6. Large format CNC (computer controlled Machining)¶

This week I worked on creating a model to cut on the CNC machine with a specific size of joints.

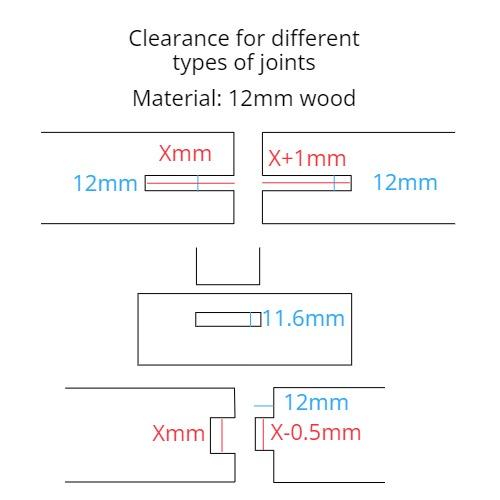

this is the gap and the joint best fitting for the material which i used for my design which is plywood.

Group assignmant¶

we did a group assignment using the CNC machine to test it. for more information about it check ayman’s page.

individual¶

Idea¶

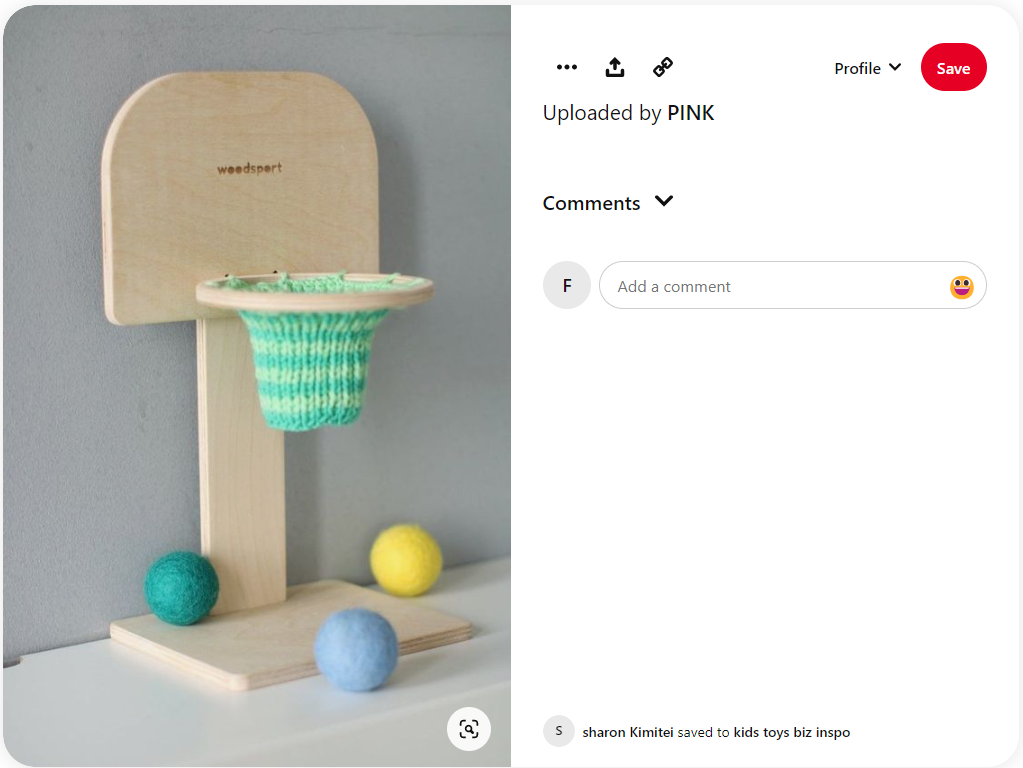

the concept of this week is to design a toy for children so I chose to design a basketball score.

