3. Computer controlled cutting¶

This week I worked on learning computer controlled cutting using vinyl-cutting and laser-cutting.

information about Laser cutting¶

Laser cutting is a thermal separation technique . When the laser beam collides with the material’s surface, it heats it to the point where it melts or vaporizes. When the laser beam passes through the material fully at a specific location and cuts it as it passes.

How Does Laser Cutting Work?¶

Laser cutting uses a high-power laser which is directed through optics and computer numerical control (CNC) to direct the beam or material. Typically, the process uses a motion control system to follow a CNC or G-code of the pattern that is to be cut onto the material. The focused laser beam burns, melts, vaporises or is blown away by a jet of gas to leave a high-quality surface finished edge.

The laser beam is created by the stimulation of lasing materials through electrical discharges or lamps inside a closed container. The lasing material is amplified by being reflected internally via a partial mirror until its energy is enough for it to escape as a stream of coherent monochromatic light. This light is focused at the work area by mirrors or fibre optics that direct the beam through a lens which intensifies it.

At its narrowest point, a laser beam is typically under 0.0125 inches (0.32 mm) in diameter, but kerf widths as small as 0.004 inches (0.10mm) are possible depending on material thickness.

Where the laser cutting process needs to start anywhere other than the edge of the material, a piercing process is used, whereby a high power pulsed laser makes a hole in the material, for example taking 5-15 seconds to burn through a 0.5-inch-thick (13 mm) stainless steel sheet

indivisual assignment¶

Laser Machine Cutting¶

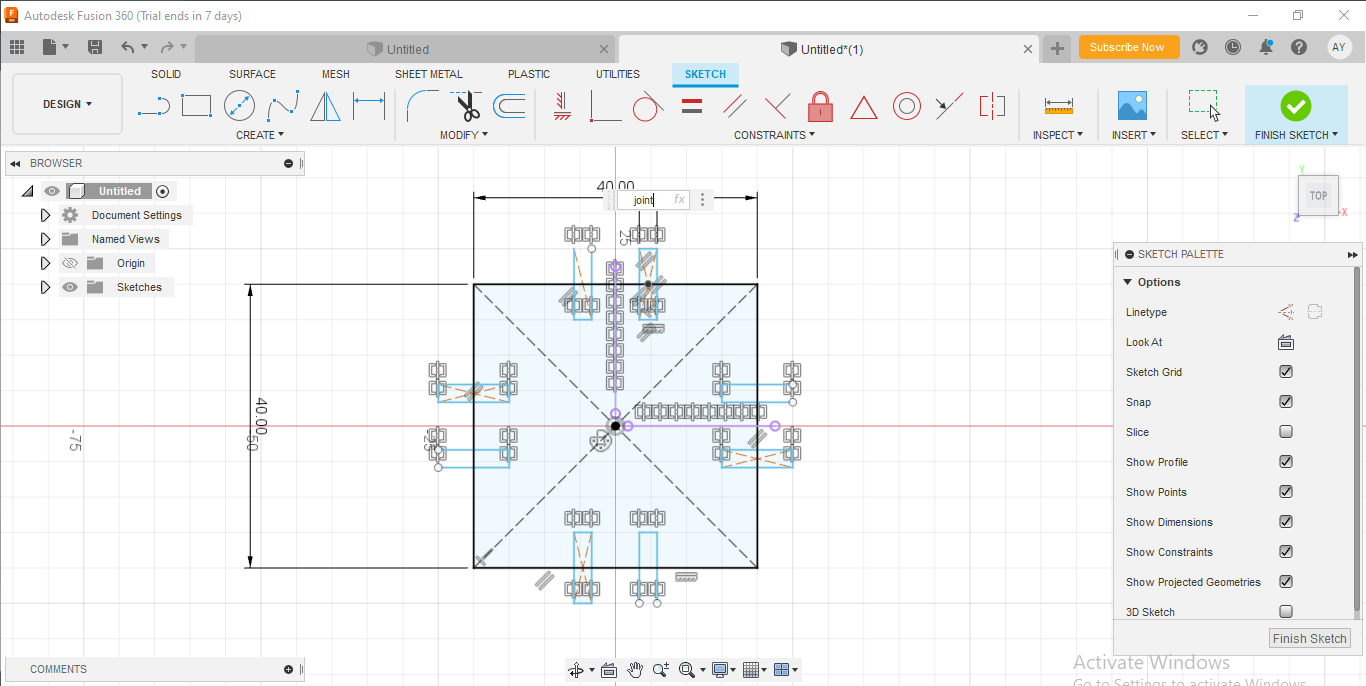

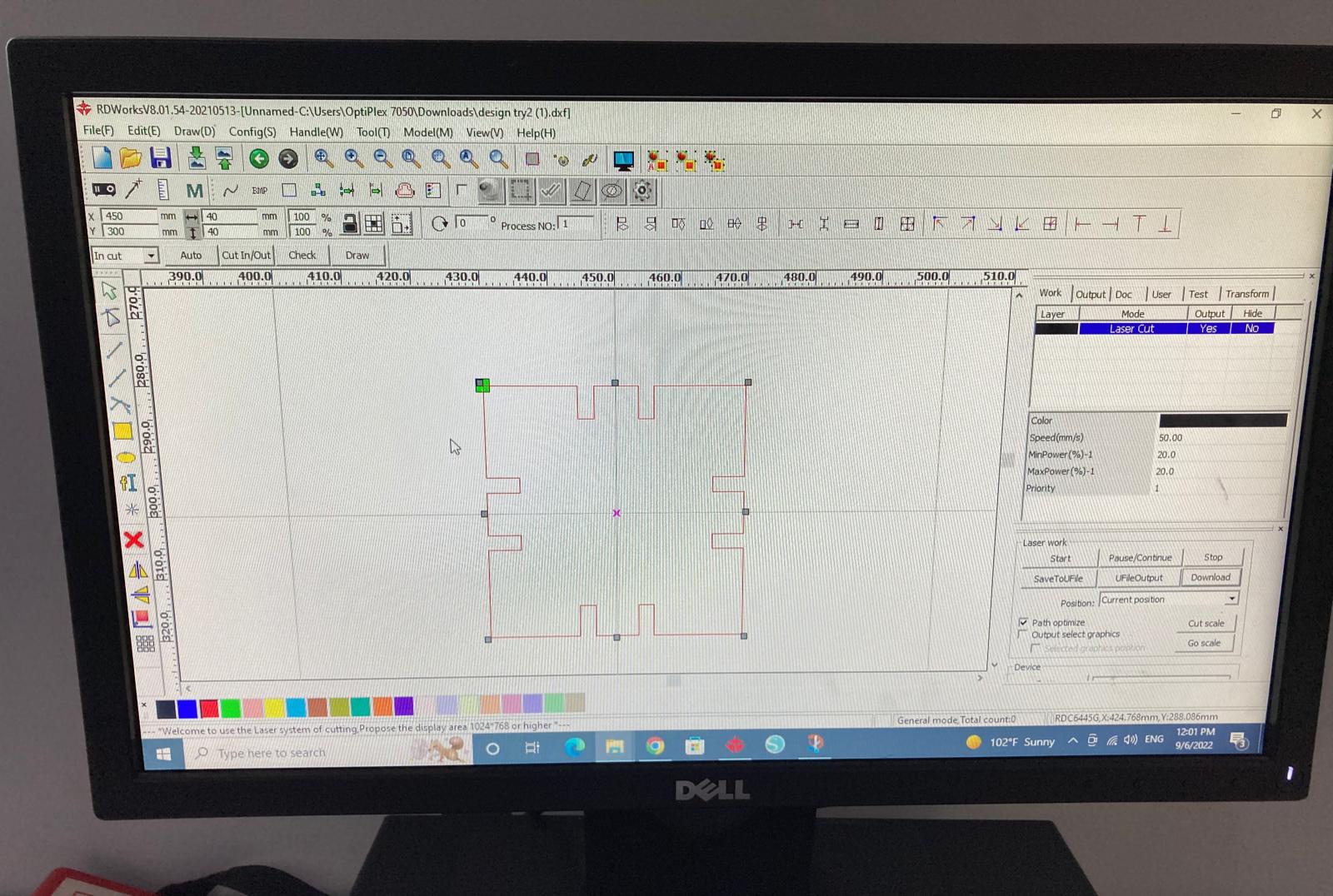

1- After calibrating the Laser Cutting Machine with the group, I started designing a model in Fusion 360

