8. Moulding and casting¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

What is the Molding and casting¶

-

Molding and casting are two processes that are often used in the manufacturing of products. Both processes involve creating a negative space in order to create a positive product. However, there are some key differences between molding and casting that you should be aware of.

-

Molding is a process that involves shaping a heated material around a mold. The material is then allowed to cool and harden, taking on the shape of the mold. Common materials that are used in molding include plastics, glass, and metals.

-

Casting, on the other hand, involves pouring a molten material into a mold. The material is then allowed to cool and solidify, again taking on the shape of the mold. Common materials that are used in casting include metals, plastics, and concrete.

Group work¶

Individual work¶

Design¶

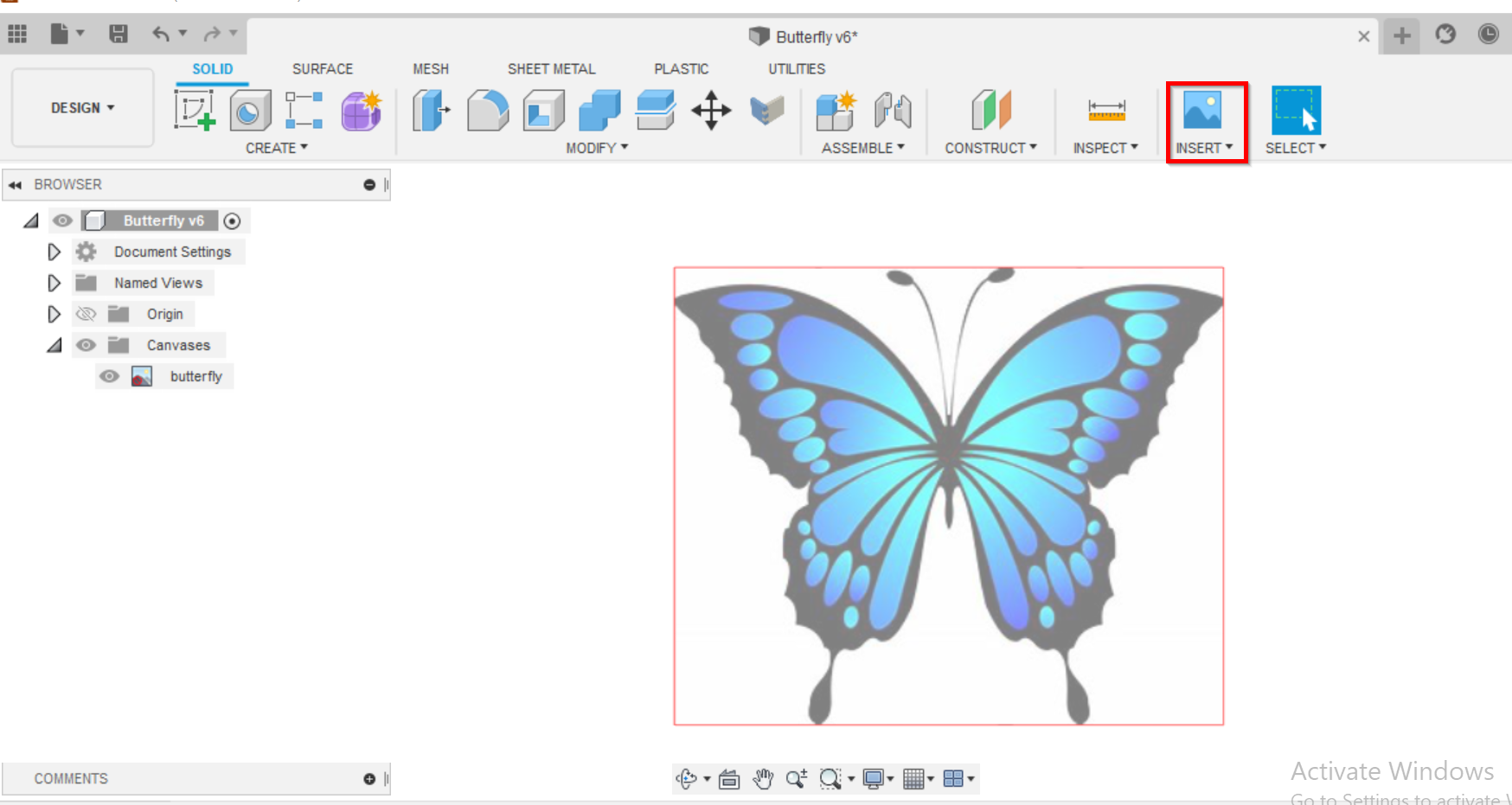

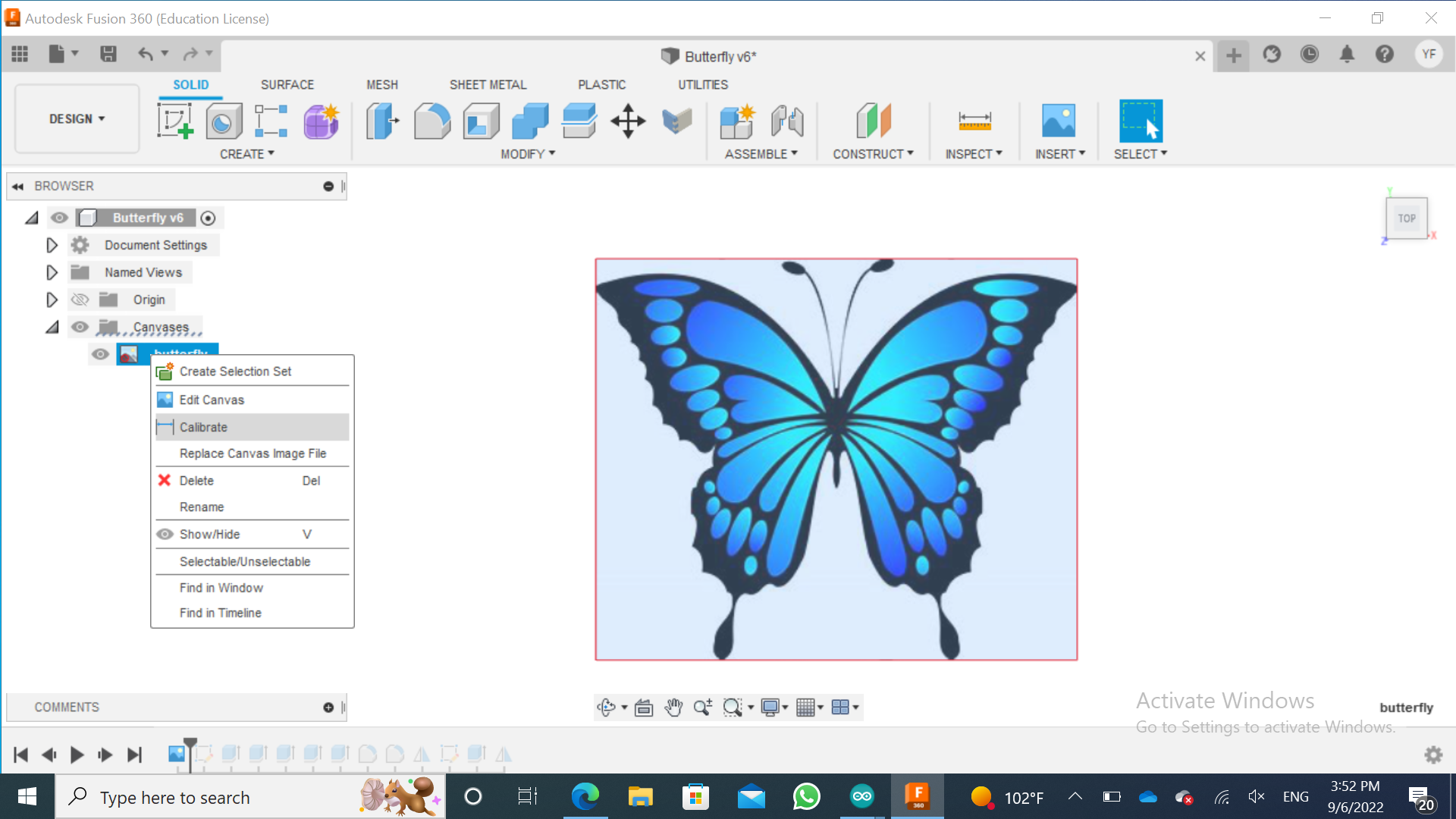

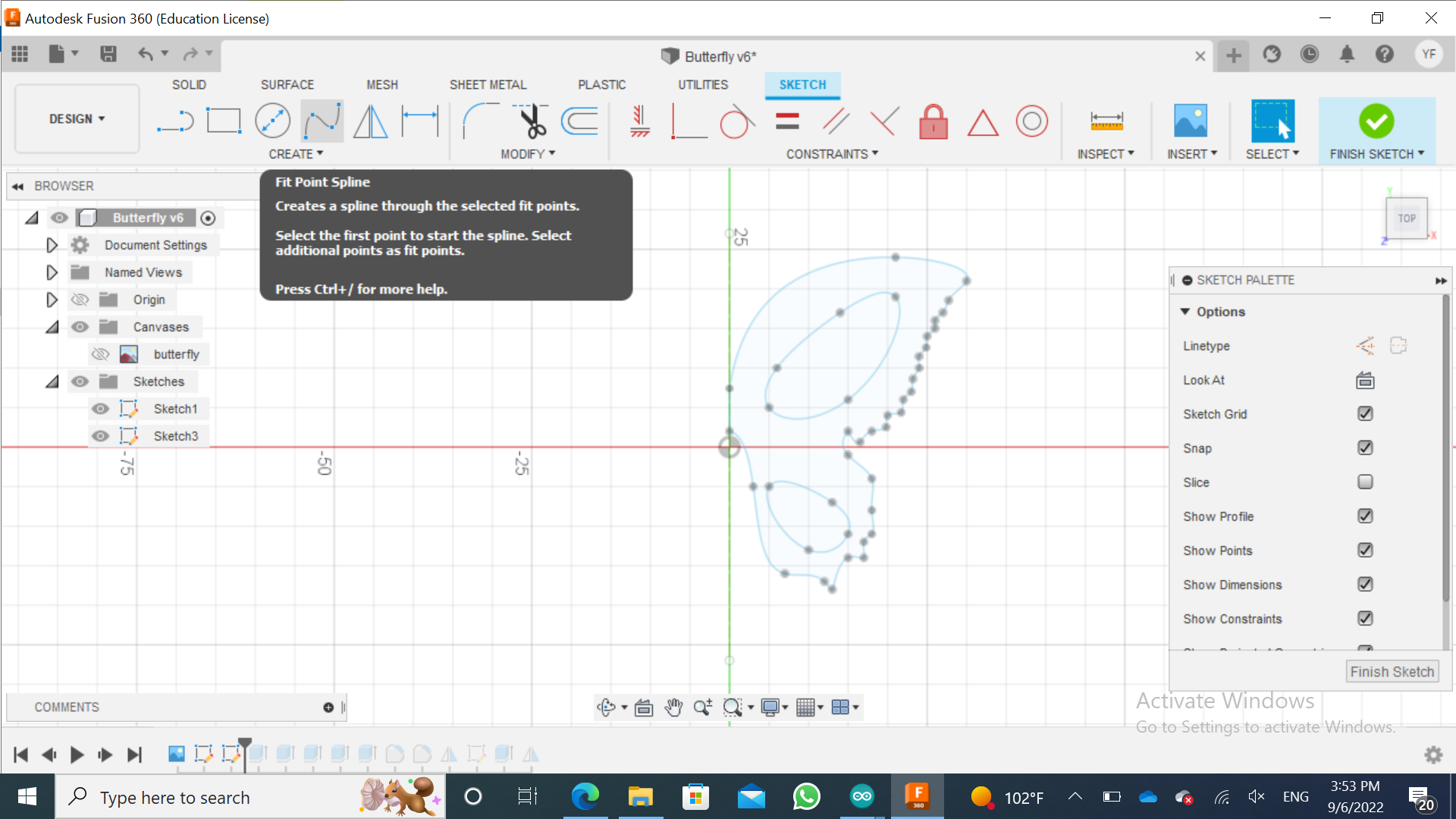

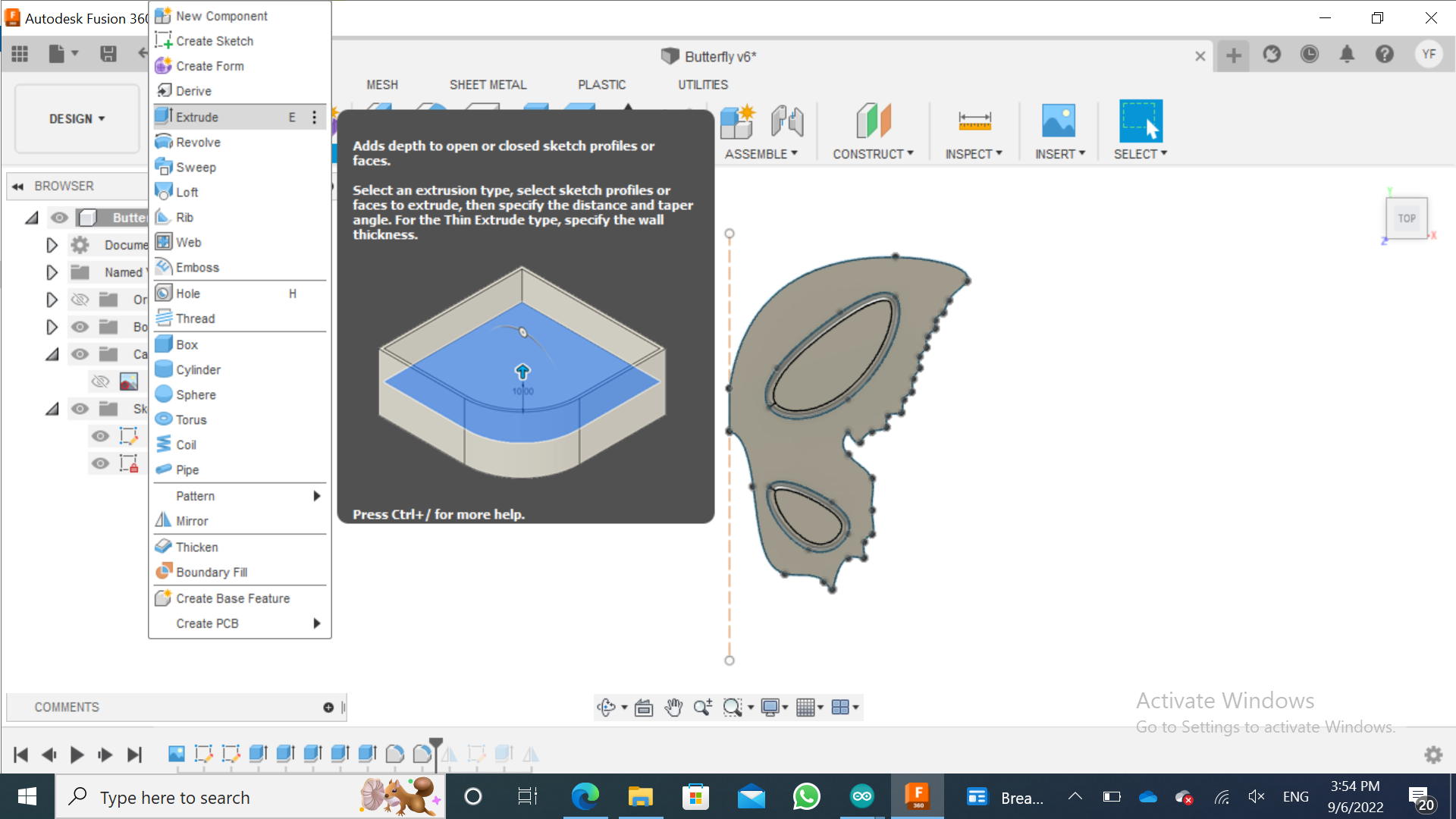

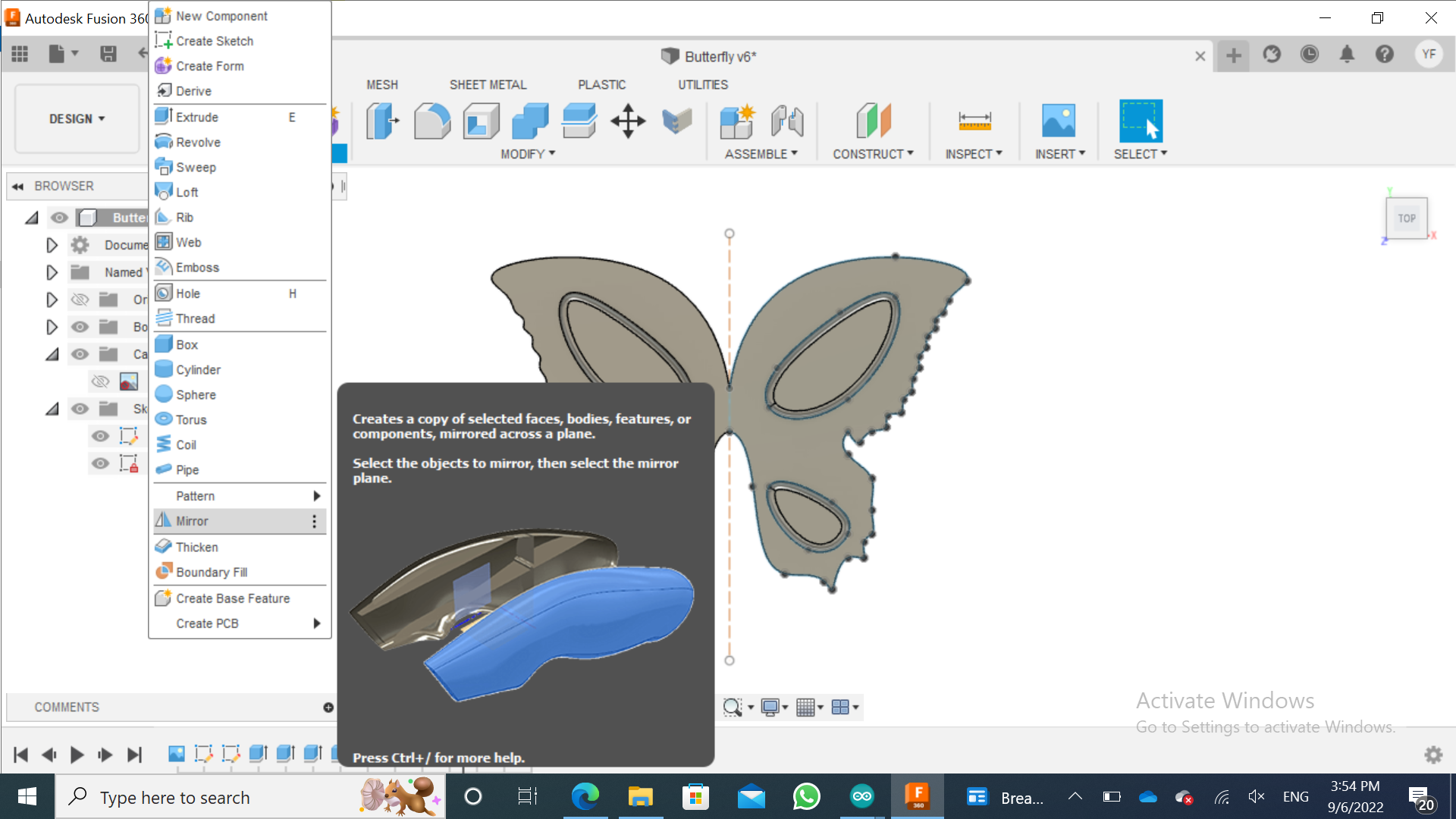

- I used Fusion360 for the design.

-

Insert canvas.

-

Draw.

-

Extrude.

-

Mirror.

Milling machine¶

-

A milling machine is an apparatus that revolves around a circular tool with several cutting edges placed symmetrically on its axis. The workpiece is often held in a vise or other similar device that is clamped to a table that may move in three perpendicular directions.

-

It is controlled by the Computer.