Design¶

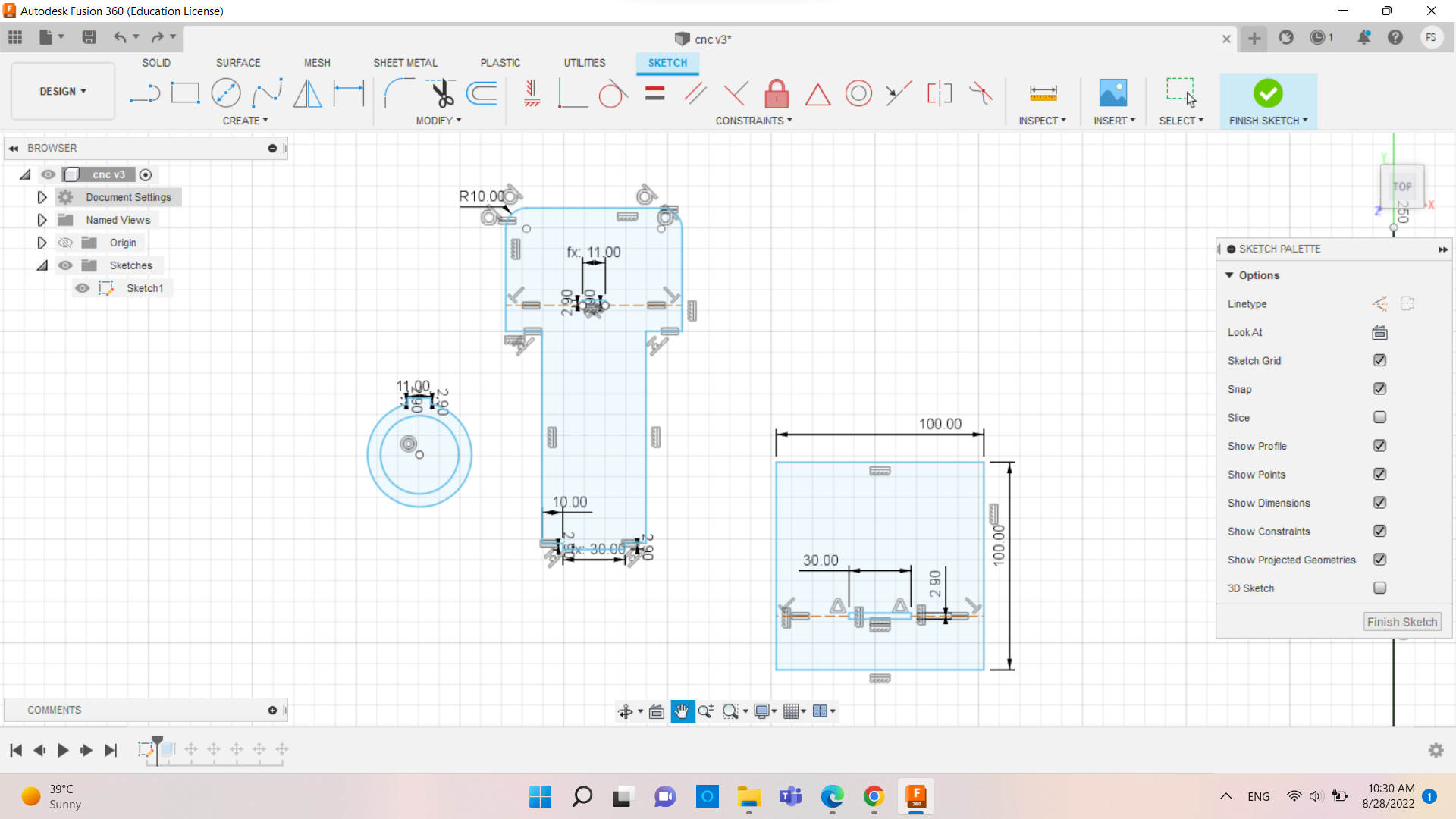

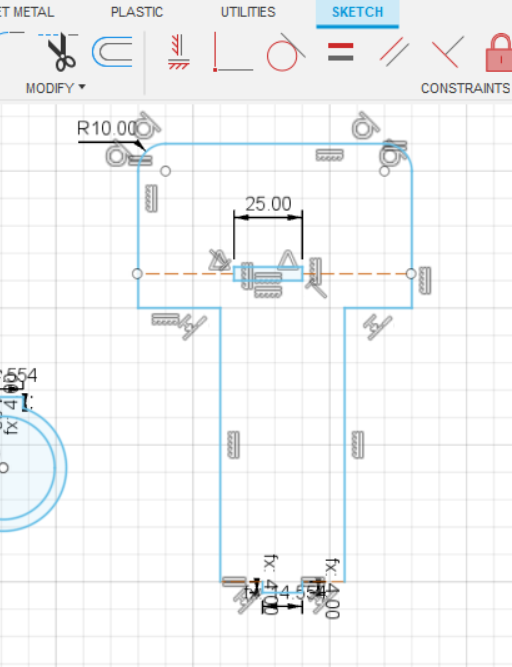

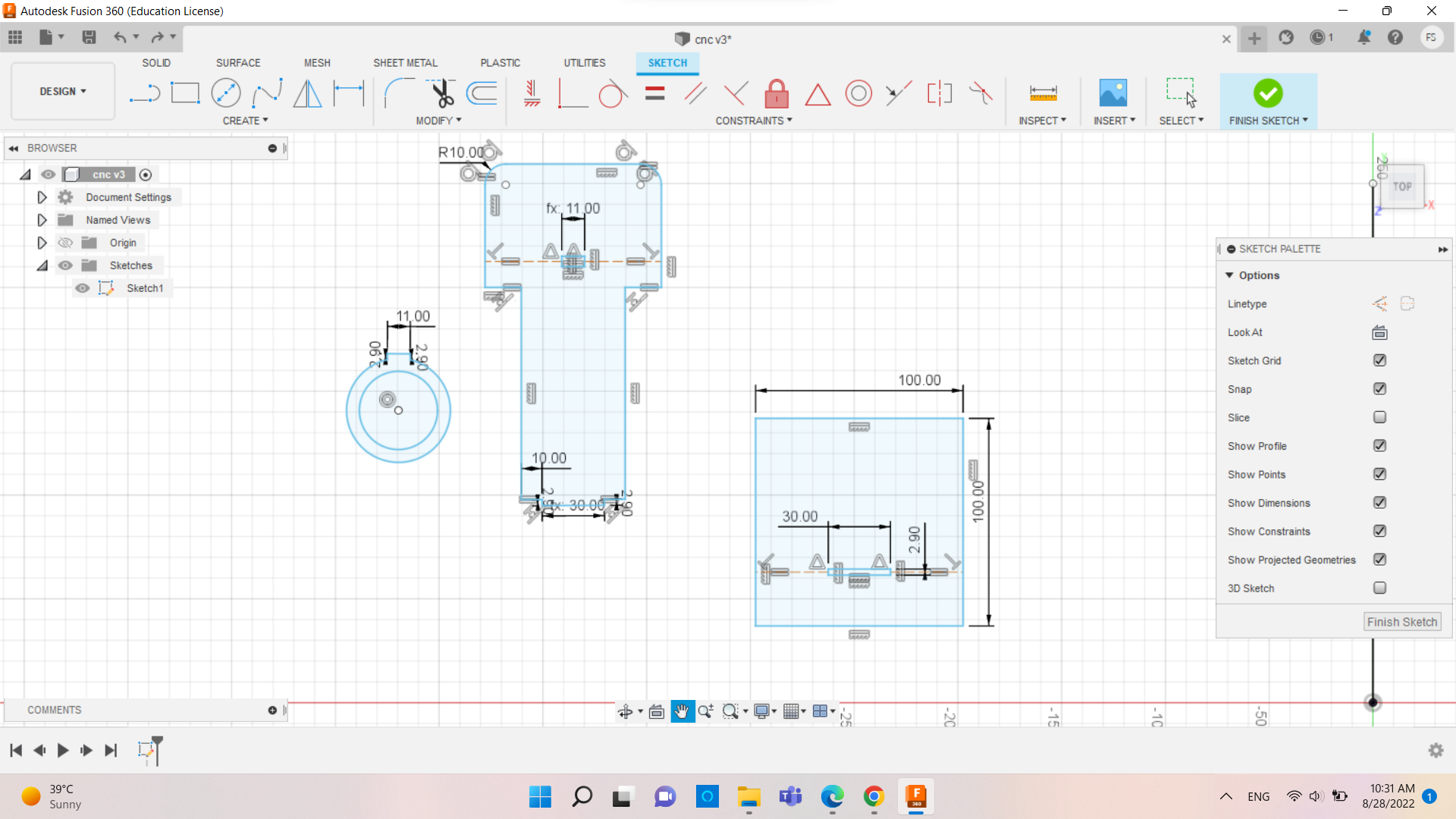

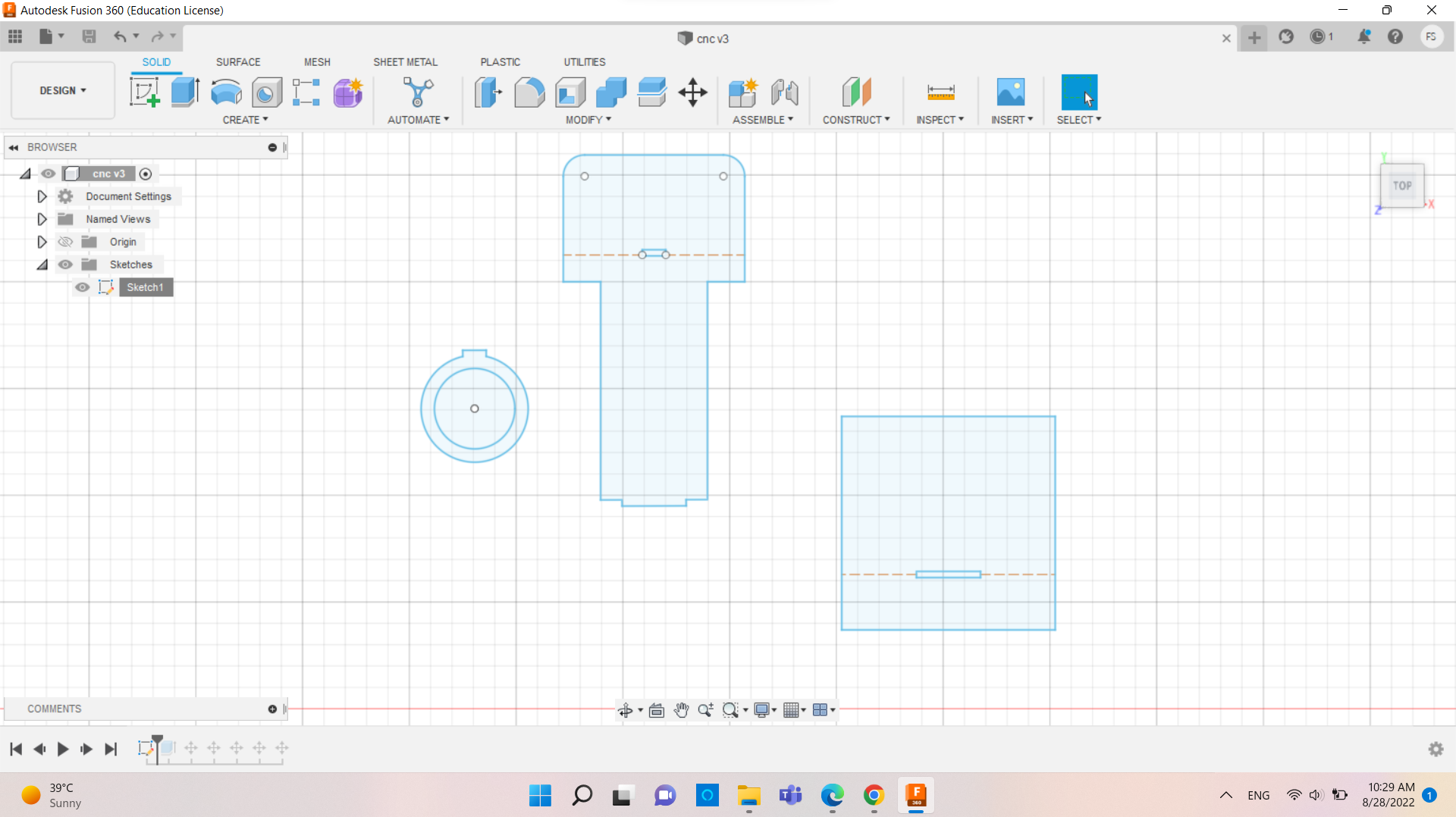

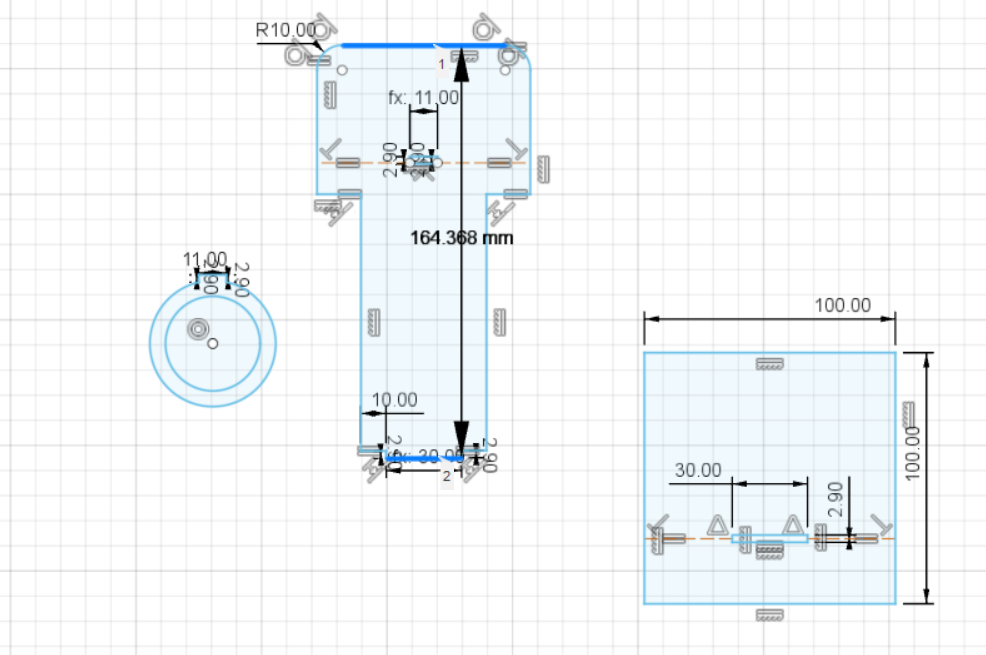

so i started designning it in Fusion 360 and below are the steps I took in designning.

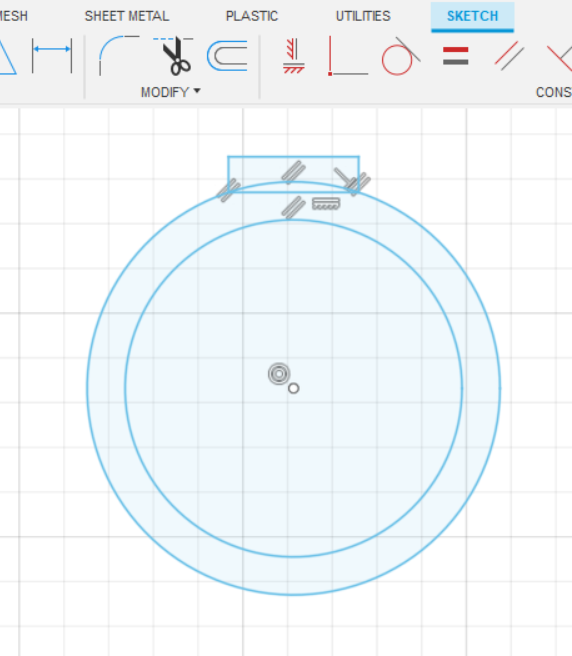

