5. 3D printing and scanning¶

Week 3:¶

3D Printing:¶

3d printing according to the dictionary is an action or process of making a physical object from a three-dimensional digital model, typically by laying down many thin layers of a material in succession.

When was it discovered:¶

The first known examples of 3D printing may be found in Japan in the early 1980s. Hideo Kodama was looking for a technique to design a quick prototyping system in 1981. He devised a layer-by-layer manufacturing method based on a photosensitive resin that was polymerized by UV radiation.

1990-2010 Growth:¶

Many firms and startups began to emerge in the 1990s, experimenting with various additive manufacturing methods. The first commercially accessible SLS printer was produced in 2006, completely altering the game in terms of industrial part manufacture on demand. Currently, CAD tools were more widely available, allowing users to create 3D models on their computers. In the early phases of making a 3D print, this is one of the most significant tools. The machines at the time were considerably different from what we have now. They were difficult to use, costly, and required a lot of post-processing for many of the final prints. However, new discoveries, techniques, and practices were being developed and invented daily. Then, in 2005, Open Source altered the game for 3D printing by allowing more individuals to use it. The RepRap Project, founded by Dr. Adrian Bowyer, was an open-source attempt to develop a 3D printer that could construct another 3D printer as well as other 3D printed things.

3D Printing now:¶

3D printer prices began to fall in the 2010s, making them more accessible to the general population. Along with the cheaper pricing, the printing quality and convenience of use improved. Printers’ materials have progressed as well. A wide range of polymers and filaments are now readily available. Carbon Fiber and Glass Fiber, for example, may be 3D printed. Some artists are even experimenting with chocolate and pasta as printing materials! The world’s largest operable 3D printed building was finished in 2019. Hearing aids and other healthcare applications are now routinely 3D printed, and many companies and sectors have integrated the technology into their daily operations.

Group Assignment¶

Individual Assignment¶

Now since we know all about 3D printing and its history lets continue and look at the things that Fablab academy allows us to experience.¶

First, we downloaded Ultimaker Cura software from the link down here. (https://ultimaker.com/software/ultimaker-cura)

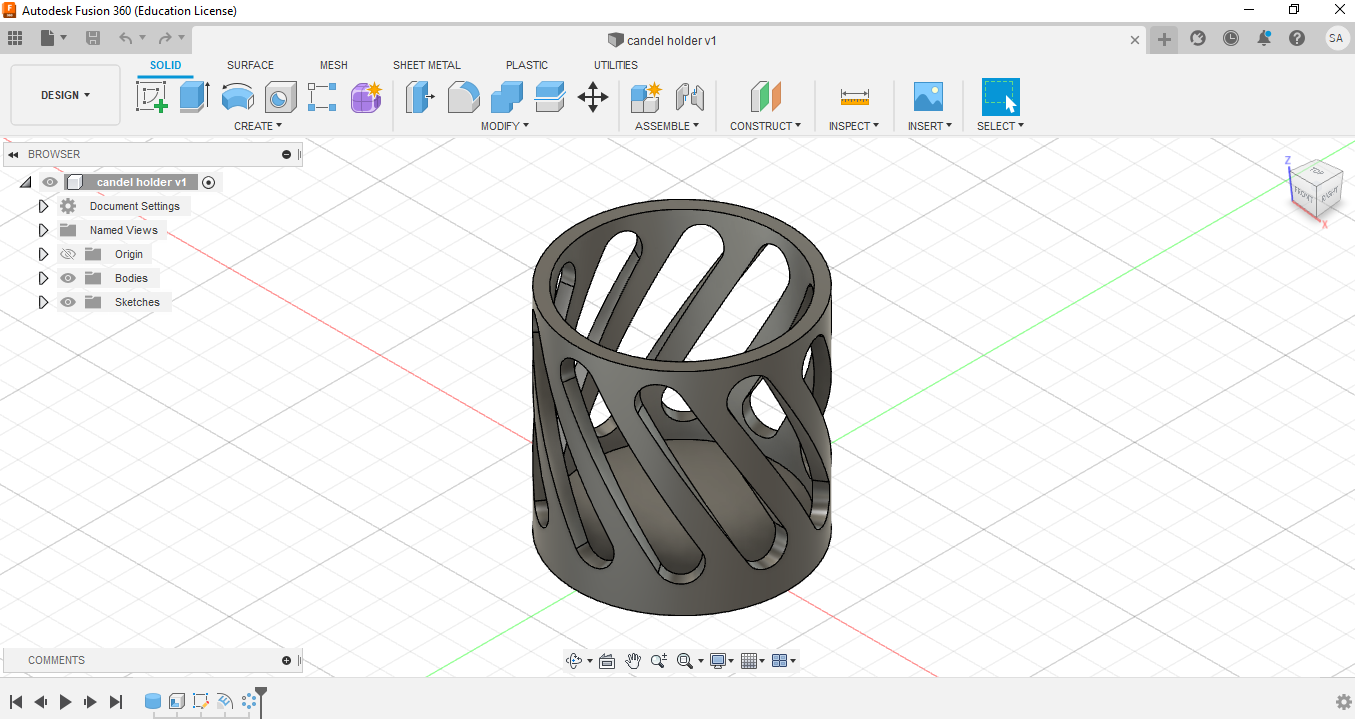

Later, I decided on an Ultimaker printer and began designing using Fusion360.