-

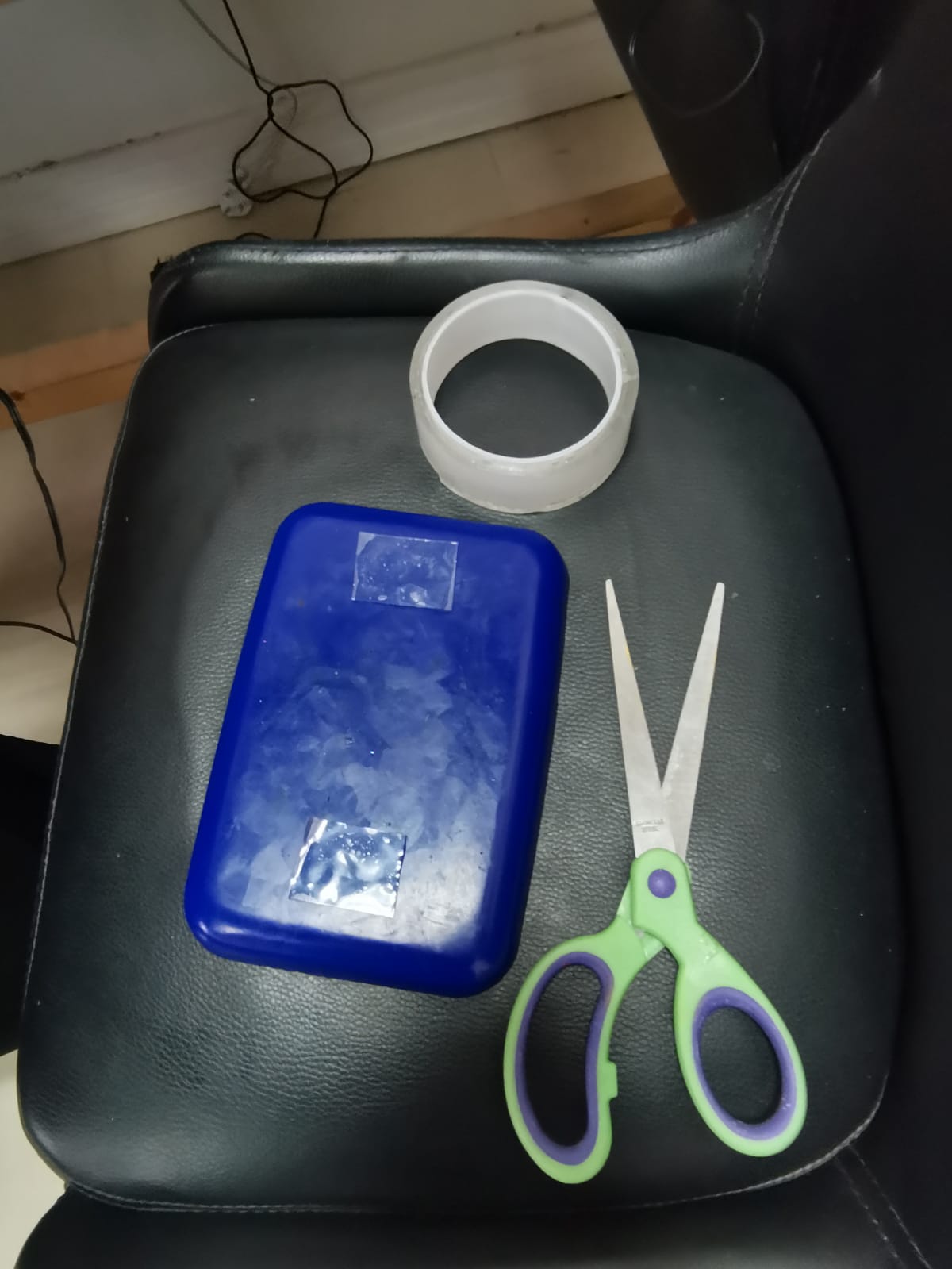

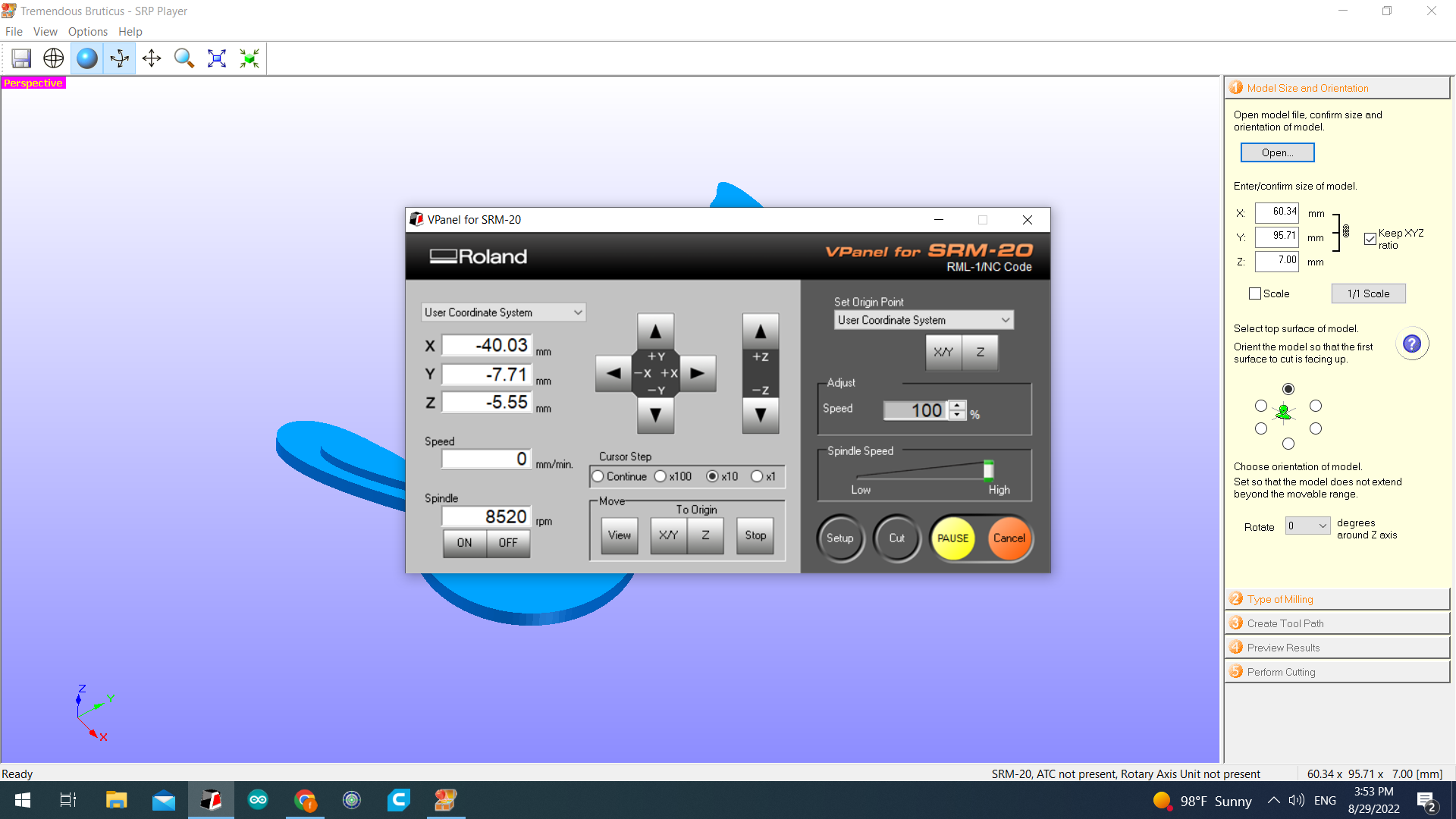

There is many steps befor the molding part, Step 1: We taped the wax plastic with double-sided tape.

