5. 3D printing and scanning¶

In this assignment, I have learned the basics of 3D scanning & printing.

3D printing is an additive process first commercially introduced by Chuck Hull in the late 80s/ early 90s, the first printer was called SLA-1, named after the printing process “Stereolithography”, which uses a UV laser head that hits a resin surface and cures it, making the desired shape.

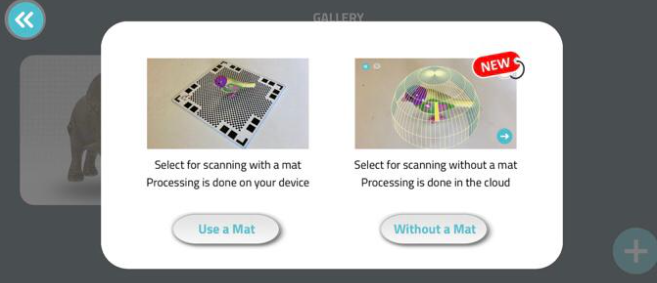

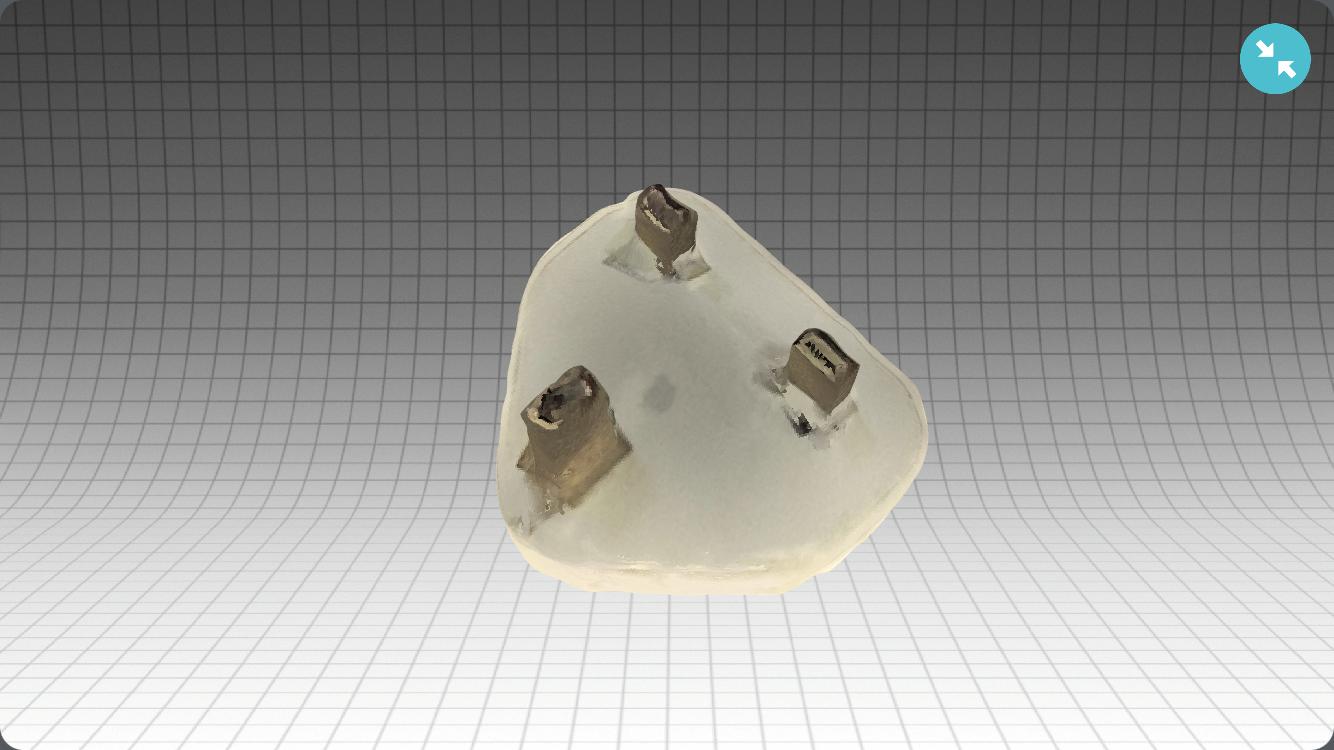

What is Qlone?¶

Qlone is an all-in-one 3D scanner app. We have made it easy and fast to create 3D models from real objects, edit them with built-in editing tools and seamlessly export the result to popular platforms, 3D file formats and 3D printers. You can even animate your models in AR! it is available on both but the iOS version is much more advanced, with a new option to scan objects without the Qlone mat.

