6. Large format CNC (computer controlled Machining)¶

This week started with having knowledge about CNC parameters and how to work with it. Also, I designed my own file to make it out of Plywood by CNC.

for information about cnc machine and safety…etc please refare to the group assignment, i will put the link bellow

Group Assignment¶

Individual Assignment¶

for my design i will use fusion360 (i am designing a stool)

i followed a toturial that i watched on YouTube

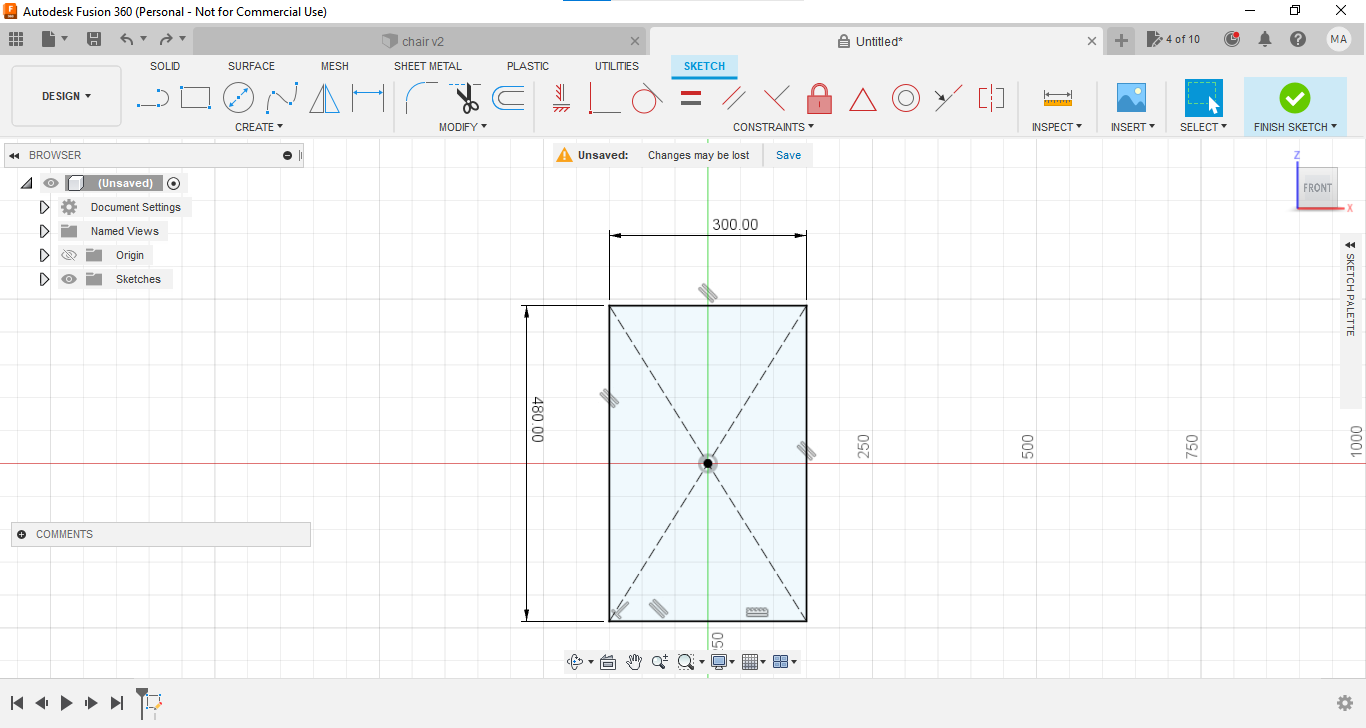

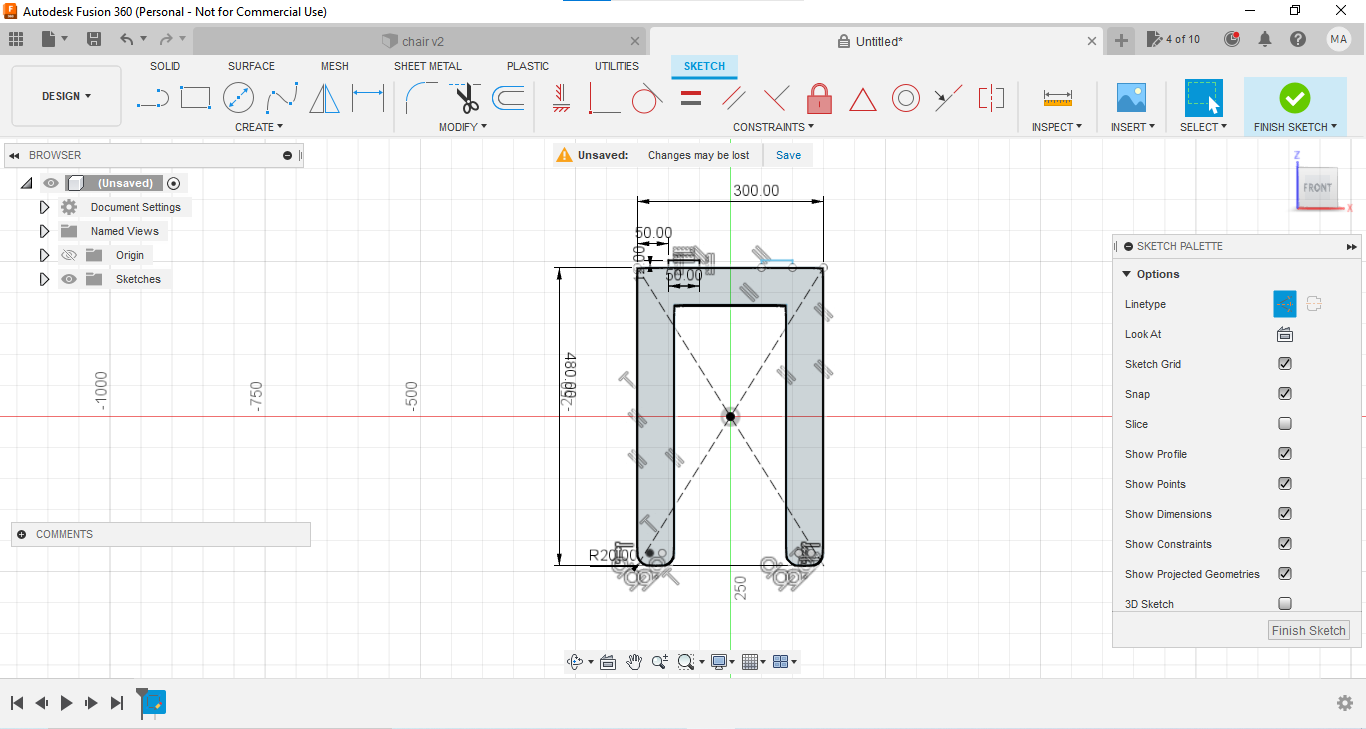

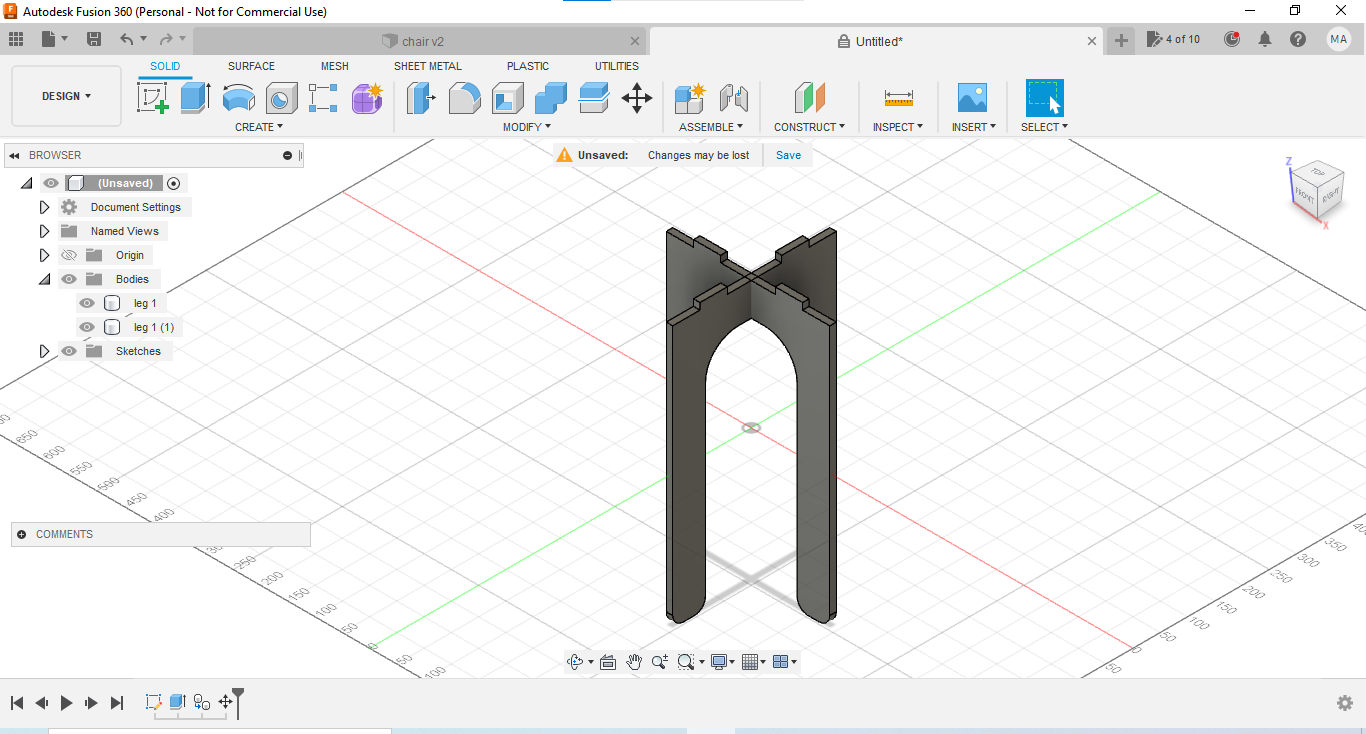

1-we draw a rectangular square by going to create sketch