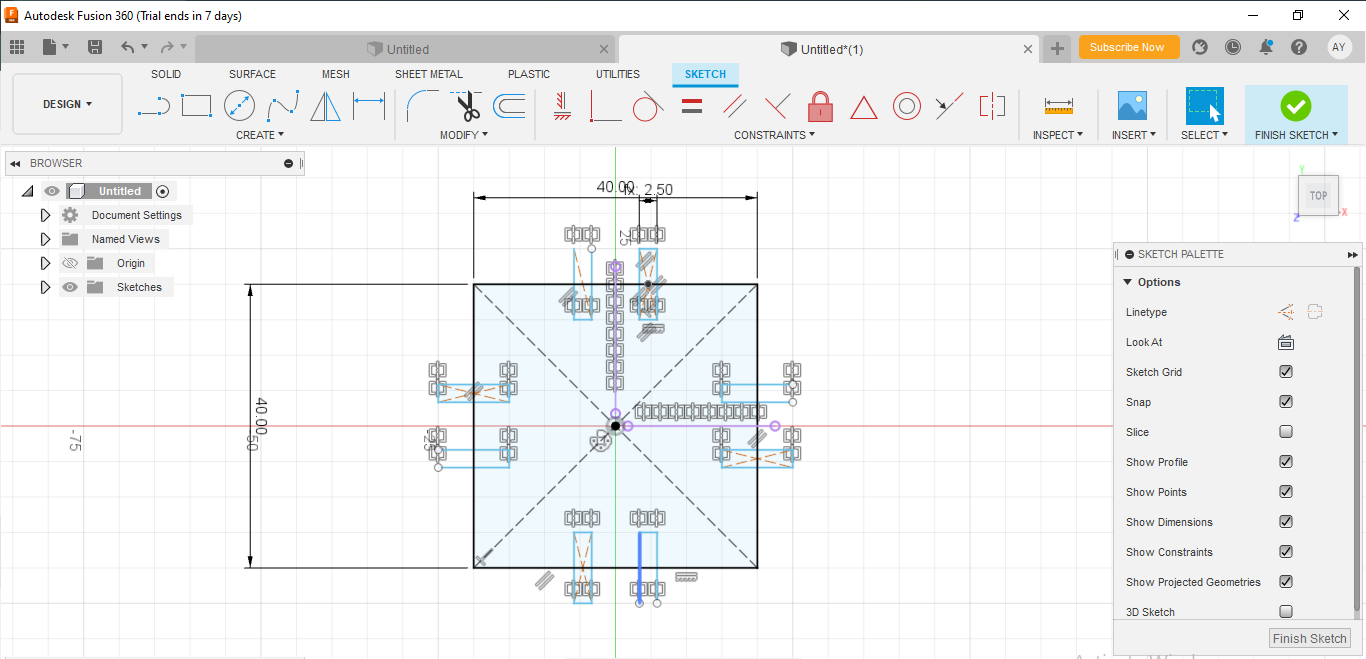

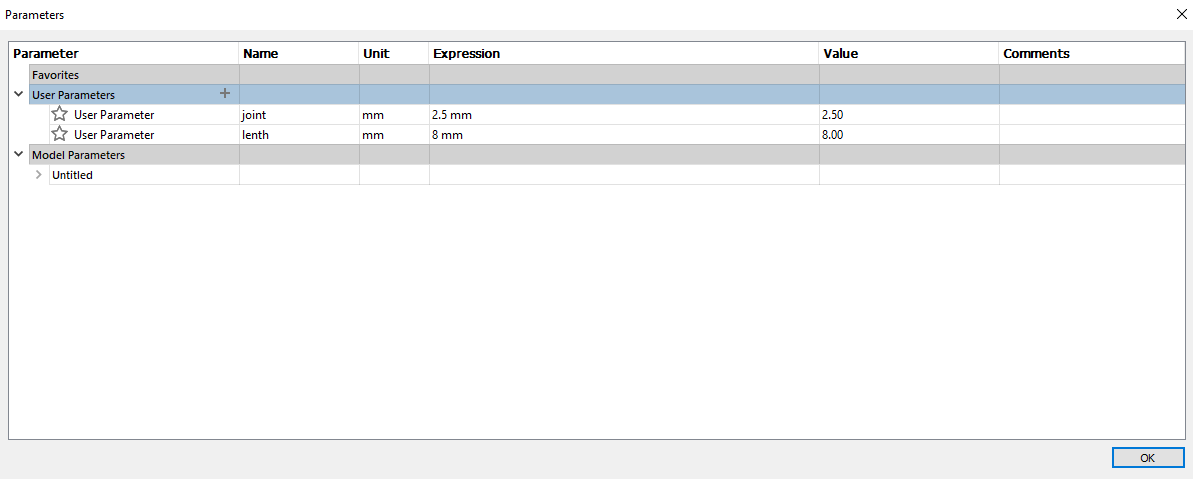

2- i save the width and length in parameter to apply the change in all spaces i want, i do this by going to modify then change parameter