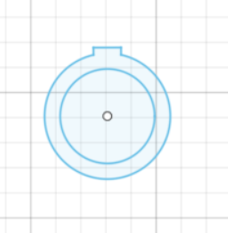

1) here i created a cirlce with another circle in it to get the basket ring.

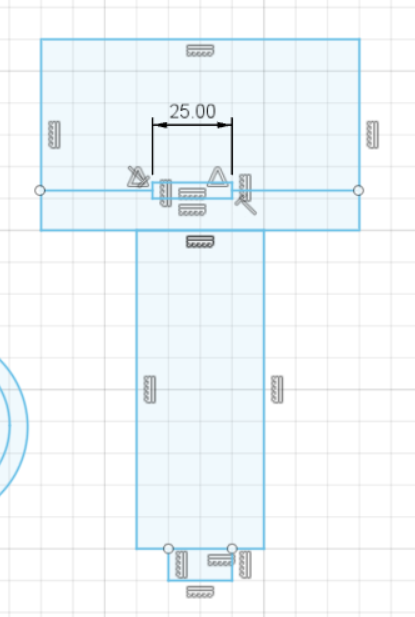

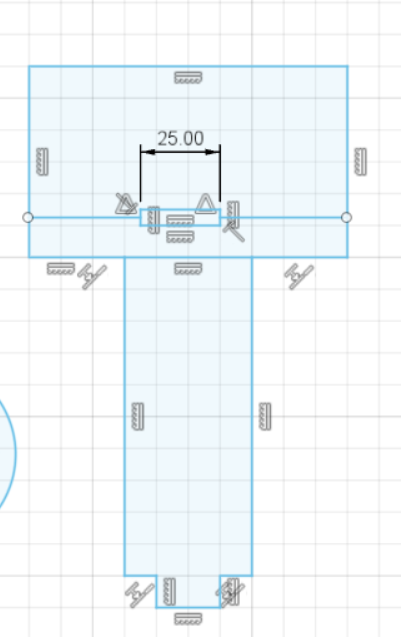

2) then i added a triangle to make a joint i can insert in the board.

3) I removed the extra line by using the scissor.