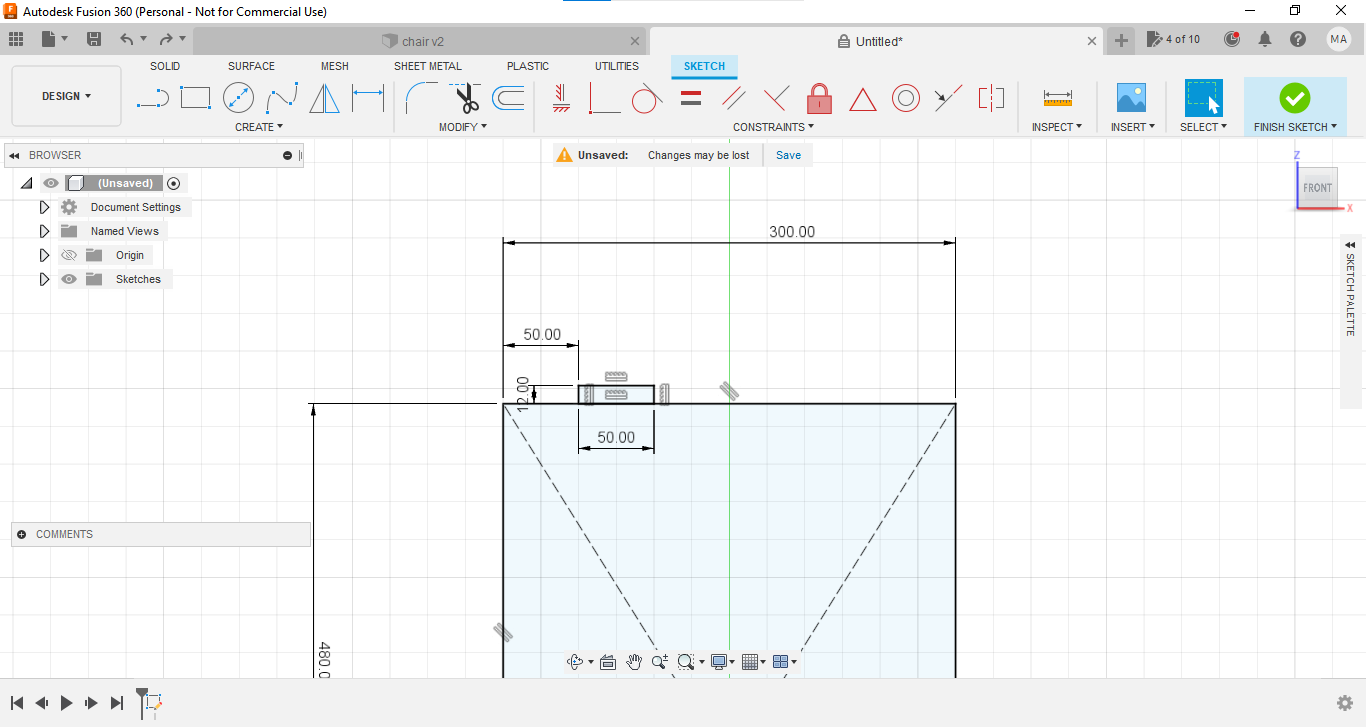

2-design the left bumps that will fit in the chair seat

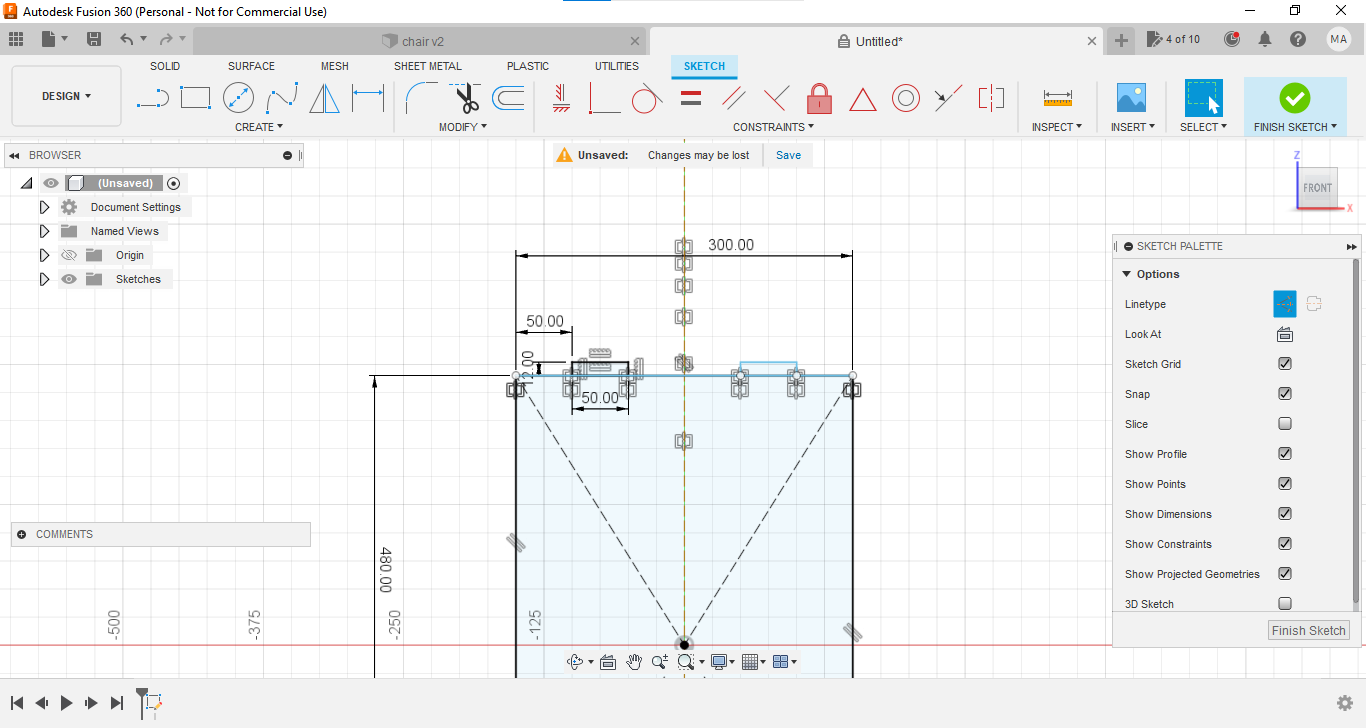

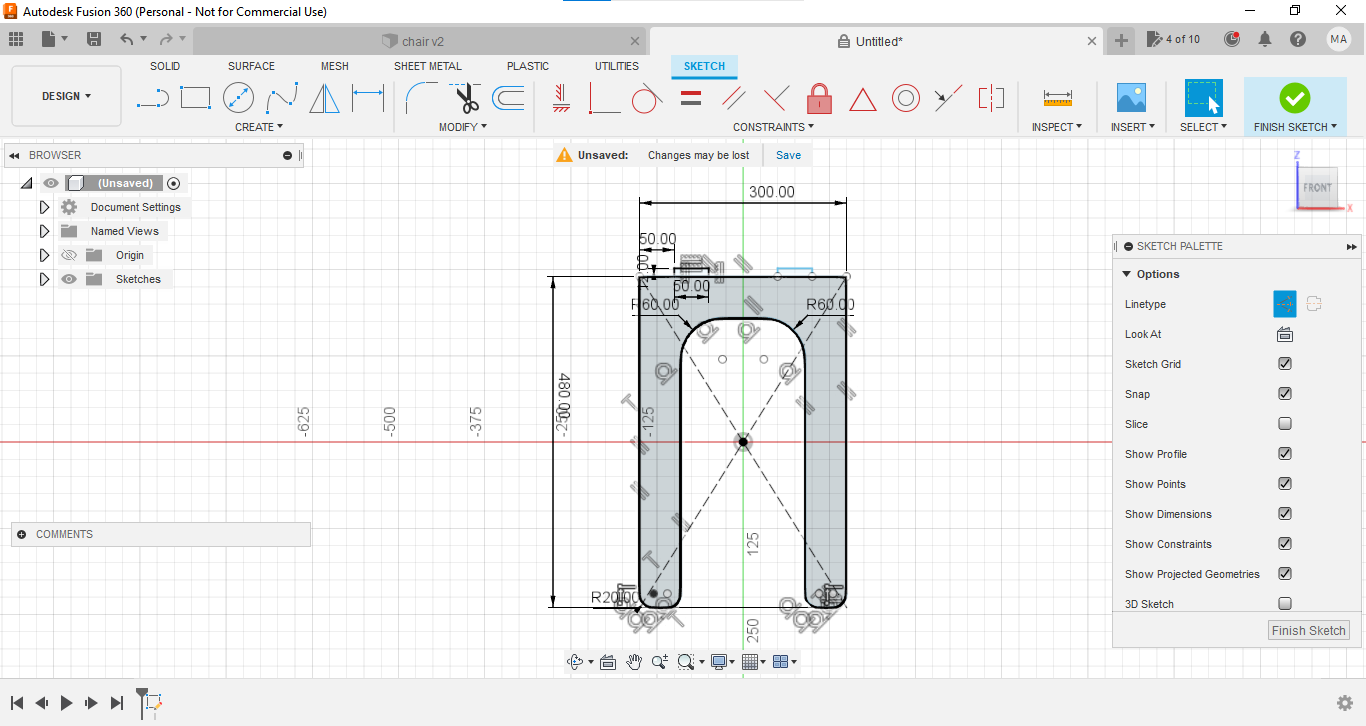

3-mirroring the left bumps to the right side

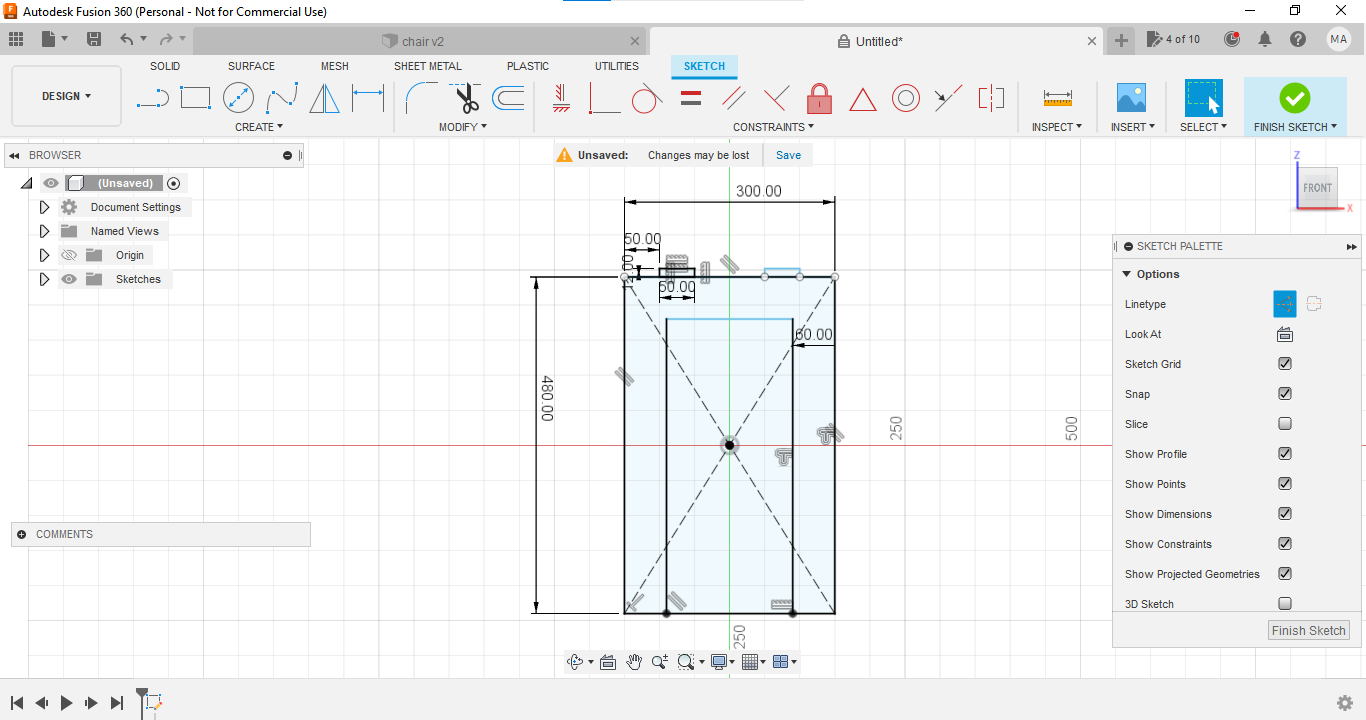

4-draw another rectangle inside the previous one and extrode it