-

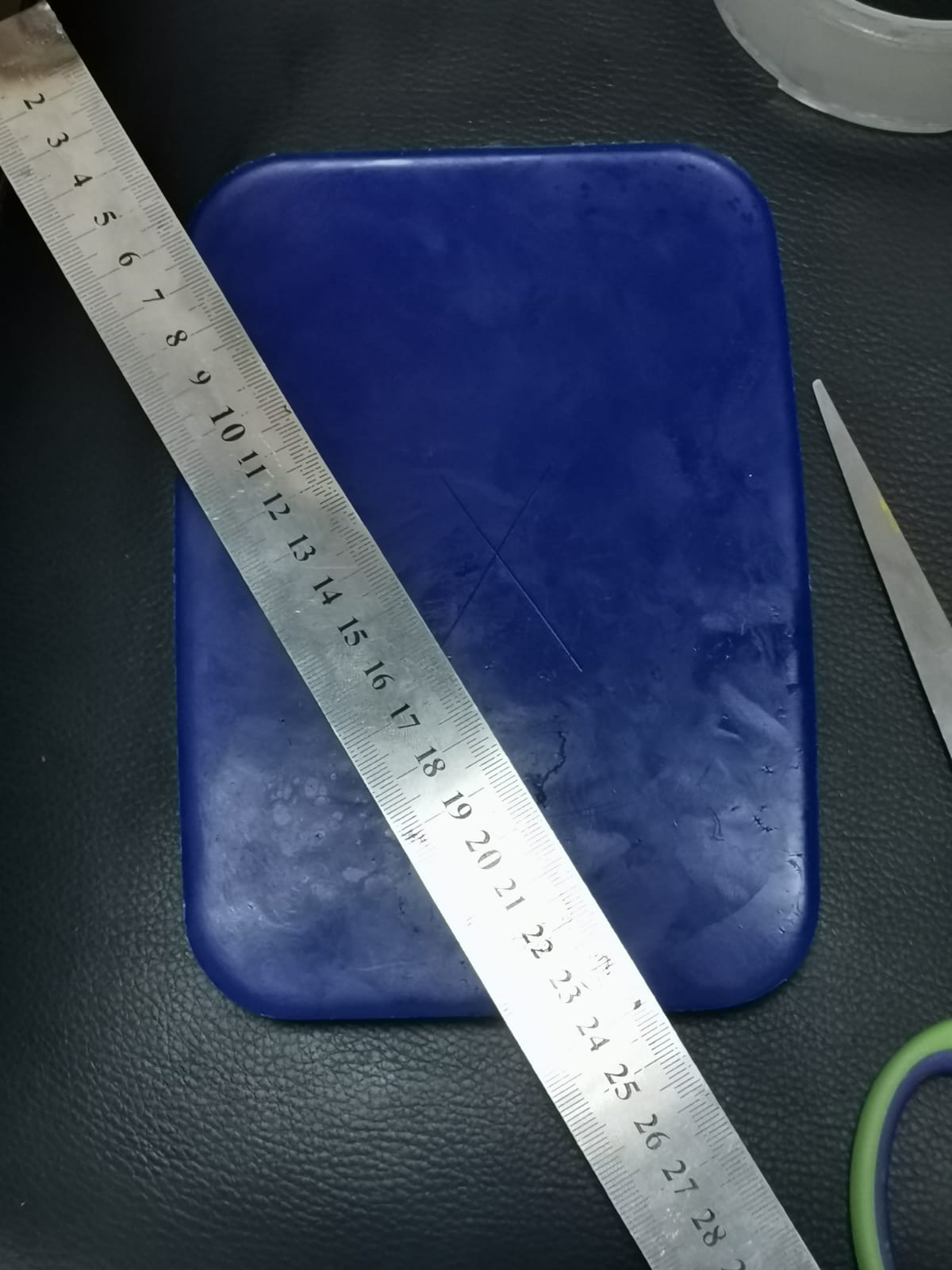

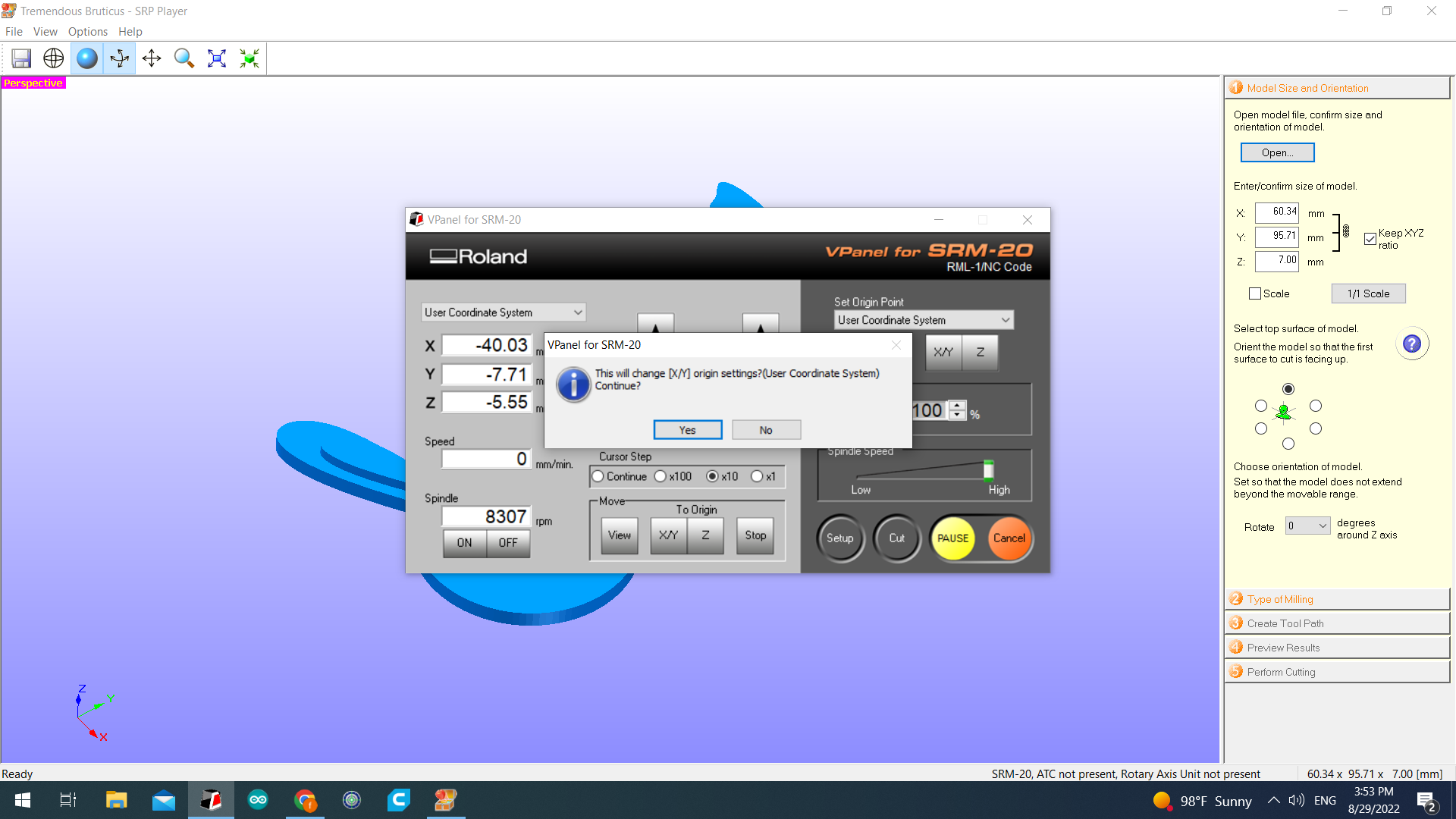

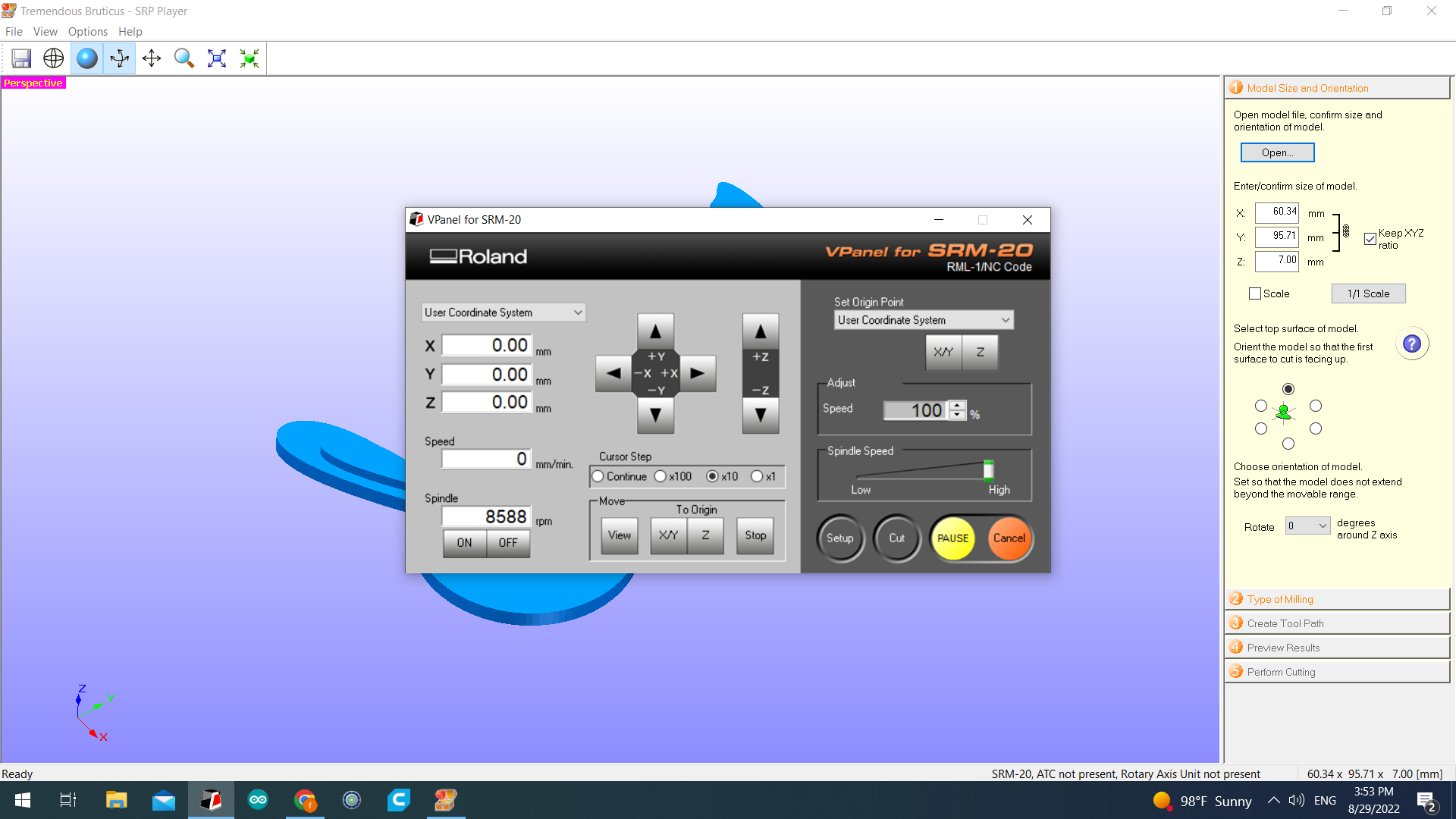

Step 2: Make two cross lines to get the origin point and placed the wax in the machine.

