8. Moulding and casting¶

Included ‘hero shot’ of the mould and the final object

Linked to the group assignment page where you reviewed the safety data sheets for each of your molding and casting materials, then made and compared test casts with each of them

Documented how you designed your 3D mould and created your rough and finish toolpaths for machining, including machine settings

Moulding and casting¶

is a technique that implementing a design to a create a mold that can be fill and tack the shape of the mold by creation of the combination of the negative and positive area as an solid and void theory .

molding¶

id usually using a flexible material as rubbery material to take its shape in designing the molding usually we inverts the design in the Void and Solid ti the next stage

casting¶

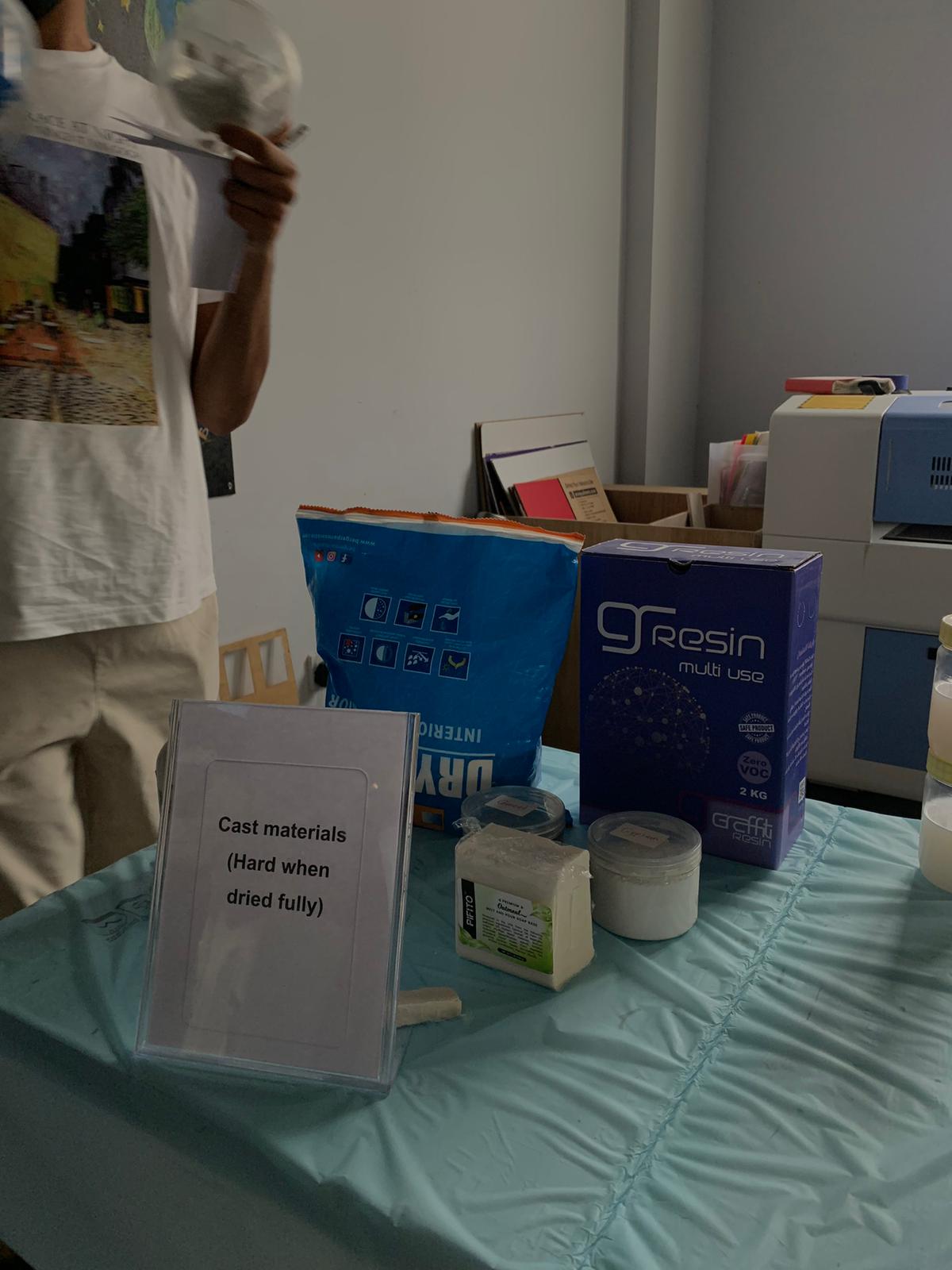

for casting there is variation of the material that can be use and it mostly using a harder material to take its shape such a

epoxy

resin

concrete

gypsum

Usually using the molding and casting method is to replicate the design that the mold will be the same and can be create the many copy of the deign by the same mold that been create