send the dxf file to fablab.share email

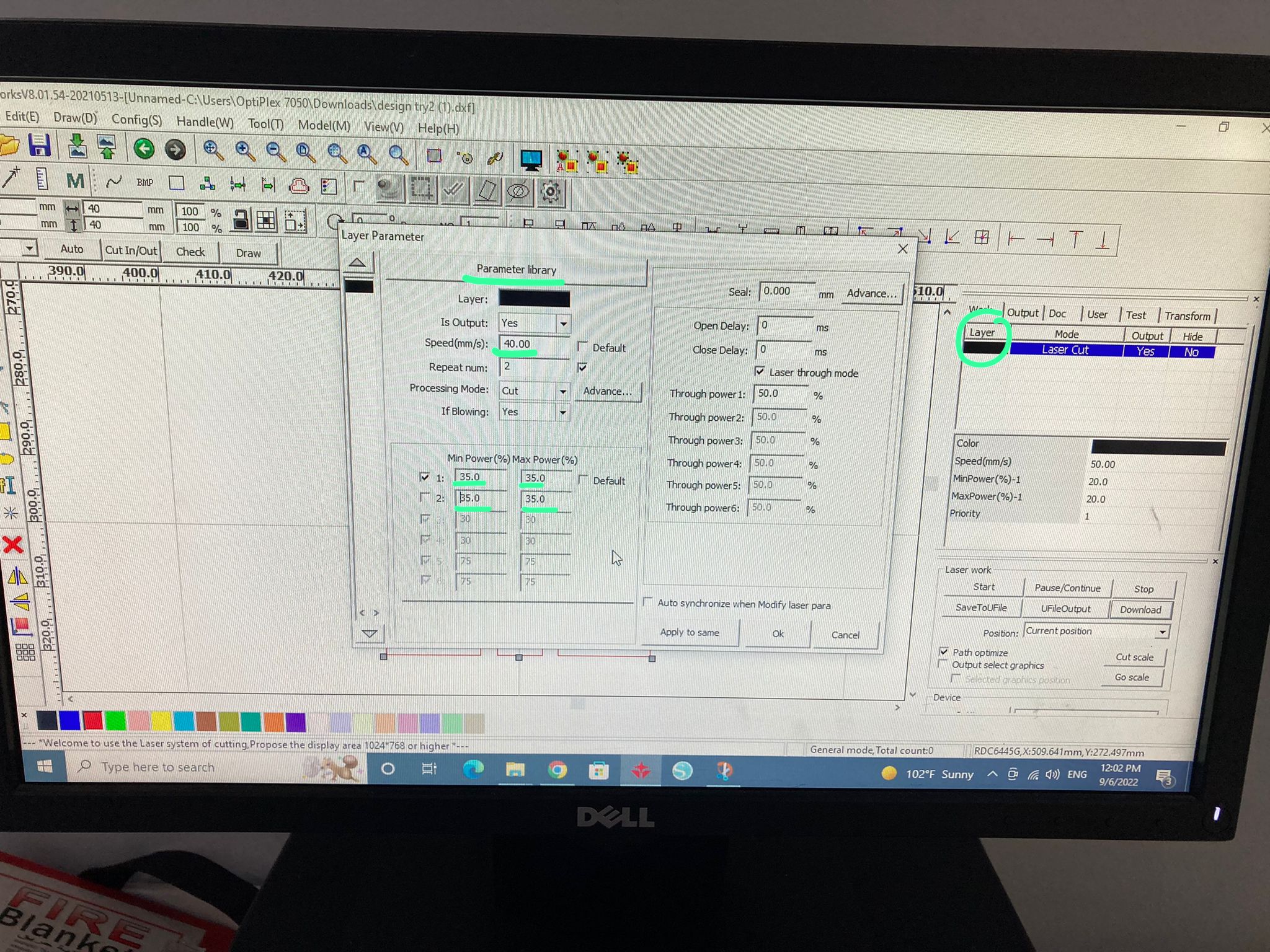

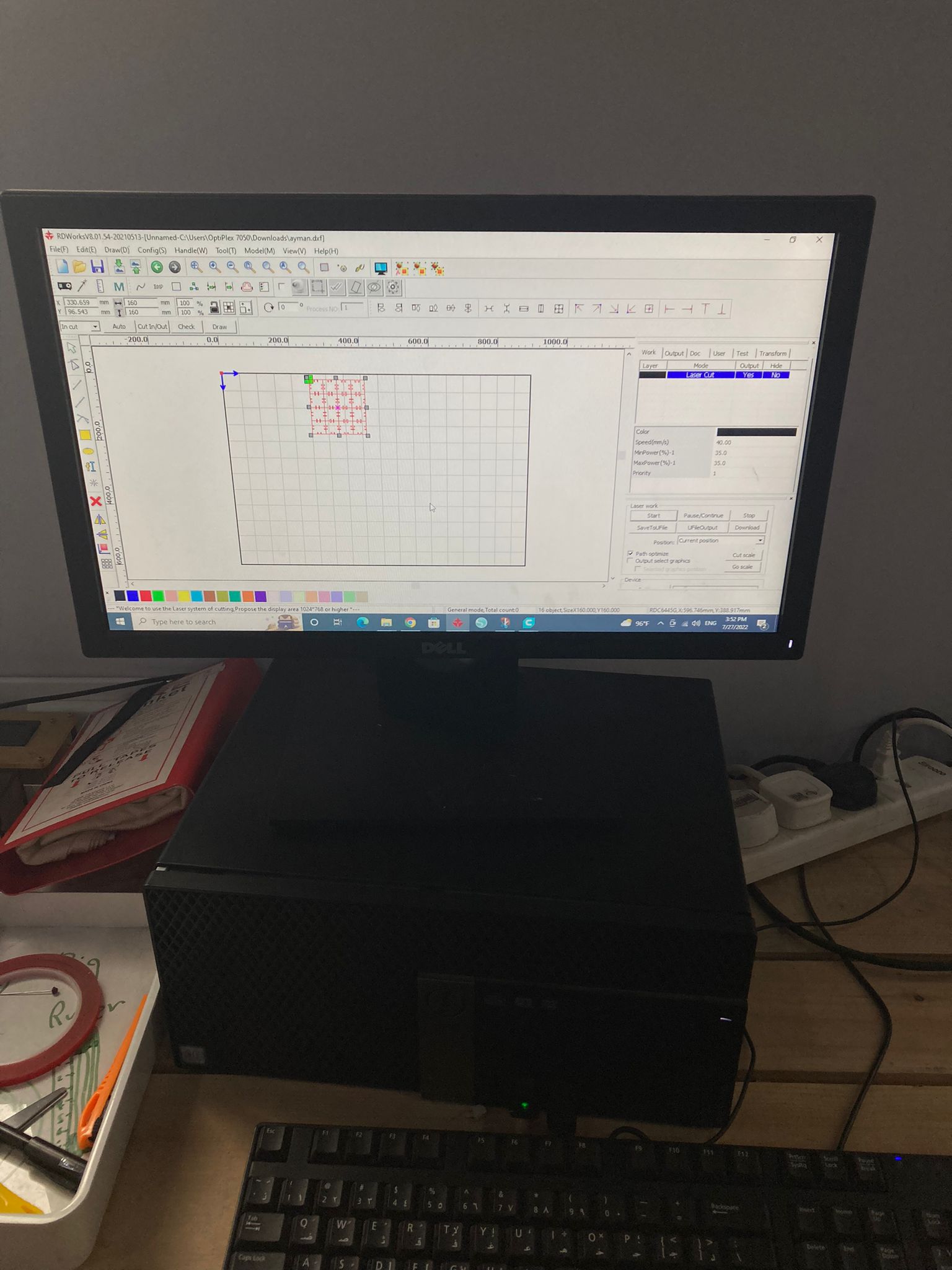

layer - parameter library - speed(mm/s)=40.00 - min and max power(%)=35.0

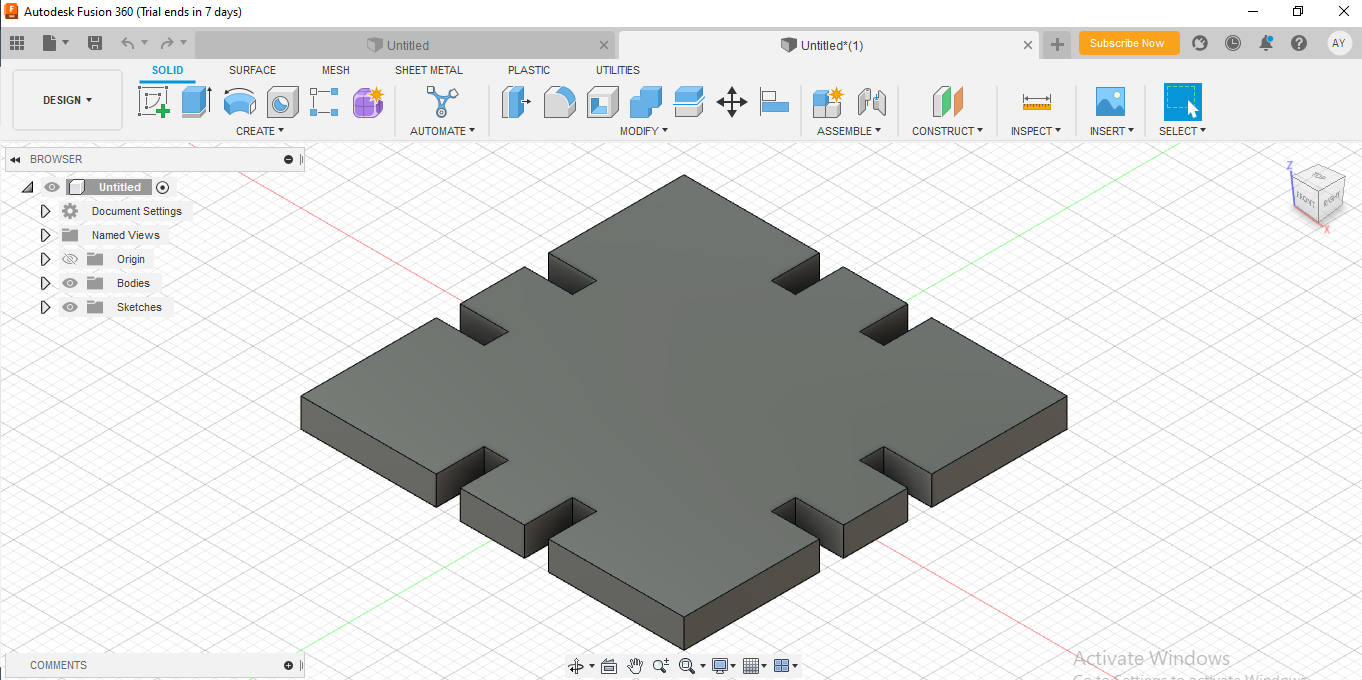

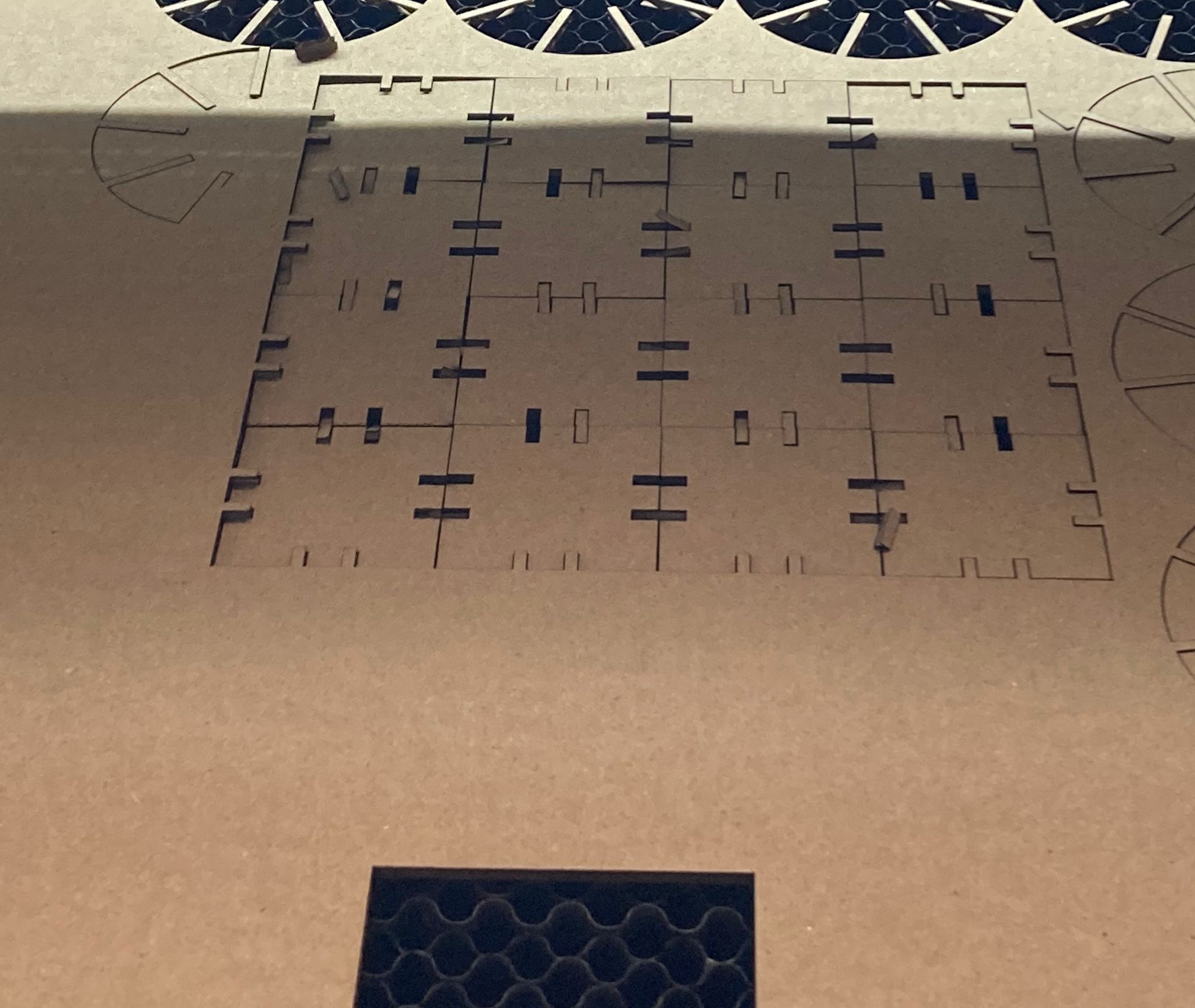

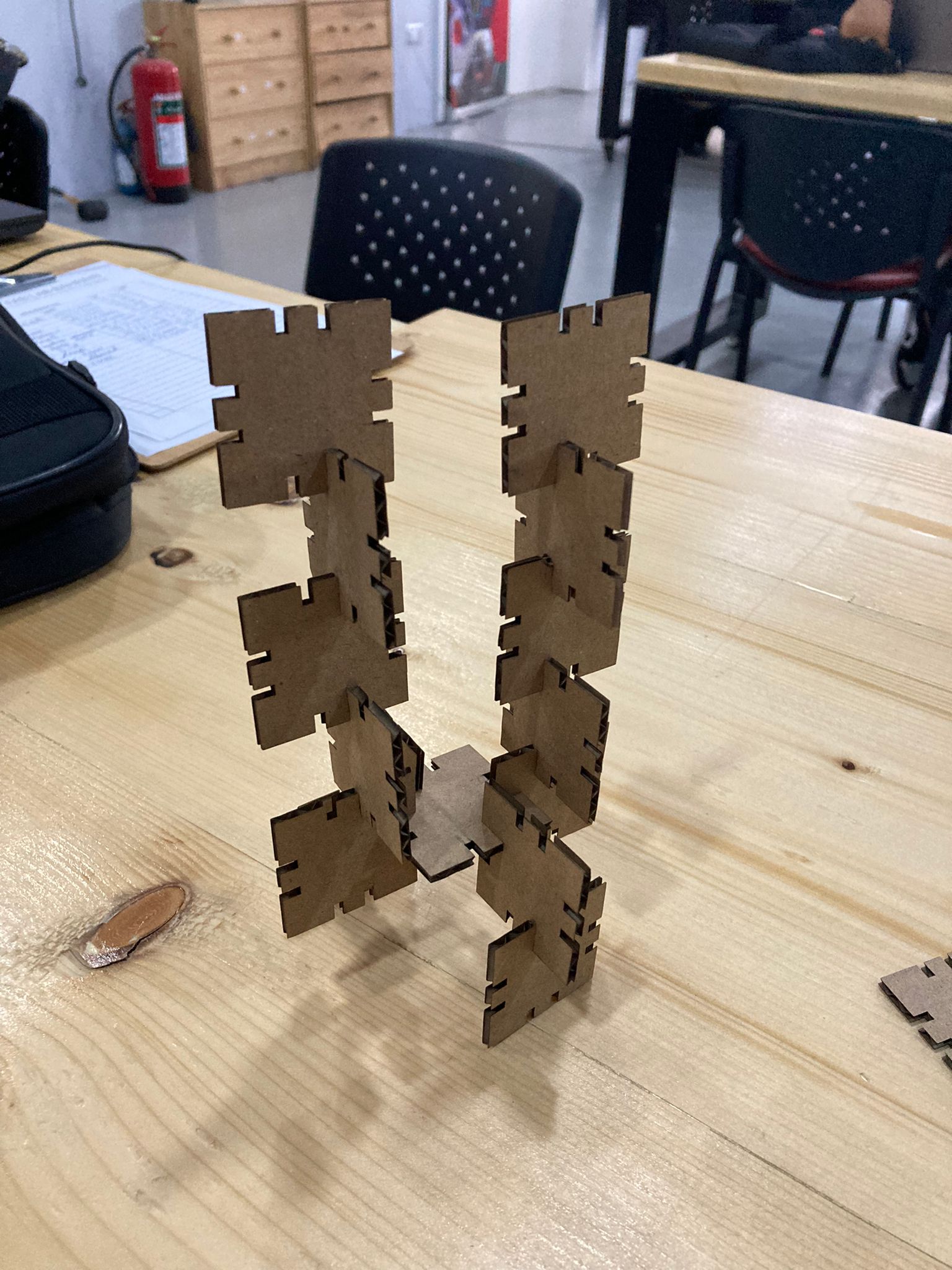