-

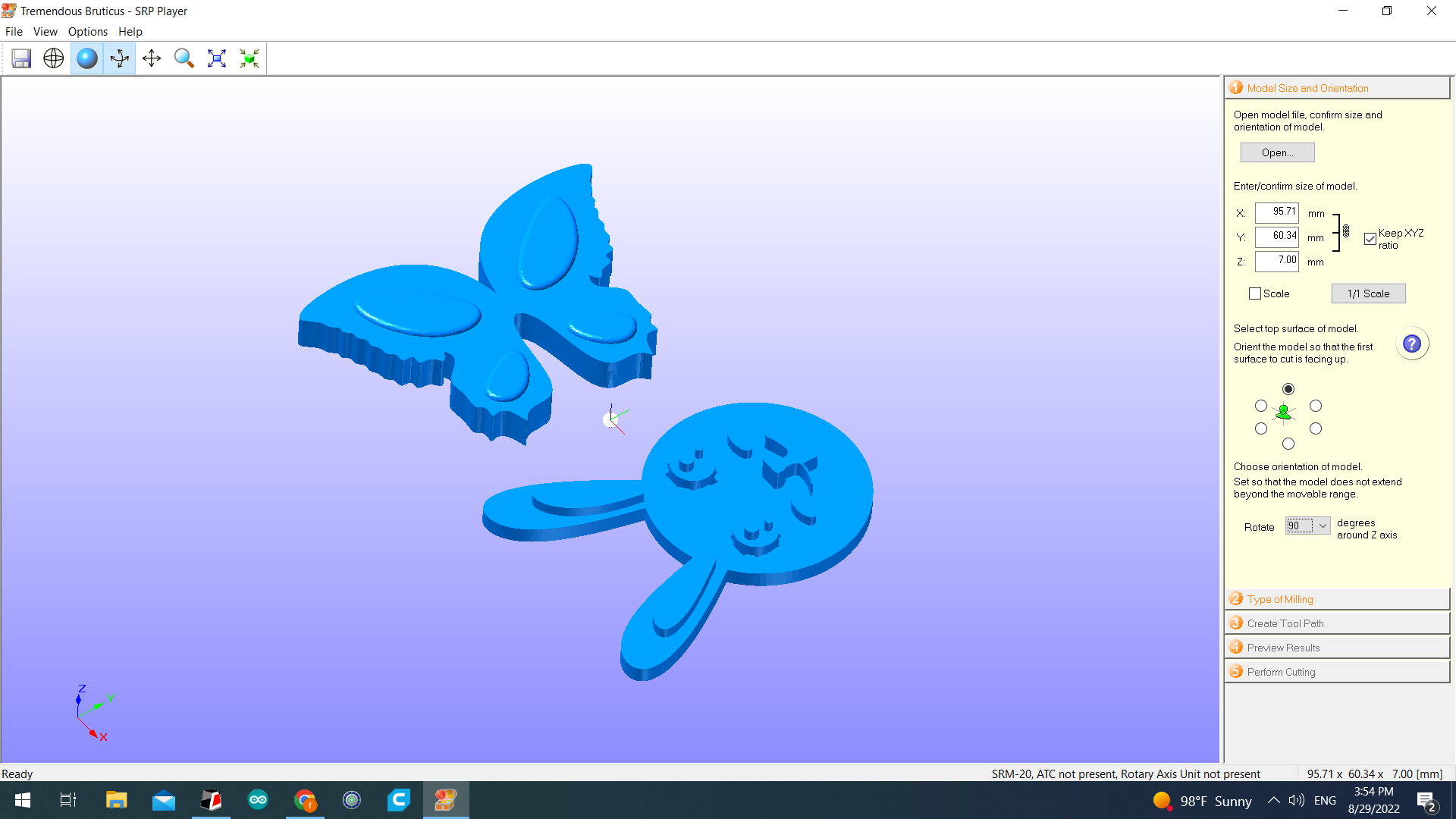

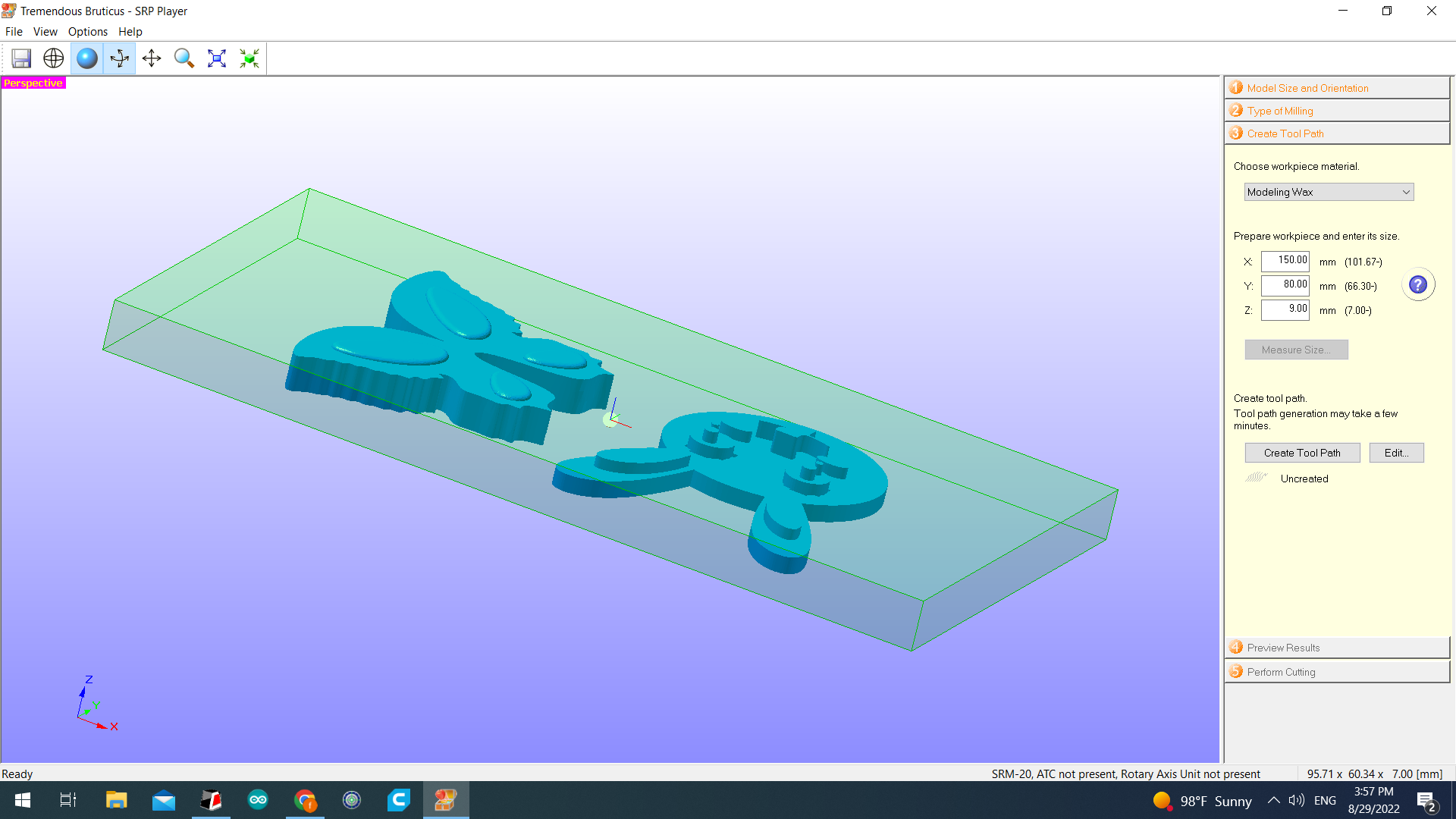

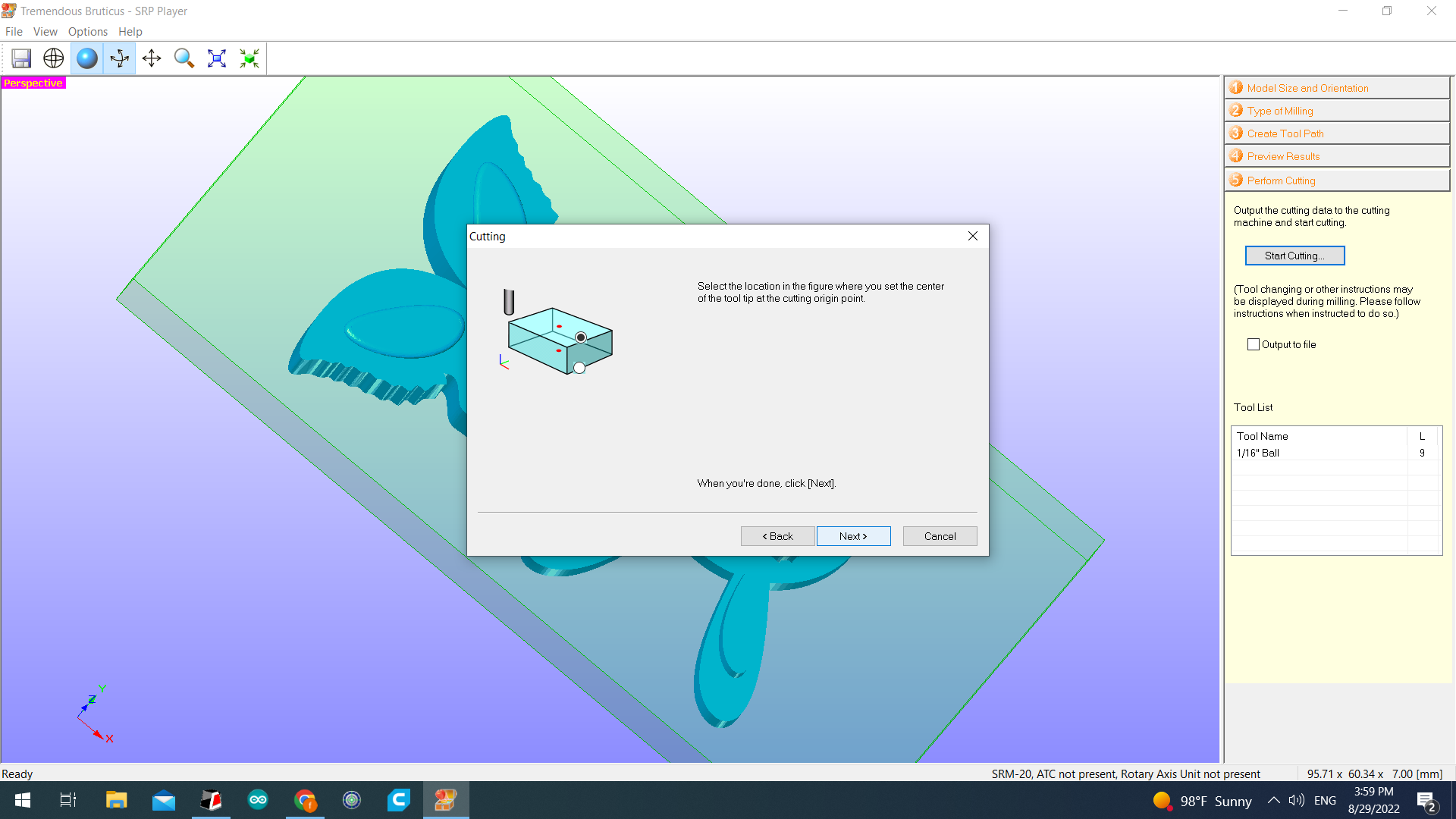

Step 3: Specifying Model size and Orientation.

