4. computer controlled cutting¶

This week we learned digital fabrication specially laser cutting and vinyl cutting.

In general there is two types of fabrication.

-

Additive.

-

Subtractive.

This week we will deal with the Subtractive type of fabrication

Group Assignment:¶

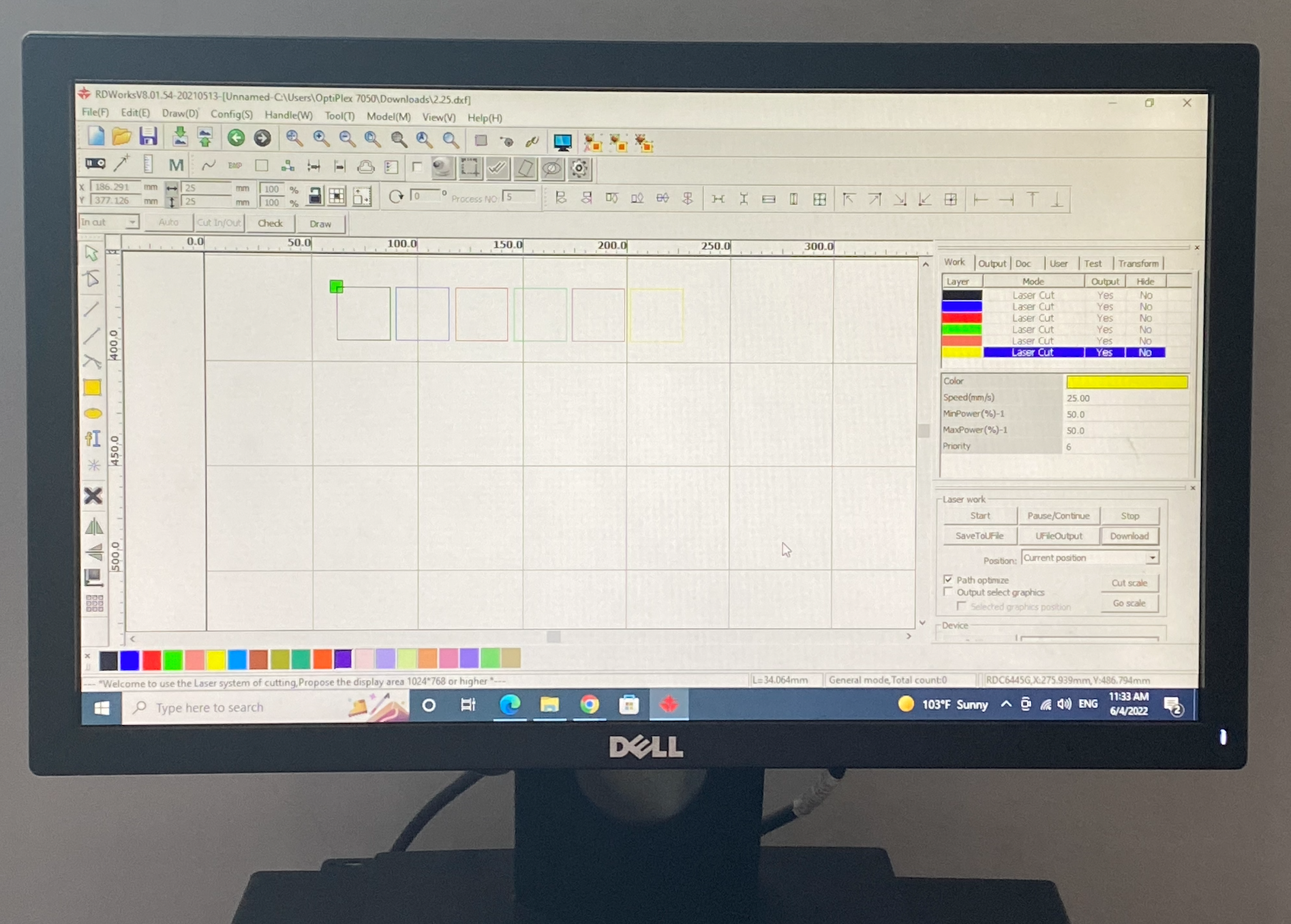

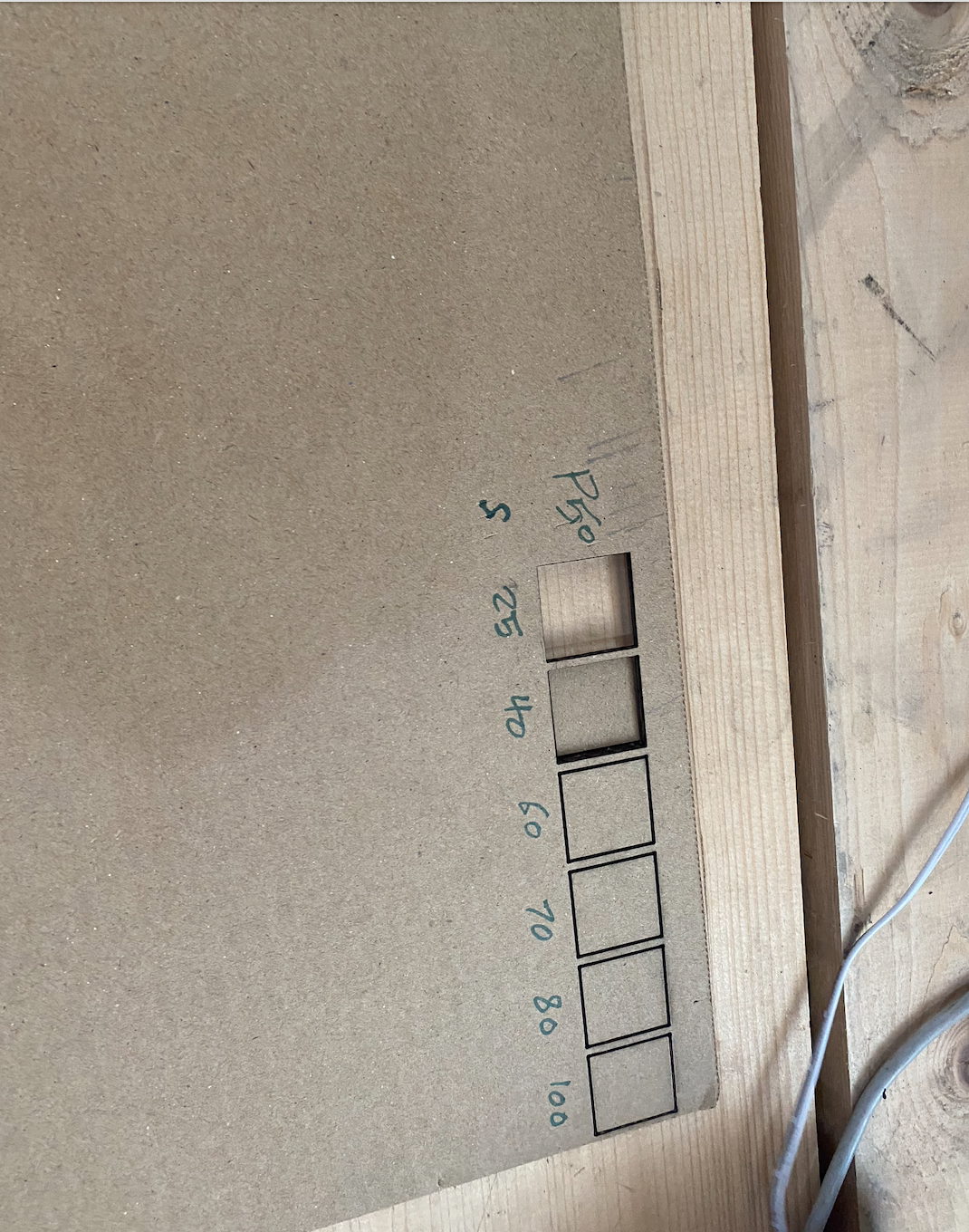

The group assignment for this weak is to experiment different variables in the laser cutting machine.

There are three variables we can change.. the first variable is the power (unit watt), the second is the speed (mm/s), and the third variable is the focus (z-axis distance).

To test the power: fix focus distance and speed, make the power variable that changes (25, 40, 55, 70, 85, 100), see the results to determine the best power setting.