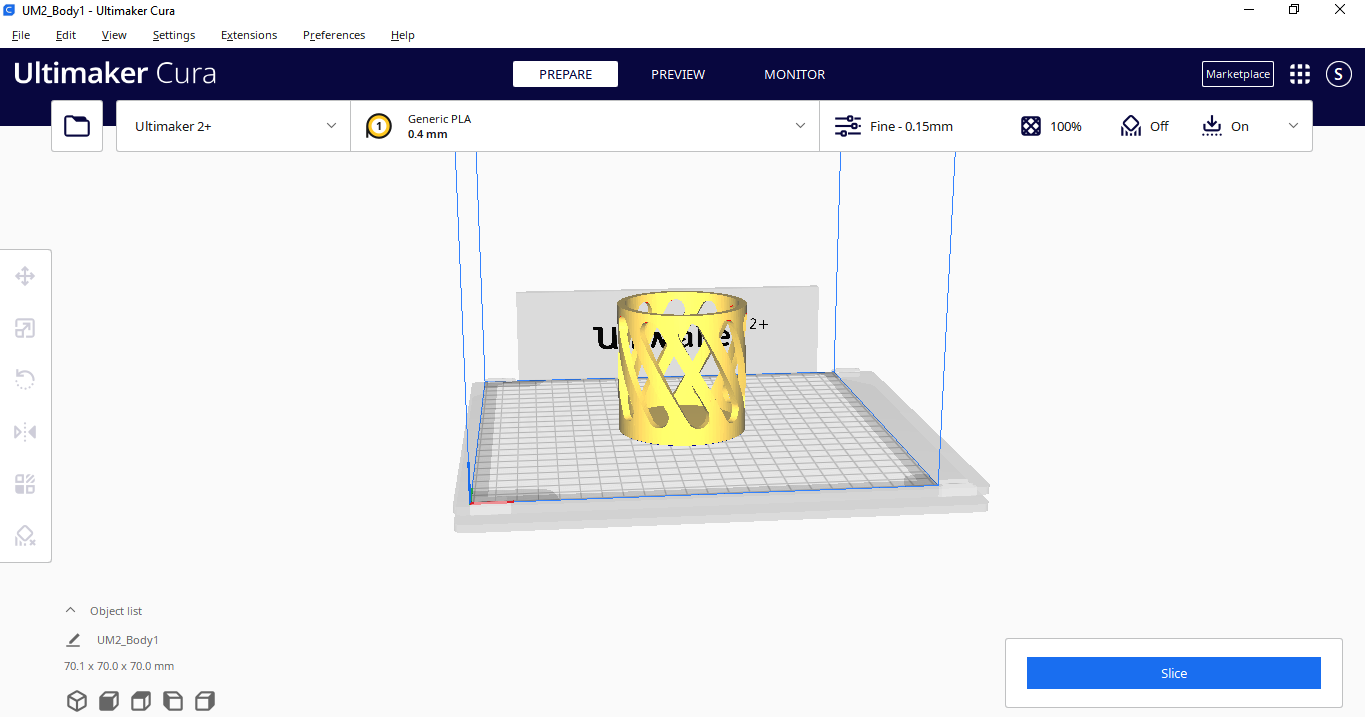

I thought a candle holder would be useful this time because I love candles a lot. Then I saved the file as an STL file and sent it to the Ultimeker cura software. I added on the printer I am going to use (Ultimaker), the material PLA, and the nozzle size of 0.4 mm. I changed the print settings to (Infill = 100, Material / Printing Temp = 215 / Build Plate Temp = 60 3. Speed = 50 4. Build Plate Adhesion (Brim)).

I thought a candle holder would be useful this time because I love candles a lot. Then I saved the file as an STL file and sent it to the Ultimeker cura software. I added on the printer I am going to use (Ultimaker), the material PLA, and the nozzle size of 0.4 mm. I changed the print settings to (Infill = 100, Material / Printing Temp = 215 / Build Plate Temp = 60 3. Speed = 50 4. Build Plate Adhesion (Brim)).

The next step is to push the slice button at the right bottom, which will show you how long it will take to print; mine took 6 hours and 55 minutes.

The next step is to push the slice button at the right bottom, which will show you how long it will take to print; mine took 6 hours and 55 minutes.

Here is the result.

3d Scanning¶

3D scanning turns actual items into exact digital models, allowing you to record the shape and geometry of your product rapidly and correctly.

Application you can use: 1- Qlone. 2- Scandy Pro. 3- Trnio Plus. All available on the App Store.

I used Trnio Plus according to the instructor recommendation.

Here is the result.

How do I feel about this week?¶

It’s been the best week I’ve had so far, and it’s because we’ve begun to turn our ideas into reality; I can’t wait for the next few weeks!.