5-curving the angle of the bottom of the chair legs

6-curving the angle of the neck of the chair legs

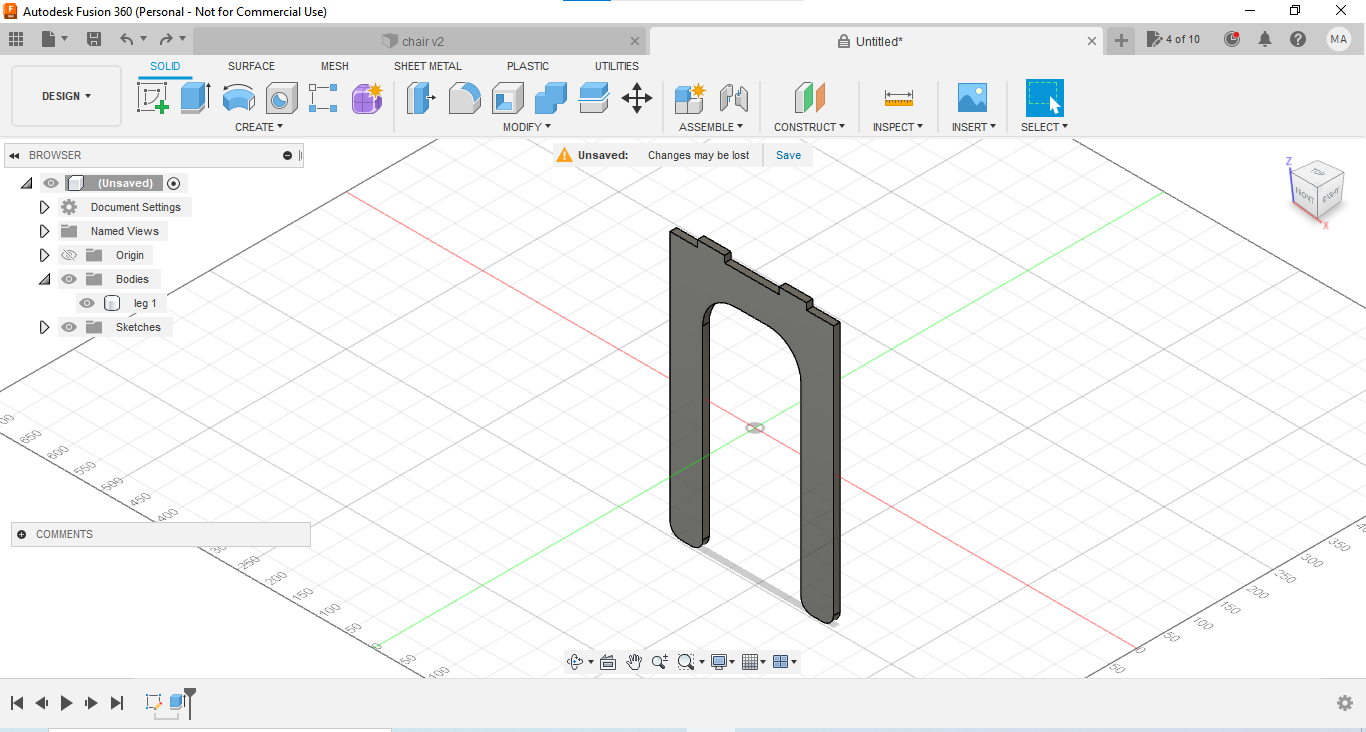

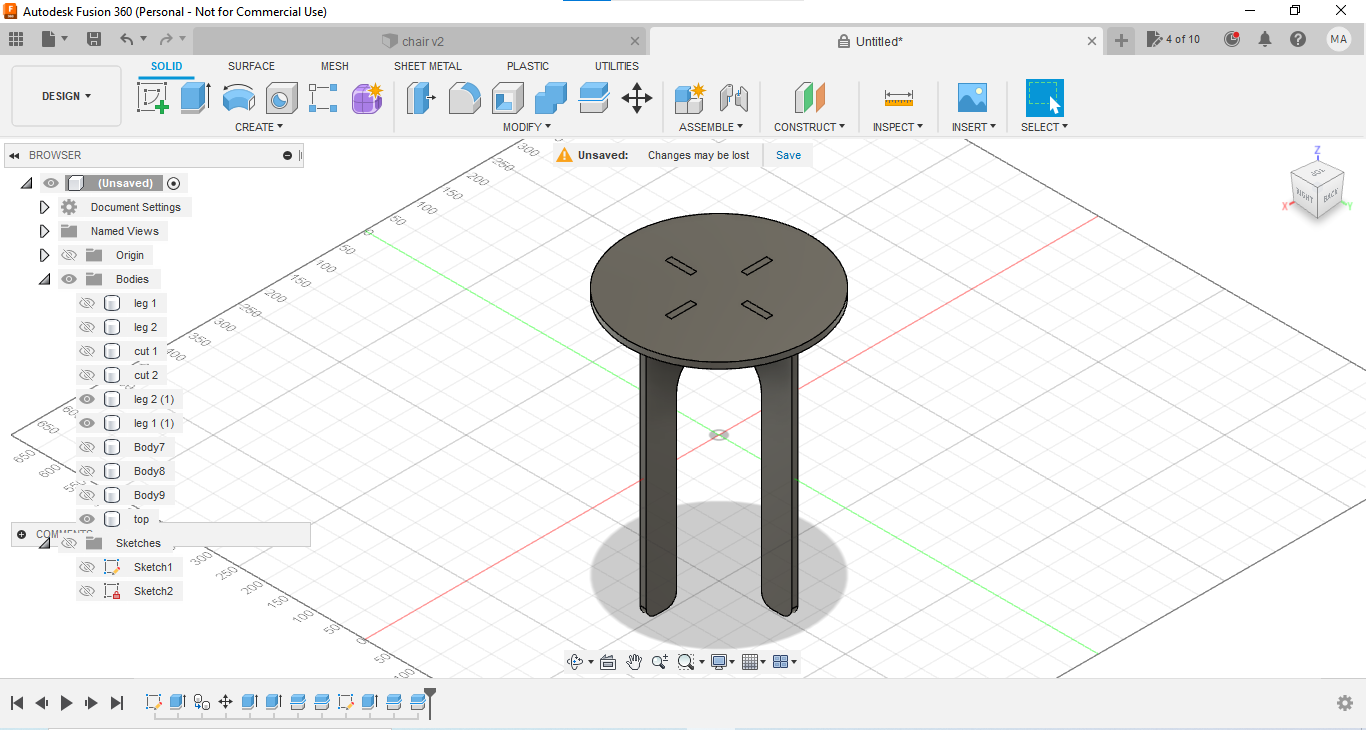

7-final result of the first legs

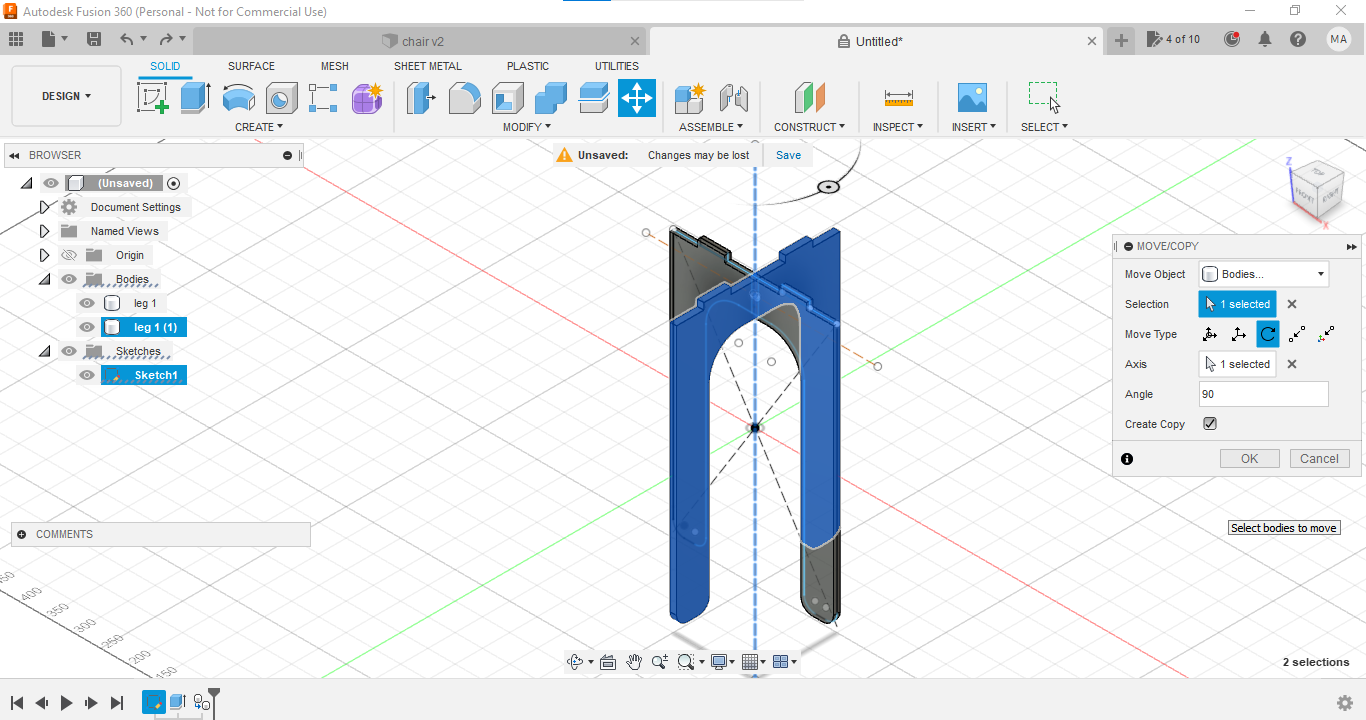

8-mirroring the first legs and rotate it

