6. Large format CNC (Computer Controlled Machining)¶

CNC¶

The term CNC stands for ‘computer numerical control’, and the CNC machining definition is that it is a subtractive manufacturing process that typically employs computerized controls and machine tools to remove layers of material from a stock piece known as the blank or workpiece and produces a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries, such as large CNC machining, machining of parts and prototypes for telecommunications, and CNC machining aerospace parts, which require tighter tolerances than other industries. Note there is a difference between the CNC machining definition and the CNC machine definition one is a process and the other is a machine. A CNC machine (sometimes incorrectly referred to as a C and C machine) is a programmable machine that is capable of autonomously performing the operations of CNC machining.

What is CNC machining?

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

The image below shows the X and Y axis of the drill.

The RED button is to STOP the machine if necessary or incase of an emergency, GREEN button is to START and BLUE is to RESET .

The 6mm spindle.

The sacrifice sheet.

What is the sacrifice sheet? To make sure the spindle is cutting all the way through the wood we add 1mm to the actual width of the wood (wood is 12mm, we cut it as 13mm) so the 1mm gets cut through the sacrifice sheet to avoid damage to the machine itself. MDF is used for sacrifice sheets and it gets changed when needed.

Precautions¶

- Make sure you are wearing the safety glasses.

- Take off jewelry.

- Leave a safe distance between you and the machine.

Joints¶

Group assignment

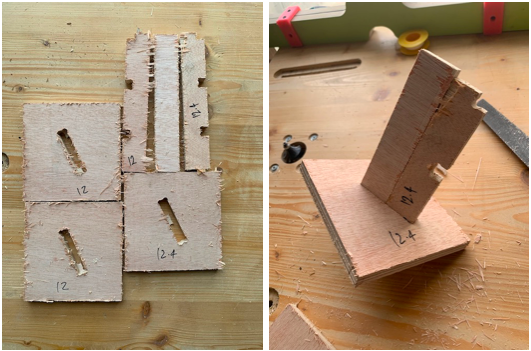

Individual project testing joints, 12.4mm is the best joint.

AutoCAD¶

There are so many CAD softwares to 2D design, what I personally find easy is AutoCAD.

AutoCAD is a computer-aided tool that allows many different types of designers to create diverse kinds of drawings and designs. This program helps designers create their designs much more quickly than by hand and offers many quick, easy and useful features. AutoCAD can create any 2D drawing and 3D model or construction that can be drawn by hand. The program also allows the user to group or layer objects, keep objects in a database for future use, and manipulate properties of objects, such as size, shape and location.

Parametric Table¶

While browsing through the internet to get ideas of cnc machining projects, I found so many interesting projects but what caught my eyes are parametric designs of chairs, tables and so on.

Here are some examples of parametric designs :

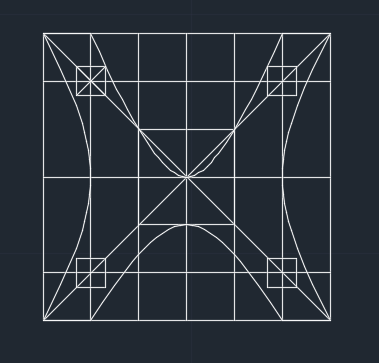

I have decided to create a table using the parametric method.

- Started with a grid.

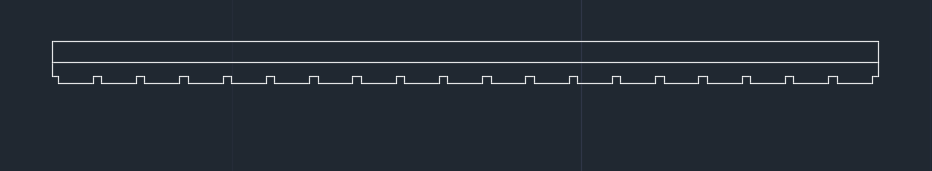

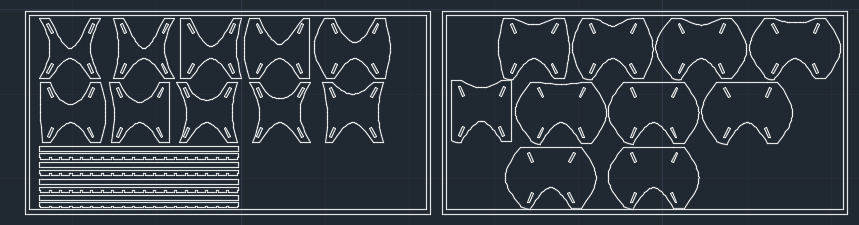

- The joints.

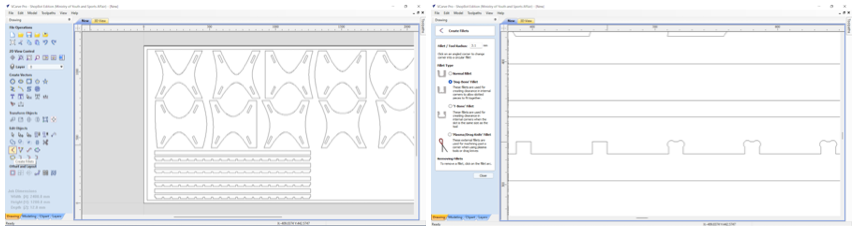

- The final sheets.

VCARVE¶

VCarve Pro provides a powerful but intuitive software solution for creating and cutting parts on a CNC Router. VCarve Pro gives the power to produce complex 2D patterns with profile, pocket, drill and inlay toolpaths, plus the ability to create designs with v-carving textures as well as import and machine unlimited Vectric 3D clipart or single model files. The ‘Pro’ edition gives unlimited job and toolpath size, true shape nesting & job set-up sheets, ideally suited to a production environment.

How to use VCARVE?¶

-

Open VCarve PRO > Create new file > Import existing file.

-

Create fillets > Dogbone fillet (set to 3.1mm)

Why do we need to create dogbones? Drill bits of the CNC can’t cut 90° angles/corners, dogbones are created for the inner corners to make it easier for the pressfits.

- Cut the design in 13mm.

Ups and downs¶

Joints ready!

Joints don’t fit the holes made due to the width.

Trying to widen it so that the joint can fit.

READY!!

Hero Shot :sparkles:

Well, not yet.