3D printing and scanning¶

group assignment¶

With the revolving of the world and the technology play a big part these time and one of the most advance technology’s these day is 3d printing from the smallest object to printing houses, which is converting a 3d designs to a physical models and in this week having an opportunity to get the knowledge to try, design and printing. Another technology is the scanning which is the invers of the 3d printing that create a digital design from a physical object by a camera that scan 360 degrees of the physical model First we need a an application names QLONE where it clone the object using a printing mat since it have made it easy and fast to create 3D models from real objects, edit them with built-in editing tools and seamlessly export the result to popular platforms, 3D file formats and 3D printers.

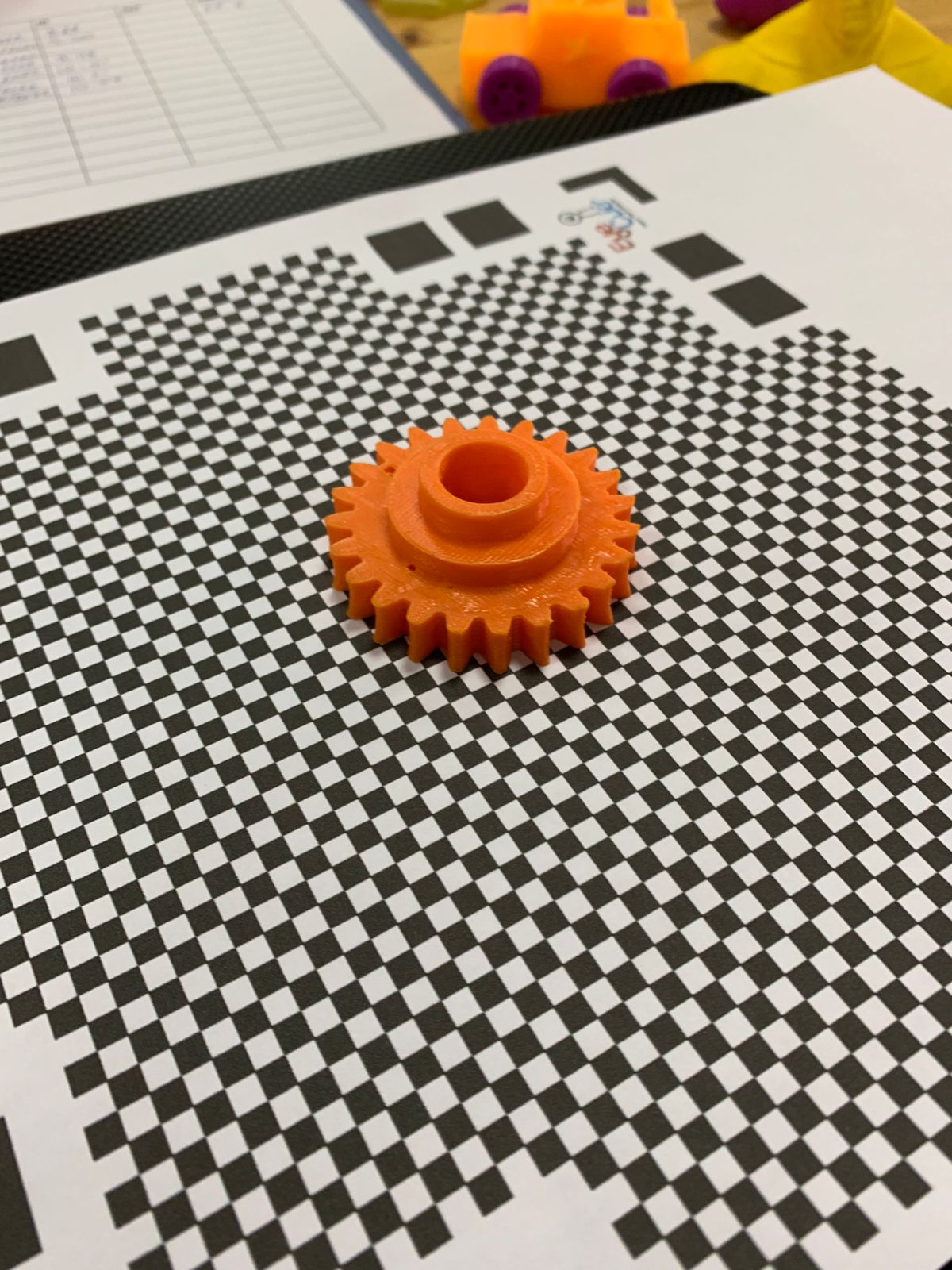

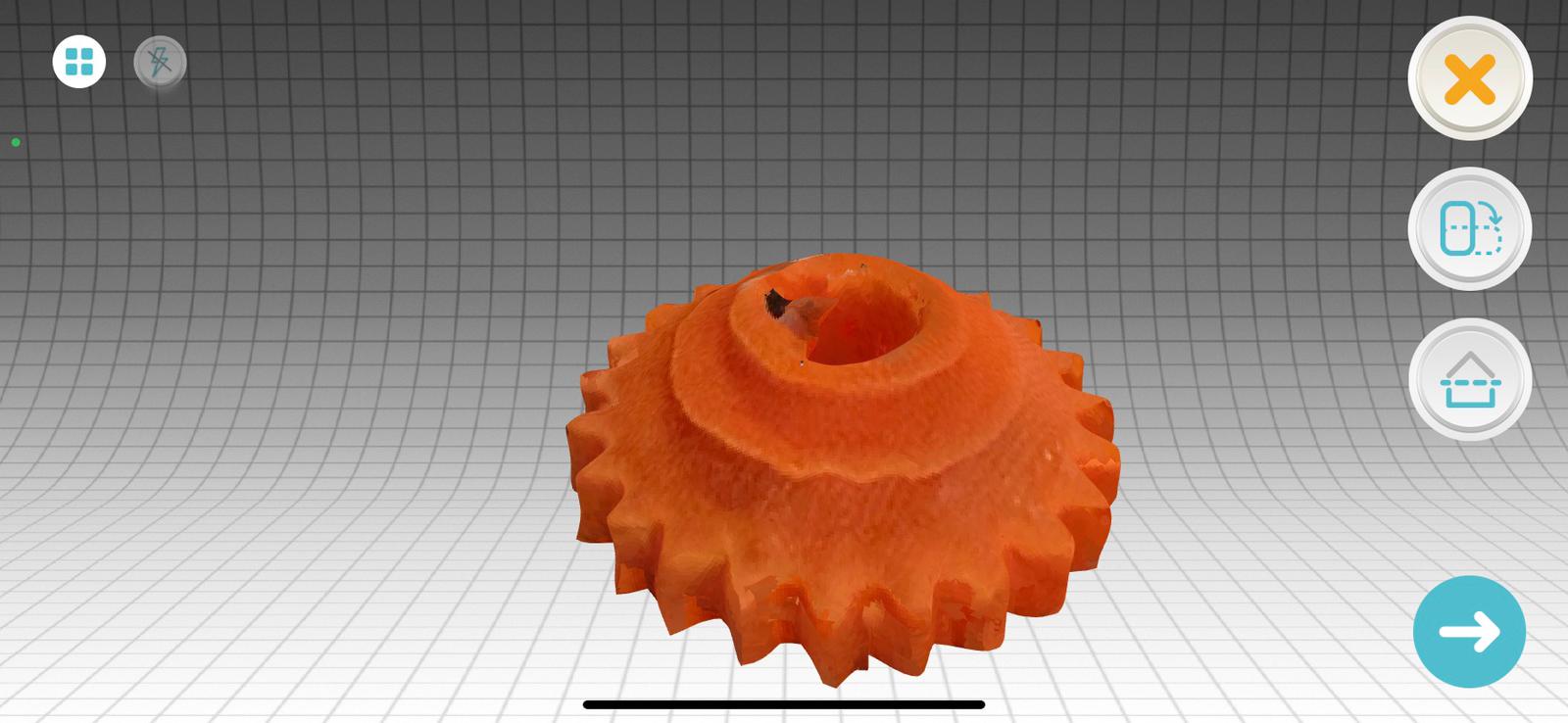

but the physical model in the mat and start scanning in 360 view

as it show in the picture below

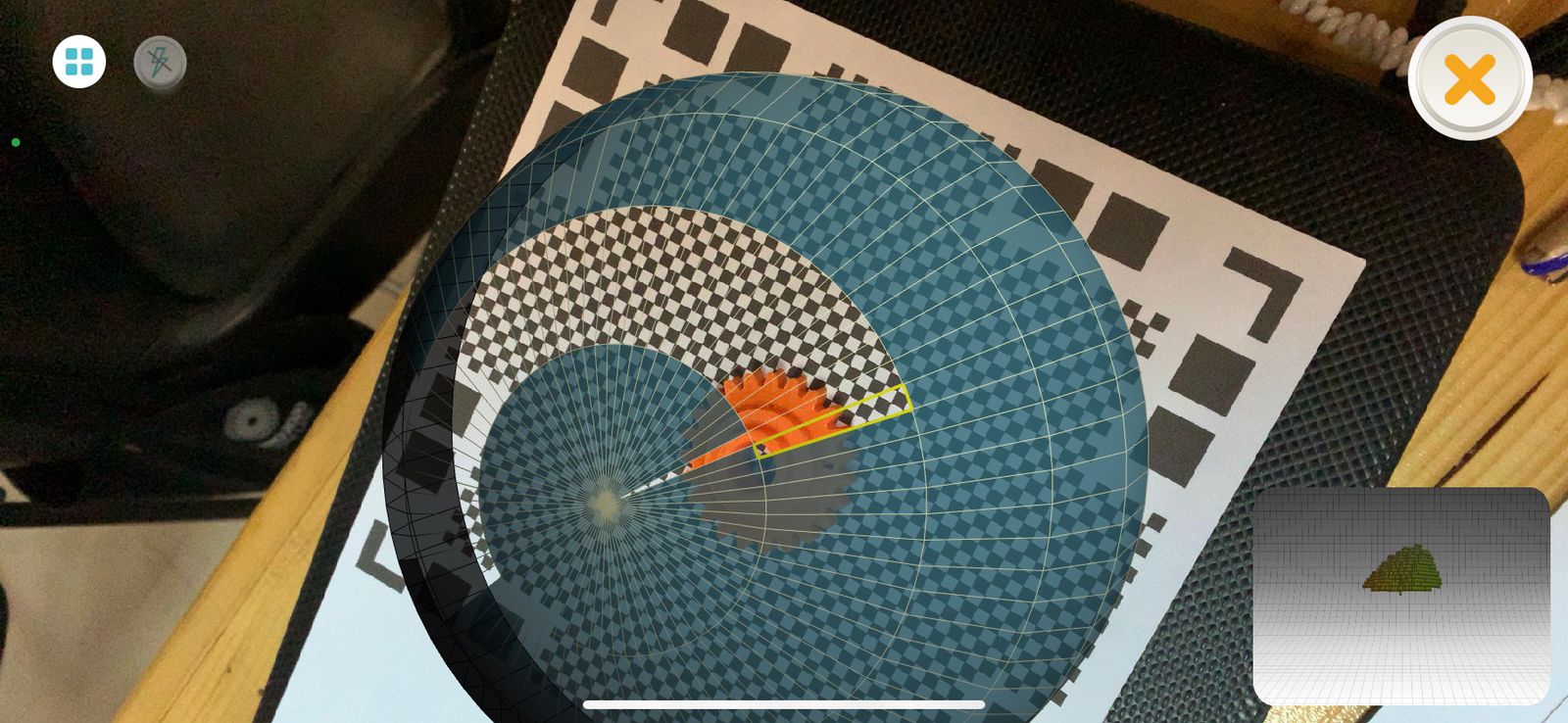

after finishing and scanning all the rectangles’ that show in the dome upon the object and it will show the result

the result of the scanning is not quit perfect it has some mistakes because the de fecality of catching the right angle and the different between the light and shadows

the result of the scanning is not quit perfect it has some mistakes because the de fecality of catching the right angle and the different between the light and shadows

the application in the phone is used for small project that can fit on the mat but for the large objects it need a special camera and rotate the object on front of the camera and open a software to start scanning