Group Assignment¶

individual assignment¶

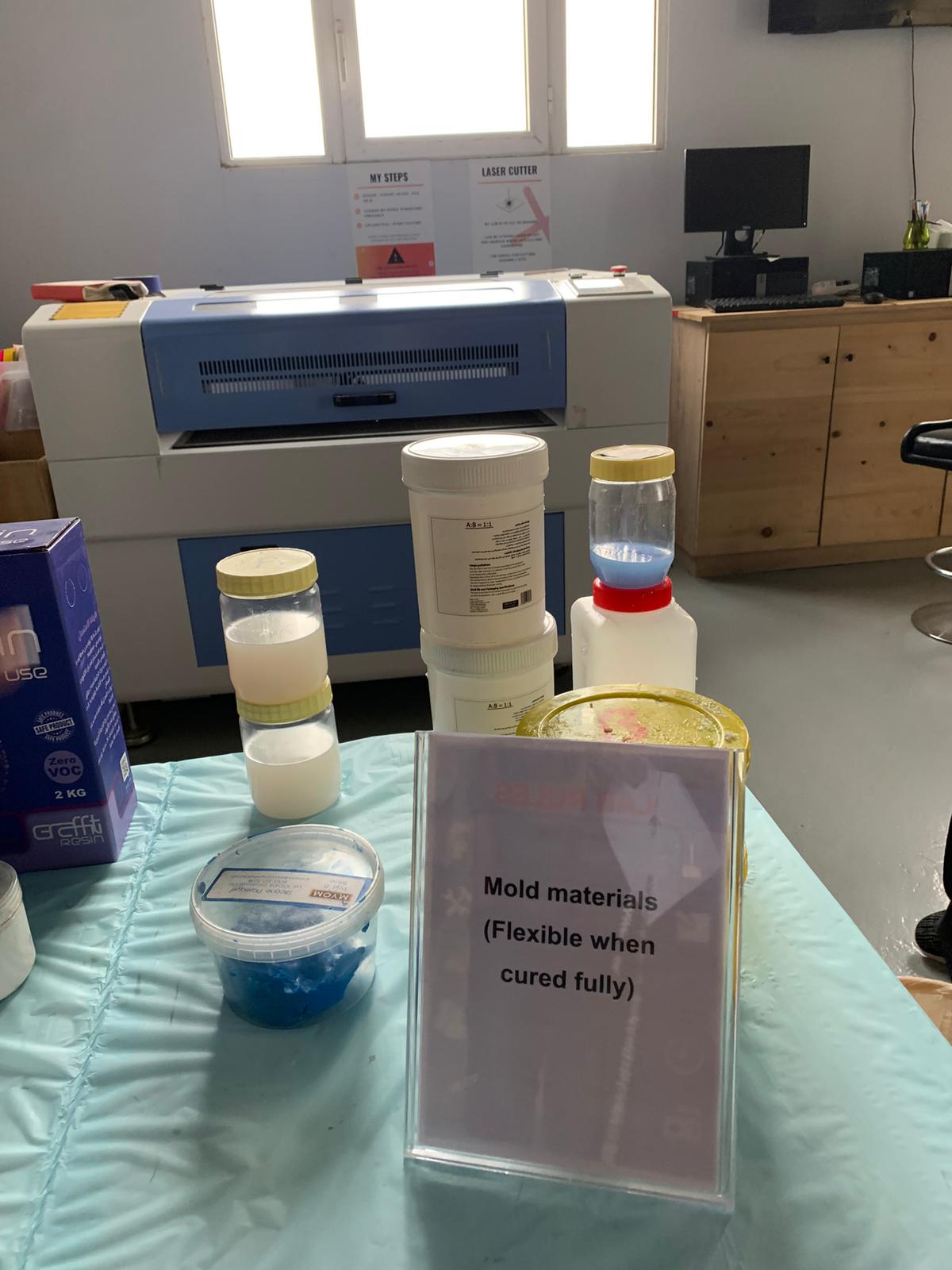

material using for testing¶

the assignment is to search and get the knowledge and test if the materials by choosing one of the molding or casting material and test it and search about its general information and name , safety precautions, mixing ratio, work time, cure time . ##### resin

| about | description |

|---|---|

| cure time | 24h to 72 h |

| work time | 15 min |

| mix ratio | 10 gram of resin and 6 gram of hardener |

| cured material state | Solid |

Food Safe after 72hours – full cure Zero VOC

odorless / Less Smell Low Viscosity

Meets the requirements of the relevant FDA listing and therefore when fully cured ideal to be used in contact with food