downlod ” Qlone “¶

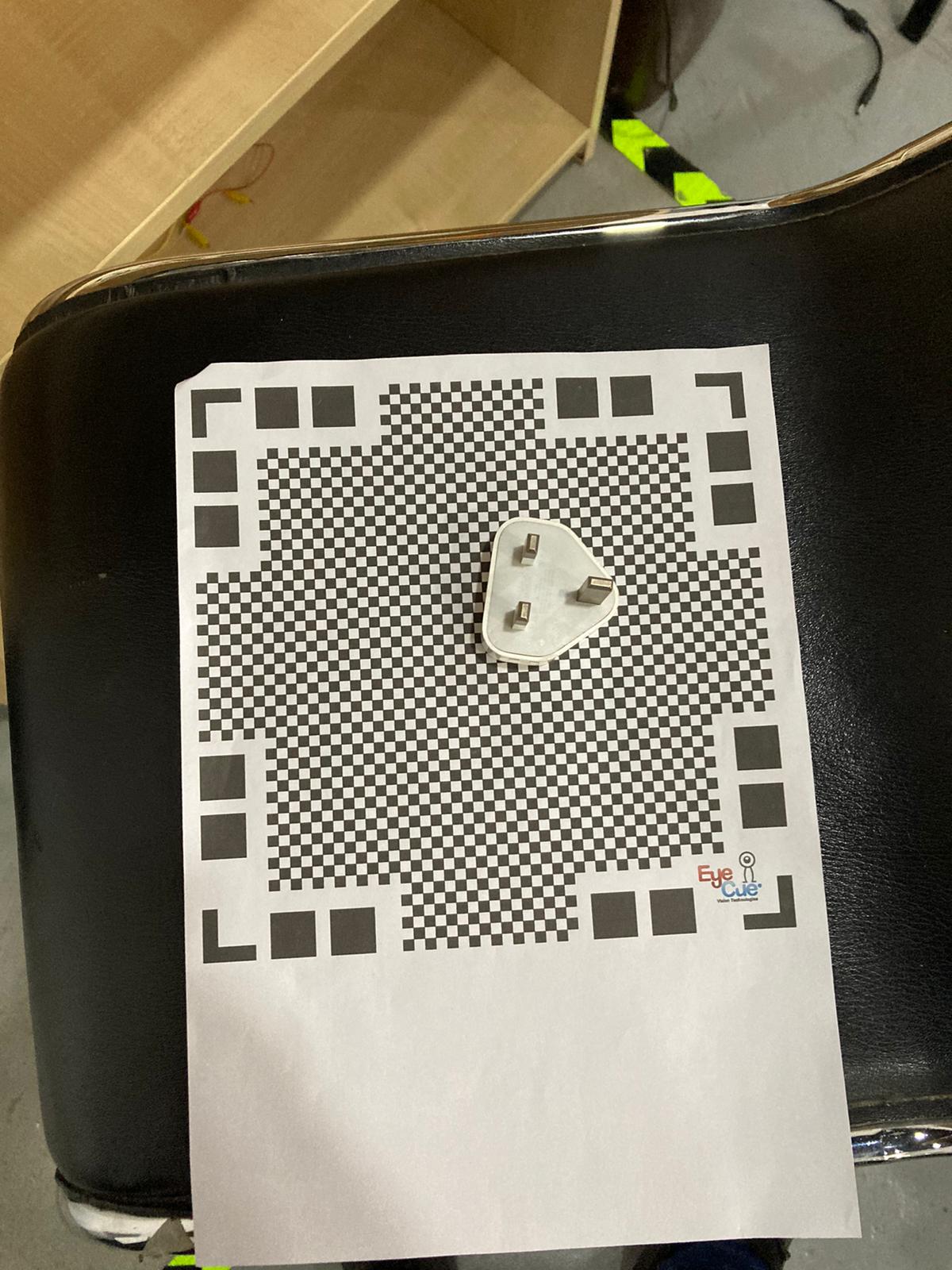

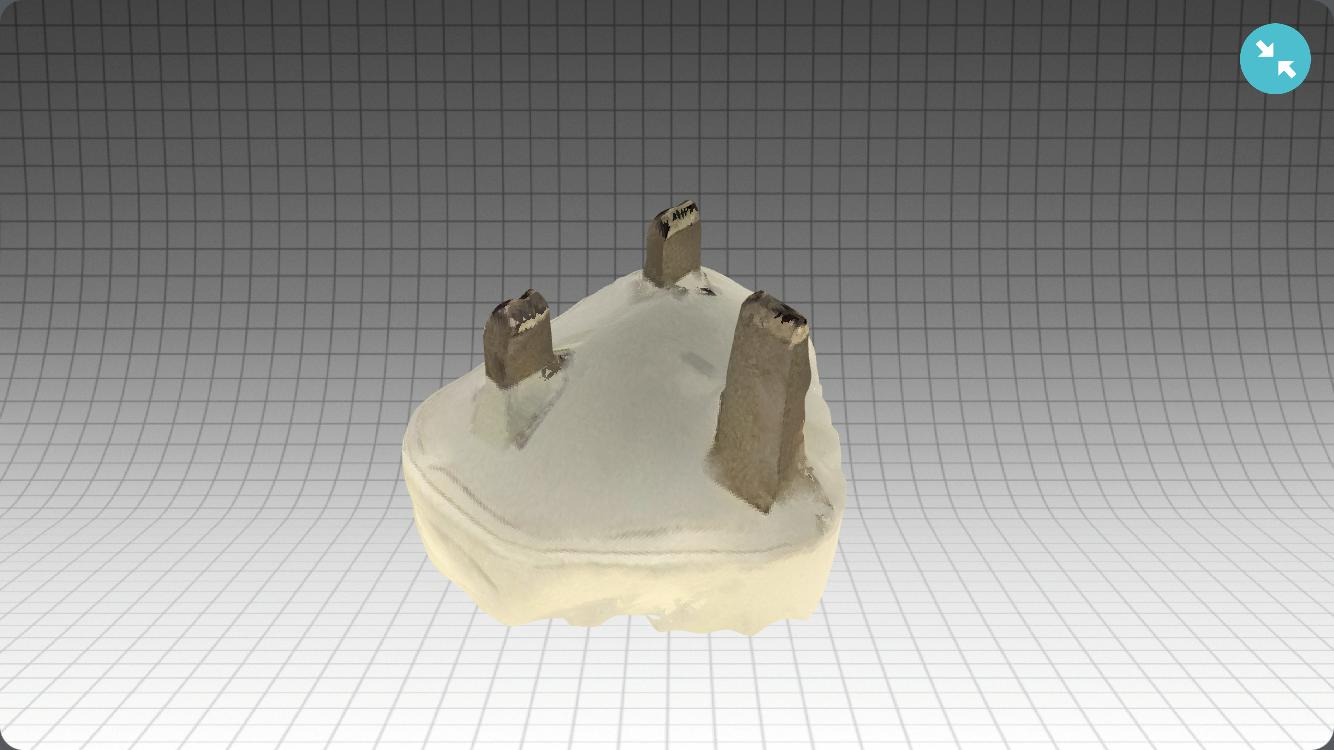

Object can be scanned without the mat

scanning¶

makerbot replicator¶

To ensure easy, accessible 3D printing, the MakerBot Replicator+ comes with the Smart Extruder+ and all the standard features of its predecessor. A few of those features include an LCD display, an on-board camera, as well as USB, Ethernet, and Wi-Fi connection.

3D Printing¶

In Fab Lab Bahrain, the type of 3D printers that we have are FDM (Fused Deposition Molding) printers, which means that:

-

The filament (Thermo-plastic) is heated just above the melting point

-

It goes through an extruder, which then extrudes the plastic to the bed (surface of the printer).