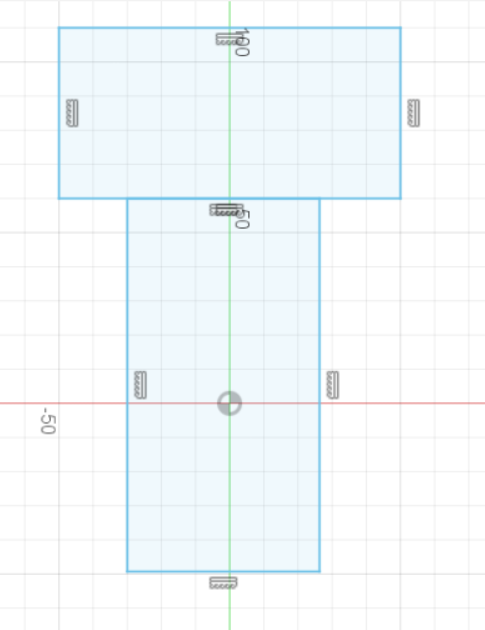

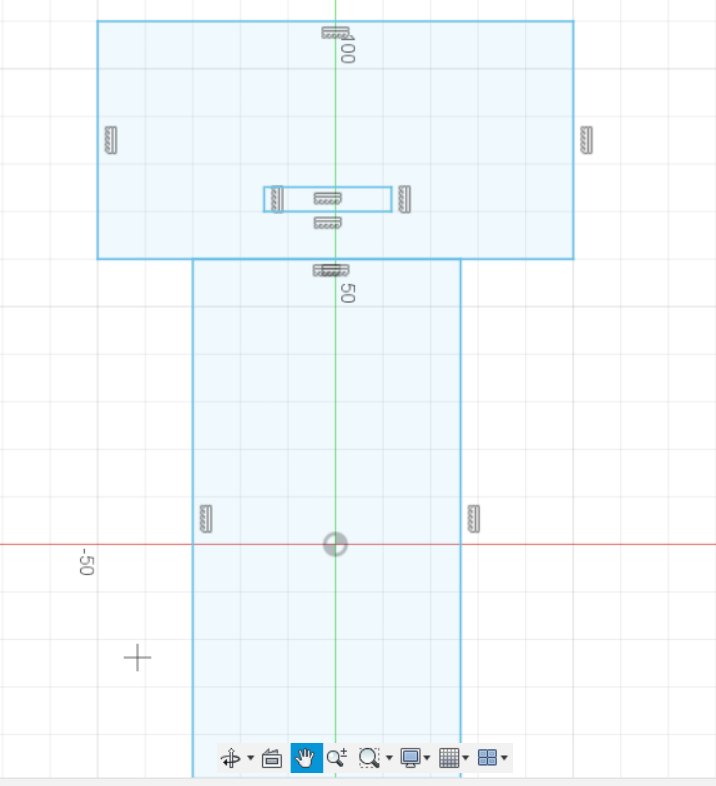

4) here to make the basketball board with the support by using two rectangle.

5) here a recangle hole so the joint could fit in it.

6) putting a line connected to the hall on both side.

7) there is a joint in the bottom which i removed the line between it and the upper rectangle so it would be a one piece.

8) I made the base of the basketball by creating a squar then putting a rectangle hole then putting a line connected to the hall on both sides and constrained both the square hole and the board hole so i could make them equal on both sides.

9)

10)

11)