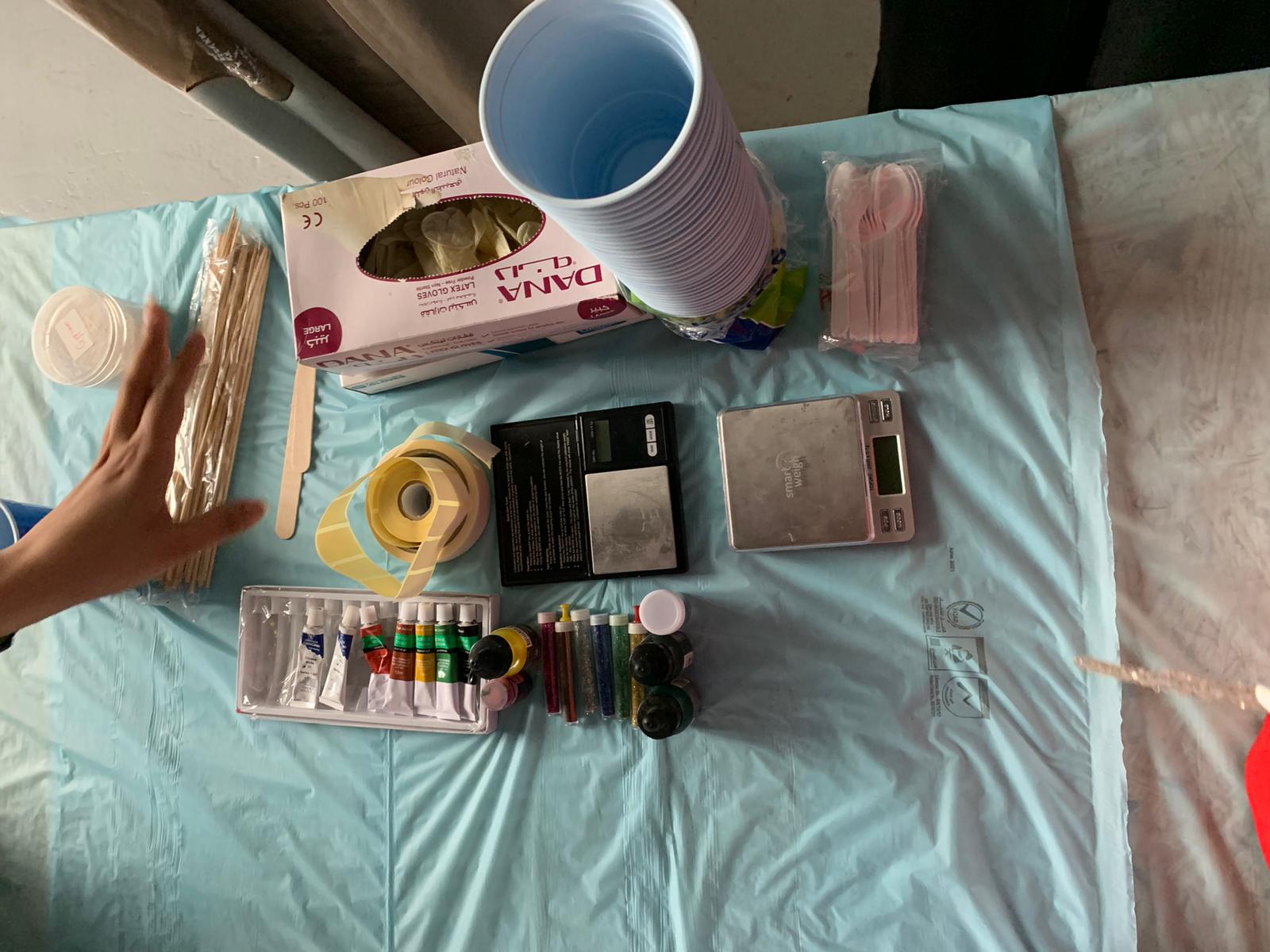

material can be using

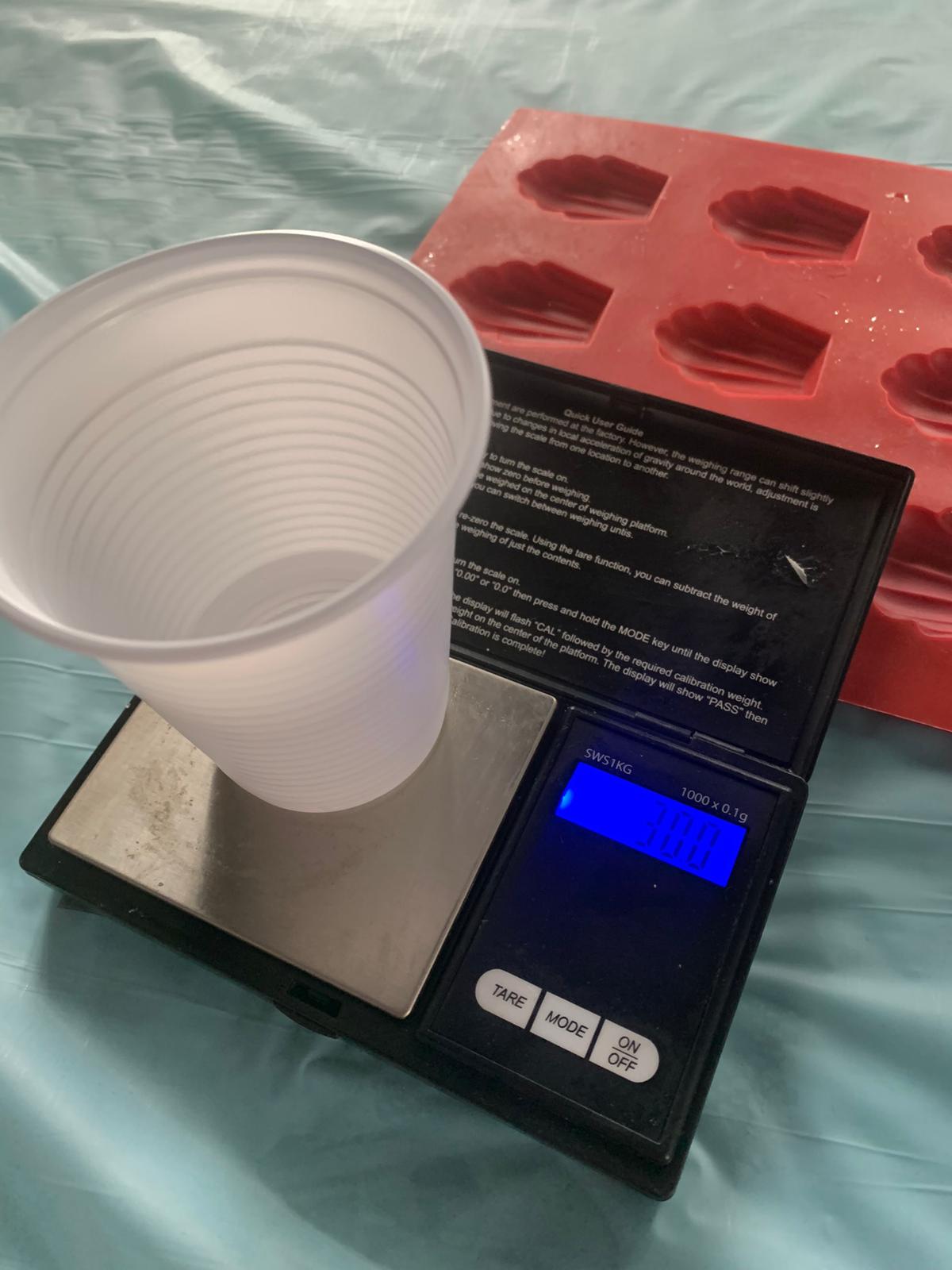

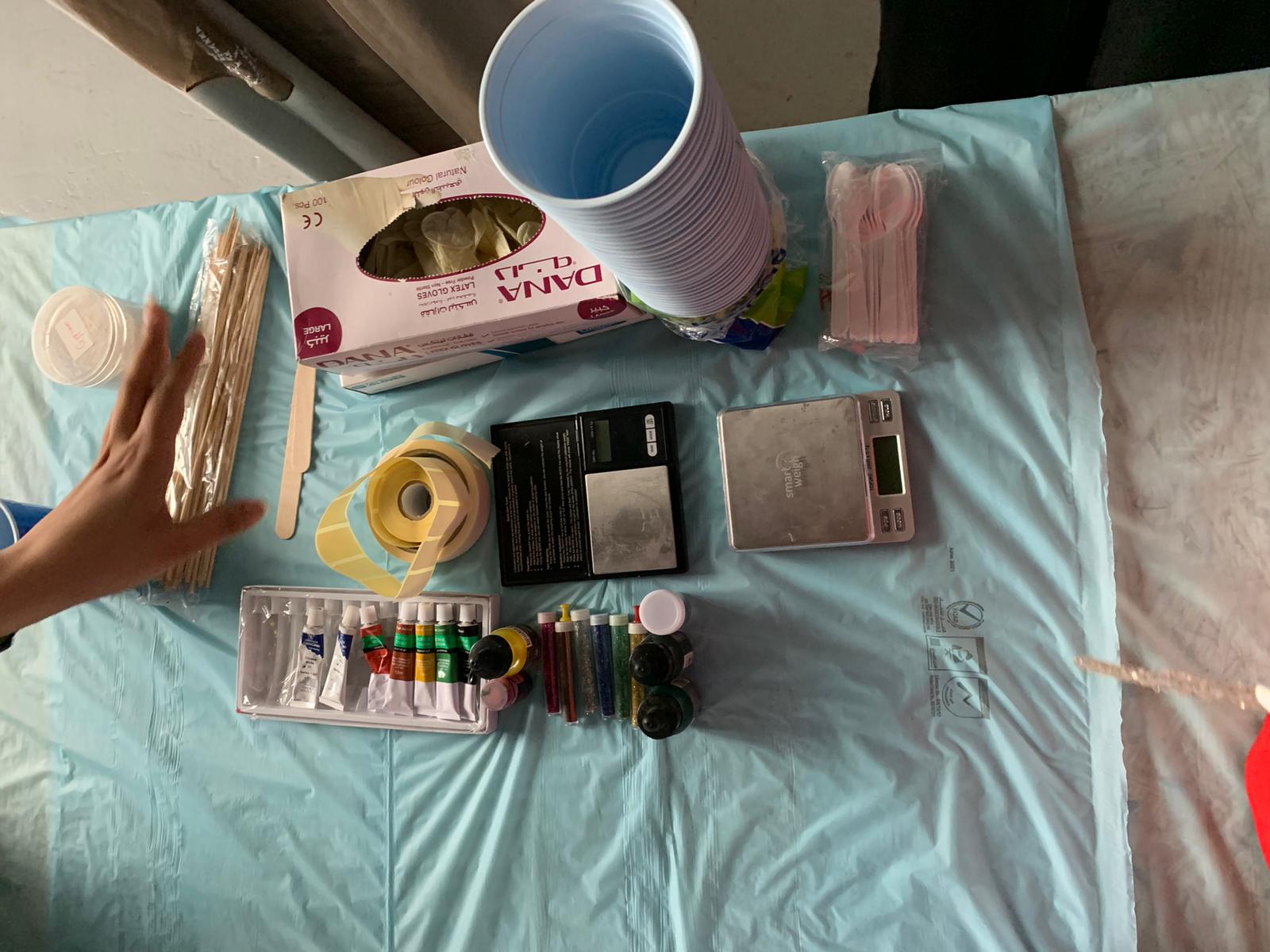

cup - colors - glitter - weighting scale - wood stick or plastic spoon for mixing and gloves for safety

material can be using

cup - colors - glitter - weighting scale - wood stick or plastic spoon for mixing and gloves for safety