9-final result of both first and second legs after i merge it together

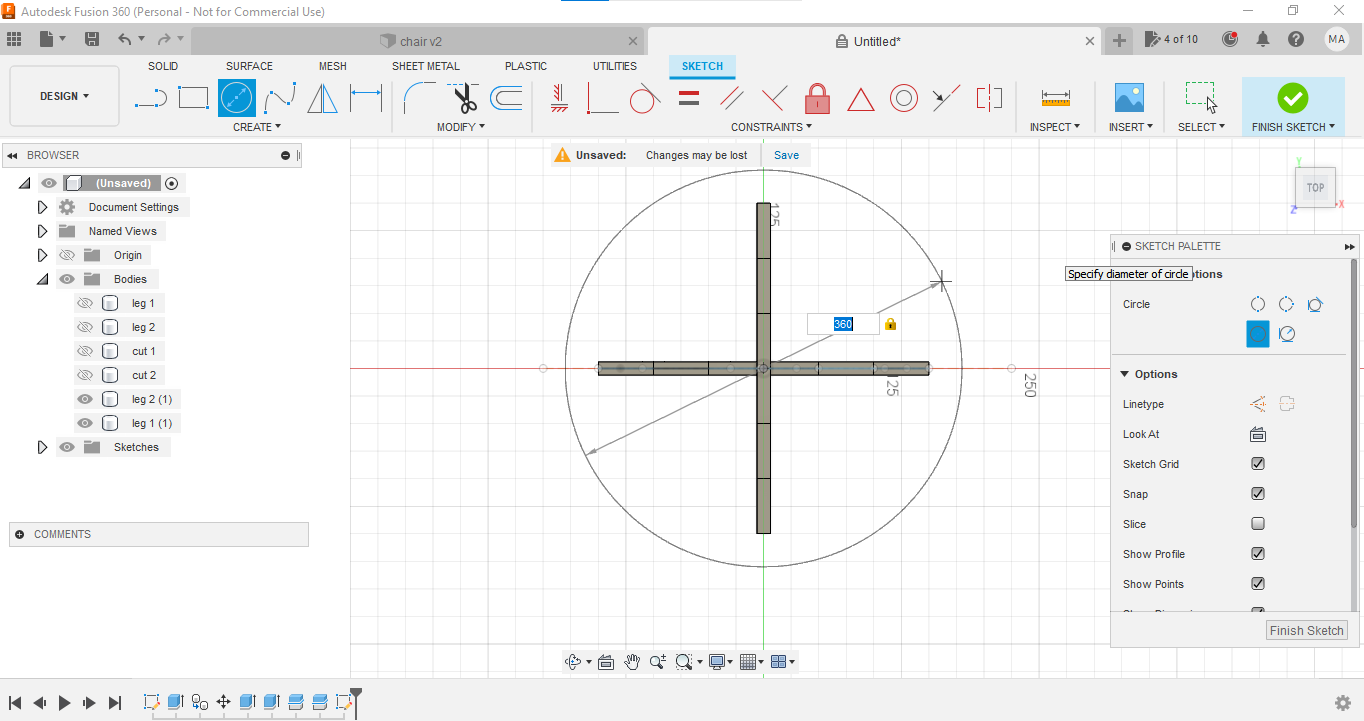

10-i draw a circle on the top of the legs and cutt 4 fitting rectangles to fit the legs with it

final result(after cutting and sanding)¶

this is the short steps for the details i recommend to watch the tutorial that i saw. i will put the link bellow¶