i have repetition it 16 time to do a nice shape

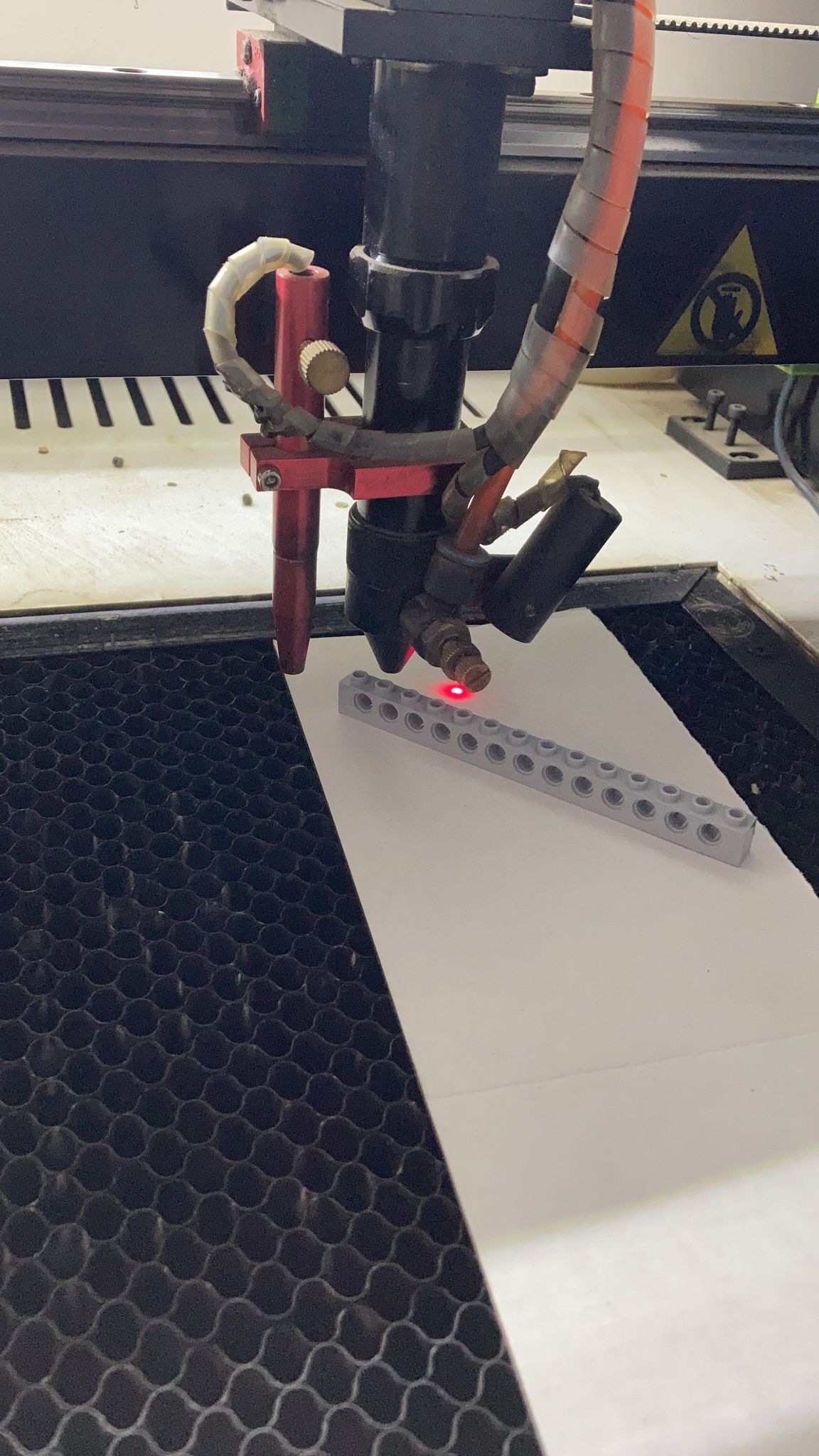

we must be sure that the distence between the card bord and th lazer are enough

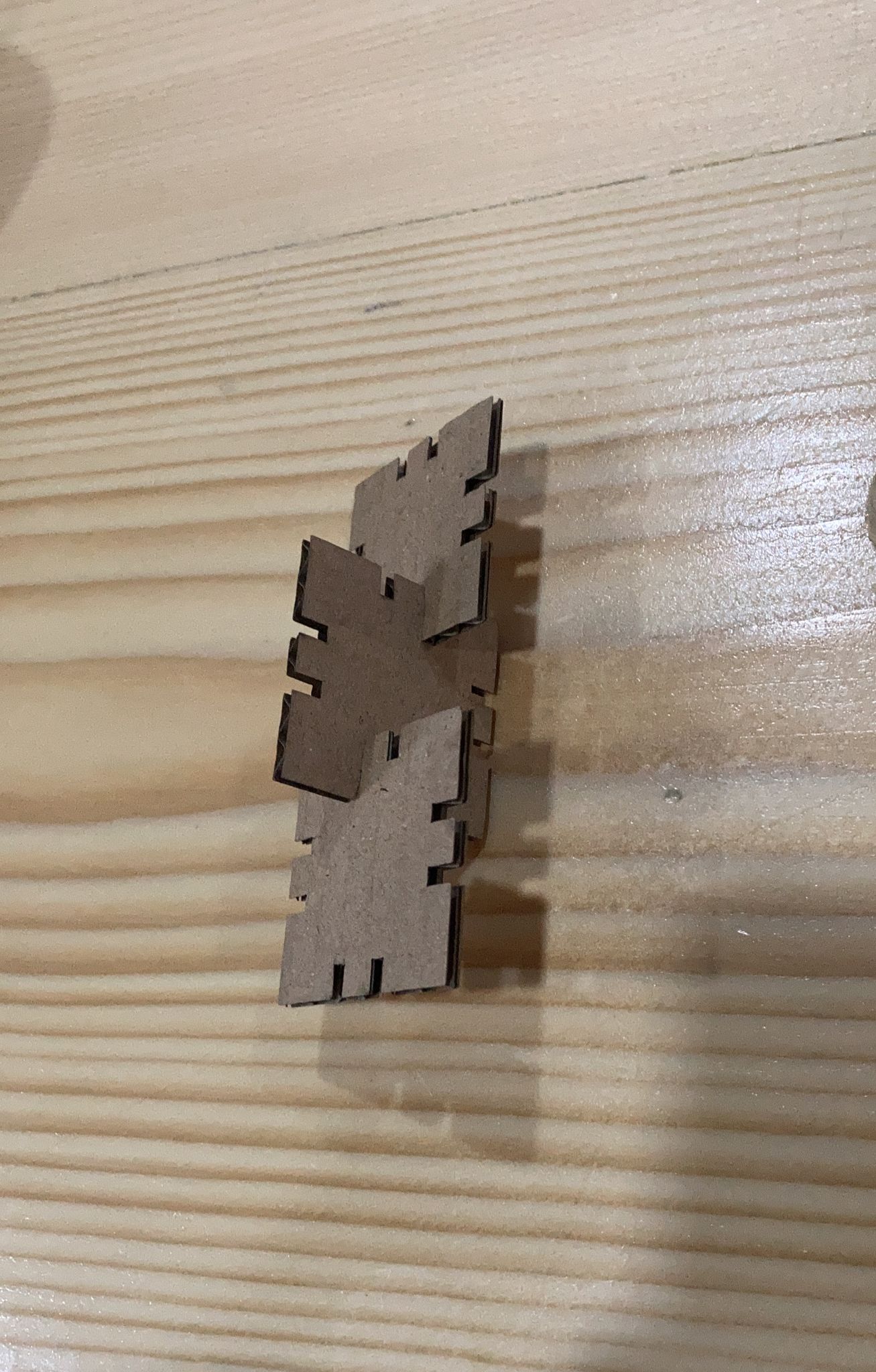

ass we can see the shapes after i cut it

final result¶

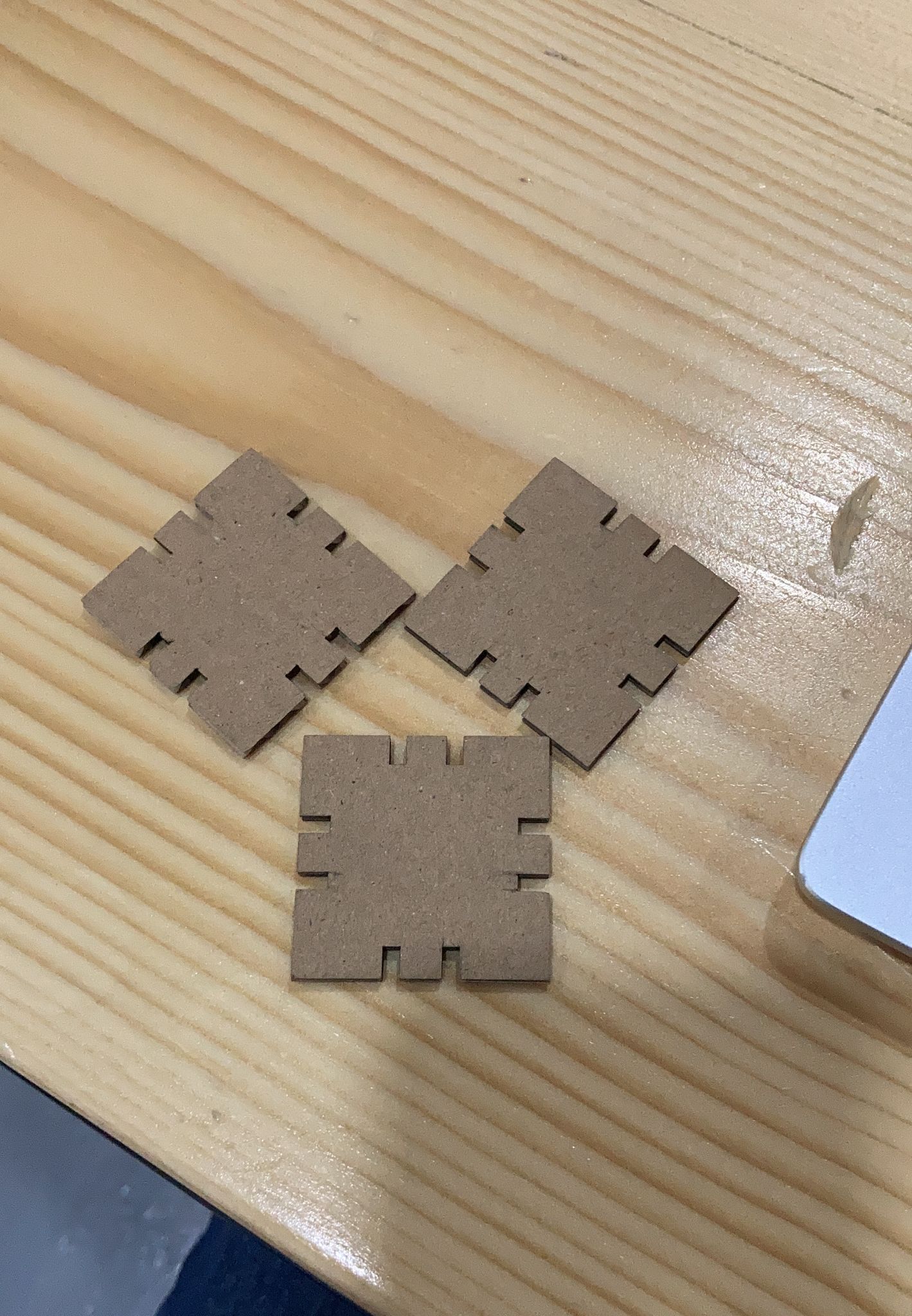

after finishing with laser machine i have assembled my design with the press