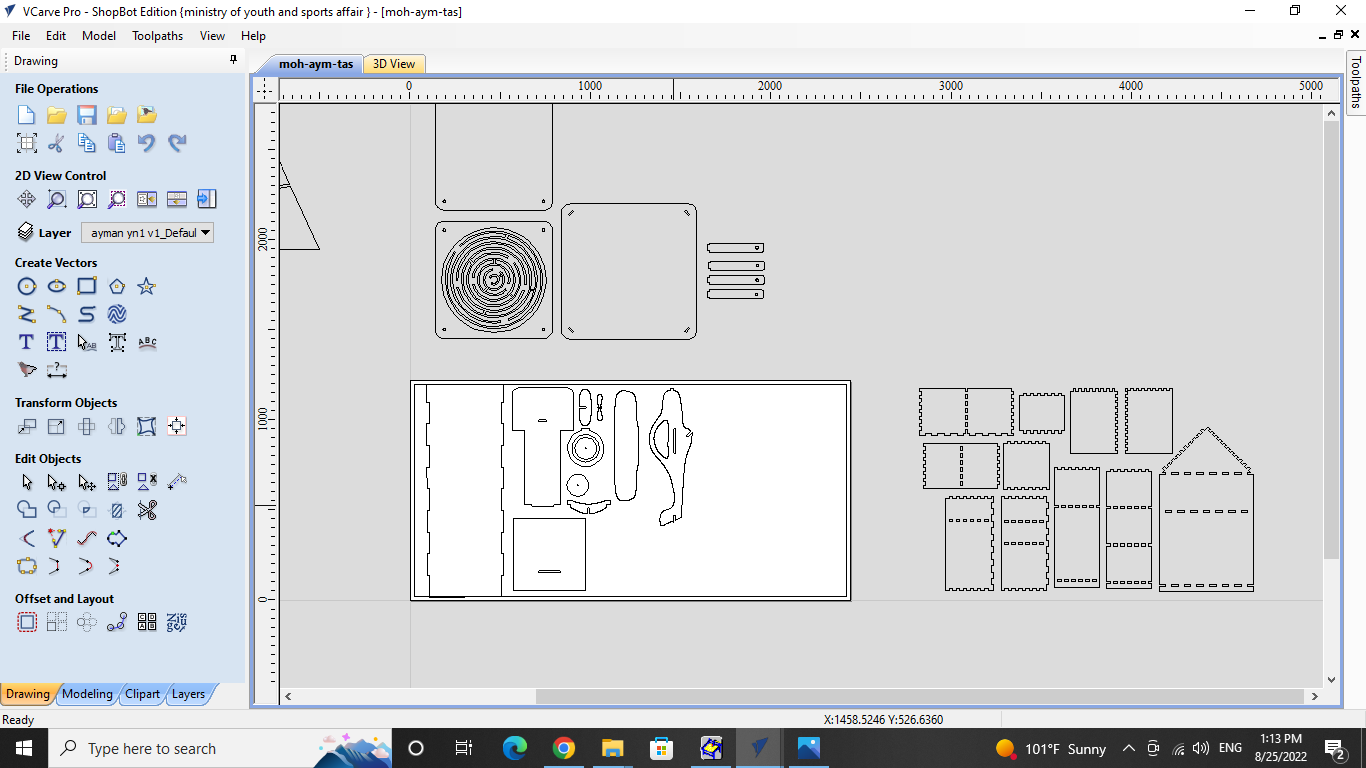

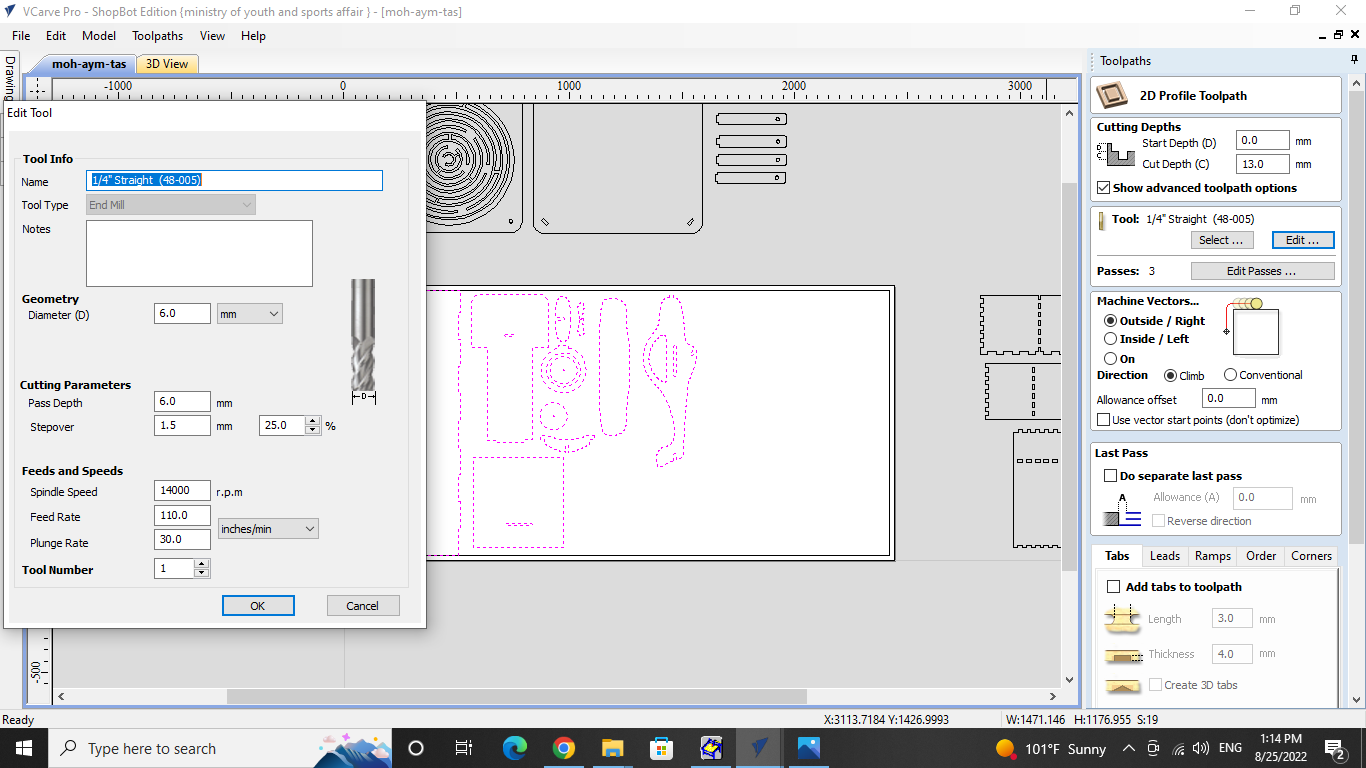

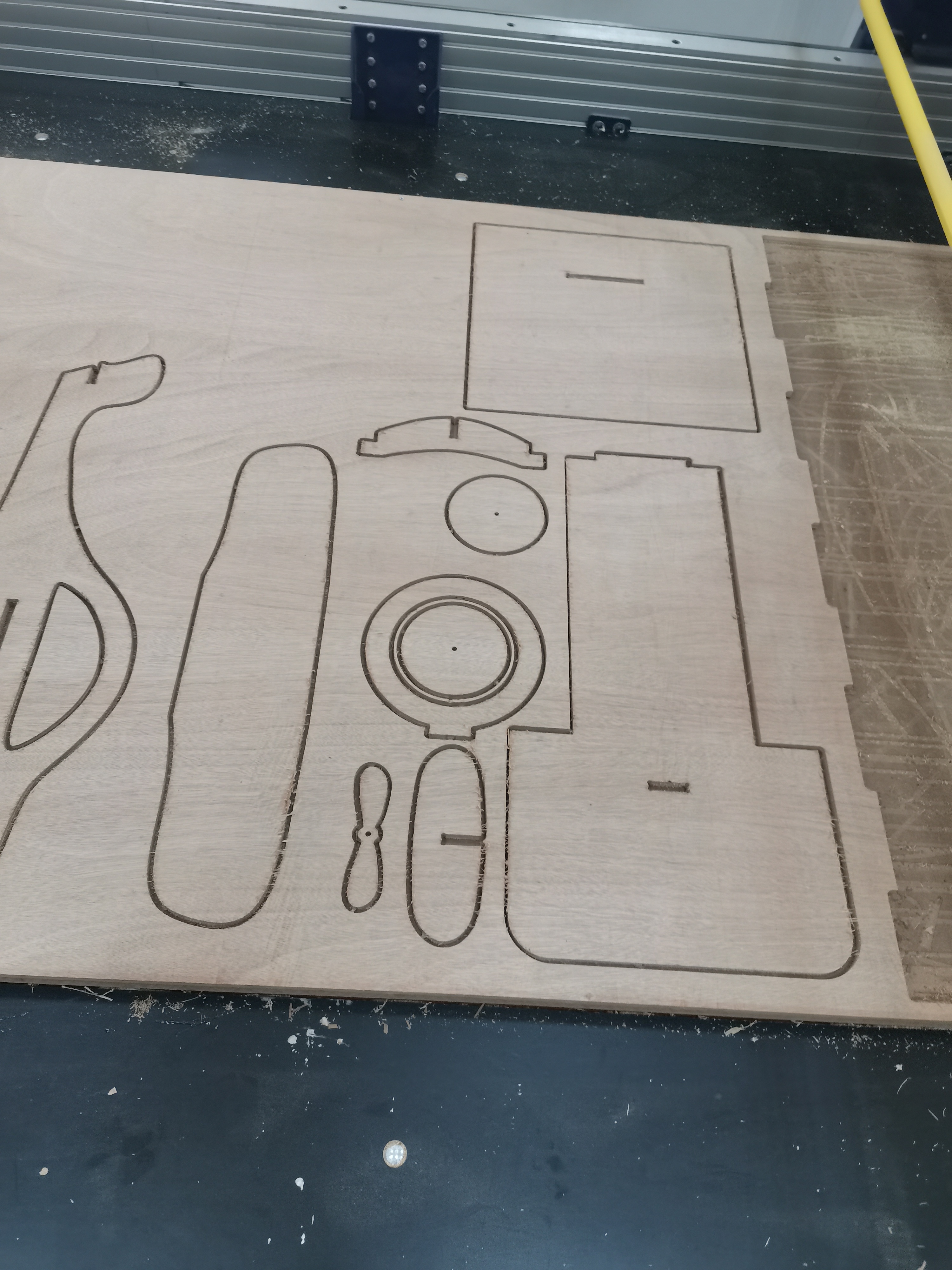

12) this is what it would look like in the cnc machine and how the machine cutting on the plywood will look like. and by using Vcarve Noting the plywood dimensions is 1220mm x 2440mm x 12mm

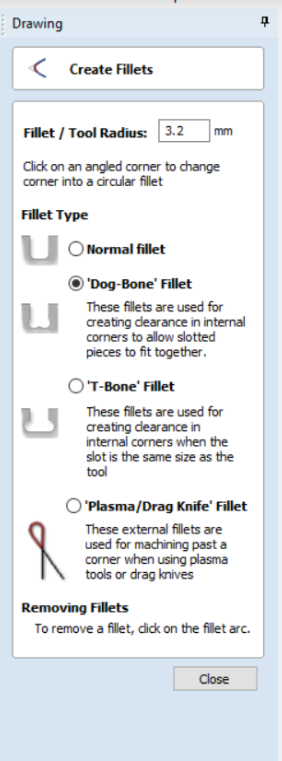

13) Since this machine cannot cut 90 degree angle in the corners so a “Dog-Bone Fillet” is accessible in the Vcrave application. then clicking on the Dog-Bone.

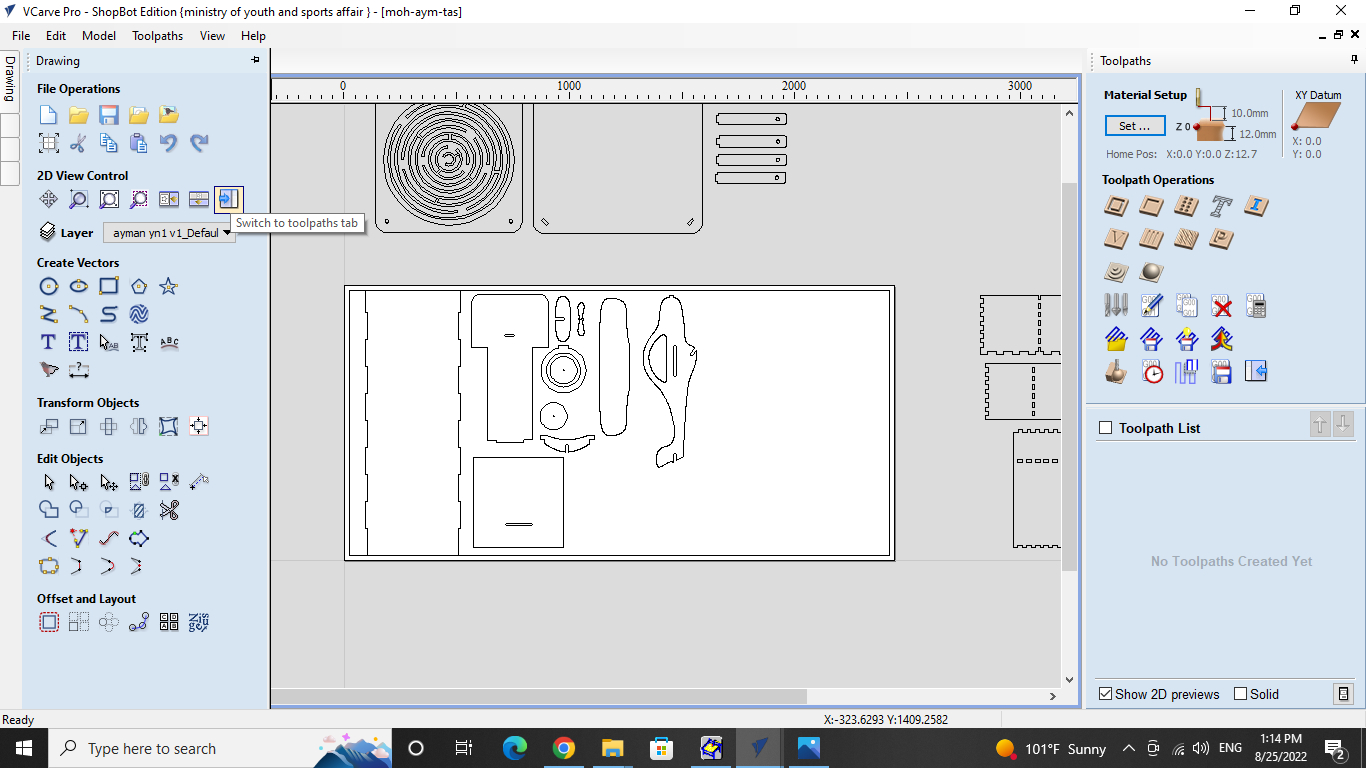

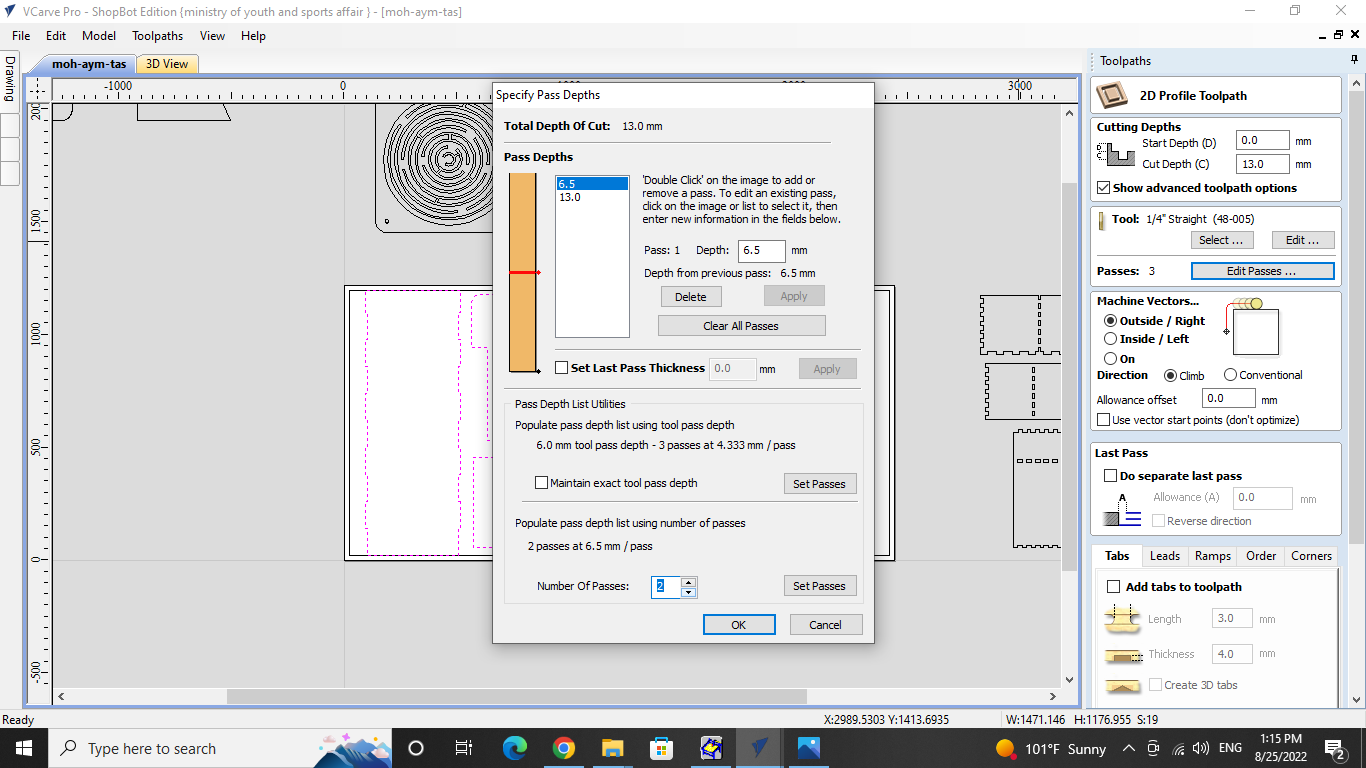

14) These are the values needed to cut with the plywood material which is defined the cutting depth 13mm, the thickness of the blade 3mm and the speed of the moving blade head 30 inch/min, The feed rate 110, and the rotational speed of the blade 14000 rpm.

