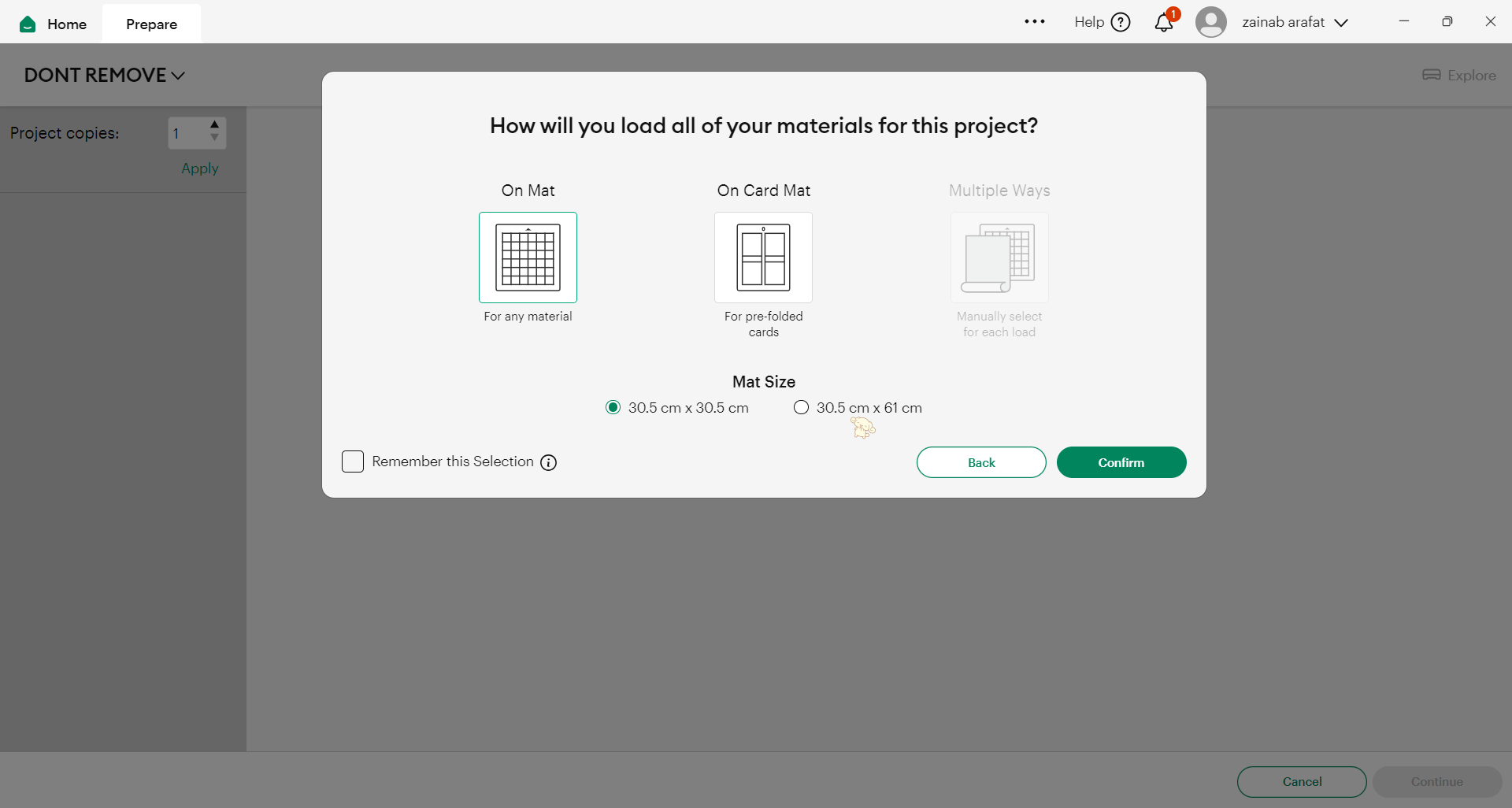

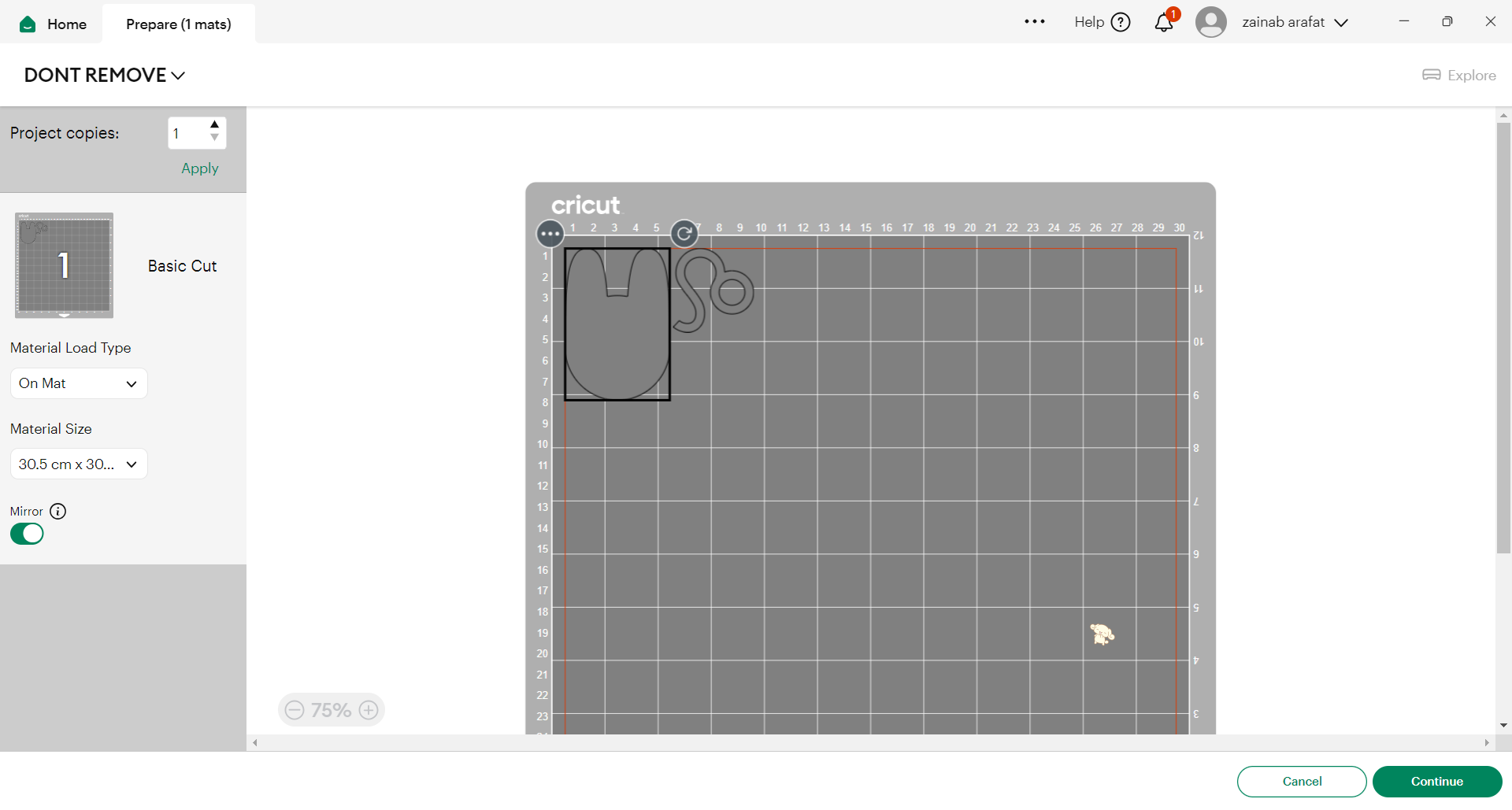

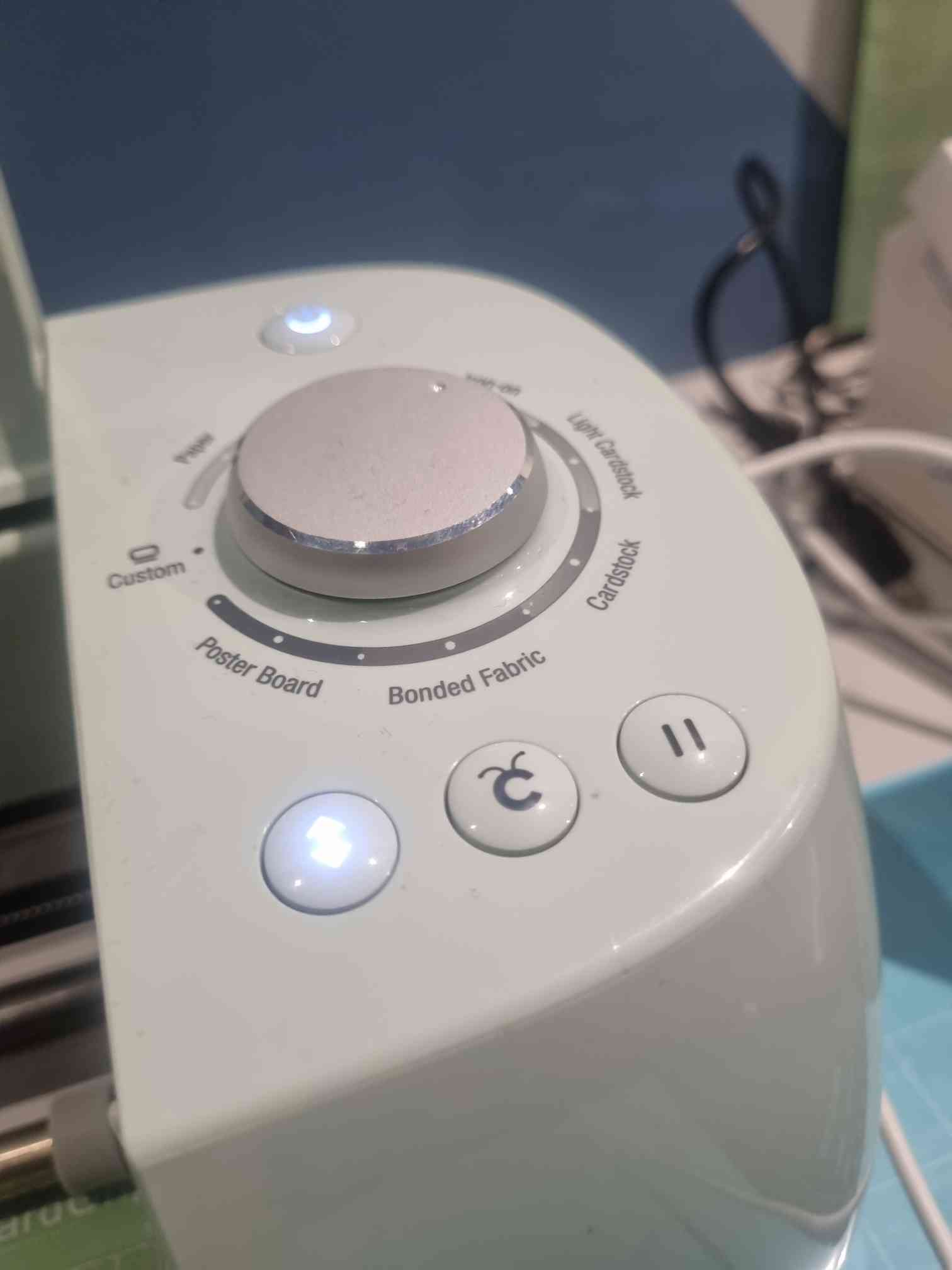

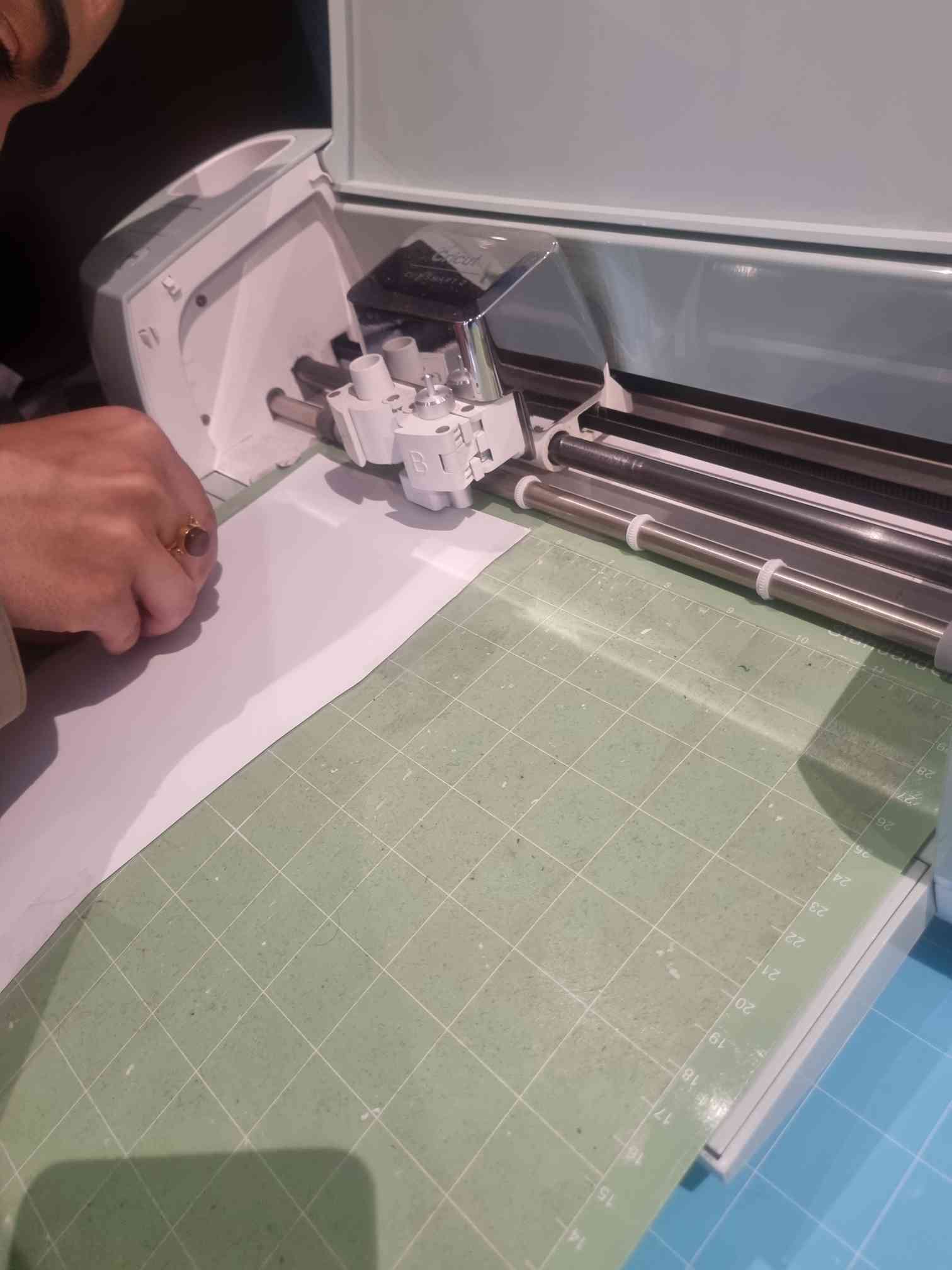

The design, originally made in canva, and the software Circut for the vynl cutter was downloaded, it was then imported into the software, uploaded and sized to match the area of the vynal that was stuck on the cutting mat. The vynl was taped on to the cutting mat in order to not be moved.

The taped vynl with the cutting mat is then moved into the machine after pressing the button to rlease the clip that olds the mat and vynl in place, and the cutting is then started.