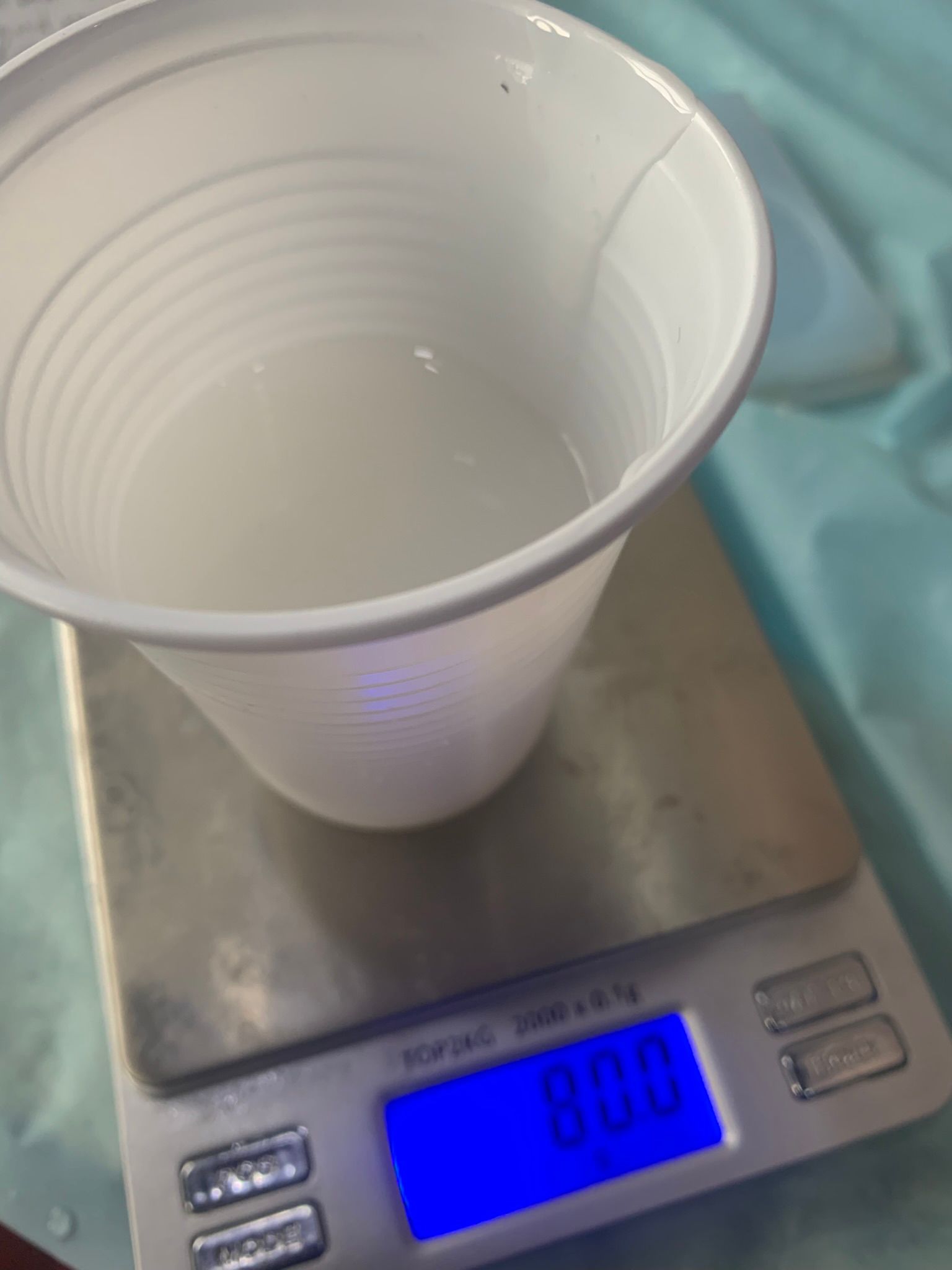

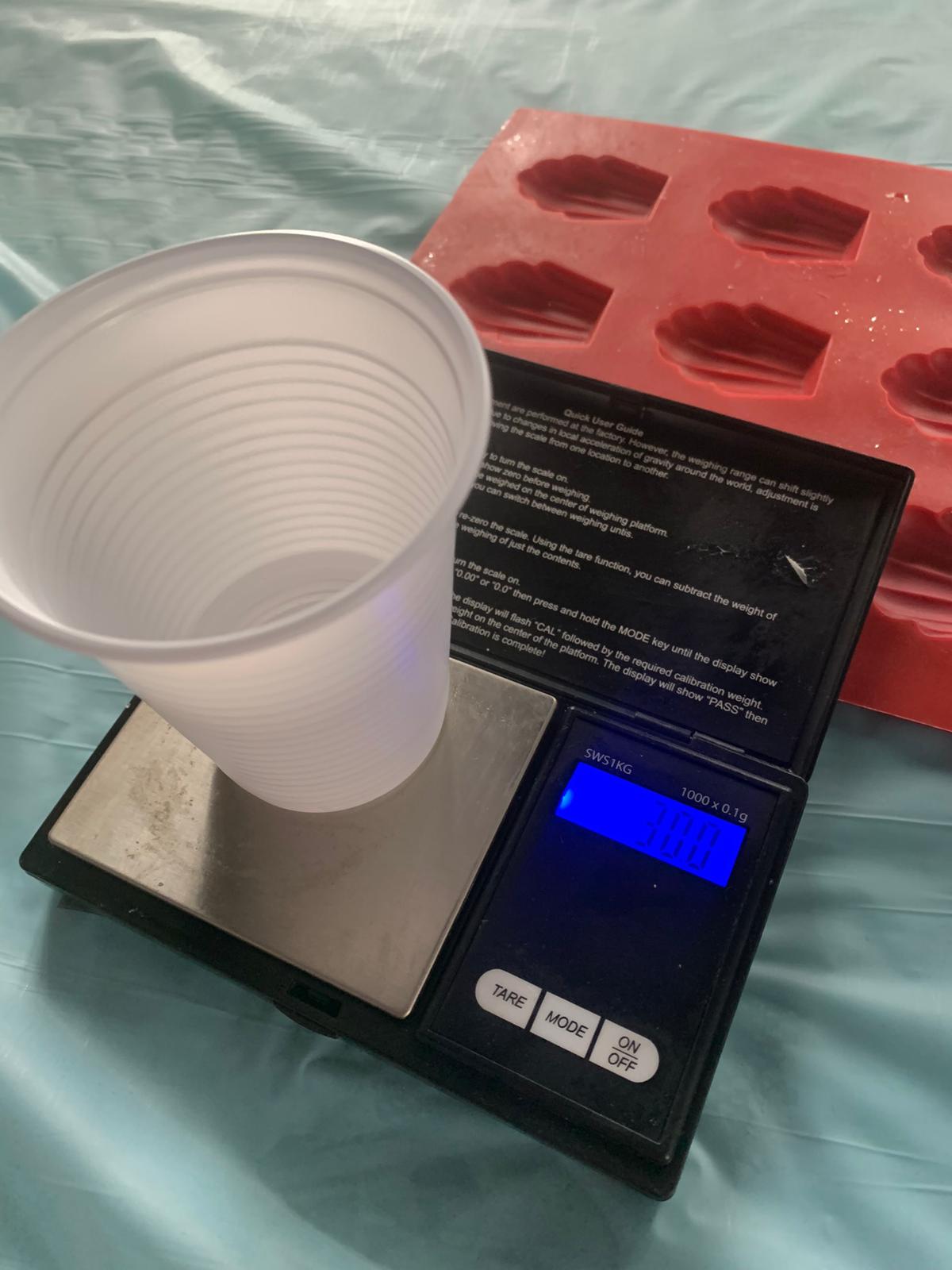

step 1 : adding the quantity want to use by that ratio 10 gram of resin and 6 gram of hardener

step 2: add any color or decoration

step 3: mix the micture for 10 min

step 4: poring on the mold

## making the mold #### CNC Milling Machines

As a small milling machine, the SRM-20 offers compact size and powerful functionality at an affordable price. Production of realistic parts and prototypes is made simple and convenient with a device that fits into any office, home, or classroom environment. For users looking for advanced milling capabilities without the need for expert operating skills, the SRM-20 is the easiest and most precise CNC mill in its class.