To test the speed: fix the focus distance and power, make the speed variable that changes (10, 30, 50, 70, 100, 150), after cutting see the results to determine the best speed settings

To test the focus: fix both the power and speed, make the focus distance variable and change a little bit up or down everytime, record the best distance..

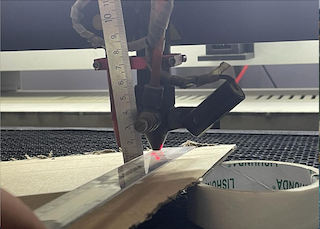

// NOTE: the reason why there is focus distance is that there is lens that focus the radiation, to have certain information about the best distance read the laser machine manual.

Here I will attach some photos of the Group Assignment progress:

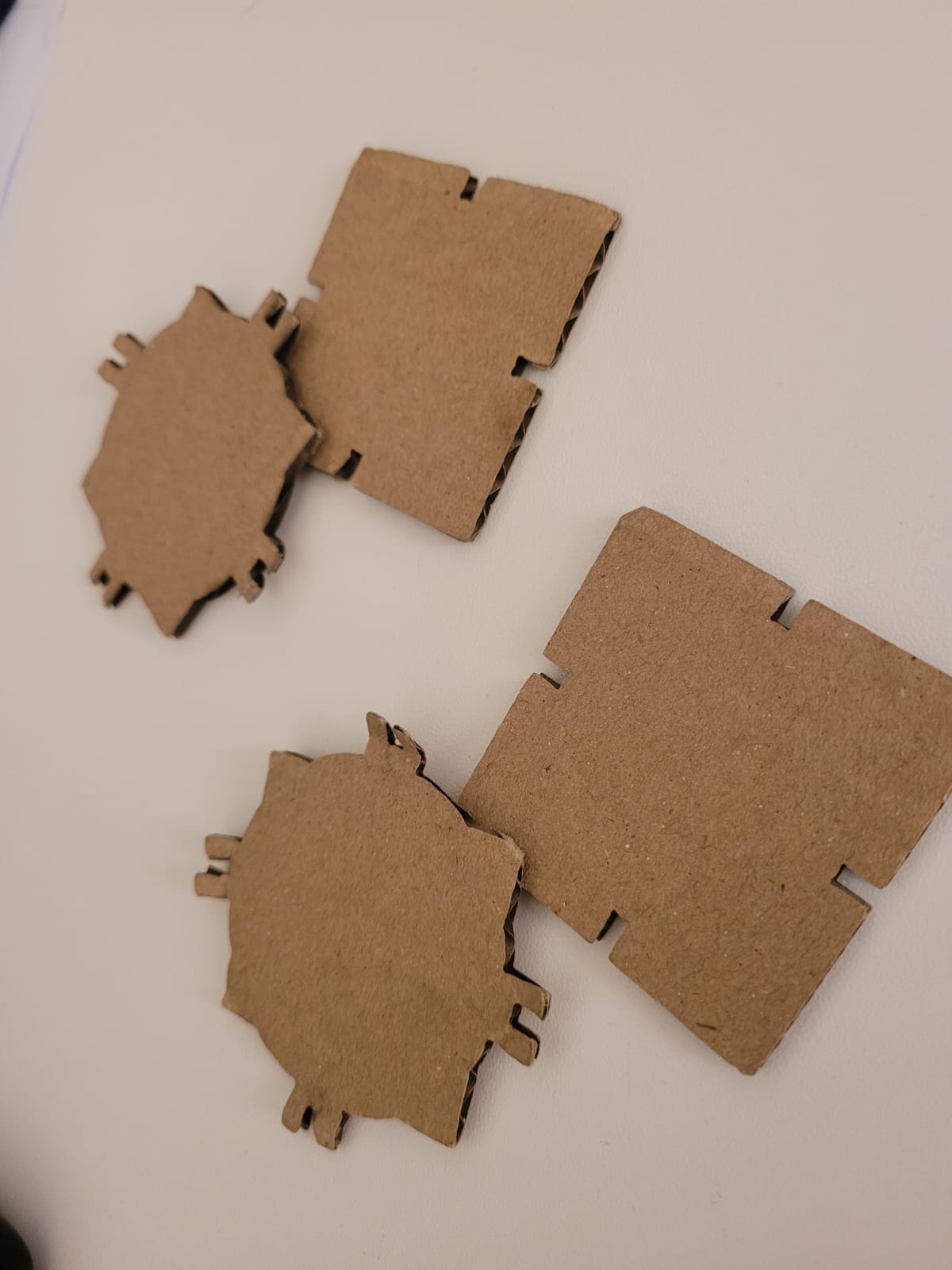

Testing the clearance: as part of the group assignment we are asked to make several joints size to test which one is the best.

Individual Assignment:¶

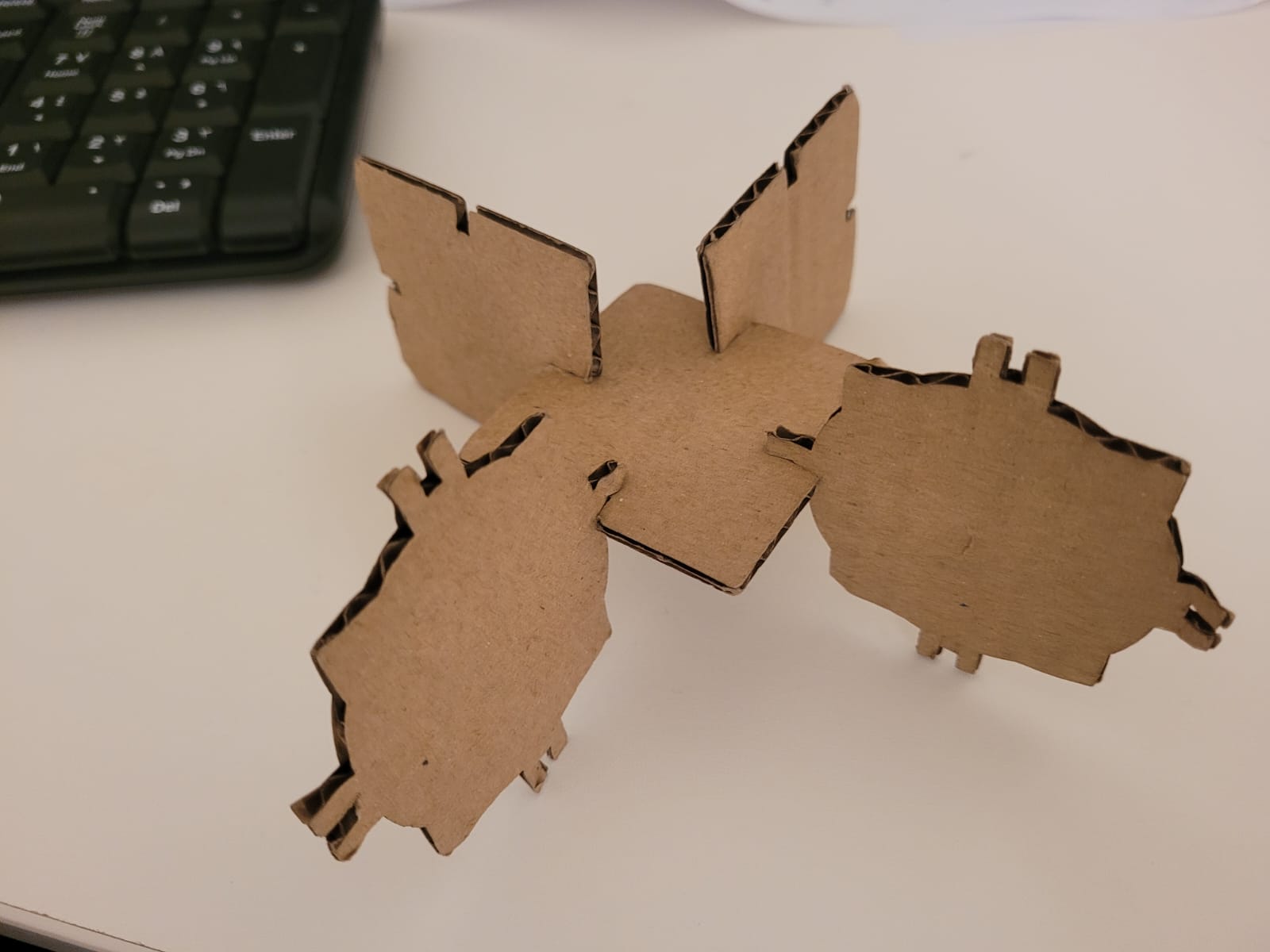

In this week we prepared a parametric design to cut using the laser machine.