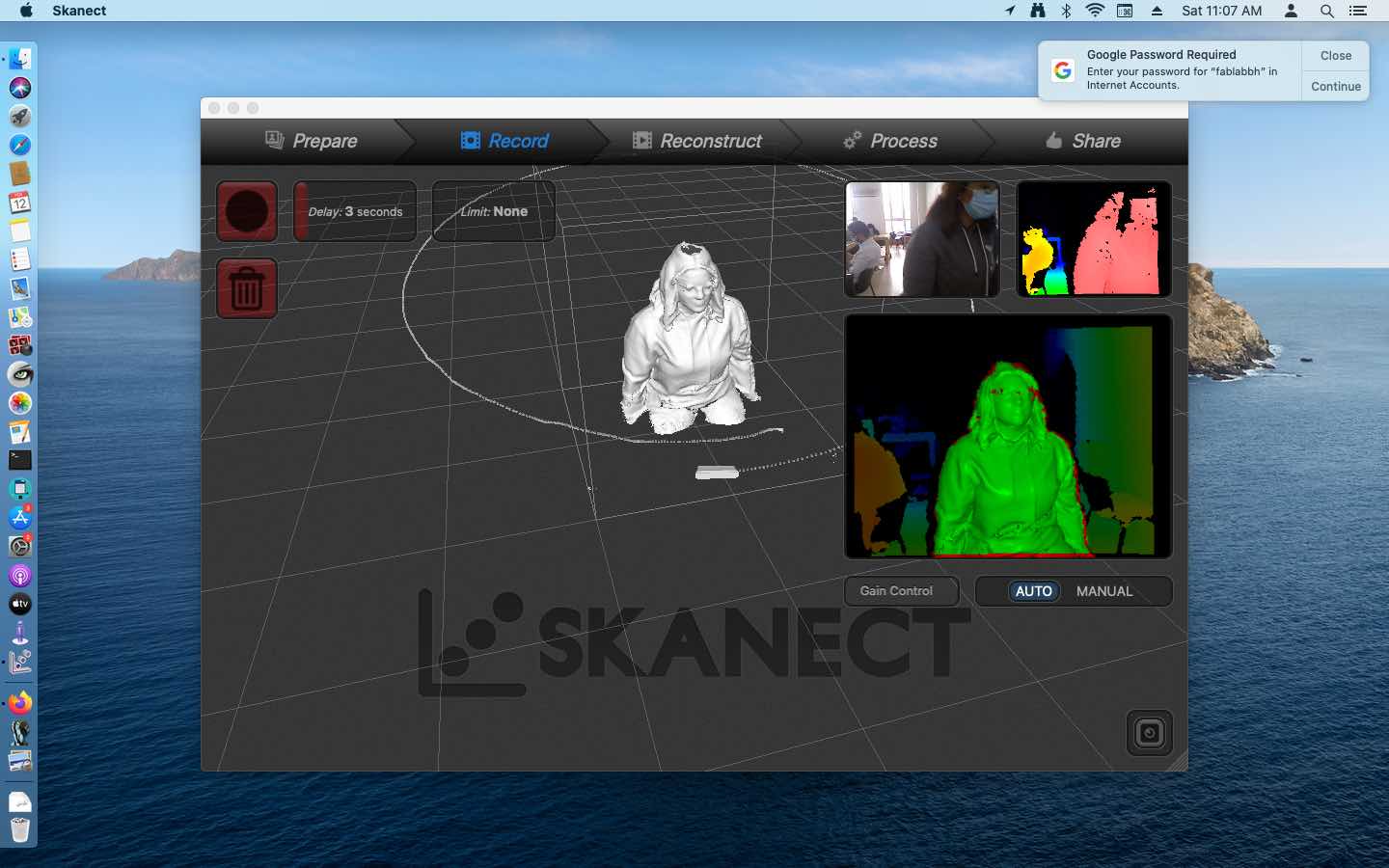

there is a 4 windows that present the camera the first one is the large left window that it show the position of the object that in our case here is human figure

the second windows is the normal one the take the real color of the object and apply it in the 3d model objects and the small one in the right its recognizing the object that need to scanning and the large one below it show a prototype of the object .

there is a 4 windows that present the camera the first one is the large left window that it show the position of the object that in our case here is human figure

the second windows is the normal one the take the real color of the object and apply it in the 3d model objects and the small one in the right its recognizing the object that need to scanning and the large one below it show a prototype of the object .