fit joints as shown in the picture our clearance (2.5mm) was perfect

final shape¶

link¶

orginal file¶

steps¶

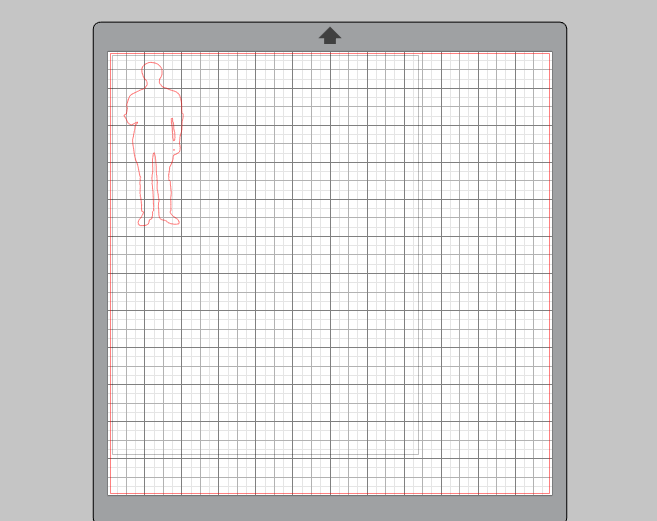

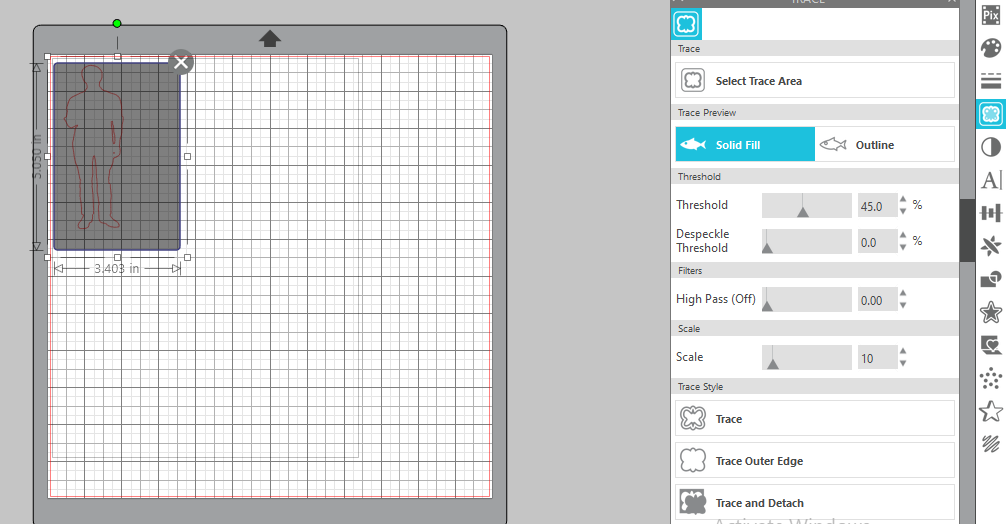

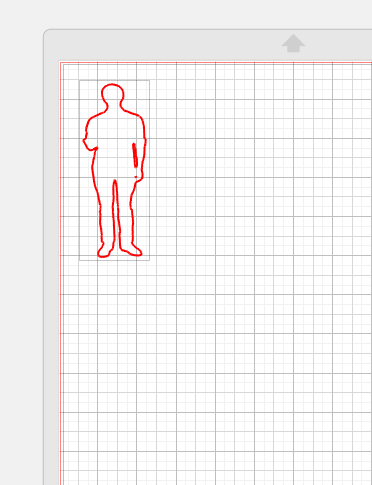

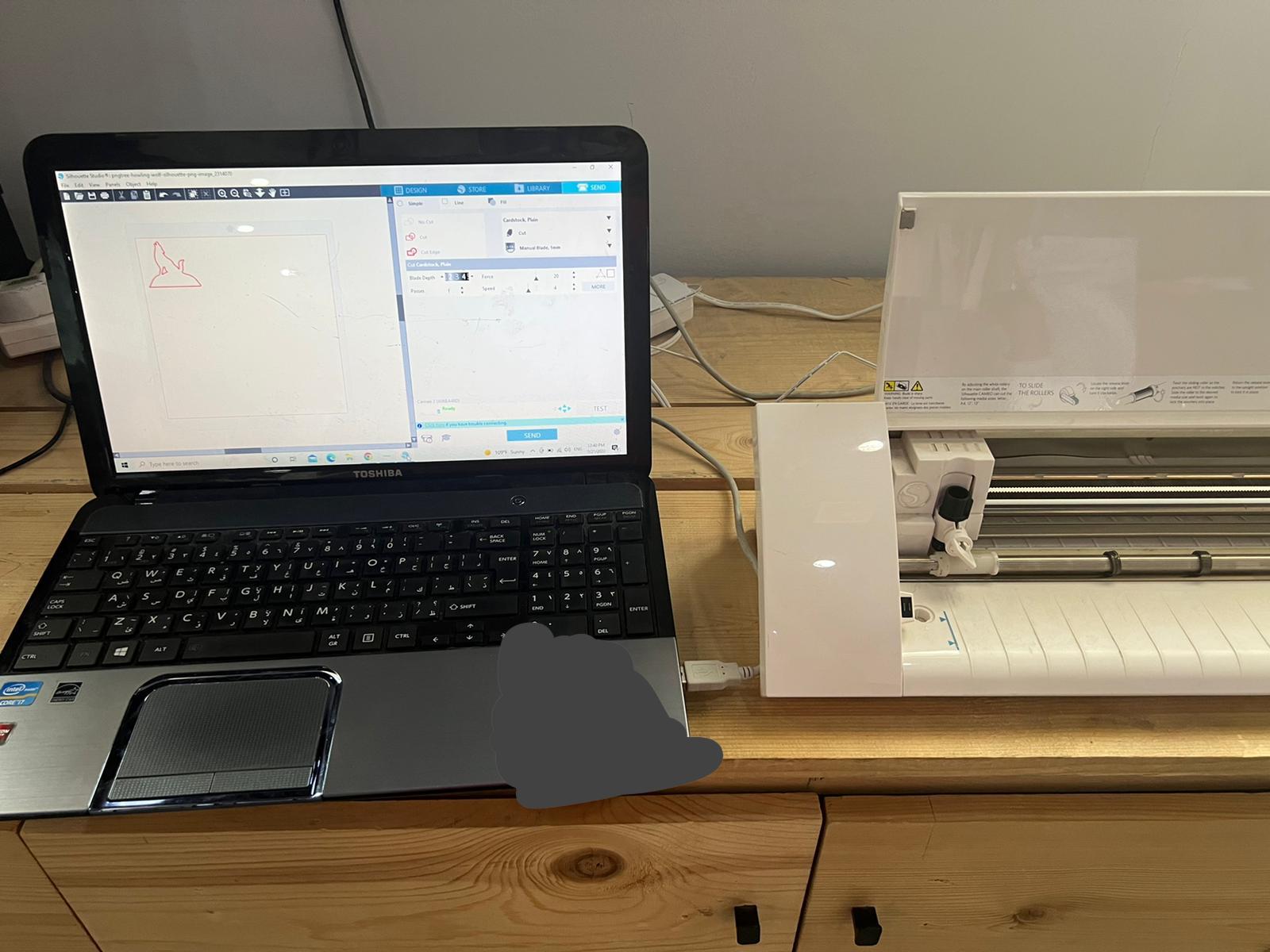

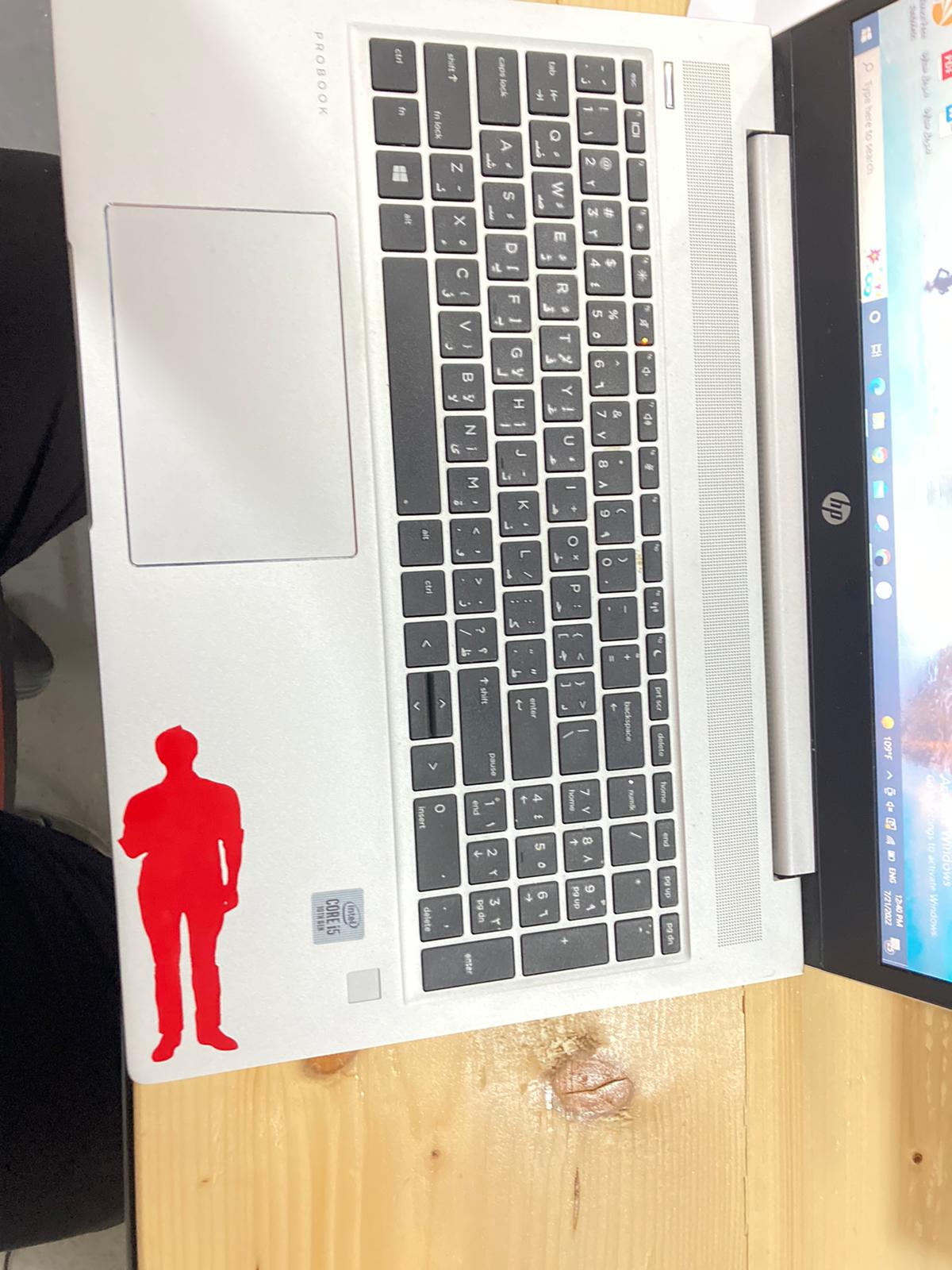