stool tutorial¶

download my design¶

to download my design just click

cnc process:¶

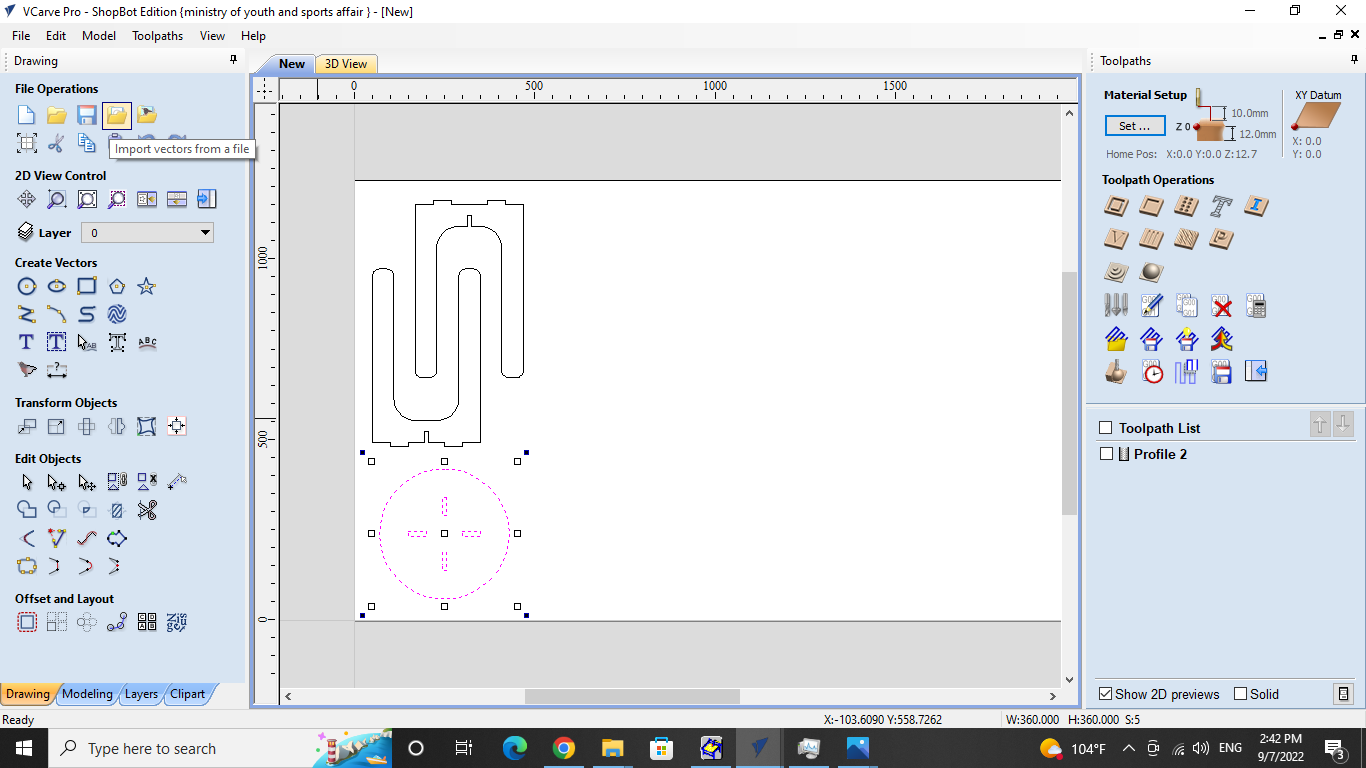

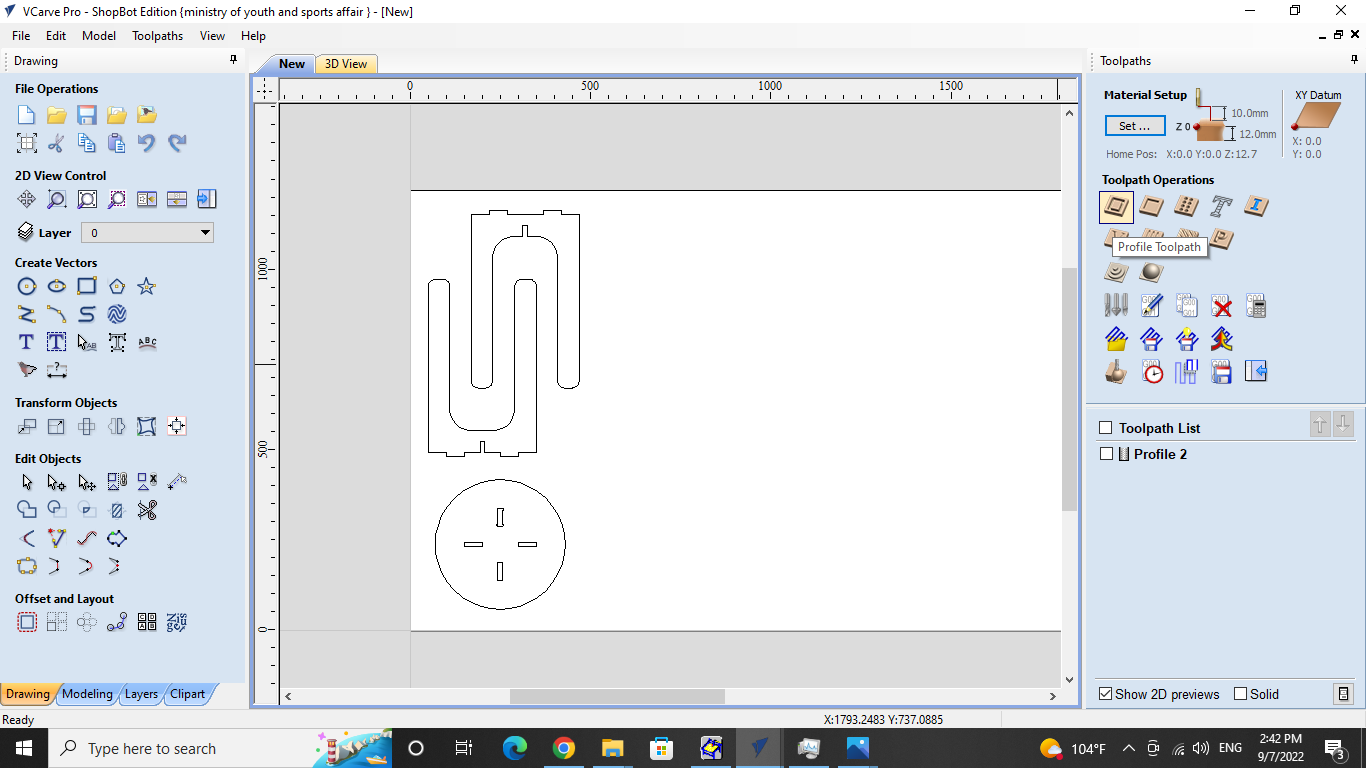

STEP1: I opened Vcarve softward and set the hegiht,width and thickness of the playwood

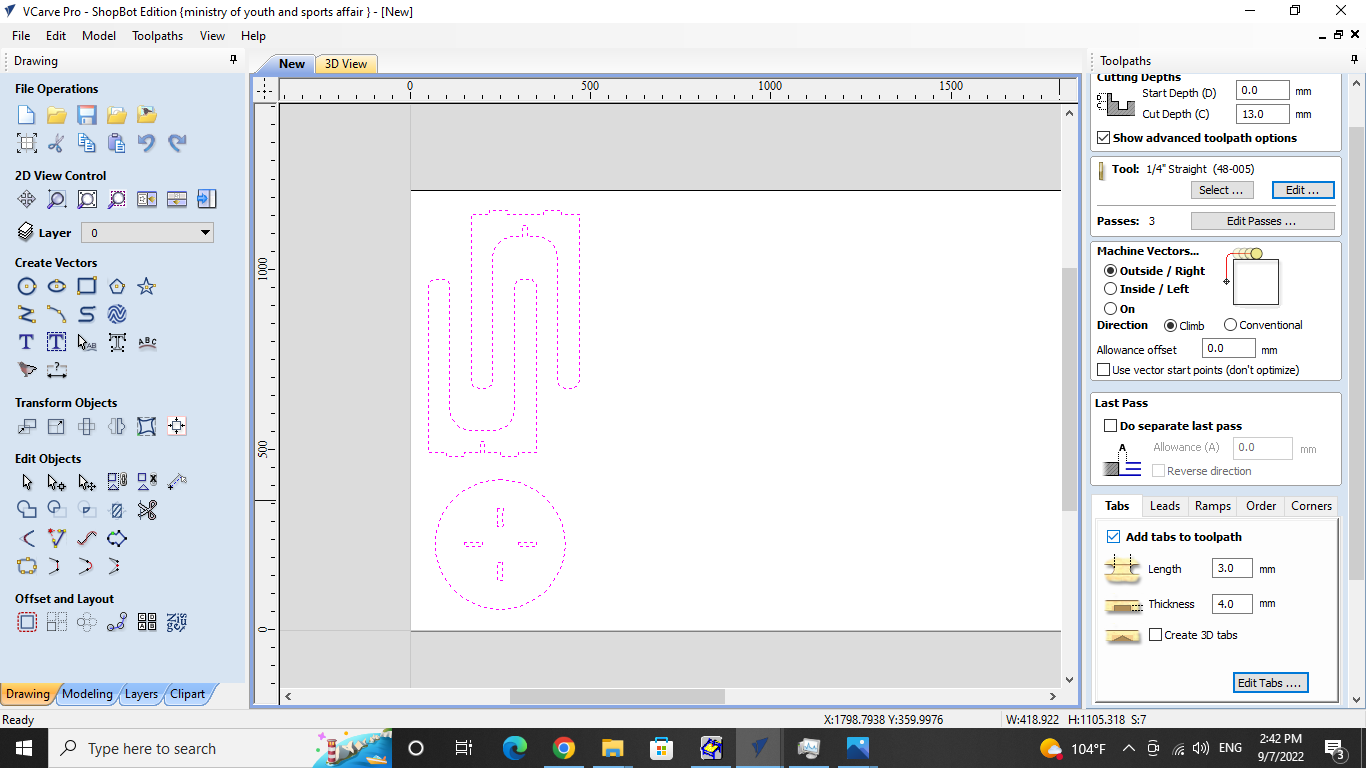

STEP2: I open my dxf files in the softwards and put them in the recentangular shown which represent the playwood sheet

