8. Moulding and casting¶

This week reallyy fun for me because I was really interested to learn about different materials that will go through different processes.

What is moulding and casting ?¶

Moulding is the process of shaping liquid or raw material using frame called a mold.

Casting is the process in which liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting.

The process¶

1- Start with a hard block of wax and plastic which is known as machinable wax

2- Pour liquid silicon into it.

3- Pour our designated material into the mould.

Group Assignment¶

Soap base-Oatmeal¶

Safety- What not to do : Free of any synthetics, chemicals, detergents or lathering agents.it is safe because it is 100% natural.

Processes & Time - The steps to make : 1. Cut the Pifito Melt and Pour Soap Base into small chunks.

-

Heat soap in a microwave, at 20-second intervals, stirring between each one.

-

wait till the soap cools down a bit. Then slowly add essential oil (scent) to the melted soap base and gently stir.

mix ratio: 1 lb of melt and pour soap base is .25 fl. oz. of essential oil.

Time - Cure & Work :

Cure : several hours on the counter or approximately an hour.

Work: Probably 15-20 minutes

Cured material state :

Bars that can popped out of the mold

Process pictures and comments

1- We cut chunks of soap that fit the design

2- We put into microwave and waited 10 seconds or 11 should be enough for soap to melt

3- We poured the melted soap into the mold

4- Have to wait for it to solidify