first we search about silhouette i chose a picture from it Then download a silhouette studio –> resize the picture as you like

download ” silhouette studio “¶

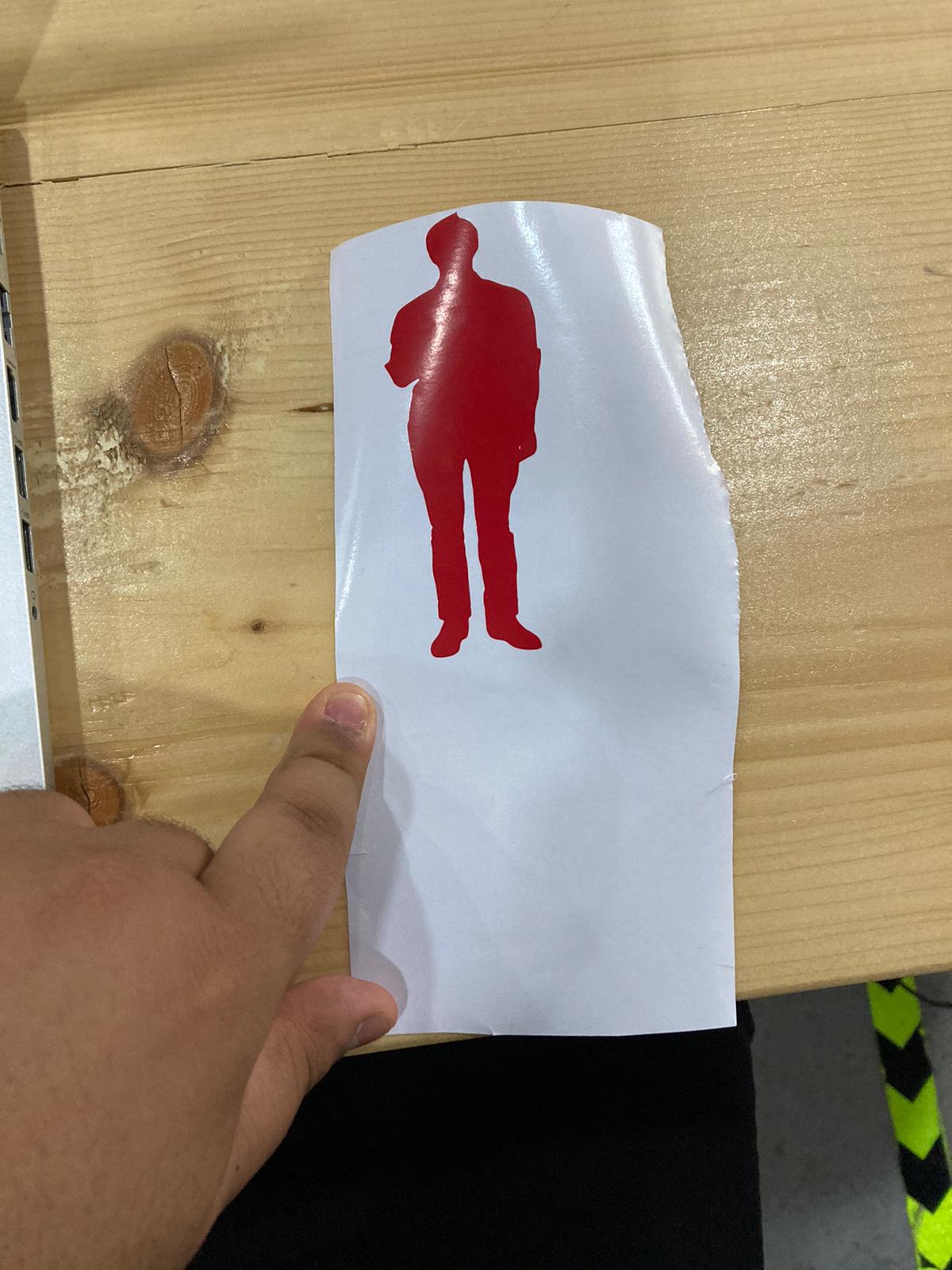

chose a figer frome gogele to cut it¶

putting the figer on the right side

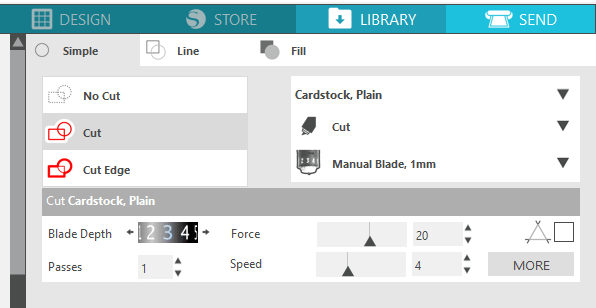

change the blade dpeth,force¶

to print this figer¶

you must select it by click on ” select trace area ” then ” trace”.

final file¶

SILHOETTE CAMEO¶

conect the labtop with the device¶

final shape¶

about vinyl cutte¶

A vinyl cutter is a low-cost sign-making machine. Vector files with patterns and letters created on a computer are immediately cut on a roll of vinyl that is mounted and supplied into the vinyl cutter through a USB or serial cable. Signs, banners, and stickers (which i made using this machine) are the most common uses for vinyl cutters. Although these machines were meant to cut vinyl, they can also cut computer and speciality papers, as well as bulkier things like as thin sheets of magnet link vinyl cutter