STEP3: rearrange them in a way to save material

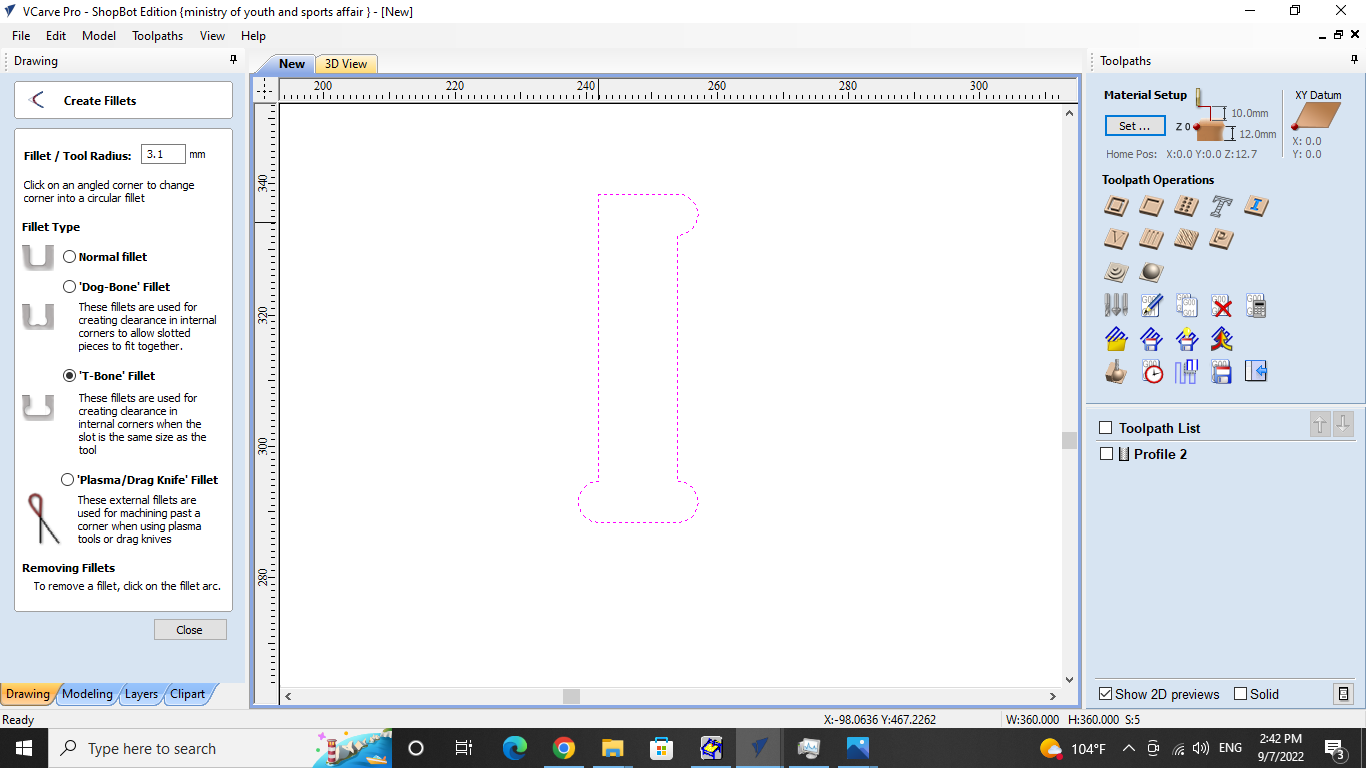

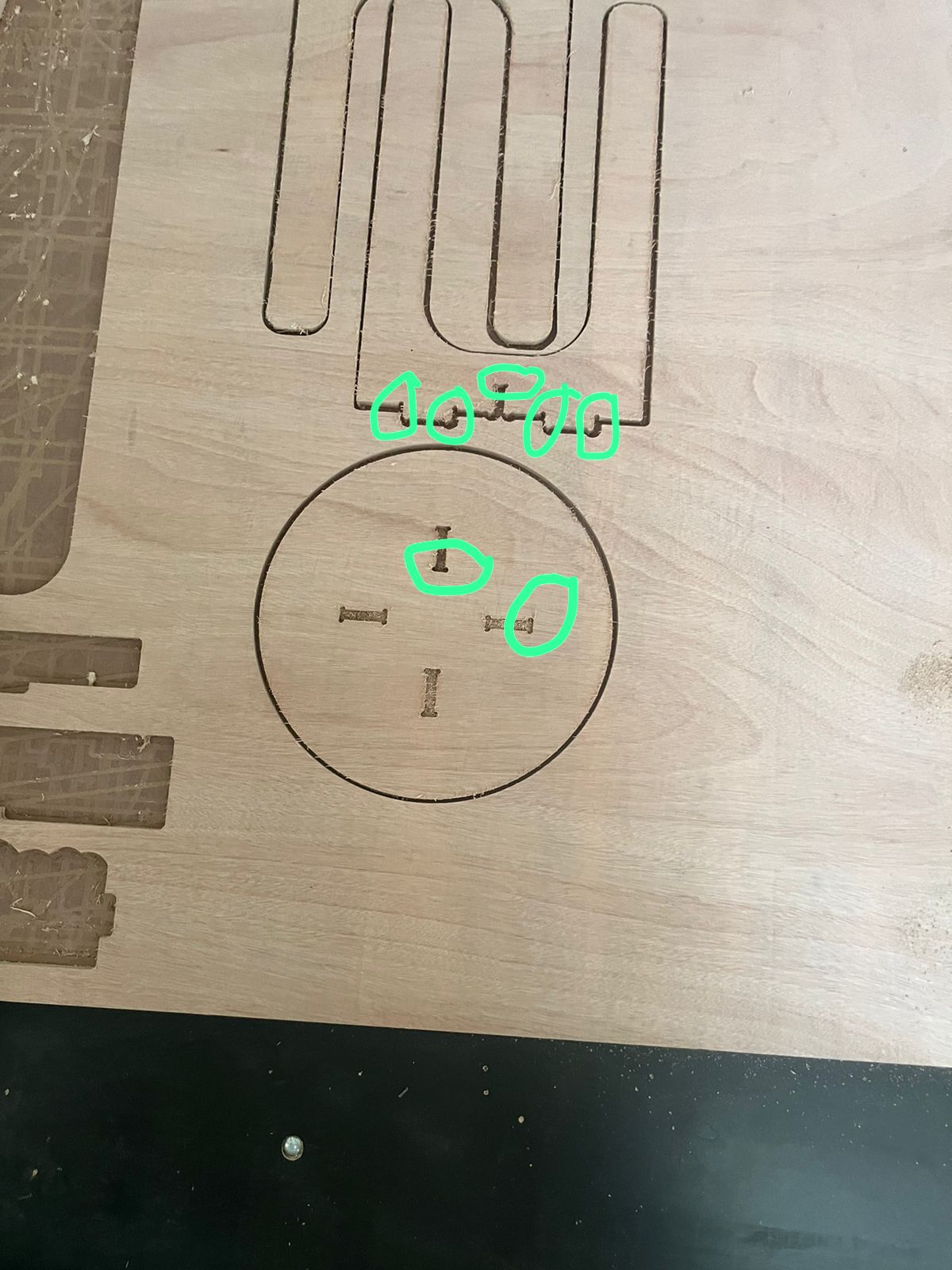

STEP4: make the angles as T-BONE

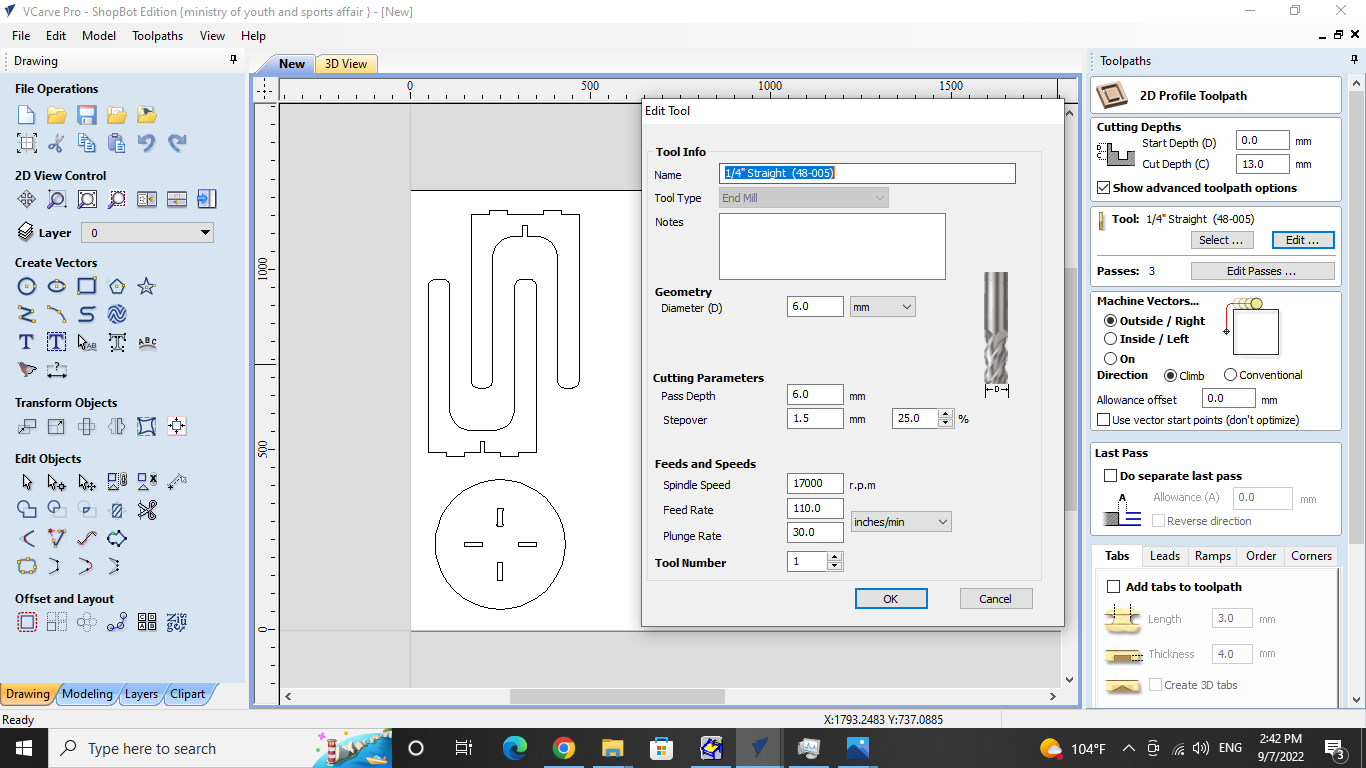

STEP5: select the tool path as selected in the image below

STEP6: 1-select the feed rate:which is the relative velocity at which the cutter is advanced along the workpiece(for me 110)

2-select the spindle speed: which is the term for the router attached to your cnc router,This speed is termed ‘spindle speed’ and is directly related to the feed rate or surface speed(for me 1700 RPM)