Individual Assignment¶

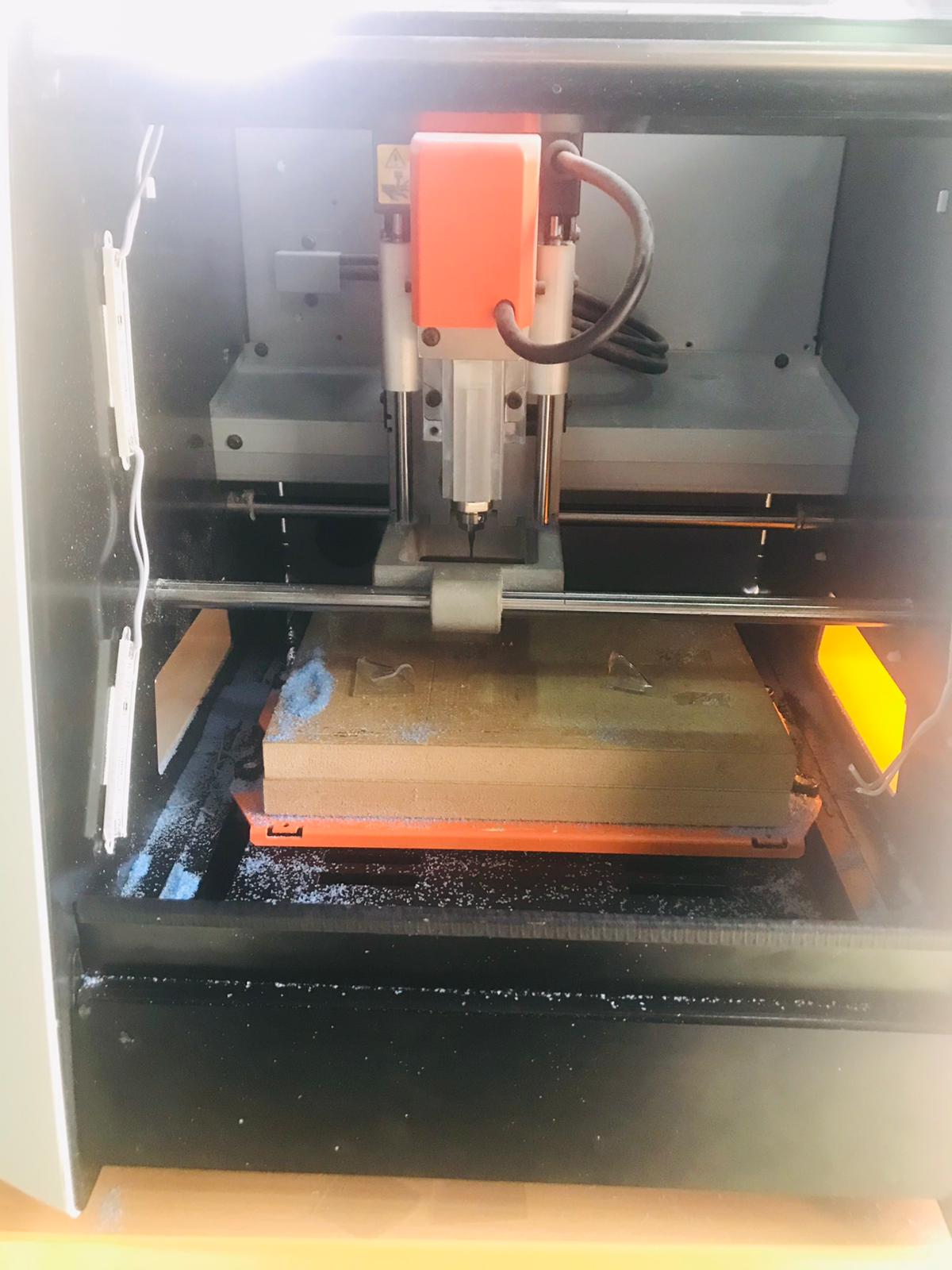

The milling machine

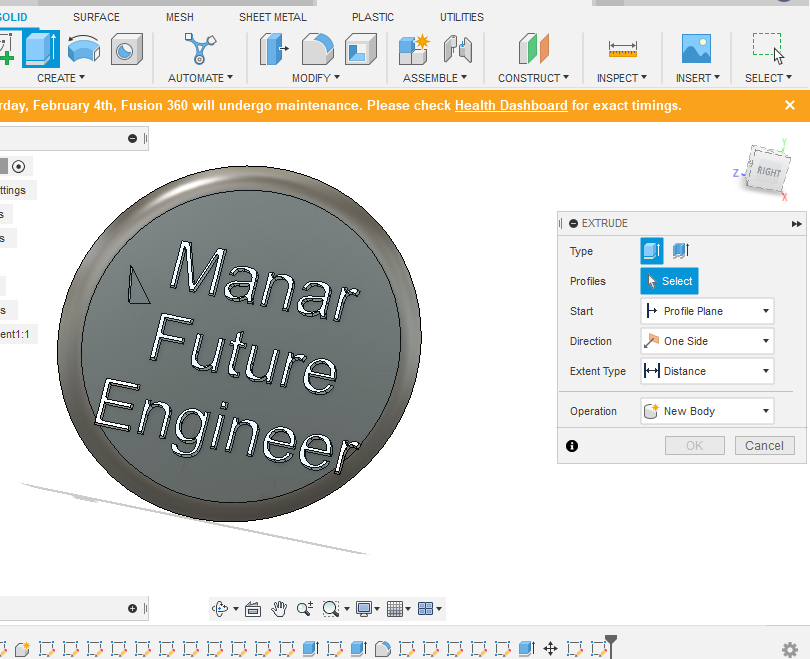

my design ” Manar Future Engineer :) “

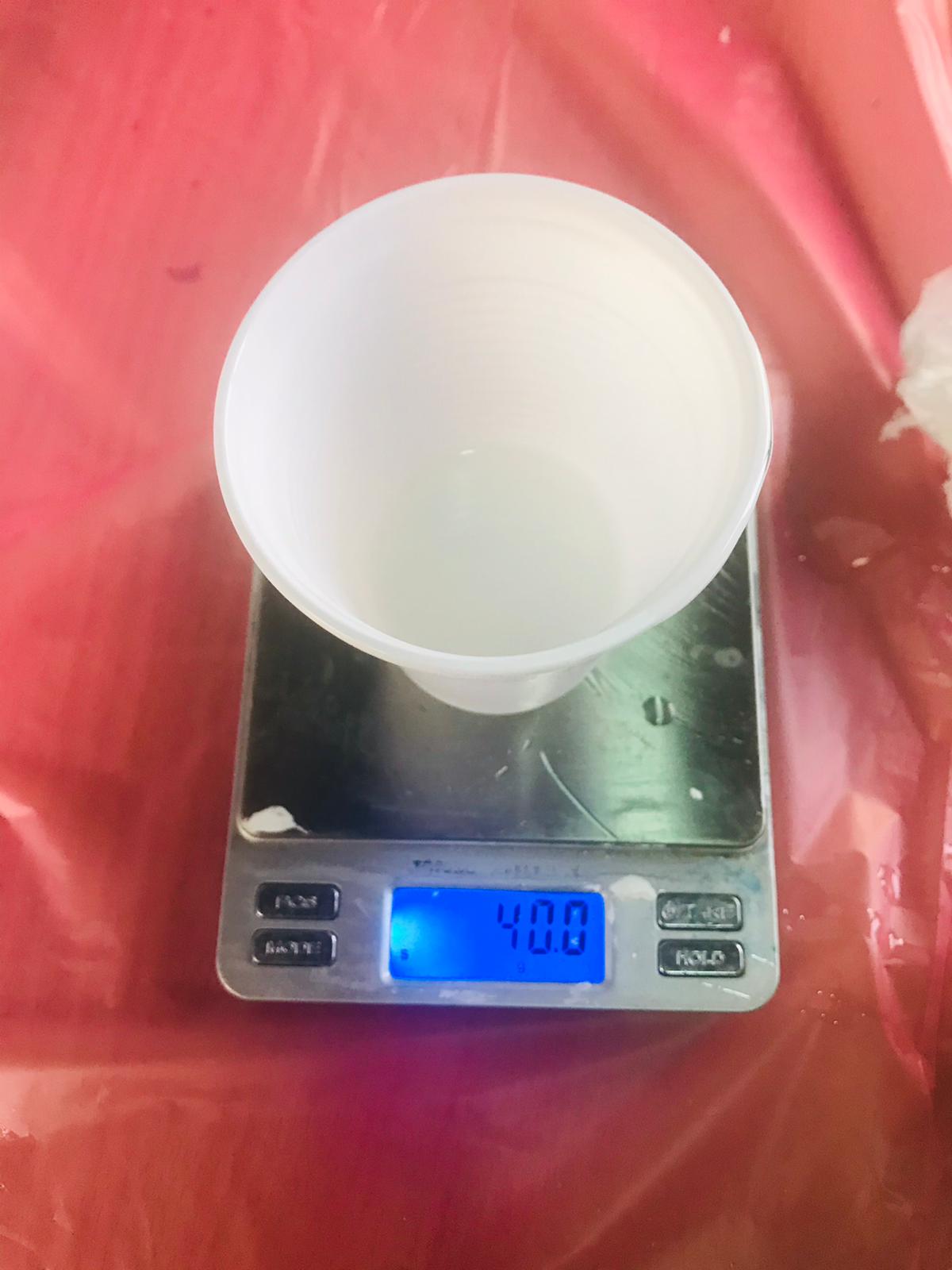

As defined above we pour silicon, so as shown here we pour equal quantity of both I estimated my design to be 40 g. so 20/20

![]()

Then pour gradually to avoid bubbles, note that I poured 50/50

20 grams from each

Then wait for 8 hours to solidify :)

After 8 hours

Second Part process¶

Now for the second part process is to choose what kind of material of your design, I chose “Resin”, I poured equal quantity of both which is 5/5 grams

added some colors and mix !, the mix time is 5 minutes

finally pour it in silicon mold we made before and tdaa!

image of heroshot

my design file

3D Mould Design¶

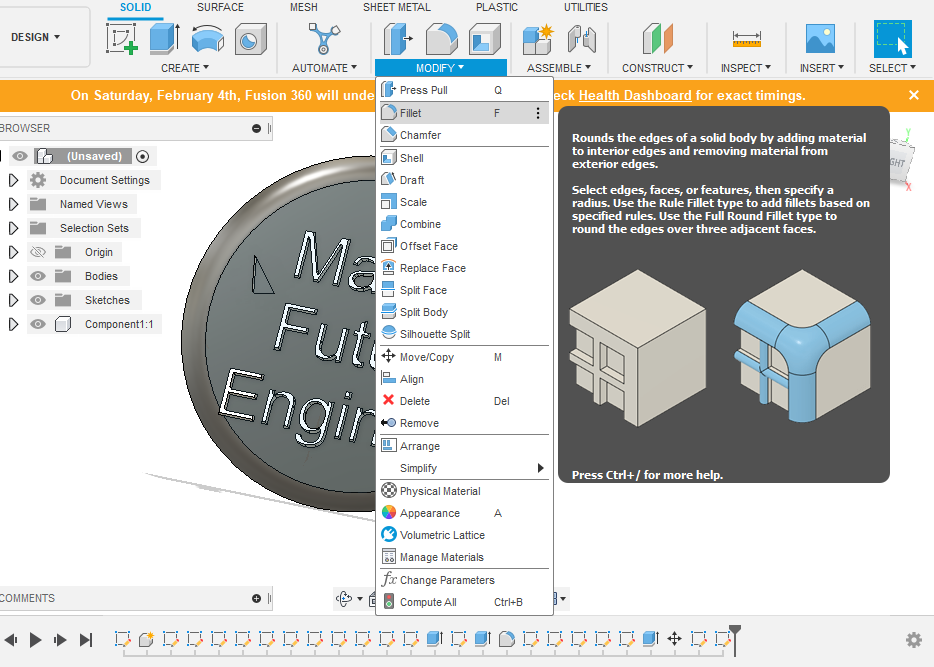

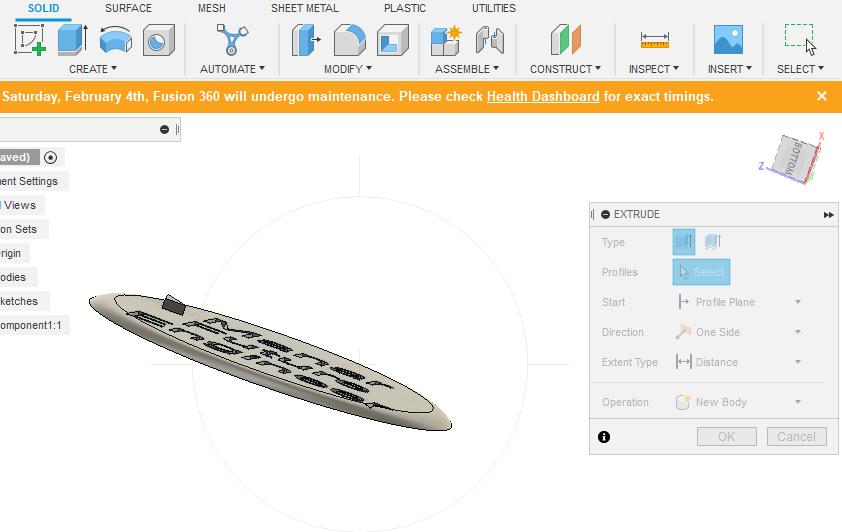

I designed my mould using Fusion360 , through my whole journey at Fab academy I always struggled with Fusion360 so make sure you do additional tutriols learning it and request help from instructor to modify it for you. I used two kinds of tools for my design fillet and extrude.

I designed my mould using Fusion360 , through my whole journey at Fab academy I always struggled with Fusion360 so make sure you do additional tutriols learning it and request help from instructor to modify it for you. I used two kinds of tools for my design fillet and extrude.

I generated a circle shape then I applied fillet to round the edges

I generated a circle shape then I applied fillet to round the edges

I applied a text and modifed its size and spacing the applied extrude down to

I applied a text and modifed its size and spacing the applied extrude down to

extrude up

extrude up

Design Files¶

Design File as .fbx(downloadable)

Problems encountred¶

1- first, I did my design from scratch tried to include some parts like hooks and knocks to satisfy the criteria due to my lack of designing skills in Fusion360, I’m determined to further do more projects where designs from scratch are required