-

The plastic then solidifies completely when exposed to ambient air or cooling fans.

What do you need to start printing?¶

-

CAD software (if you want to design your model)/ or go to thingiverse.com and download a model

-

Slicer software: It slices the CAD model into horizontal layers so that the printer can understand it and move accordingly & it converts the file to G-code

-

Filament

What is the best filament?¶

The most commonly used filament types are:

- PLA

- PETG

- ABS

i learn from 3D printing¶

3D printing makes learning active, empowering students to use critical thinking skills in creating their models. Engaging classes mean students can better learn advanced topics while improving skills like problem solving.

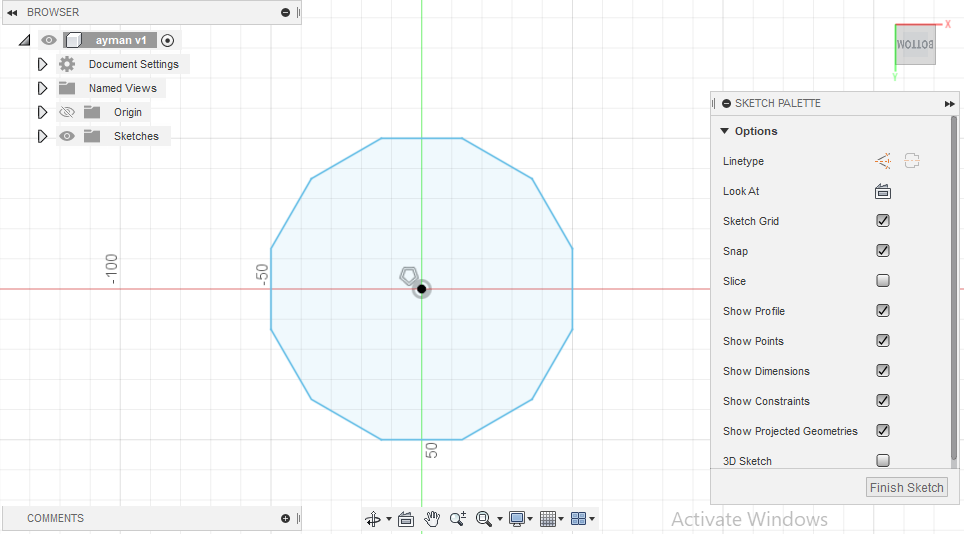

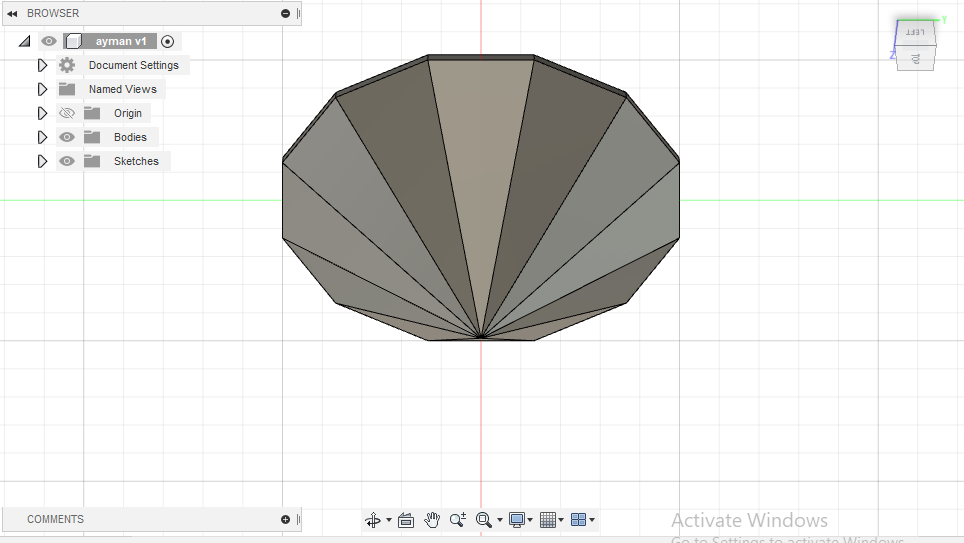

My shape¶

This is the first 3D shape ” DIAMOND “. first select the geometric shape

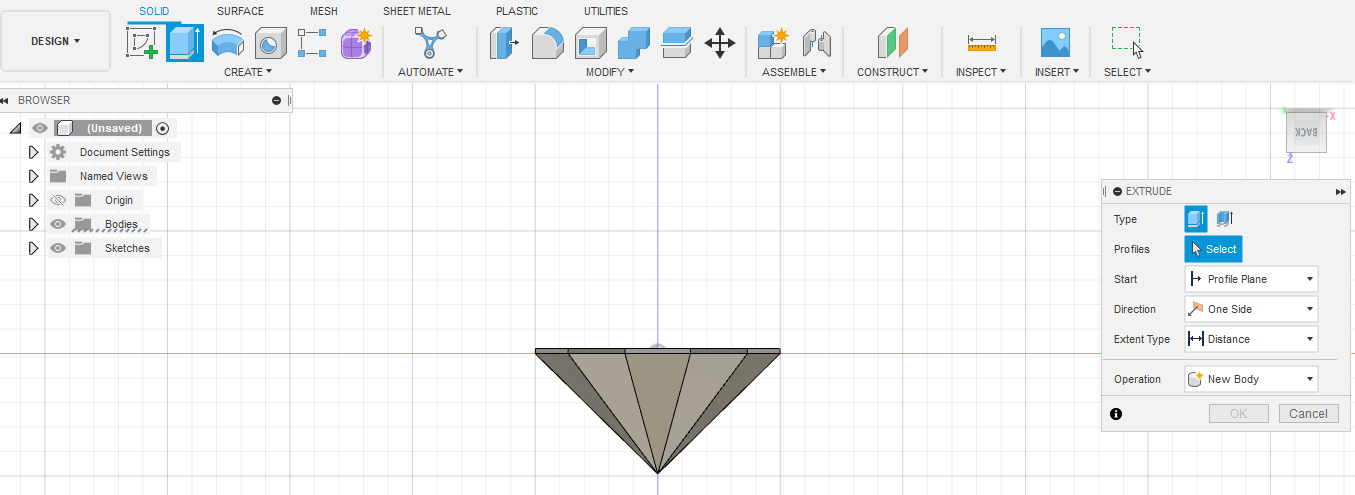

final shape to prenter as a 3D :¶