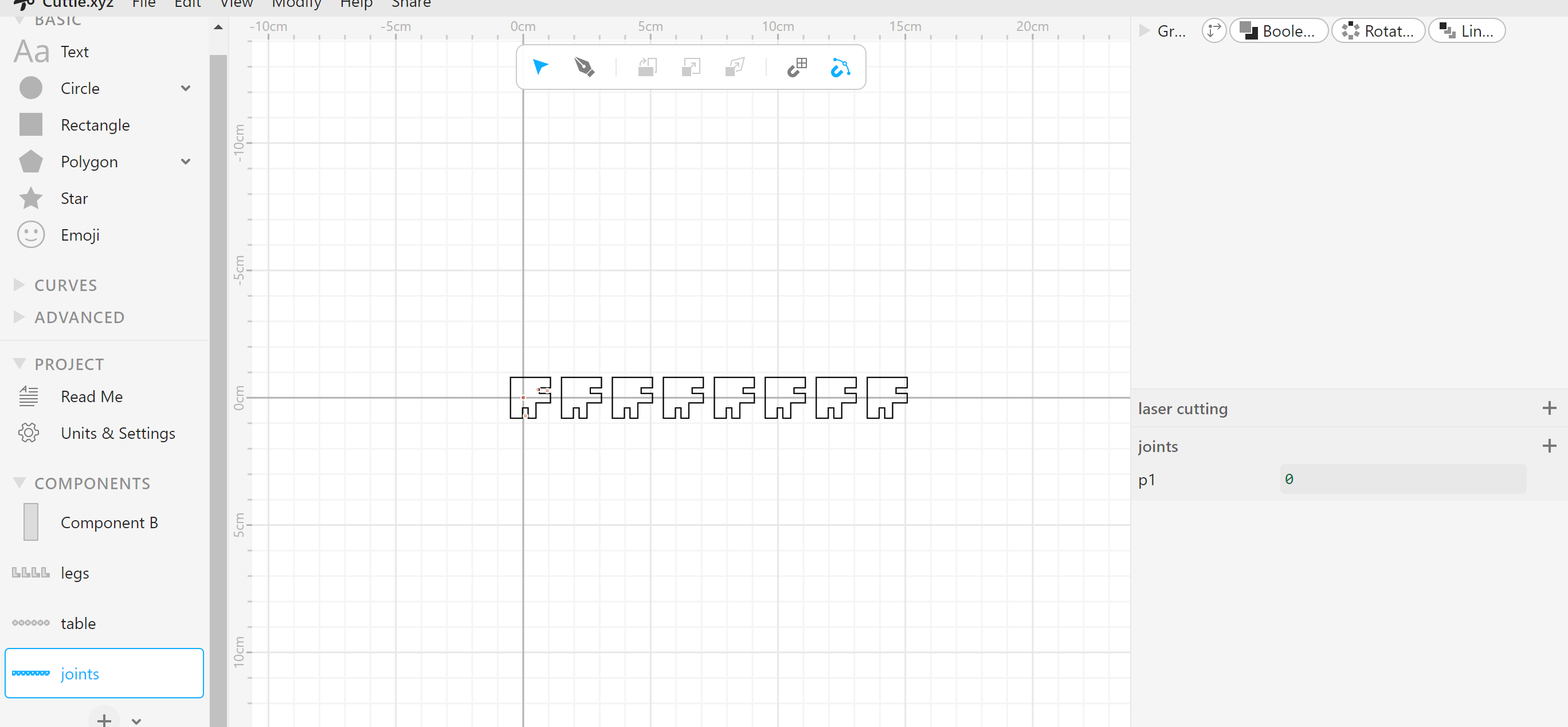

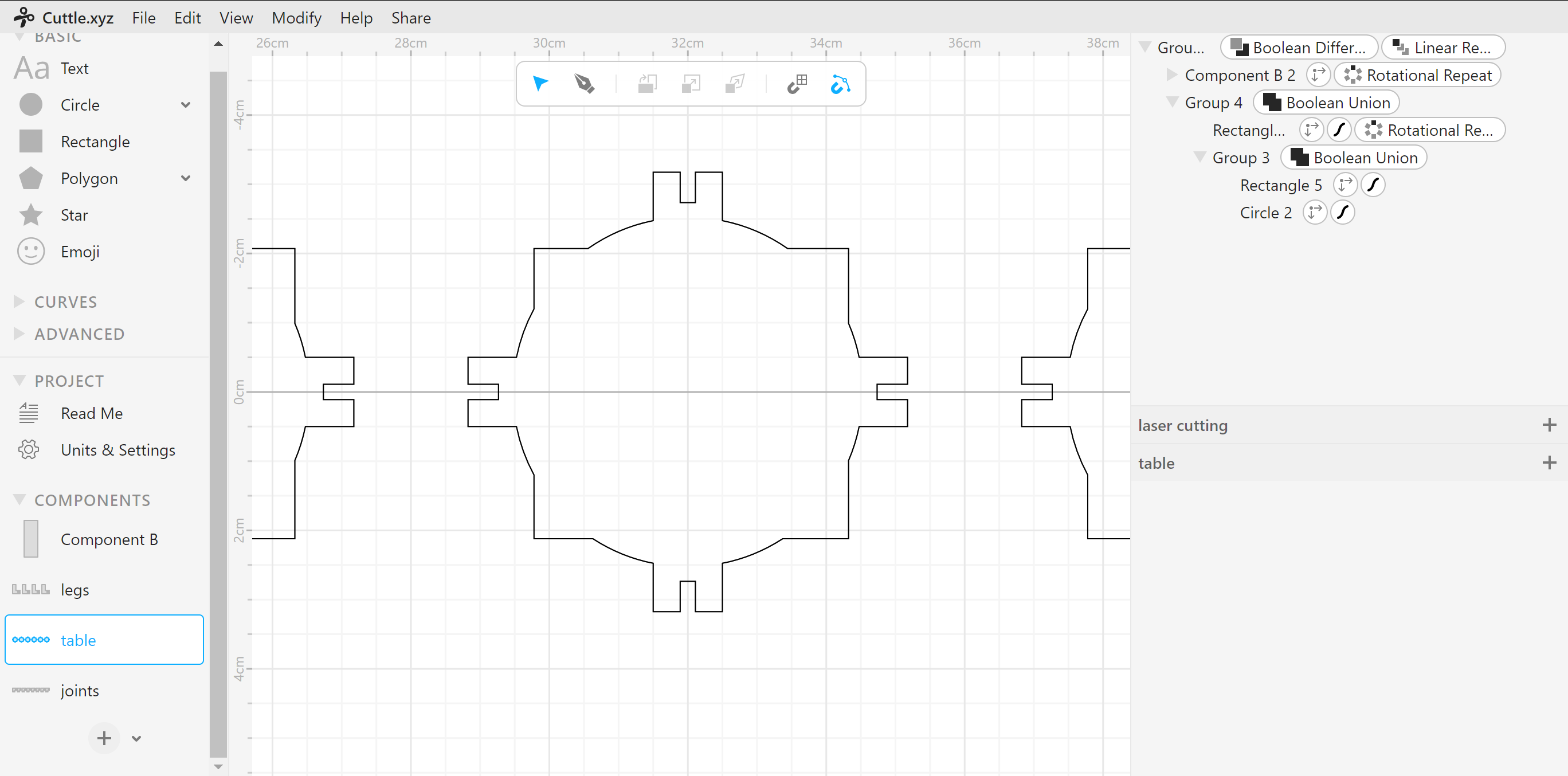

I used cuttel to do the design.

Doing a parametric design in cutlle is very simple…

Steps:

-

1: I prepared the shape I wanted to cut.