15)

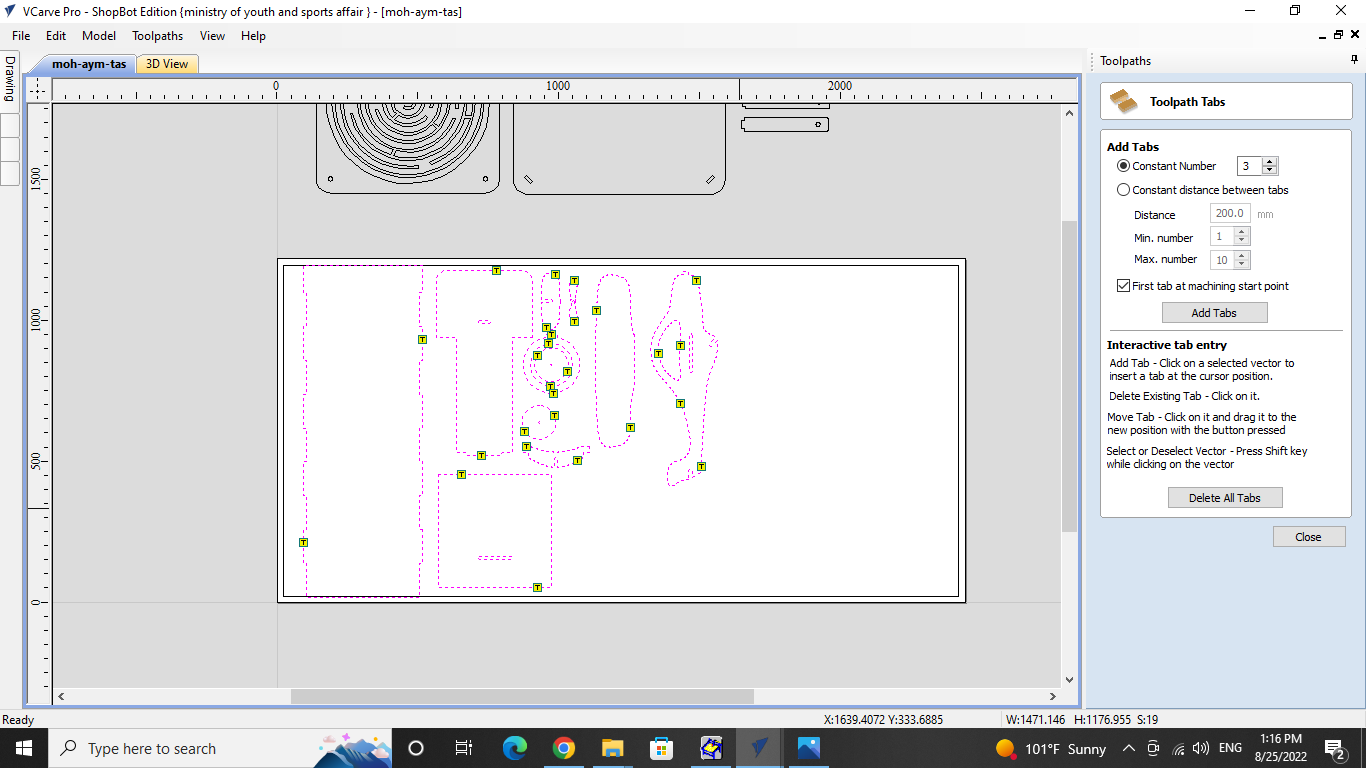

16) these are the tabs locations while the cutting process is ongoing, these tabes are utilised to keep the parts intact and prevent abnormalities.

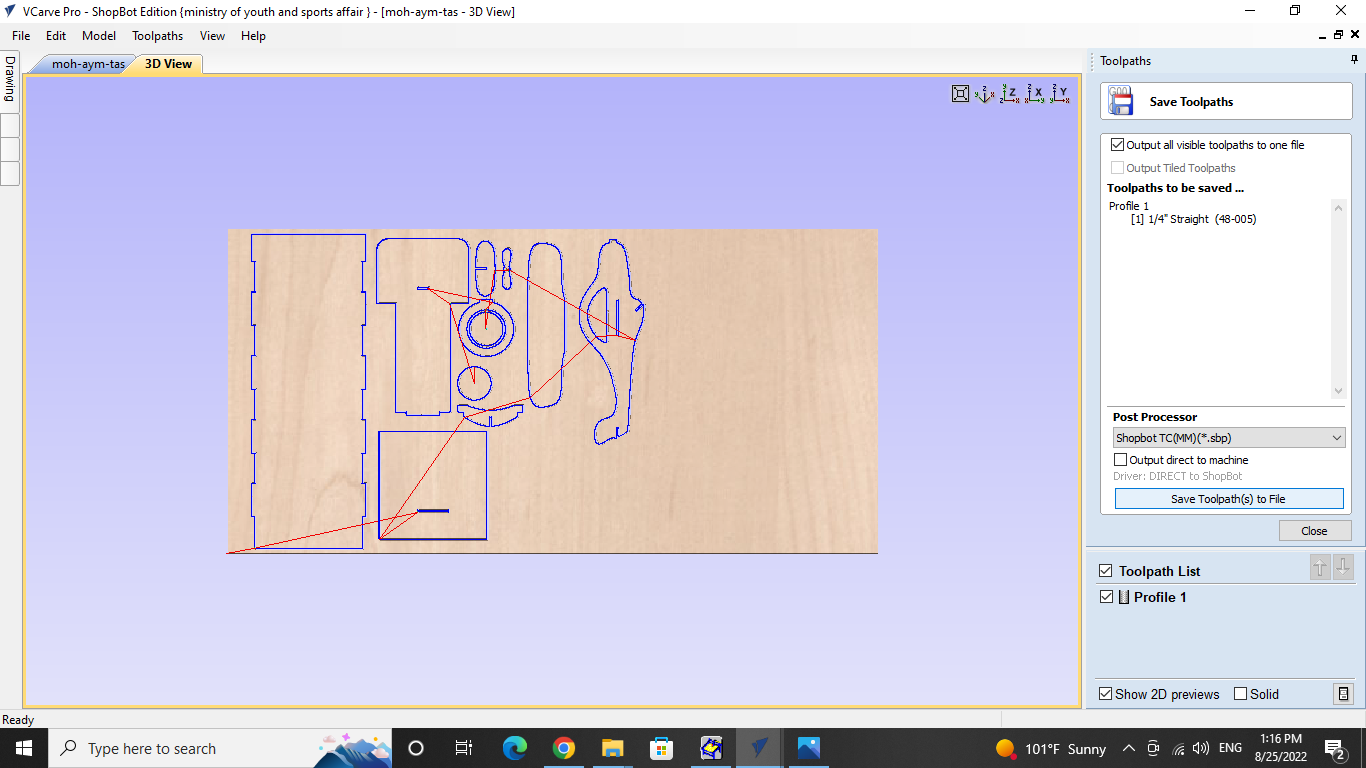

17) This is the preview of the toolpath.

