8. Moulding and casting¶

Materials¶

Cement¶

Cement is a powdered substance made of calcium, silicon, aluminum, iron, clay, and other materials that have been burned together in a kiln or high temperature oven. These ingredients are carefully chosen for their chemical properties. Cement is an important ingredient in a finished product called concrete.

Concrete is versatile as long as you know how to work with it. It’s also easy to experiment with because you can buy the raw materials at any large hardware or building supply store.

When it’s in a semi-liquid form or uncured, concrete is heavy and viscous, not easy stuff to handle. At this point, depending on how you want to use it, you can add substances to it that will slow the drying rate or speed it up, or make the wet concrete flow more freely. It all depends on how you want to use it to make art. But in all cases, to make sculpture with concrete you need something to control its shape.

You can cast it in a mold, a hollow form made of plaster, aluminum or latex into which uncured concrete is poured. The inner surface of the mold is coated with a substance like shellac to ensure that the concrete doesn’t stick to it. The concrete cures until it has hardened and then it’s removed from the mold.

Lets test Cement :

- Make sure you are wearing gloves.

Instructions :

-

Add water slowly, stir well.

-

Add more cement and mix if it seems a bit runny.

The right consistency is neither solid or liquid.

- Pour into mold.

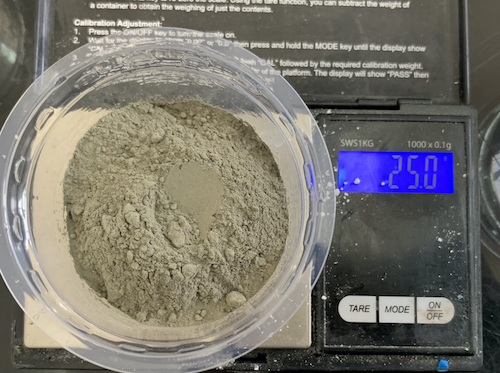

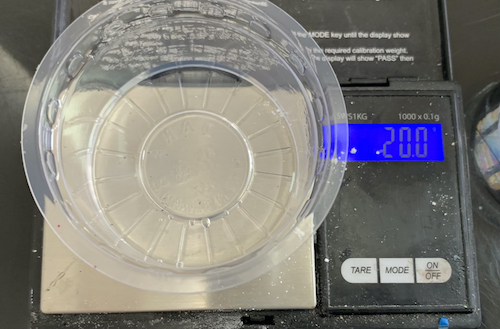

Ratio - 2.5:1

Work time = 10mins

Cure time = 24 hrs in the sun, use after 2 days.

Other materials :

-

Gypsum Refer to Hussain’s page

Designing¶

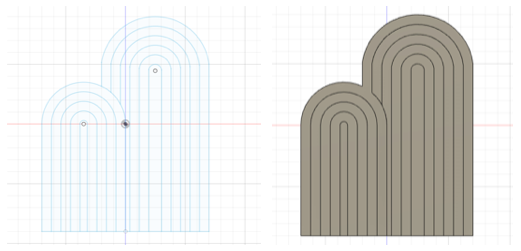

Thinking of a design to mold and cast in such small dimensions was a bit hard, the easiest thing to cast in this situation is a keychain and I didn’t want that.. thinking more of a design that can at least be lets say a decorative piece..

Biggest gap for the design 1.5mm because of the size of the drill bit.

I started sketching a pyramid then I curved the edges of it, here came the idea of a curved edge piece .. so I deleted the pyramid, drew a rectangle on the dimensions given which are 70x90x8mm then started doing the curved and layering it.

Okay I know its a bit confusing how I came up with this idea but look!

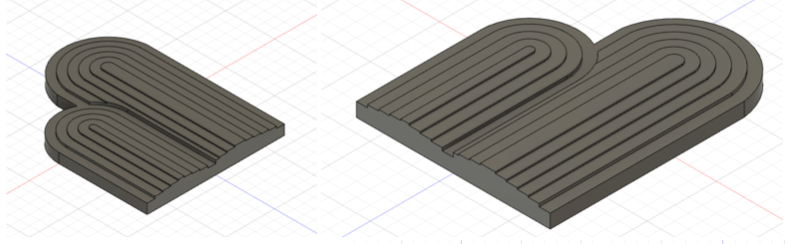

This is the final shape, lets see it in 3D.