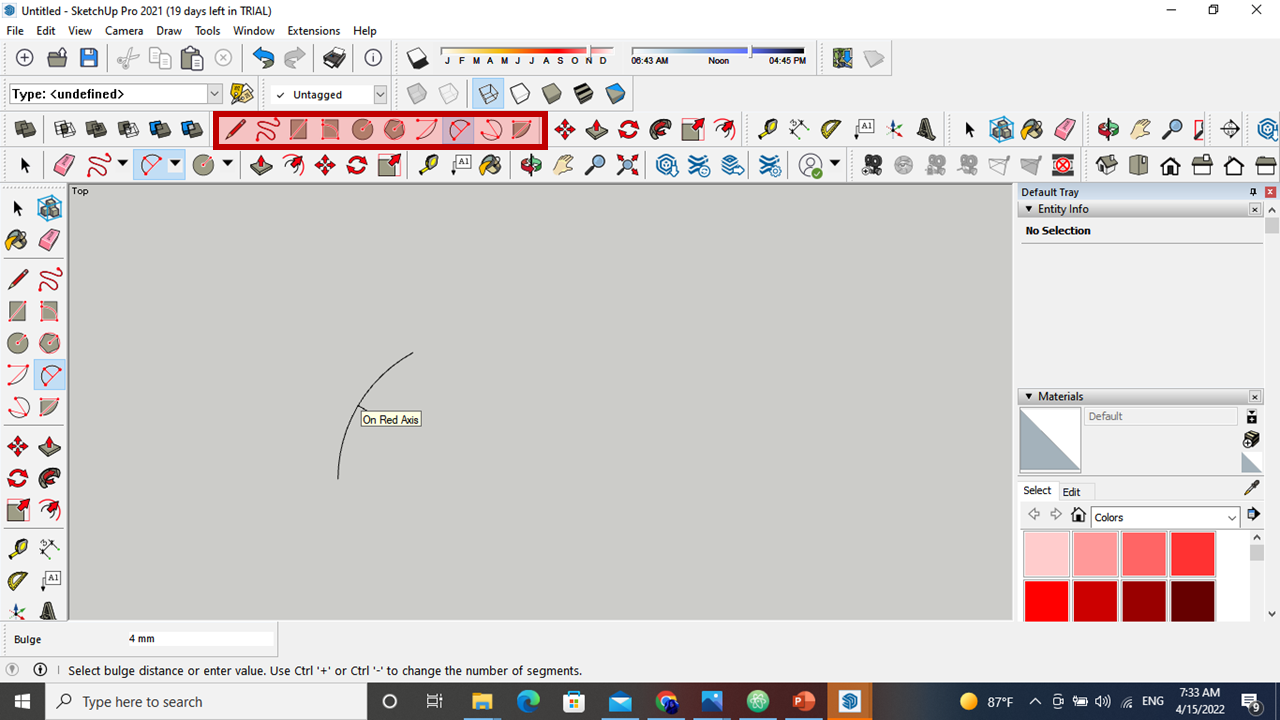

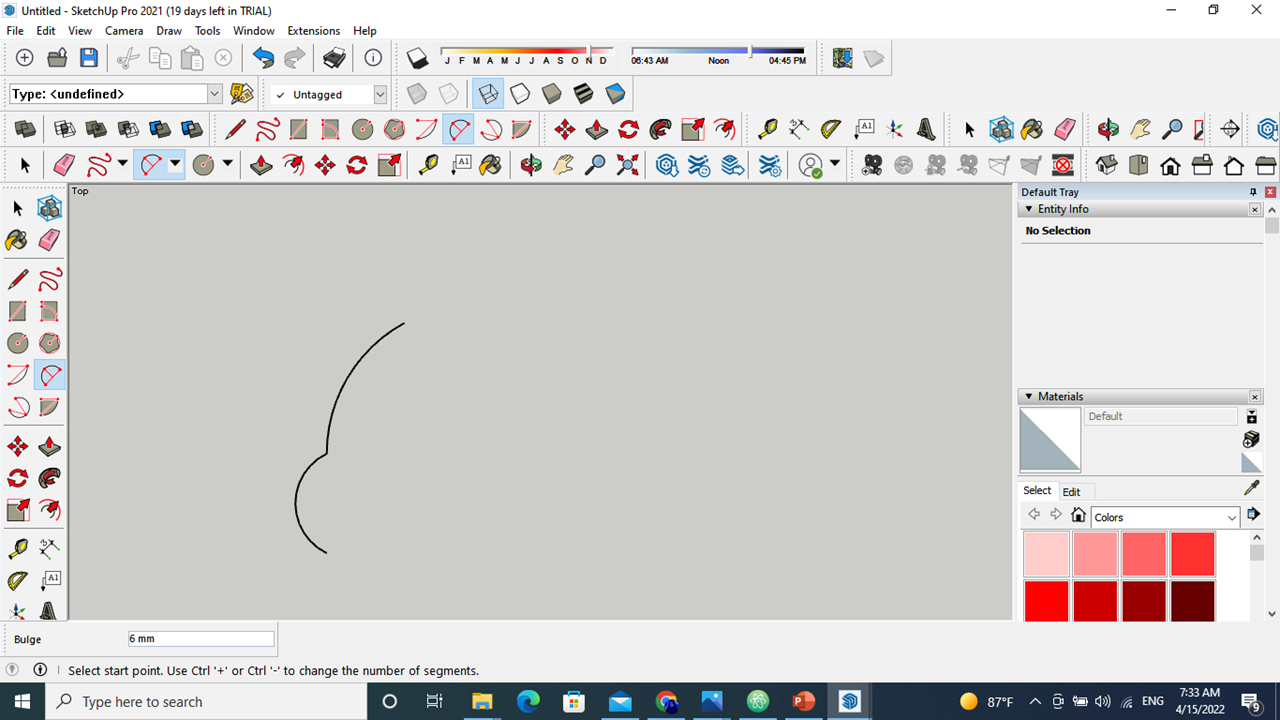