18)

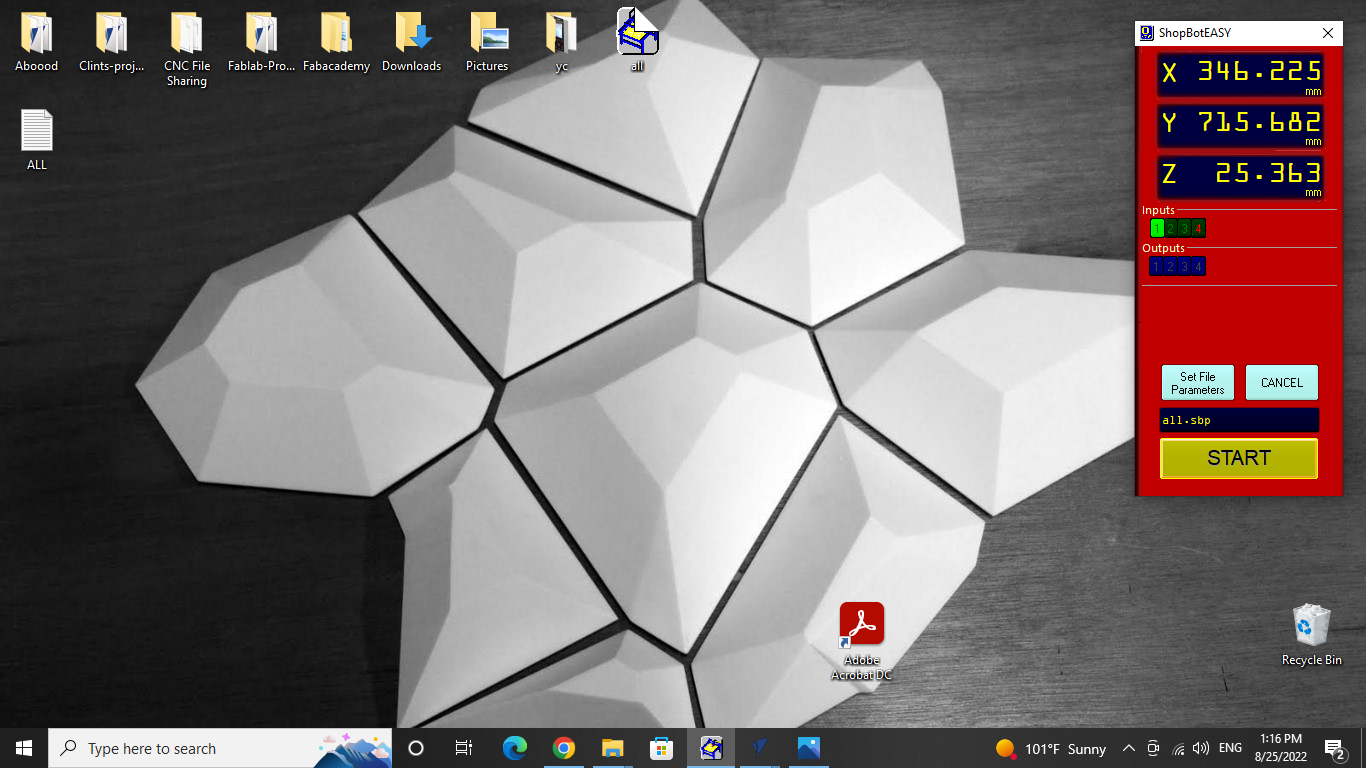

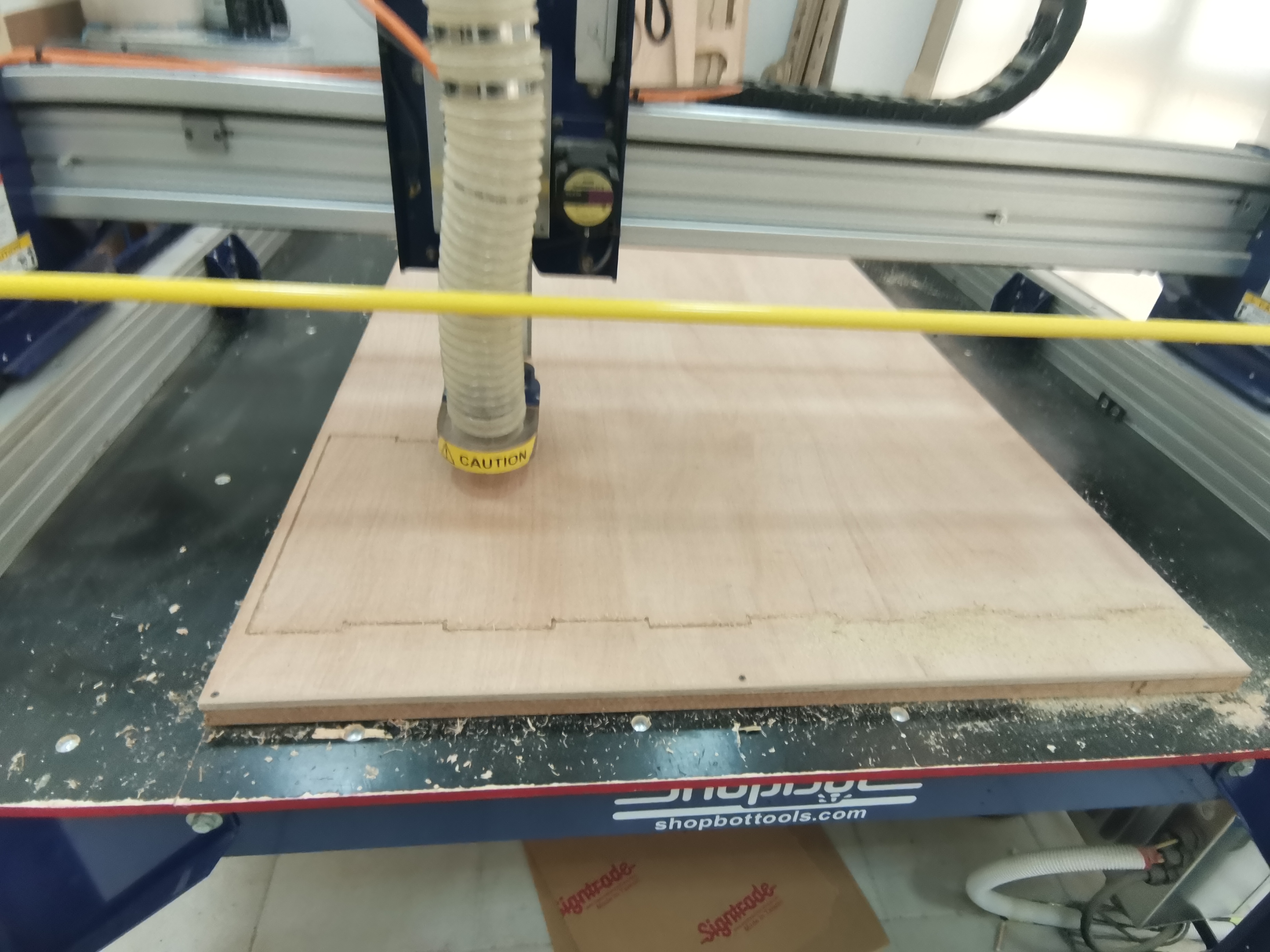

19) This is what the machine name and what it looks like while cutting.

20)

21)

Final product¶

this is the final result after putting the parts all together using a hammer.

click here to download the design

Problem¶

I faced a problem with the size of the design it was too small as you can see above the largest piece was only 16.4 cm and this maachine is designed for the large pieces since the needle is big so it is best to cut larger designs. The minimum was 70*70cm so in the last steps so In the Vcrave we just multiply the whole desing with multiplying factor of 4.

Refrences¶

program I used to use the CNC machine.