-

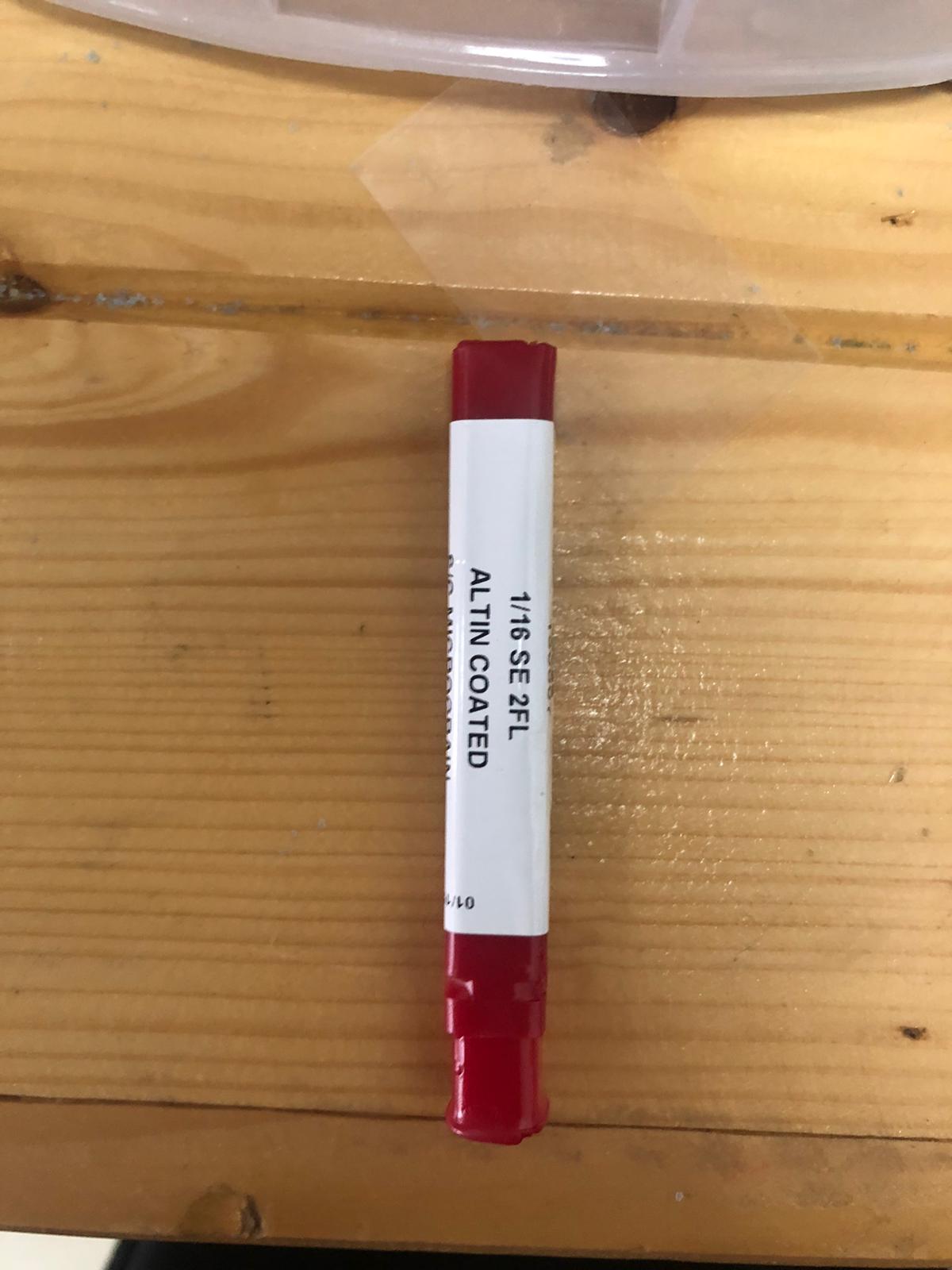

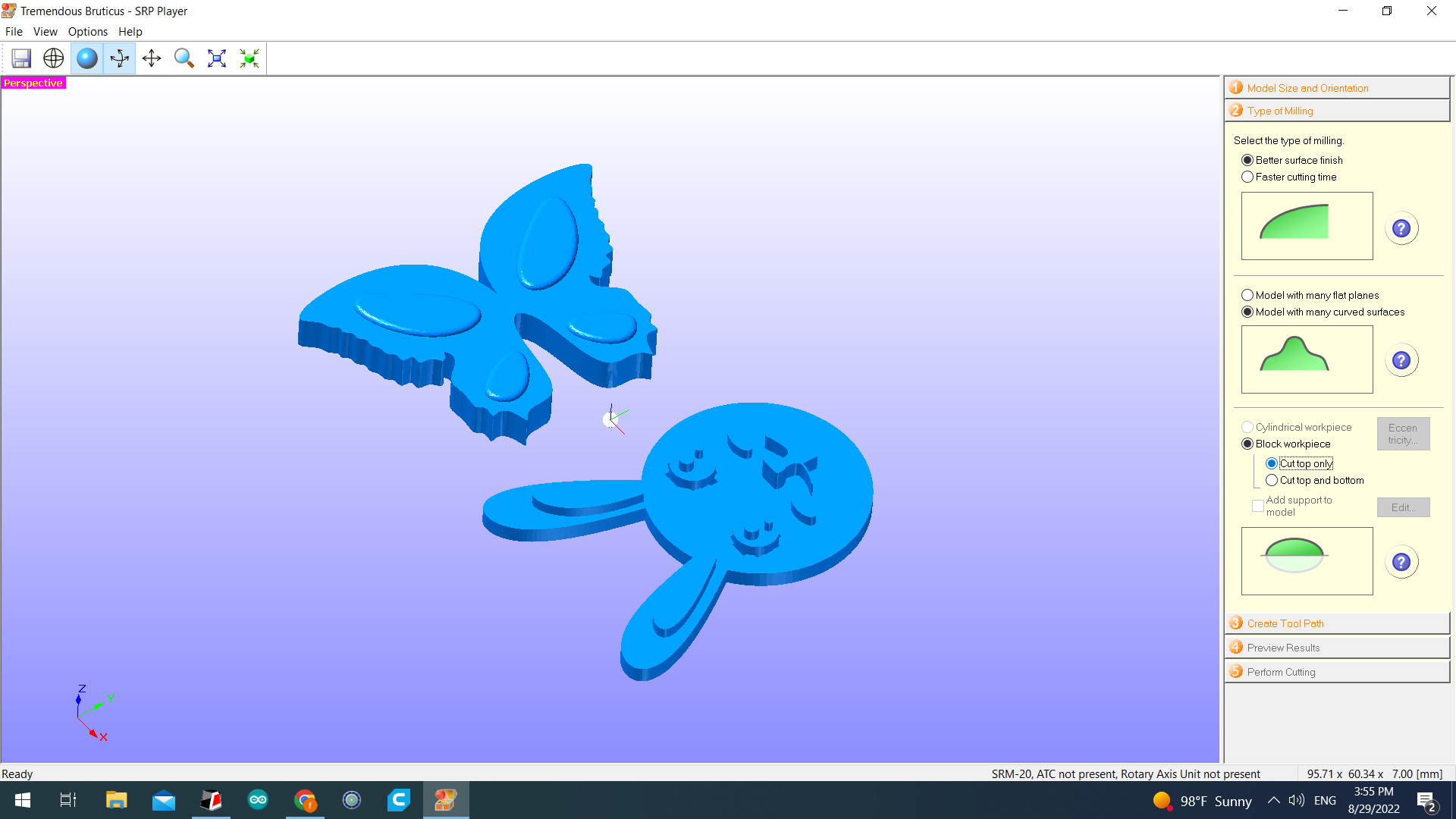

Step 4: Type of Milling.

-

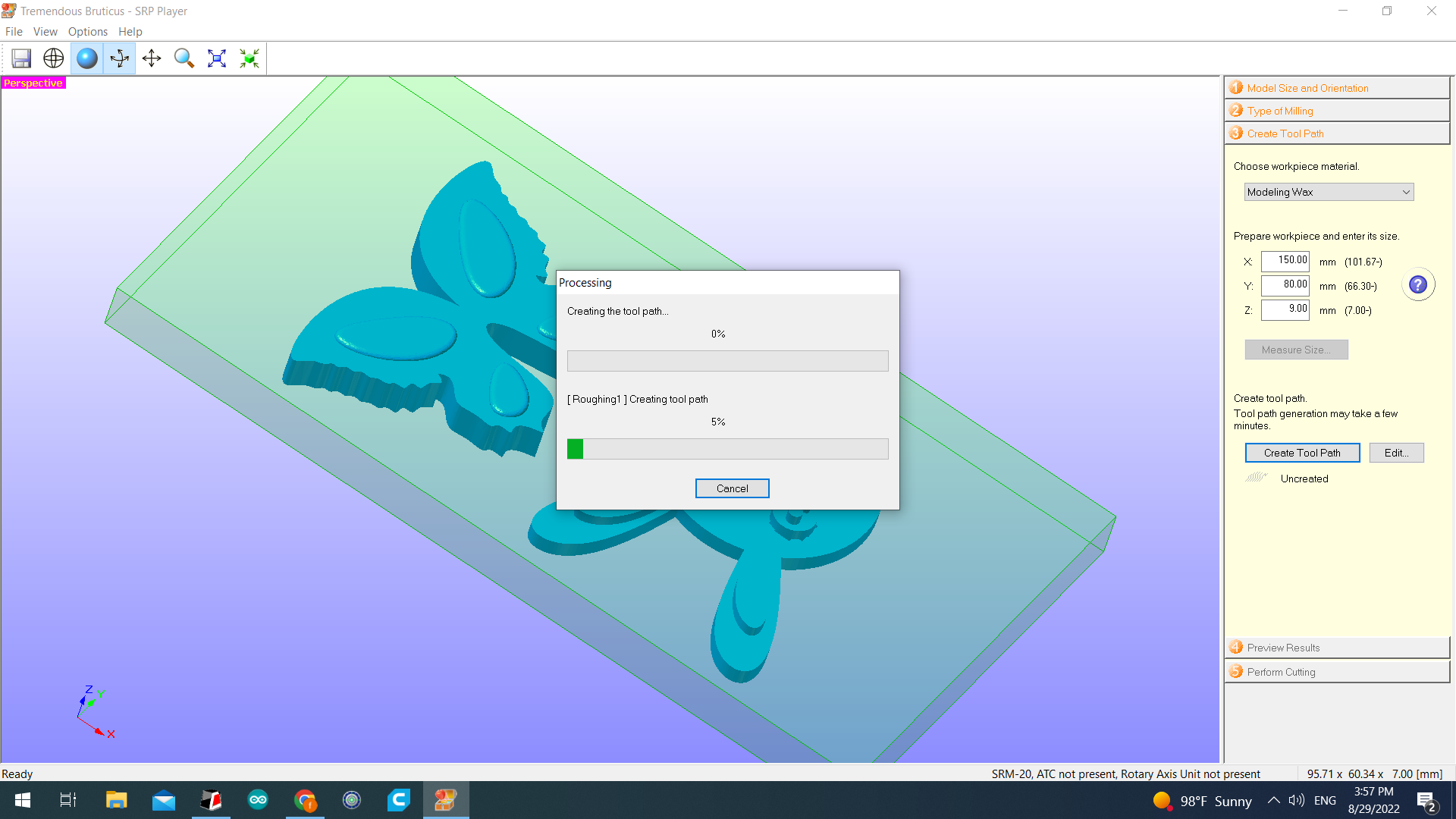

Step 5: Creating toolpath.