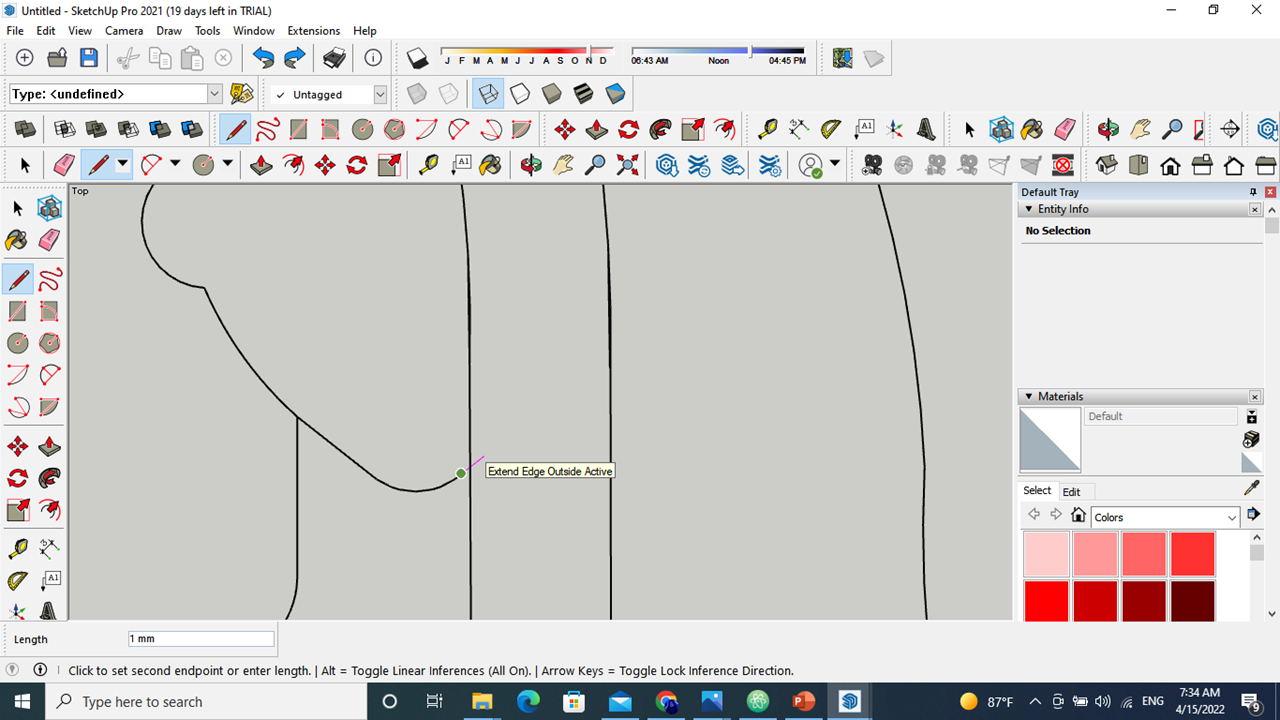