-

2: I added a parametric part in the shape to attach it with the joints,

-

3: I did the joints in a new component to fit the shape.

The design: Link

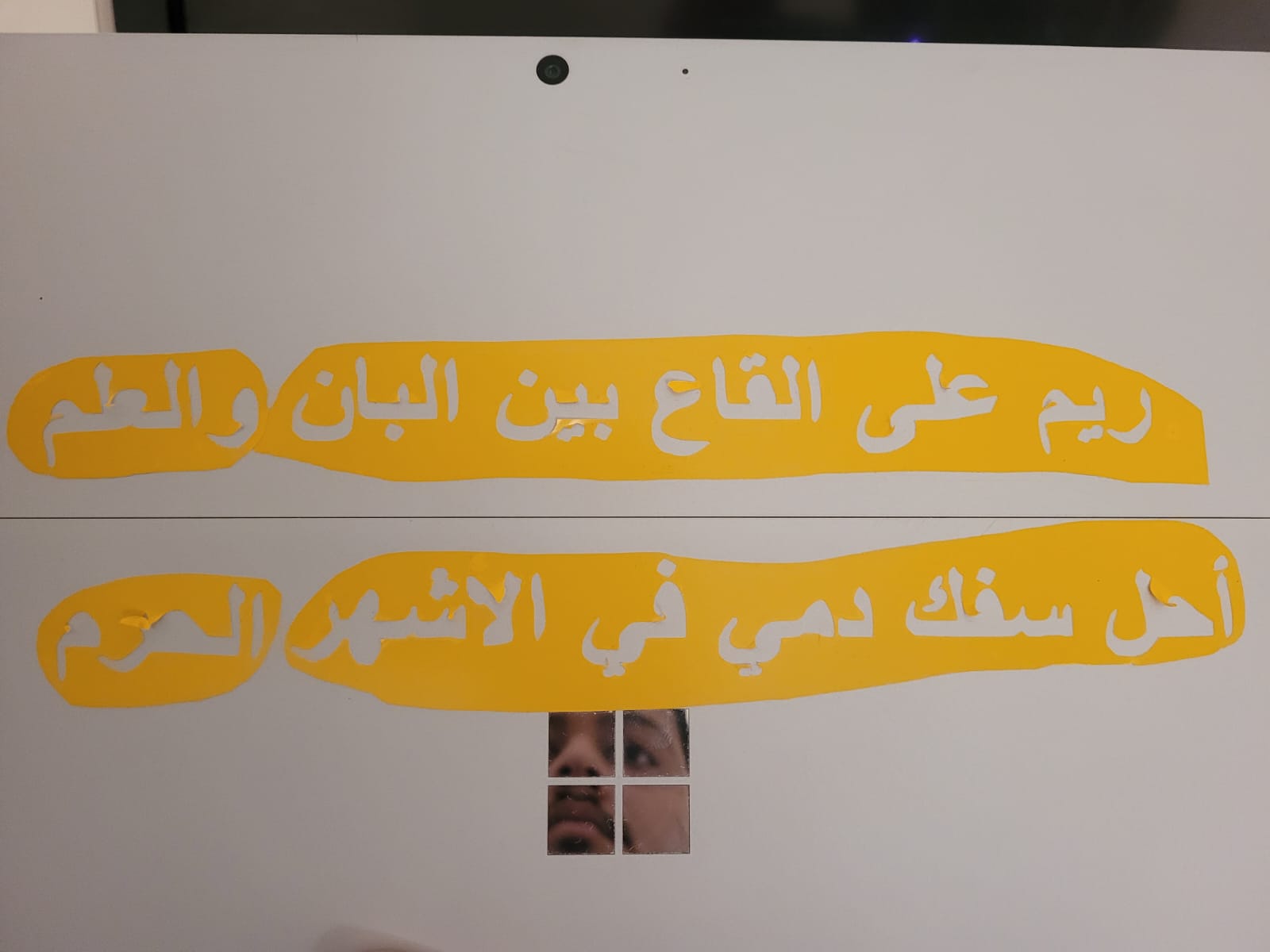

Vinyl cutting: In this part of the assignment we made owr own sticker..

First prepare the design then send it to the machine and cut it.