-

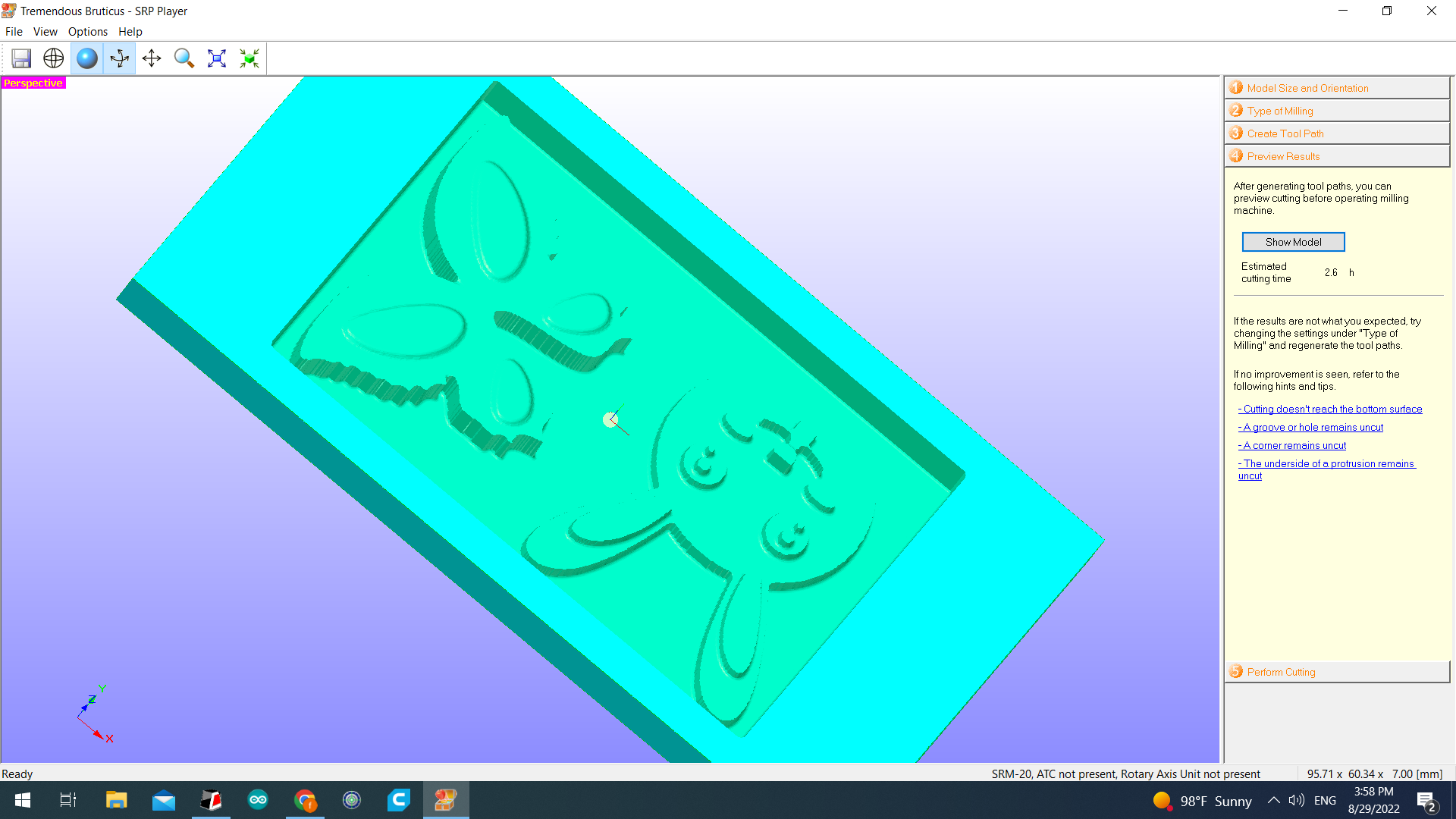

Step 6: Preview Cutting.

-

Step 7: Start Cutting.

-

Result

Molding¶

-

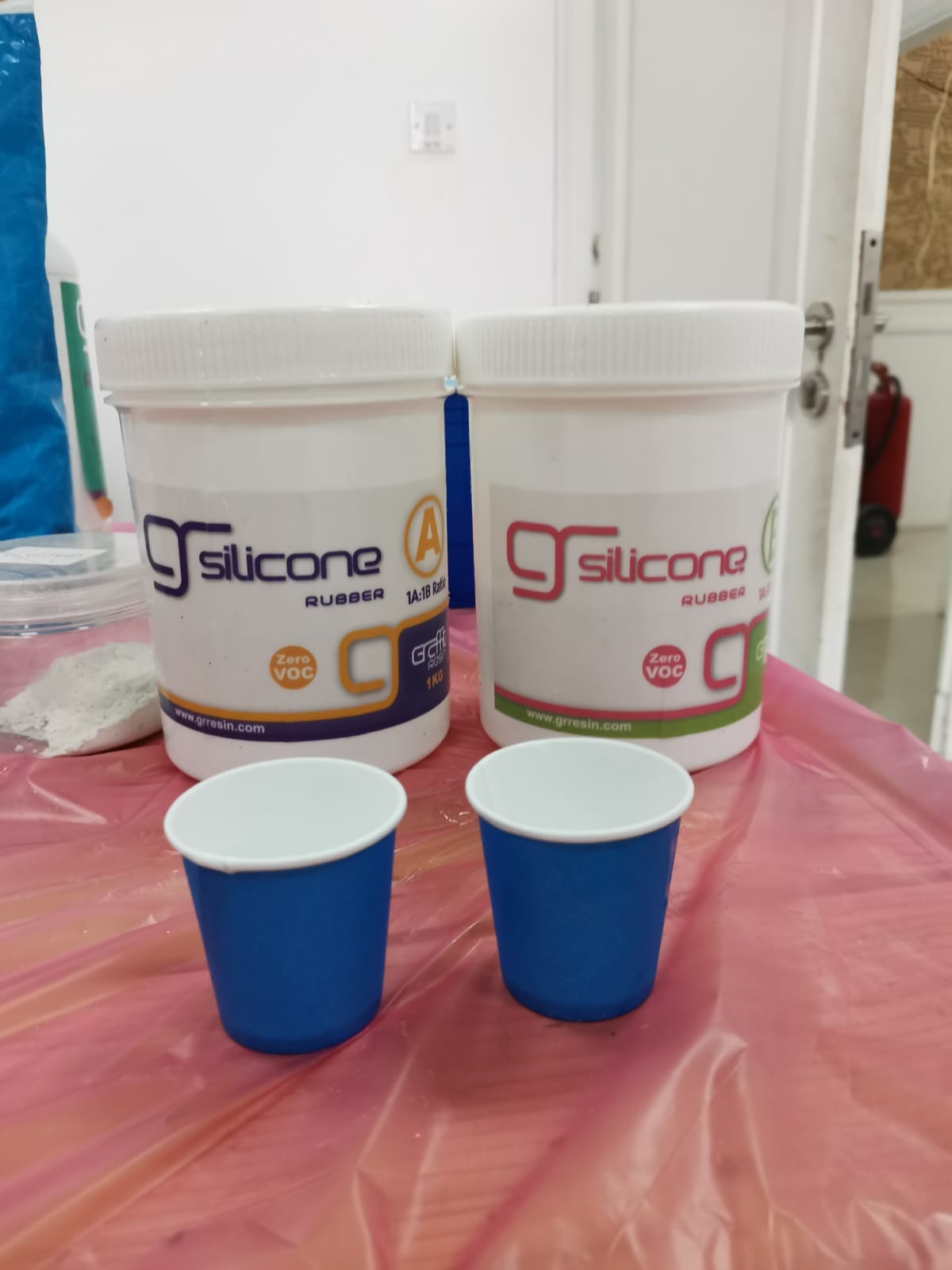

The material used Silicon.

-

Mix ratio: A:B=1:1

-

Safety: Silicon is safe in general. But maybe injected silicon move through the body, and this will cause serious health problems. So to be safe, we need to wear gloves.