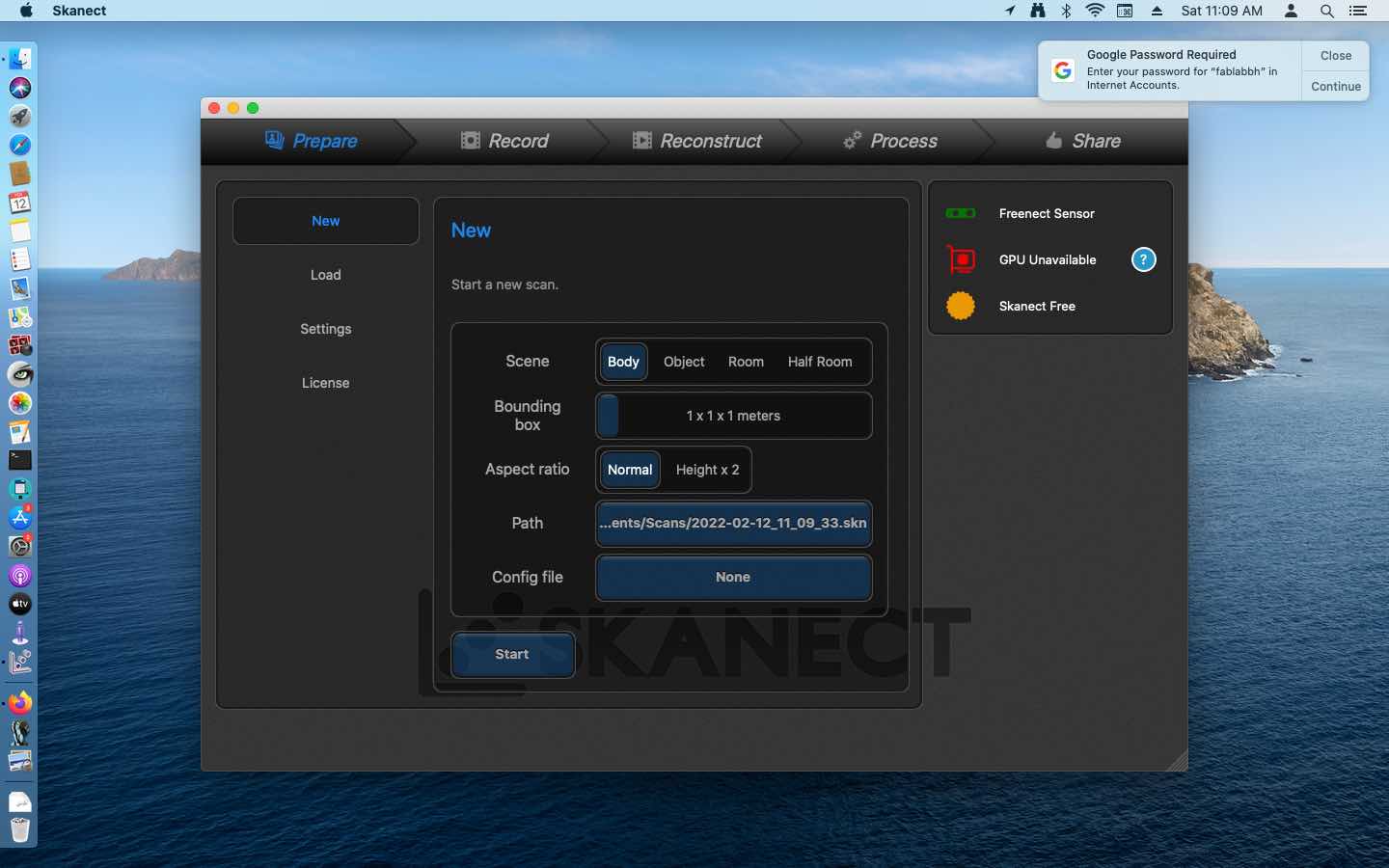

the setting of the saving

the setting of the saving

the result of the scanning

the result of the scanning

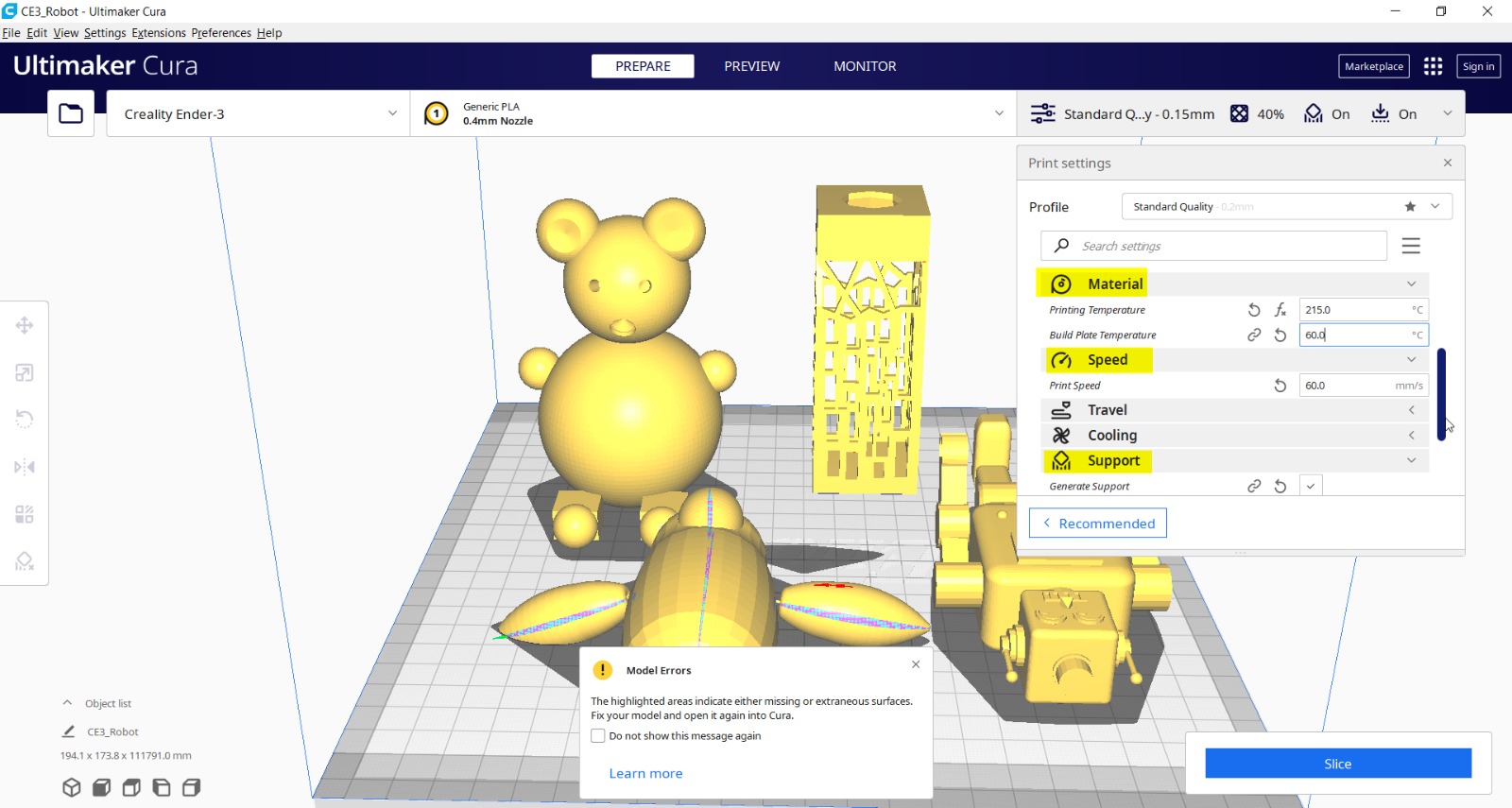

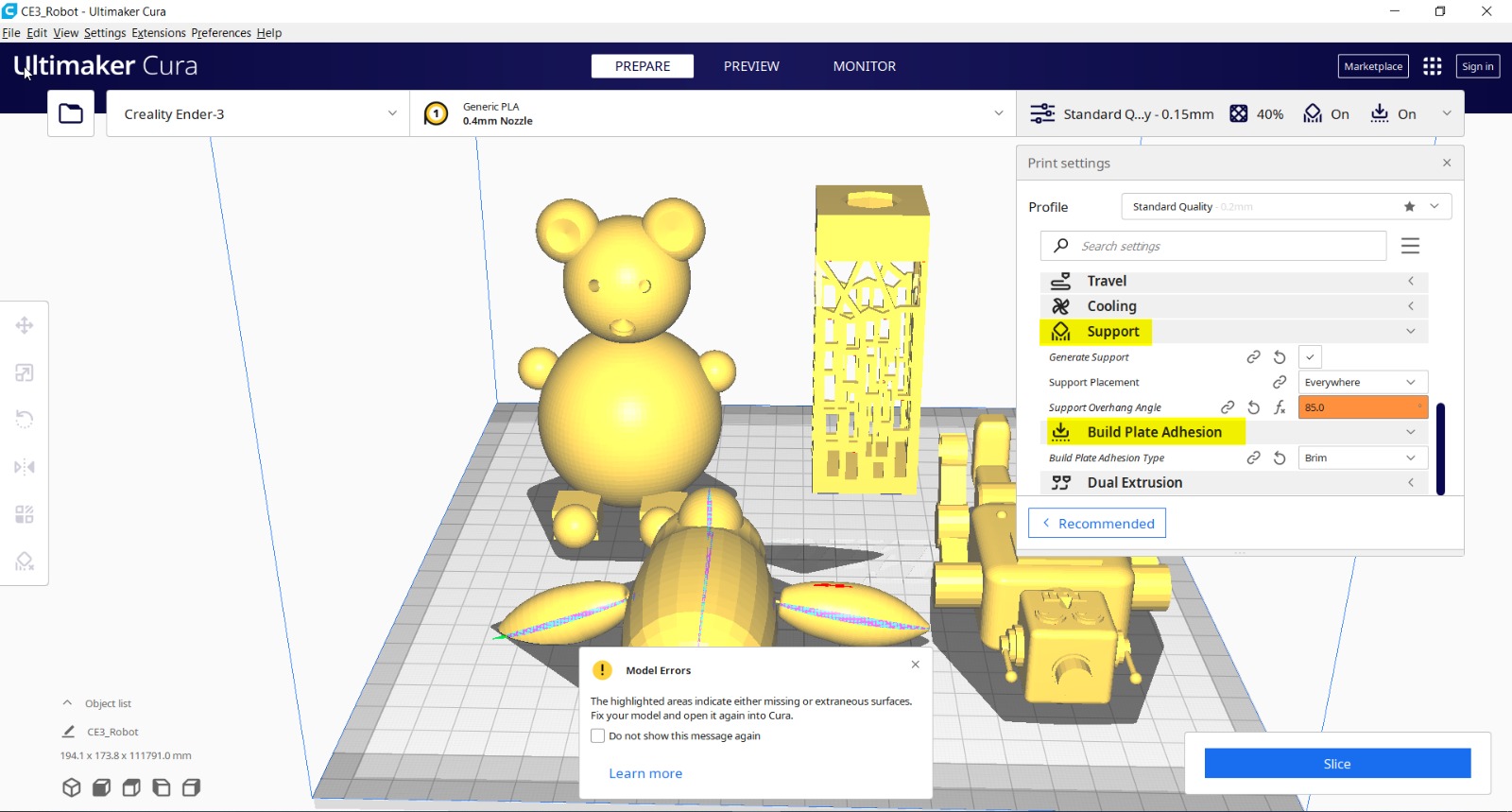

Now with the 3d printing we use (Ultimaker) 3d printer to start printing one of the important thing to know is STL file format that the printer can recognize the object and repair it for printing . first we need to downloaded an application in the pc named Ultimaker Cura .

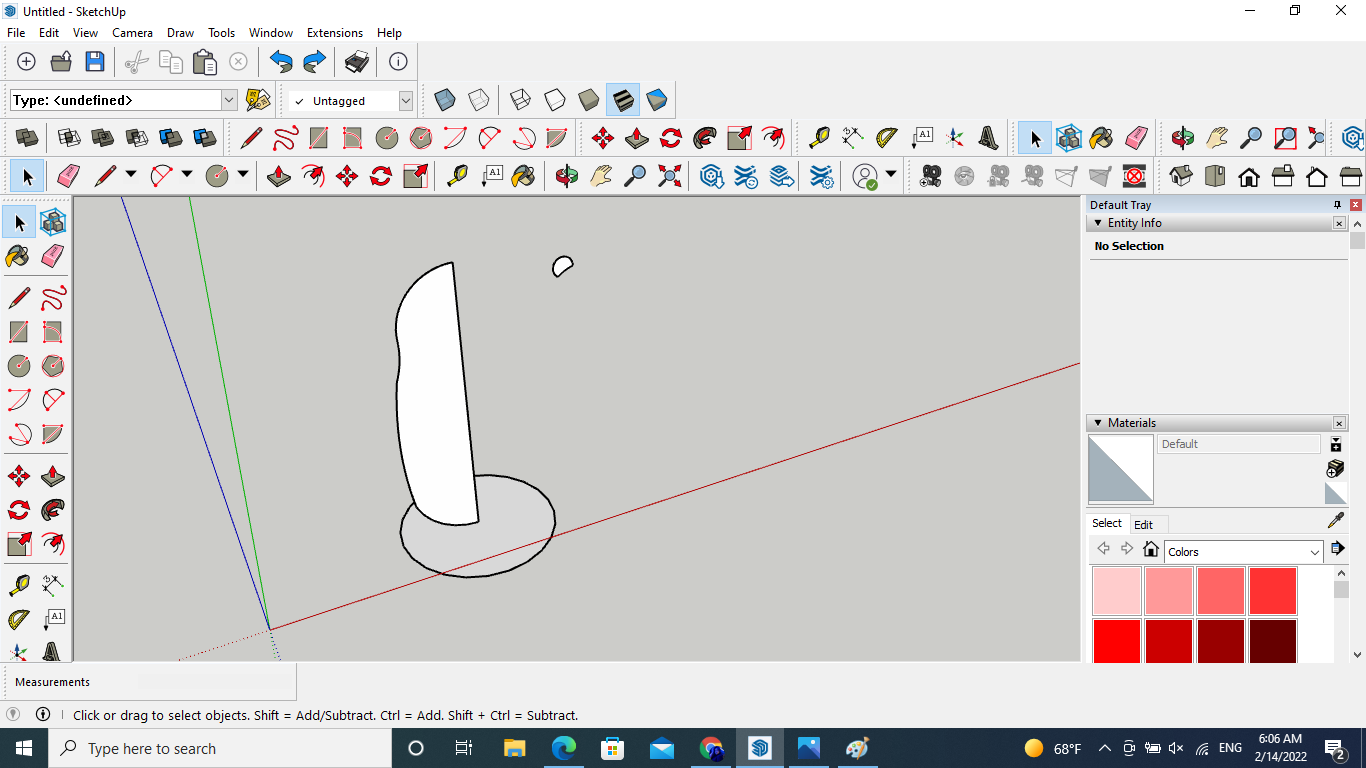

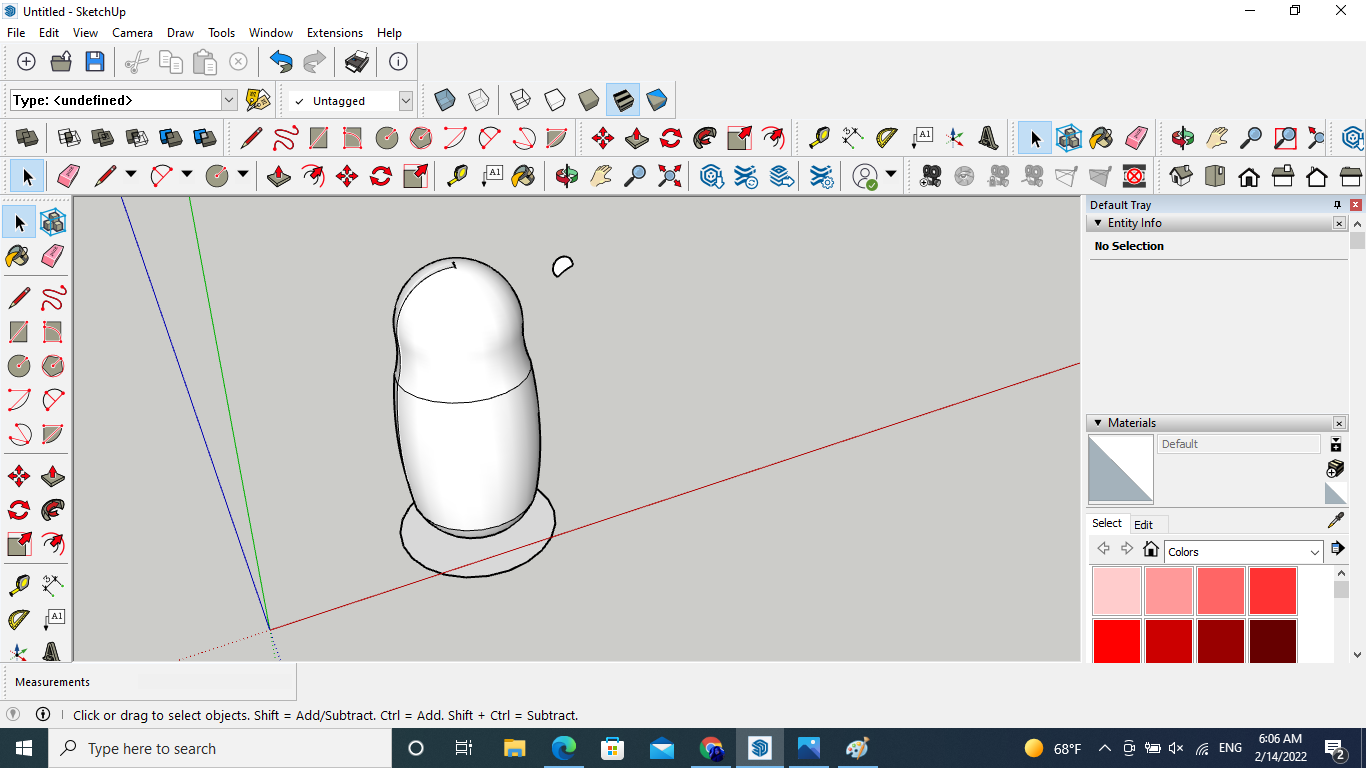

and for then stat creating the 3d design i use sketchup and trying to build a bare with moving arm and to do that I create I skitch to understand how to fixed the joint

and in the conclusion the solution was to create hole in the body and a shaft that in one side the hand and inside the body through the hole is a ball to fixit inside that can rotate in 360

the main idea of creating the object is tracing the existing 2d picture and draw the half of the object then rotate it

this object is hard to create with other machines such laser cuter or CNC because the uniform of the model have a curvatures