3-select the plunged rate: which is the speed at which the router bit is driven down into the material when starting a cut and will vary depending on the bit used and the material being processed(for me 30)

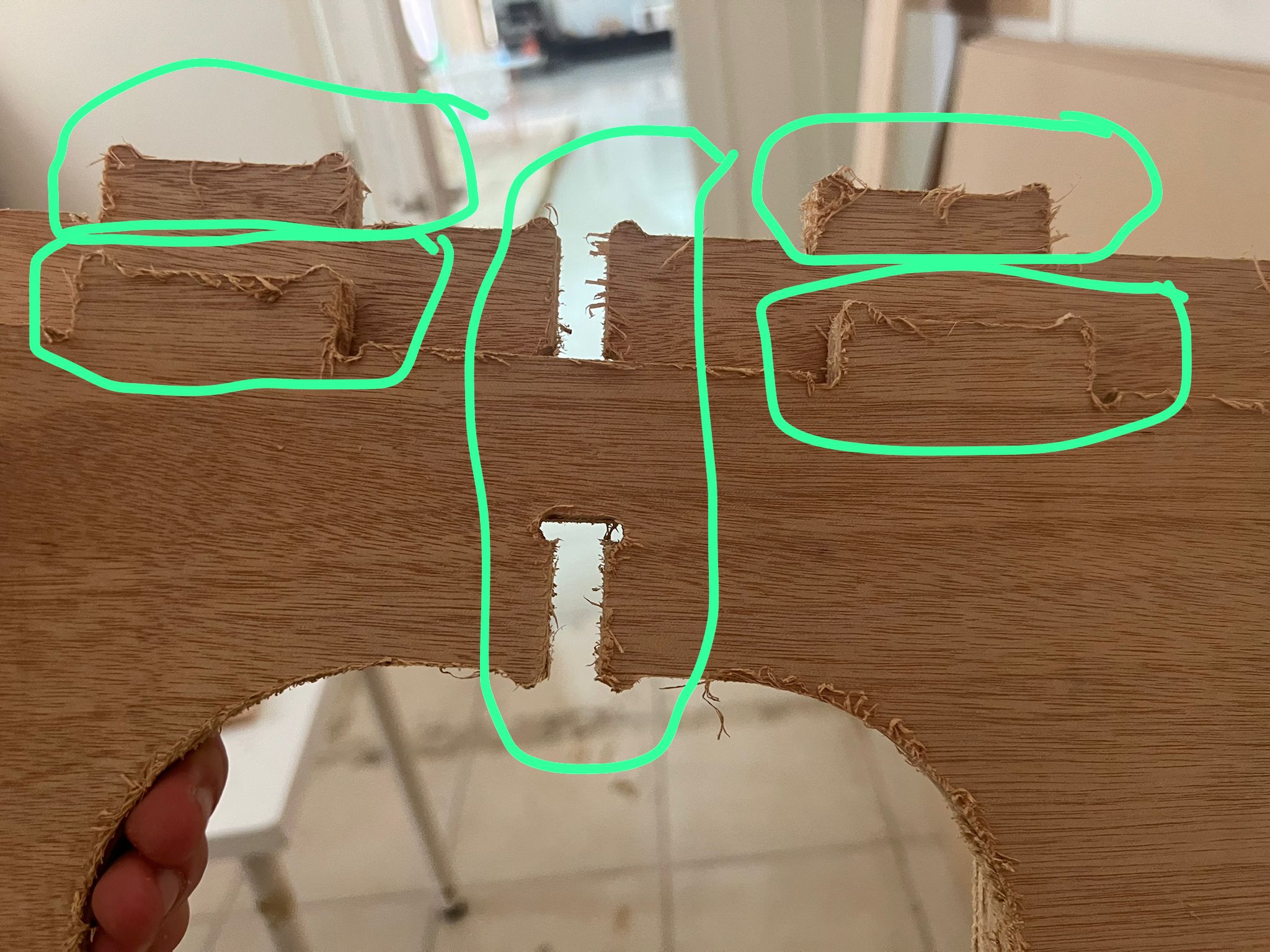

my mistakes:¶

actually i made a mistake before cutting the design which is using T-angel in every angel in the design

how i fix the mistakes:¶

to fix these mistakes i used two things

1- sanding paper by the machine and this for the big bodies

2- sanding rod by my hand and this for the small parts and the angle