Now you can dowload it and adjust the size and decorate your table with it for example ..

Milling Process¶

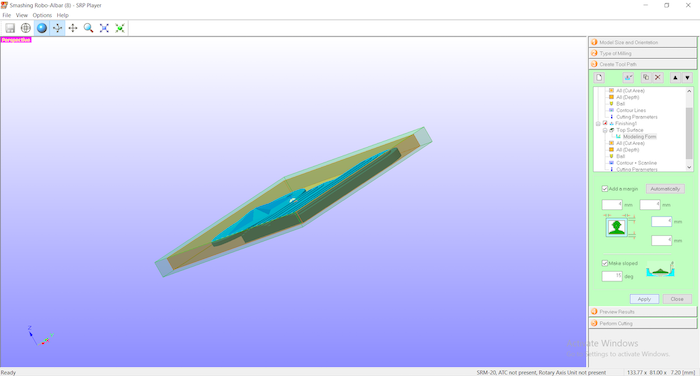

After importing our designs to TinkerCAD, we open them in SRP Player Software to start milling.

Settings :

Creating tool path Margins set to 4mm on all sides, Slope to 15°

Show model to see how the result will look like then choose the spindle and start milling.

The VPanel “the controller“

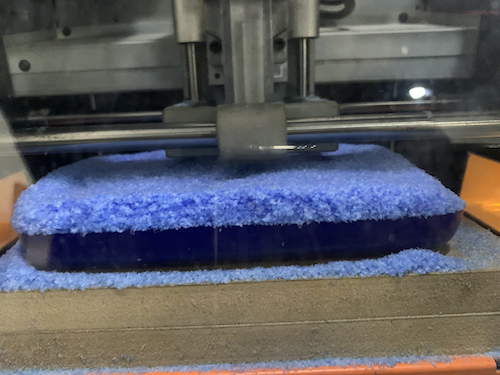

Start milling.

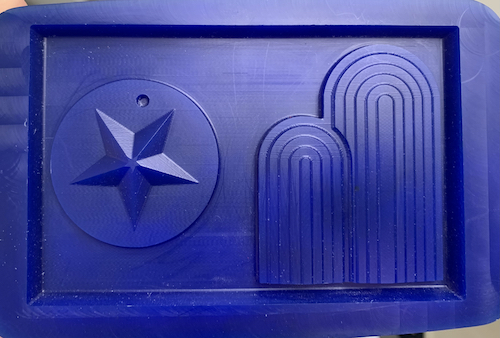

Result after milling

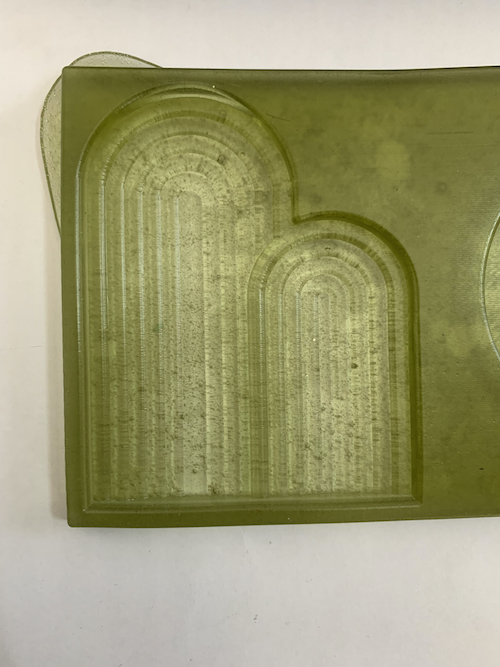

Casting it with the mixture of Reusable Mold

Ready mold.

Measuring the cement to cast.

Fail

Lets give it another try

Hero shots :sparkles: