6. Large format CNC (computer controlled Machining)¶

about CNC¶

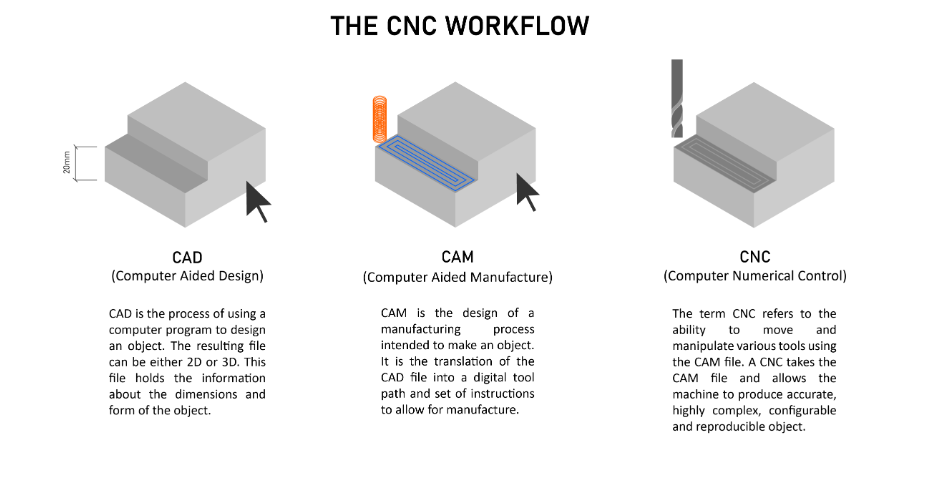

what is CNC ?

Computer Numerical Control (CNC) Milling and Machining, is a subtractive machining process that uses computer-controlled tools that utilize bits such as ball end mills, flat end mills and single flutes to remove material from a solid block of material.

This process is suitable for creating products from a wide range of materials including non-ferrous metals, plastic, glass, wood, and various types of foam.

Types of CNC Machines

The most common types of CNC machines are those that use cutting tools to remove excess material from the workpiece. While there are CNC machines that employ water jet cutting and electrical discharge machining (EDM) operations, this guide will focus on the five most common categories in the following list, divided into two basic classifications:

3-axis and multi-axis machines.

3 Axis CNC Machines (CNC Milling Machines - CNC Turning Machines (Lathes))

Multi-Axis CNC Machines

Indexed 5-axis CNC Milling Machines

Continuous 5-axis CNC Milling Machines Mill-Turning CNC Centers

Benefits of CNC Machining

CNC machining offers several competitive advantages, including:

Quick order lead times High precision Highly customizable Creates products with exceptional physical properties and performance thresholds

CNC Machining Applications

steel

Food and beverage

Plastics

Paper

Textile

Recycling

Oil and gas

Fluid power

Construction

CNC Machined Parts at Technox

Boring

Milling

Drilling

Tapping

Threading

Counterboring

Countersinking

Knurling

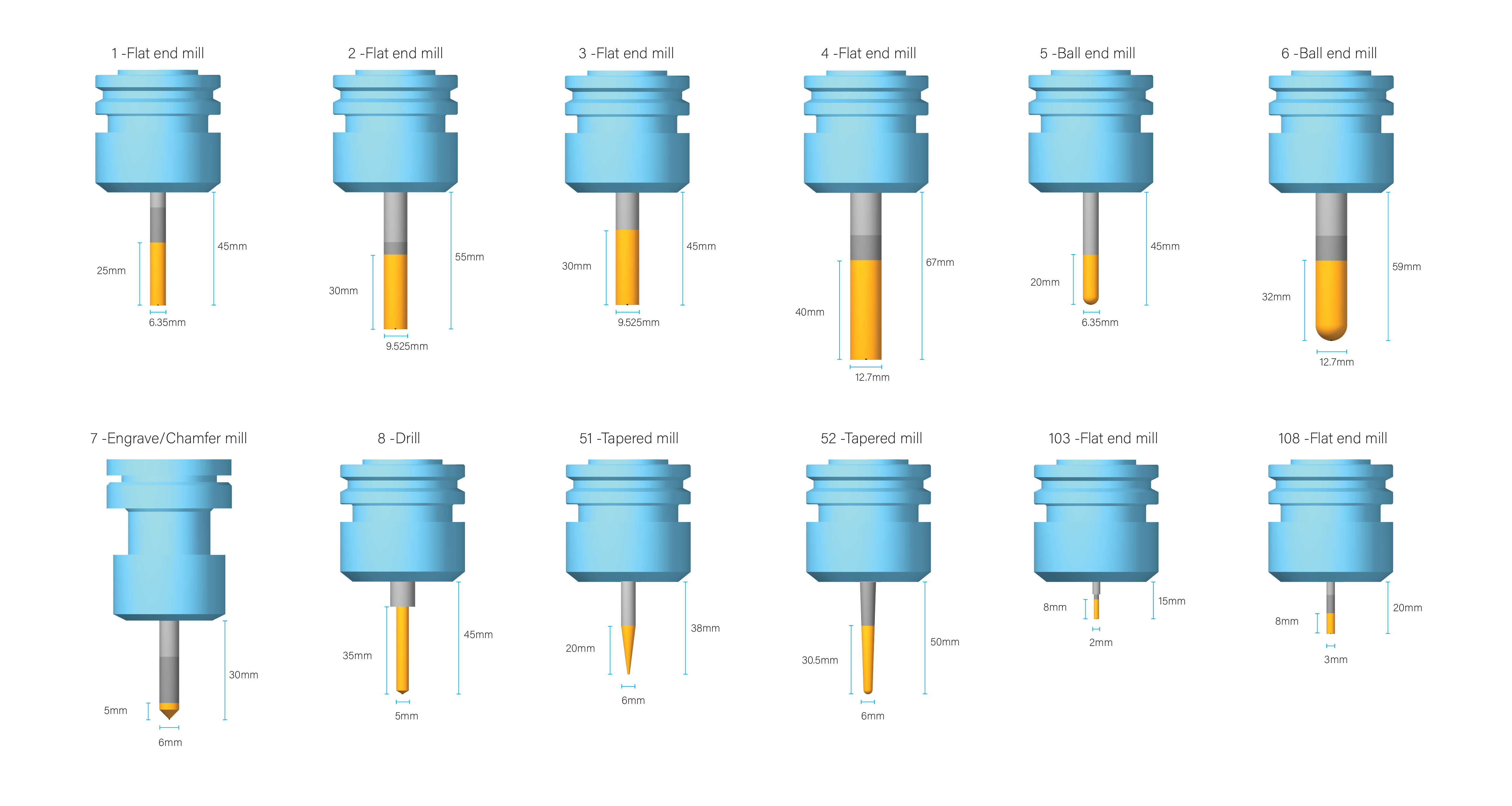

type of Milling

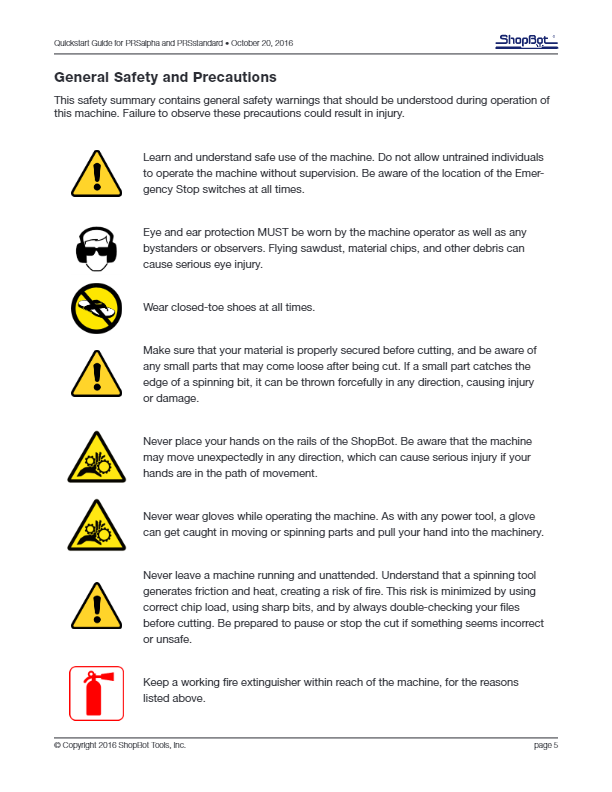

General Safety and Precautions

there is a 3 emergency bottoms to stop the machine from working

group assignment¶

Test runout, alignment, speeds, feeds, and toolpaths for your machine

For the group assignment, we were shown a previous sample done by the previous batch of students, and we discussed the fitting joints process.

testing previous sample of CNC project file that show the changing in F in/min , S RPM and deferent fitting size .

You can check Yousif’s website to view the group assignment.

induvial assignment¶

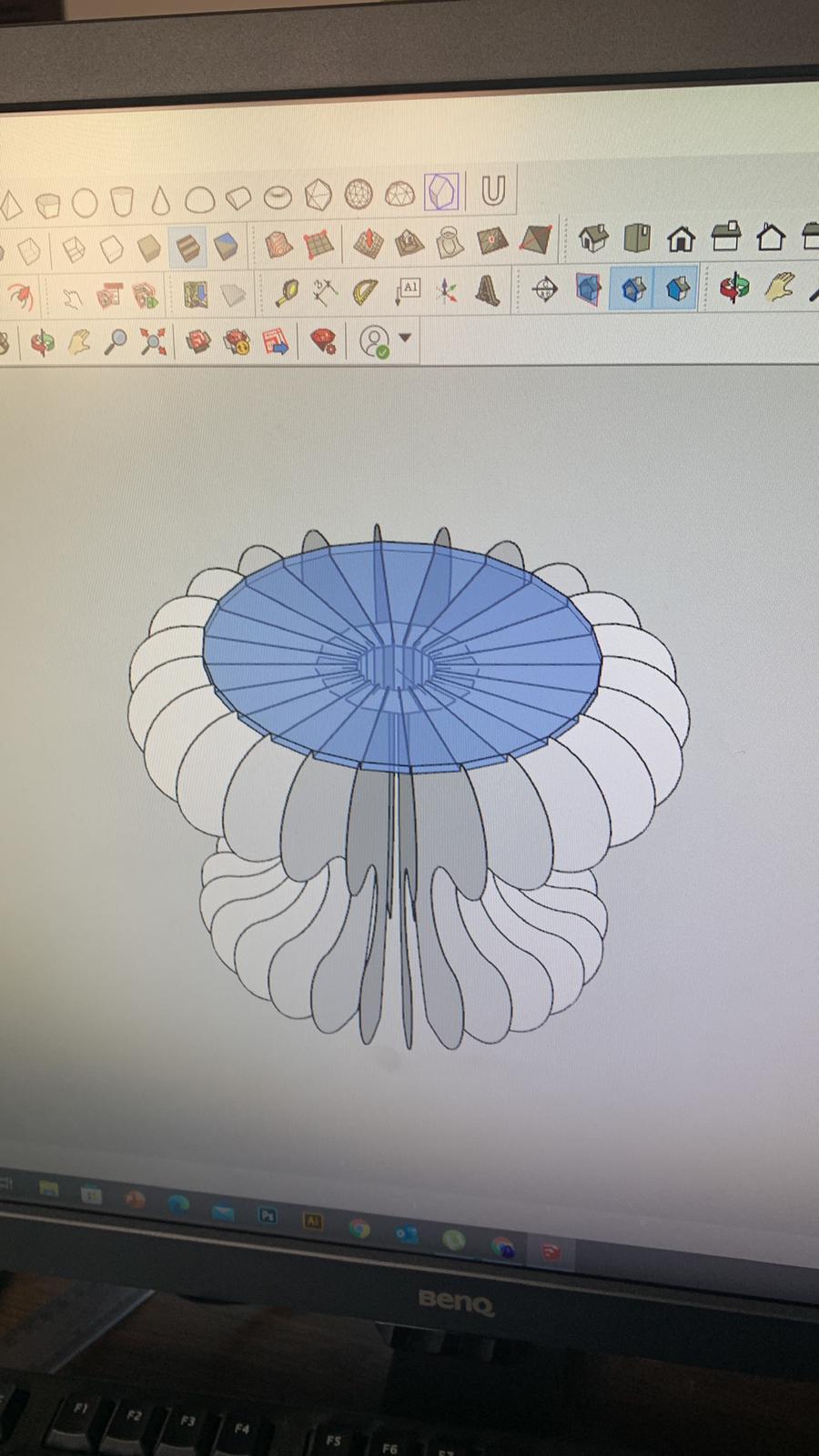

starting with searching about Coffee tables standard sizes and the design and determinate the joint size and thickness

design a 3D form in Sketchup to visualize the final result

design the cutting testing the part in AutoCAD

Editing phace

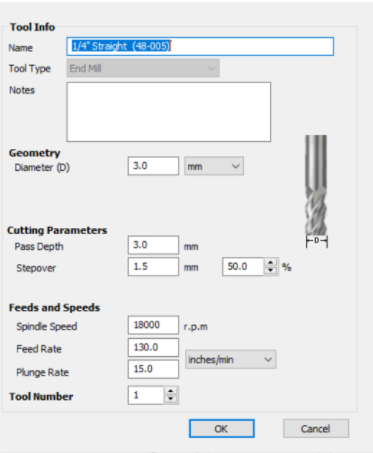

editing for the speed and feed of the pit tool

editing for the speed and feed of the pit tool

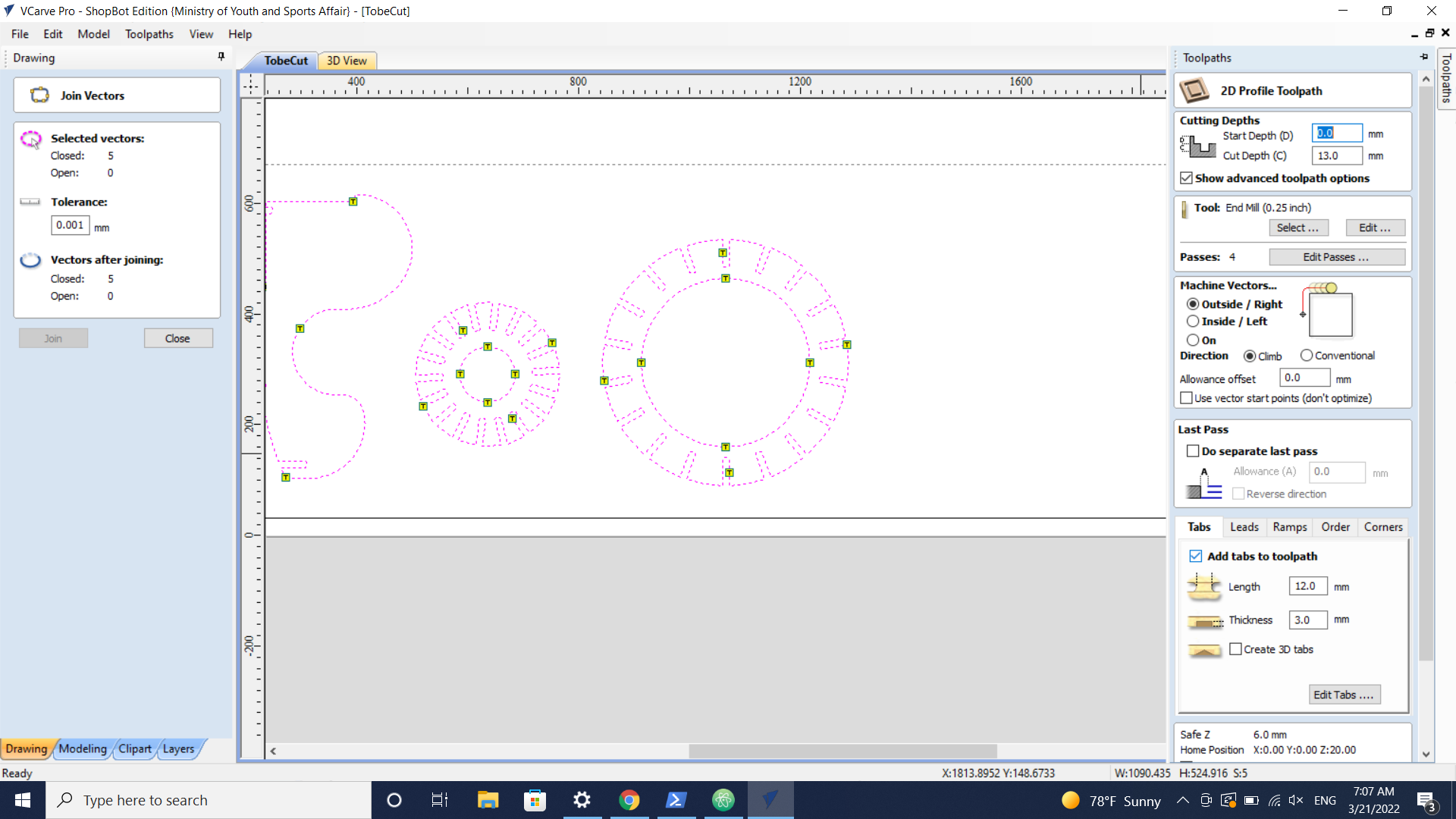

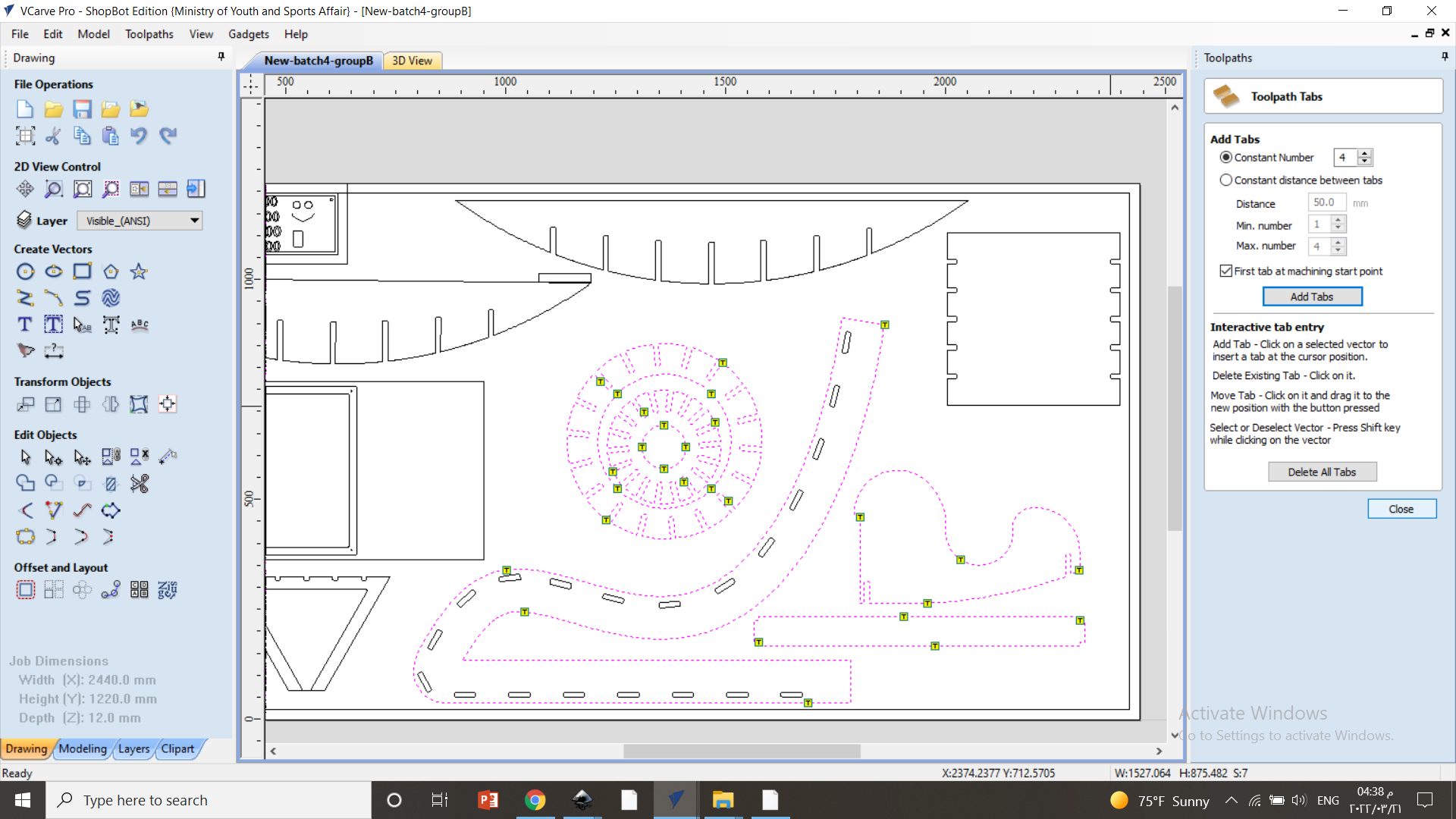

and the ( Tabs ) is to make sure that the object not moving after it cutting its connect the sheet with the object and choosing the number of the tabs and it show the spaces of the tabs .

choosing the cutting depth more then the sheet to ensure the cuttings the sheet is (12mm and we choose 13mm)

toolpath operation ( profile toolpath pathed) just to cut its profiles

toolpath operation ( profile toolpath pathed) just to cut its profiles

start cuttings

start cuttings

the testing cuttings

the testing cuttings

the fitting

the fitting

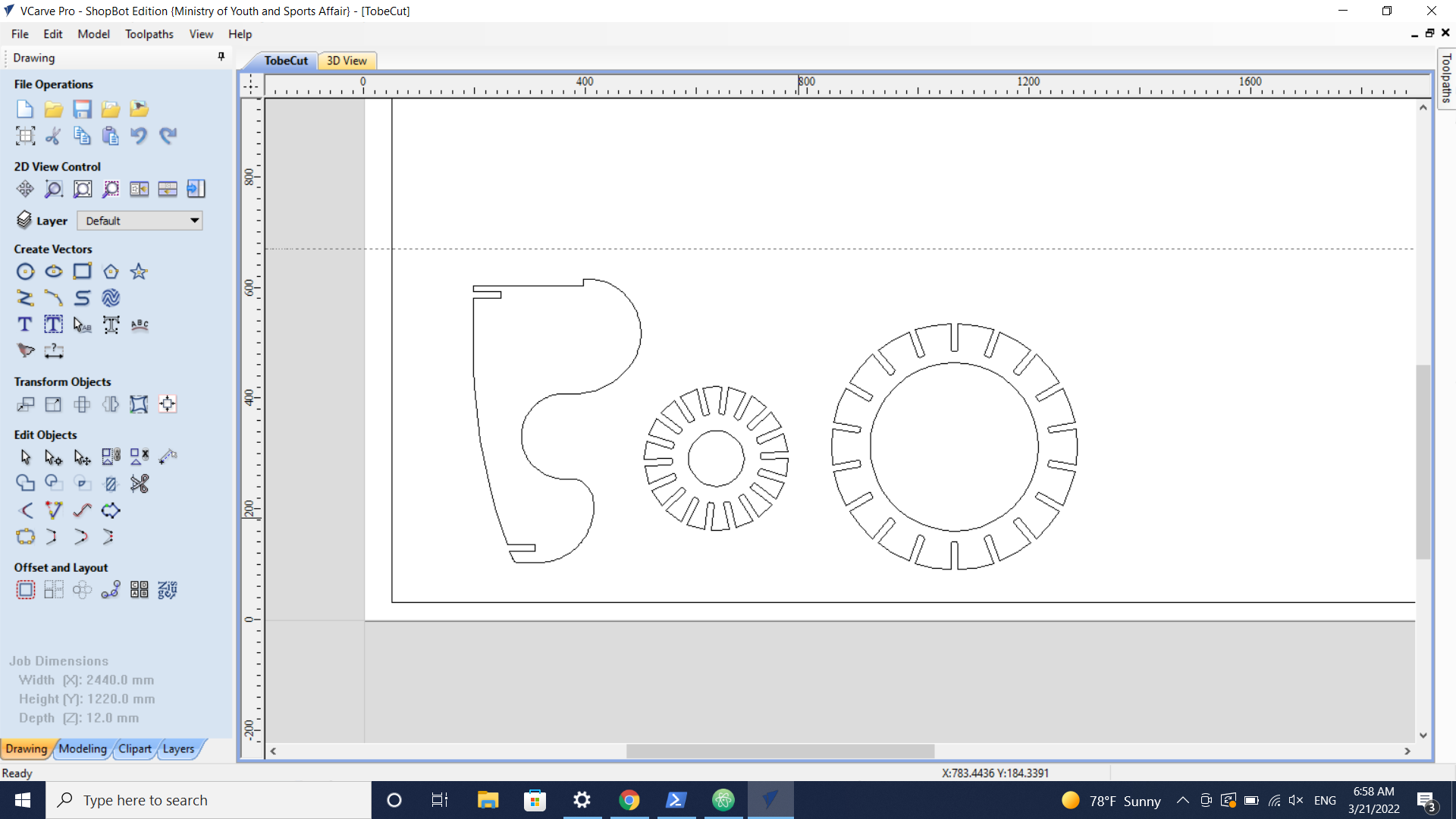

editing the joint because some joint is nit connected and it will be not cited

editing the joint because some joint is nit connected and it will be not cited

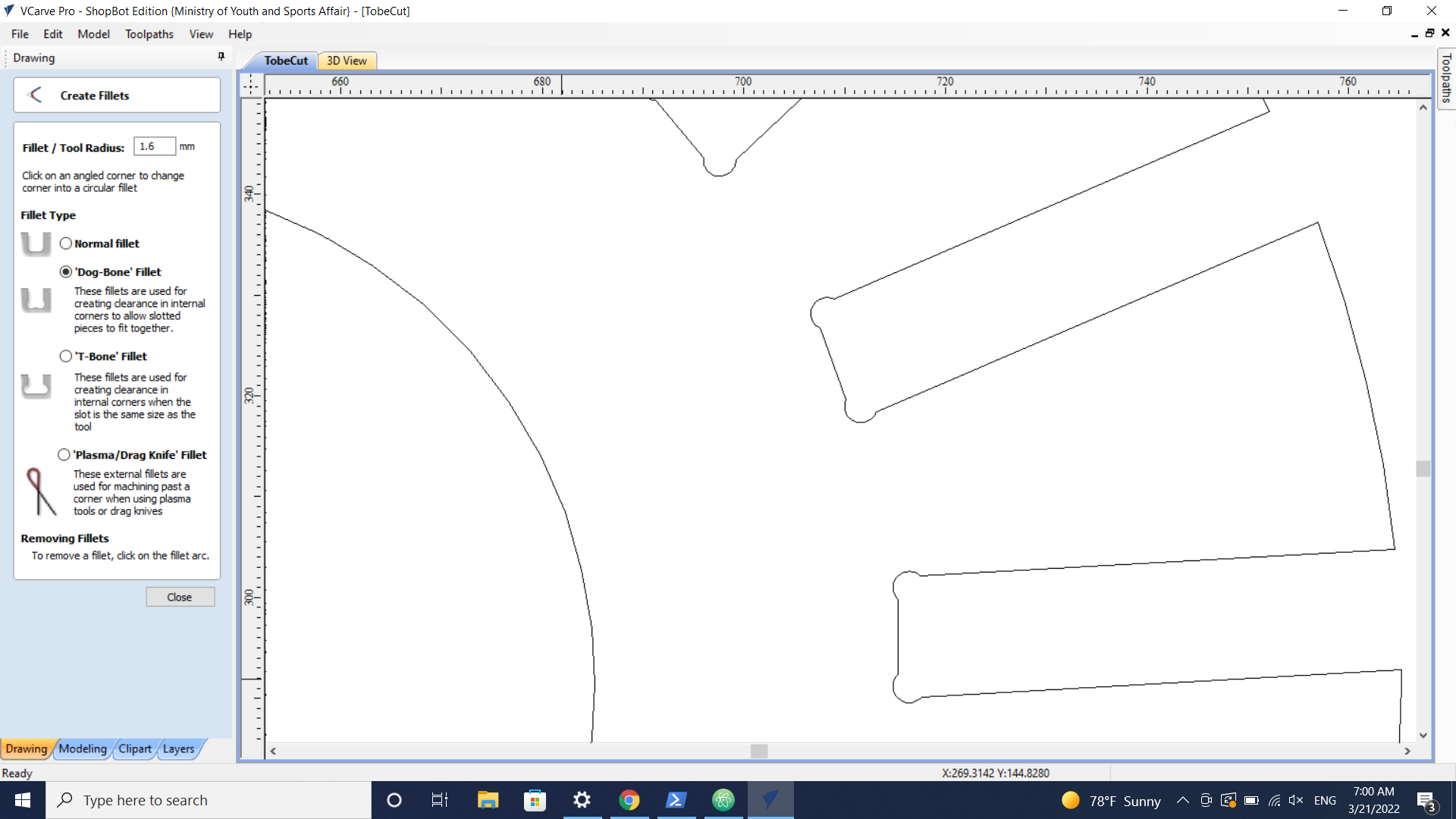

and make all the inside edges normal fill to make it easy fot the pits

and make all the inside edges normal fill to make it easy fot the pits

the edges after editing them by the tool

the edges after editing them by the tool

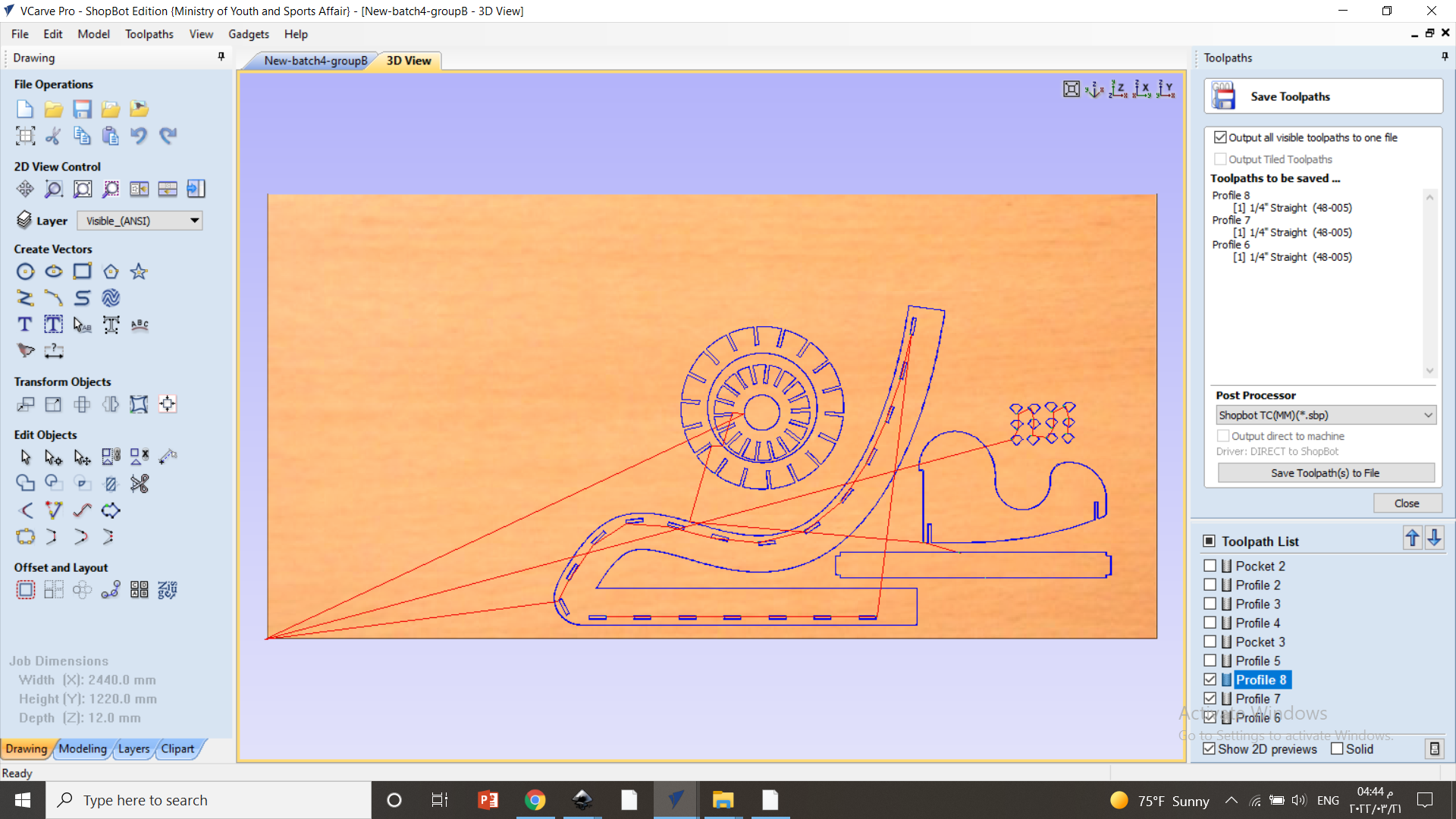

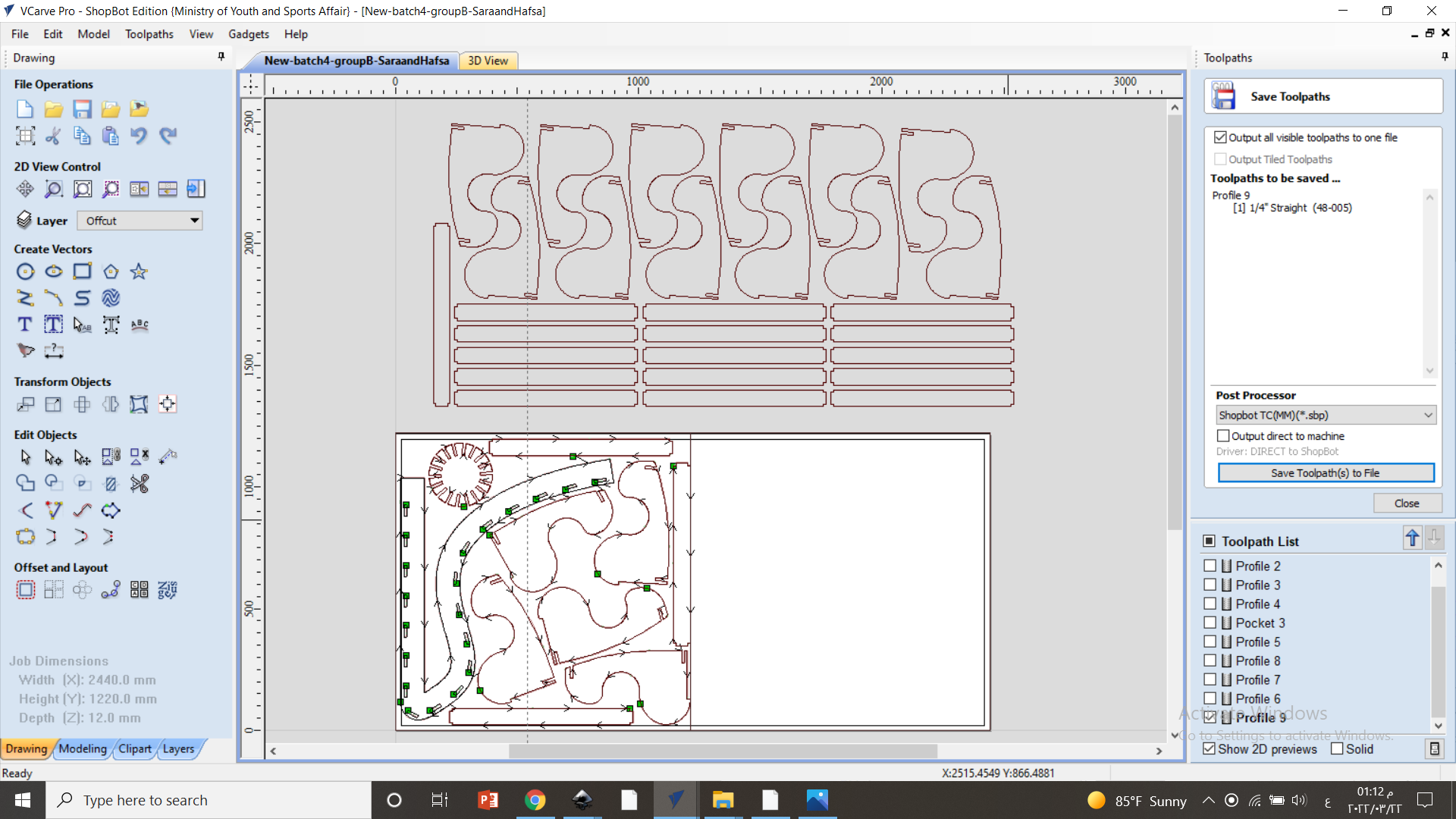

fitting every thing in one sheet

fitting every thing in one sheet

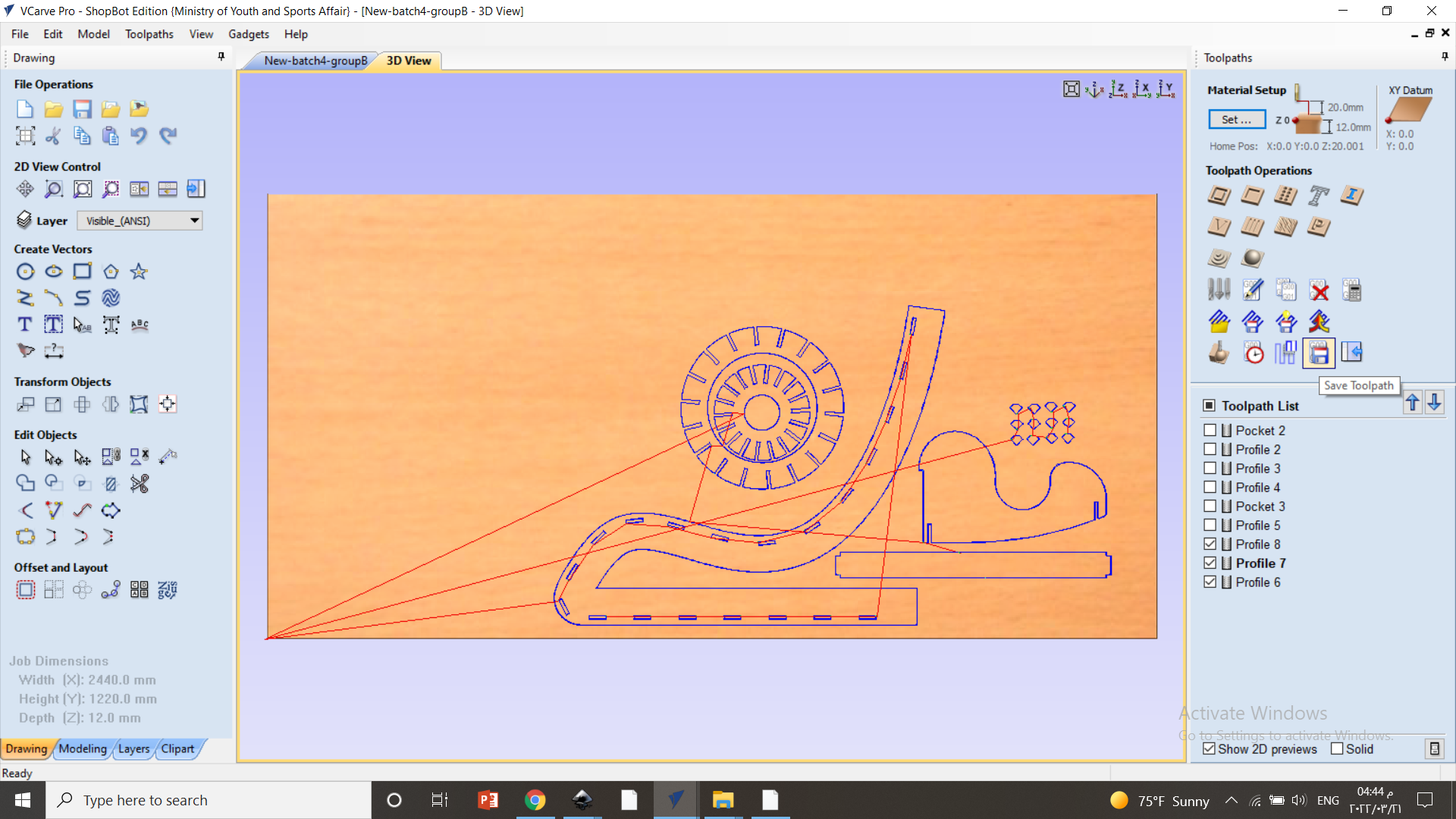

cuttings preview

cuttings preview

hero shot¶