The 3d printer need some adjustments first

editing the nails the 3 corners to get the bade balance to provide any errors in the printing phase .

the base and the pike of the printing should be similar to the thickness of a4 paper to burring the filament in the right way and potion as you can see in the picture

editing the nails the 3 corners to get the bade balance to provide any errors in the printing phase .

the base and the pike of the printing should be similar to the thickness of a4 paper to burring the filament in the right way and potion as you can see in the picture

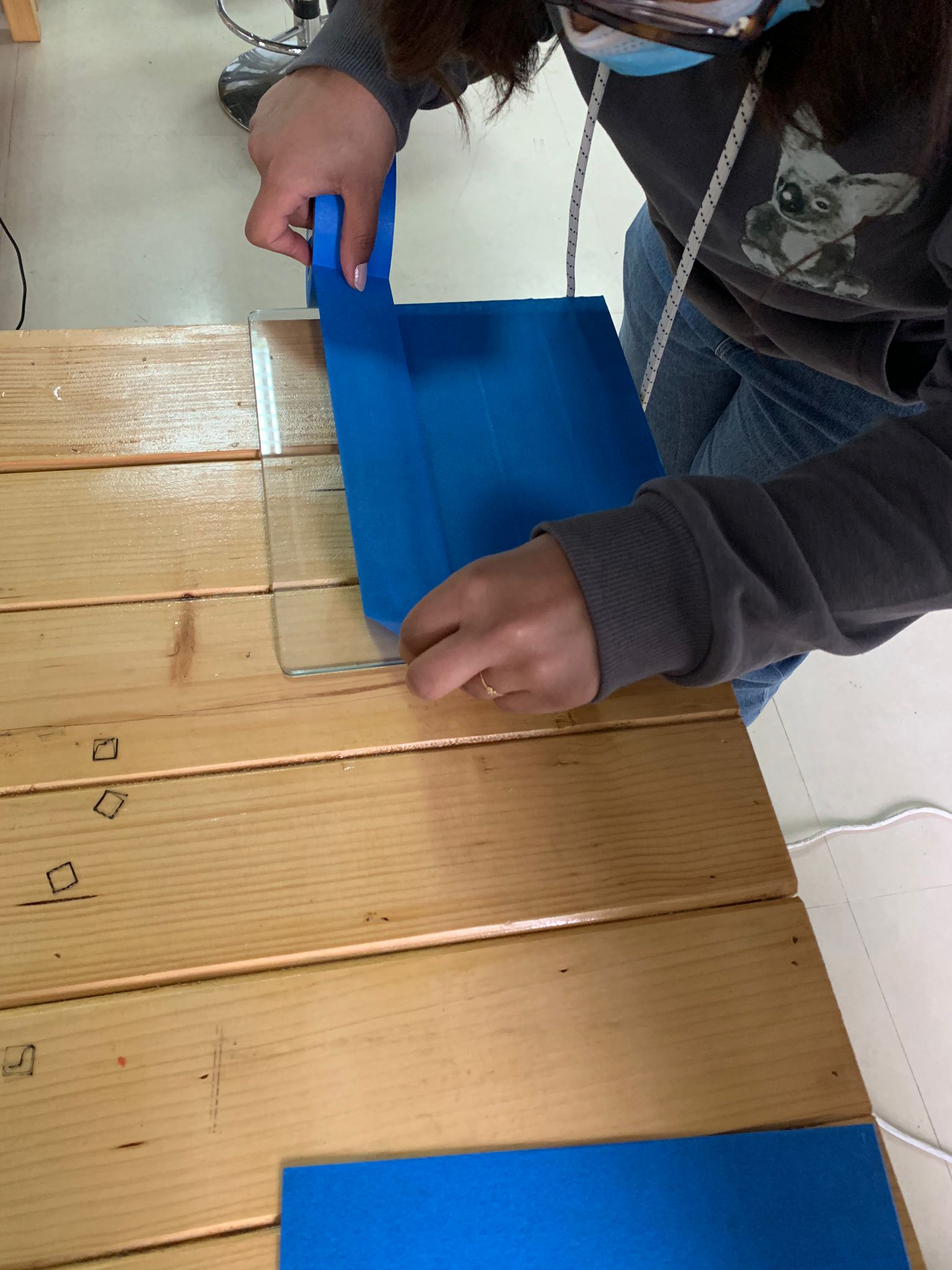

and because the base is smooth some time the object while its printing move and ruin the machine sequins of printing and destroy the object so there is a tape that has very fine bristles that can attach more with the filament to prevent any object movement

after finishing all the setting it need to oben the cure appliccation and do the final setting

start printing from the printer by choosing the file name.

start printing from the printer by choosing the file name.

the testing was failed 2 time fits the power has off the second the design was empty from inside so he was printing in the air and to fix that designing again and add a thickness to the object and not fill the inside cure of the bare

the testing was failed 2 time fits the power has off the second the design was empty from inside so he was printing in the air and to fix that designing again and add a thickness to the object and not fill the inside cure of the bare

MODLE

hero shot¶