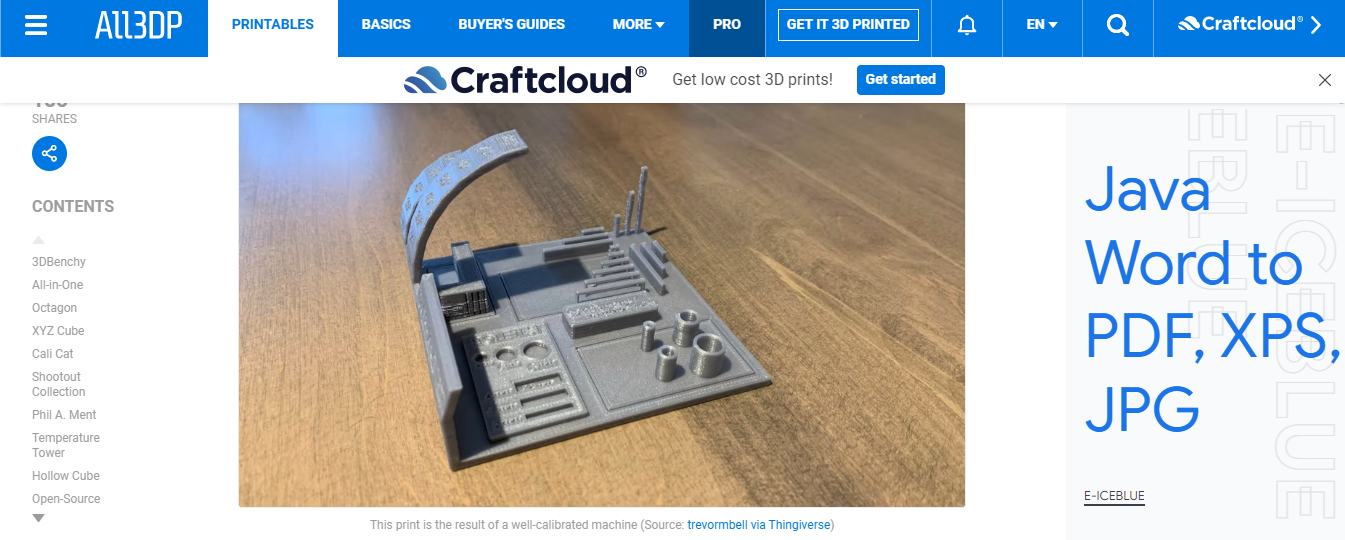

3D print test¶

This eight-sided calibration test has an empty center and devotes each side to a few specific 3D printing challenges. A total of 21 different elements are tested including negative space (indentations), dimensional accuracy, overhangs, warping, and spikes (sharp points).

as you can see my shape (diamond) cnot be cut it by CNC mashine becase it is not a strate shape so well hapend a undercut

why it could not be easily made subtractively¶

In manufacturing, an undercut is a special type of recessed surface that is inaccessible using a straight tool. In turning, it refers to a recess in a diameter generally on the inside diameter of the part. In milling, it refers to a feature which is not visible when the part is viewed from the spindle. In molding, it refers to a feature that cannot be molded using only a single pull mold. In printed circuit board construction, it refers to the portion of the copper that is etched away under the photoresist.

orginal file¶

makerbot¶

open new file

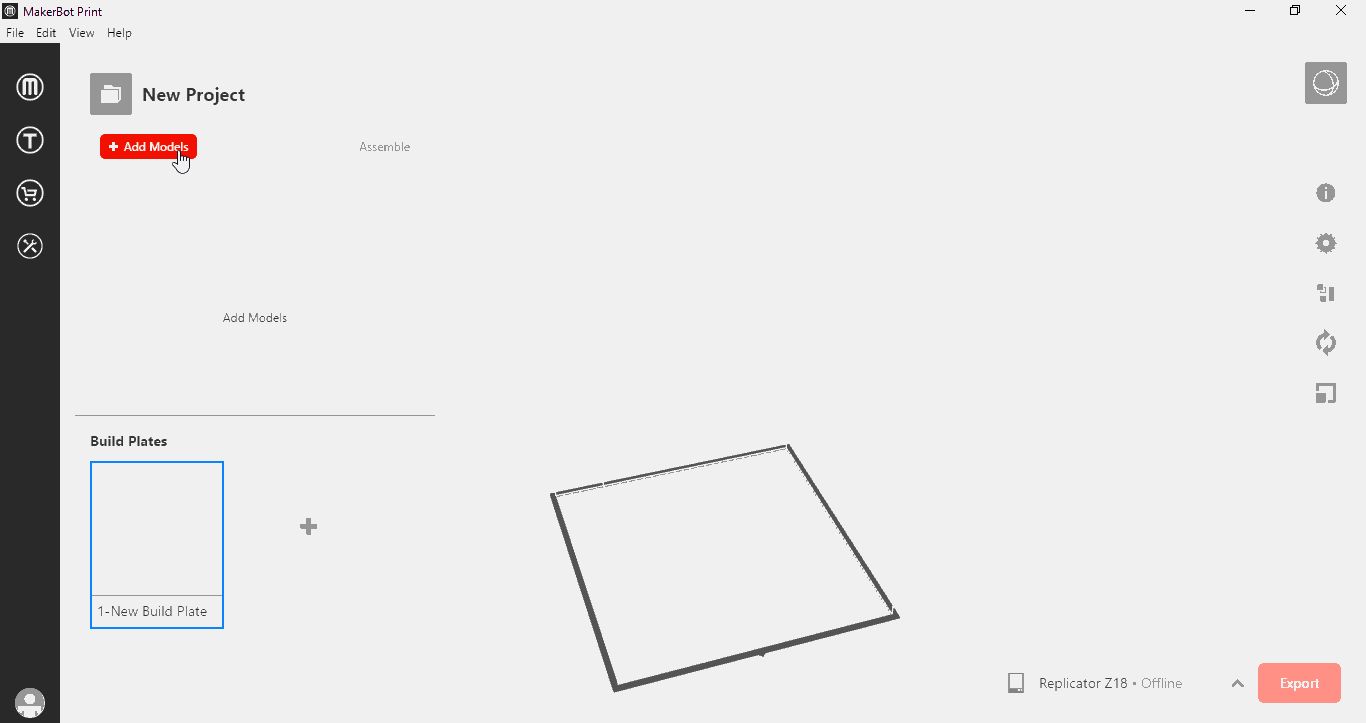

add model new project

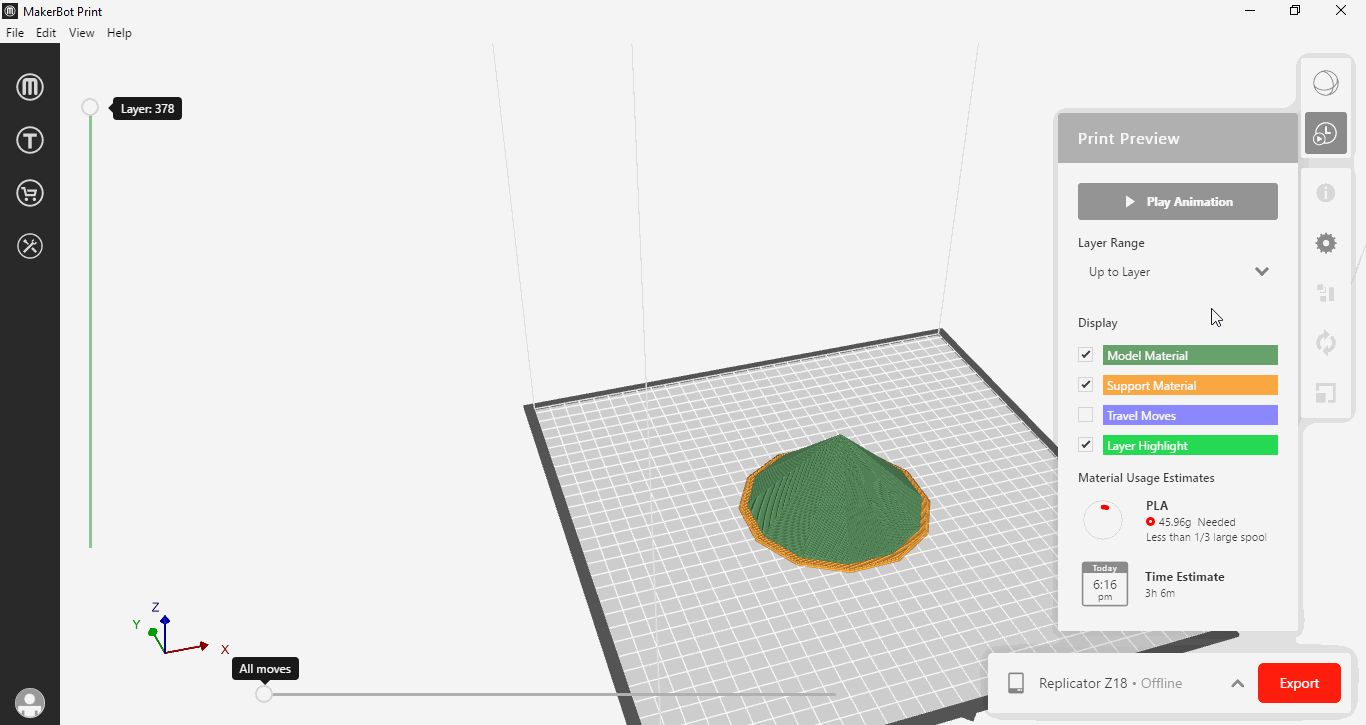

play animation¶

this the final shape in the makerbot it is raedy to print

final 3D file¶

Group Assignment¶

Group assignment was in two parts, the first one to learn about 3D printer and its prints, and we saw some samples. Then, we have to print something to learn how to do it by ourselves, check Hamad’s page to see how we did it.