-

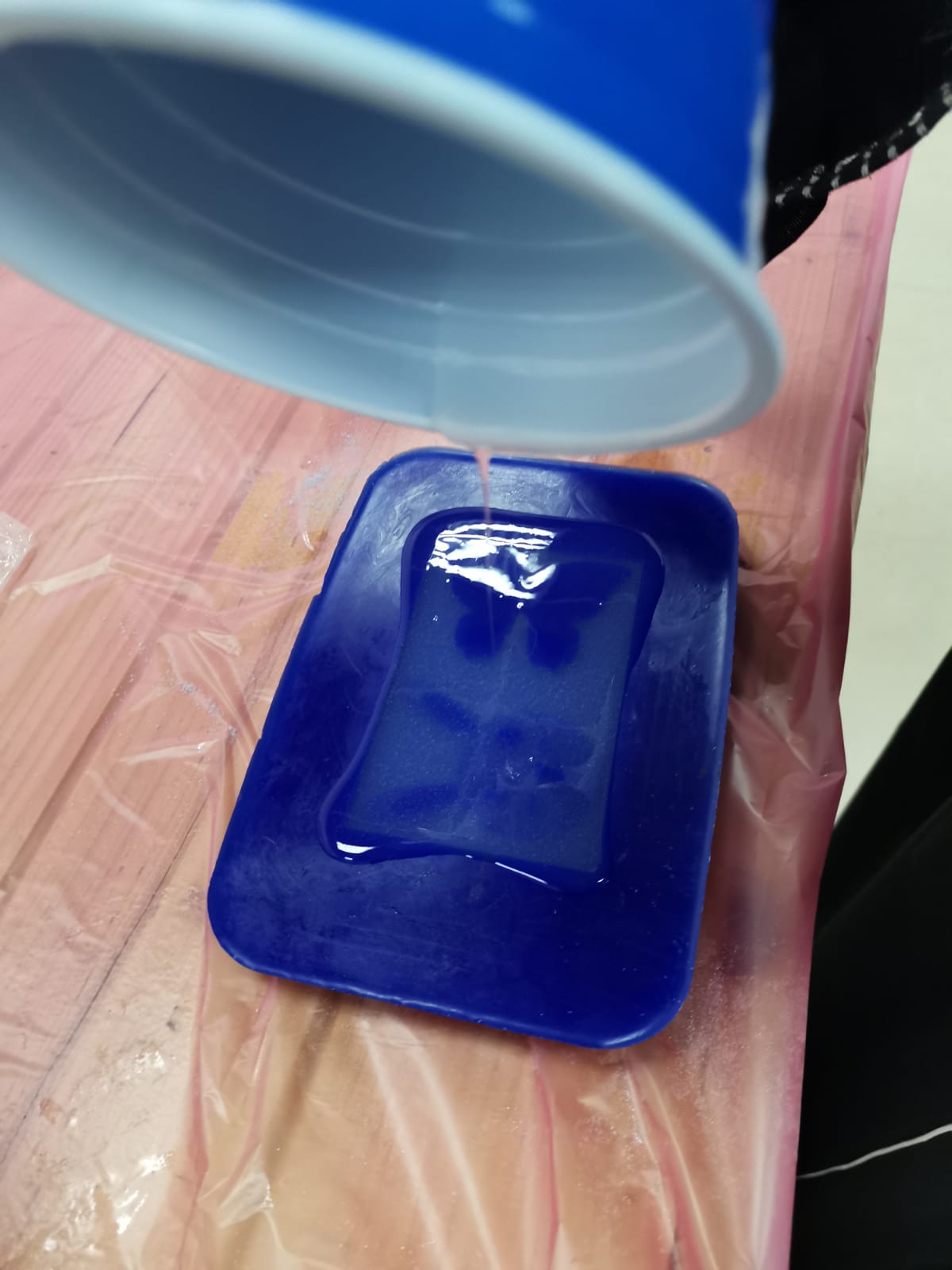

Process Mix part A and B evenly 1:1, and then pour it in vacuum to get rid of bubbles. Then, pour the mixture into a mould and let it dry.

-

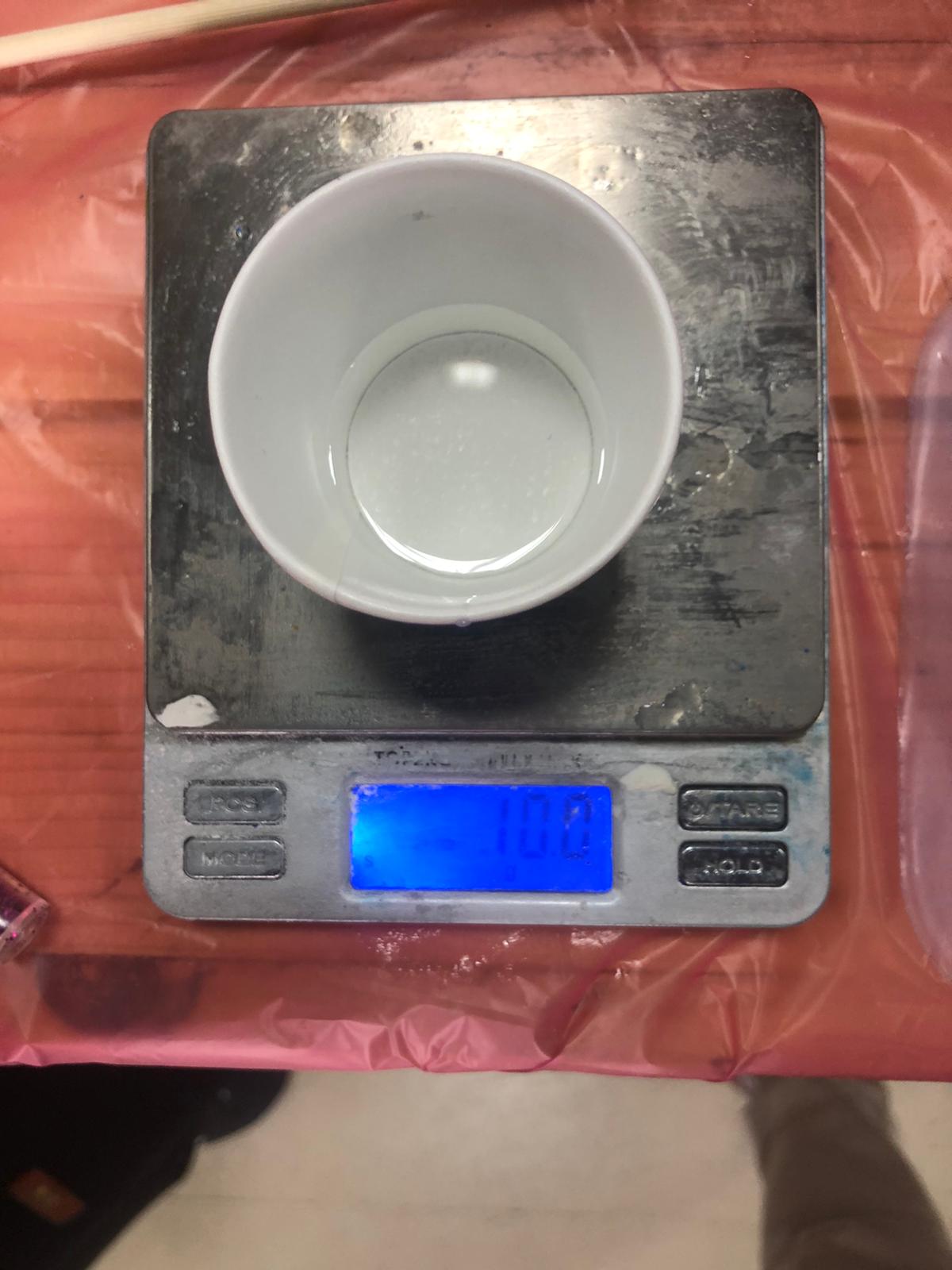

We should fill the mold with water which was 45.8g to find the amount of the silicon in grams.

-

We add the grams of water and extra 5 to 10 grams to make sure that the silicon be hard.

-

Result

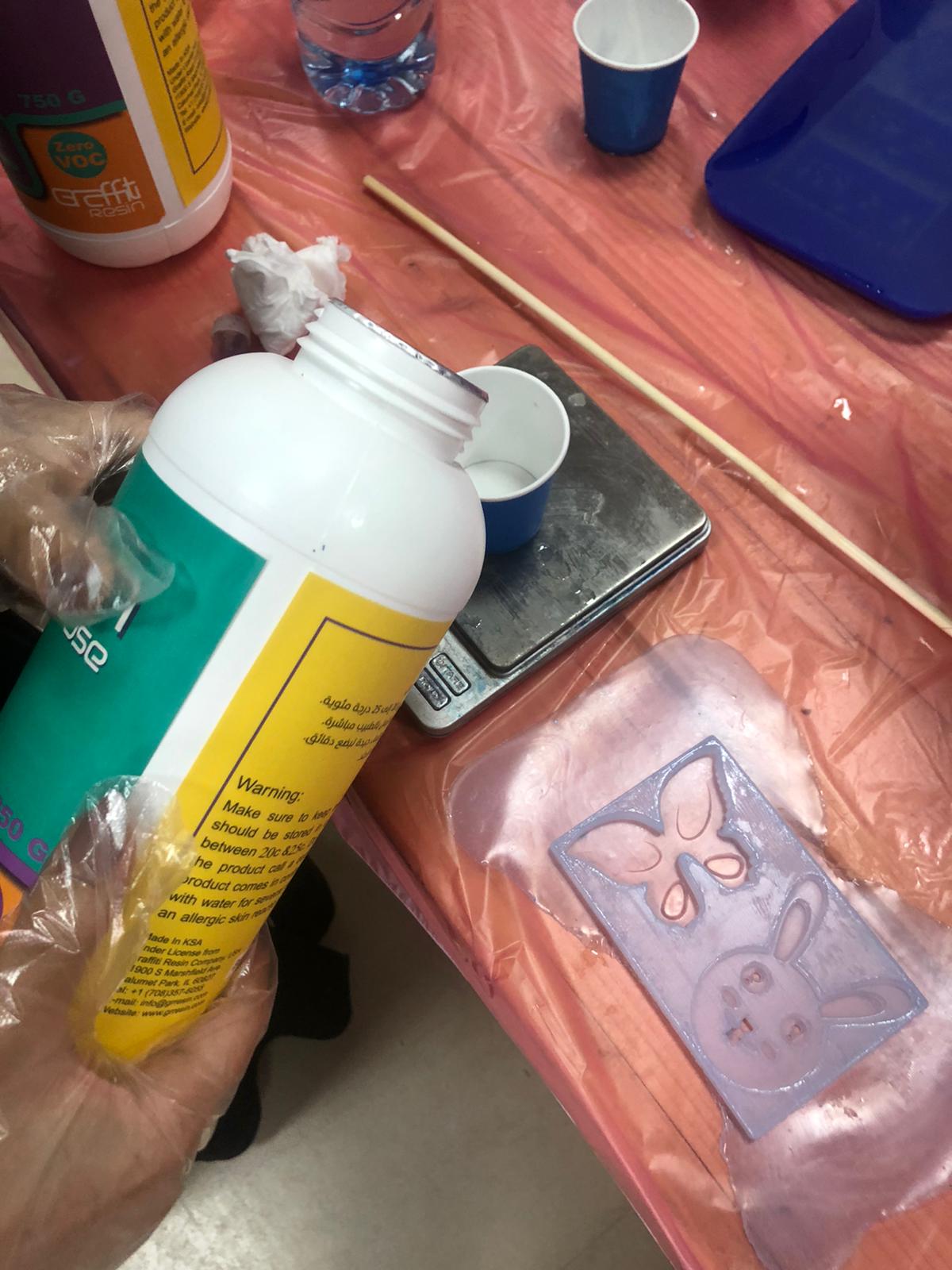

Casting¶

- We chose to use resin, which is available in two different types, for the casting. As a result, we blended in the ratio 10A:6B. After 3 minutes of blending, we added pink glitter to modify the hue.

Safety:¶

- Make sure to keep away from kids.

- Should be stored in a dry place. Preferably in the sealed original container, at a temperature between 20c & 25c.

- Wear face masks for pregnants when using the product.

- Wear protective gloves when you use the product.

- Do not swallow. If you swallowed the resin, call a doctor immediately.

- In case the product comes in contact with eyes : rinse cautiously with water for several minutes.

-

Caution it may cause an allergic skin reaction.

-

Fill the mold, then wait 24 hours to see how it turns out.

Final result¶