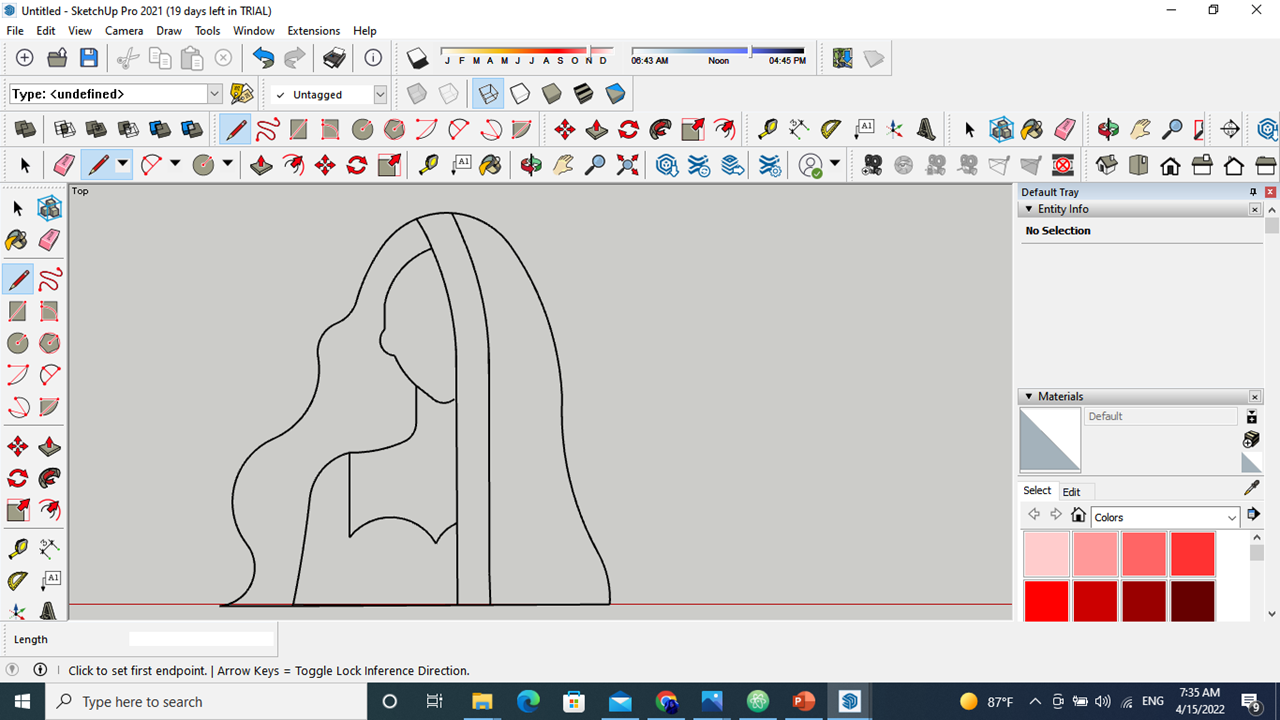

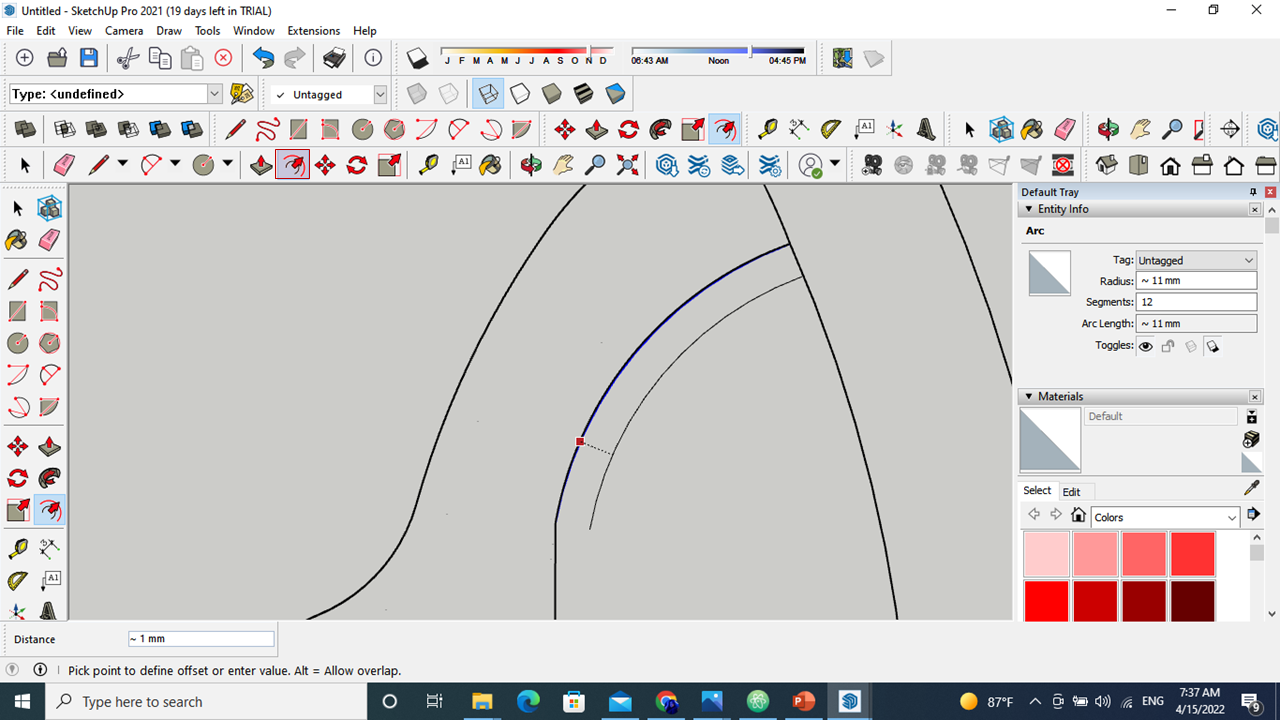

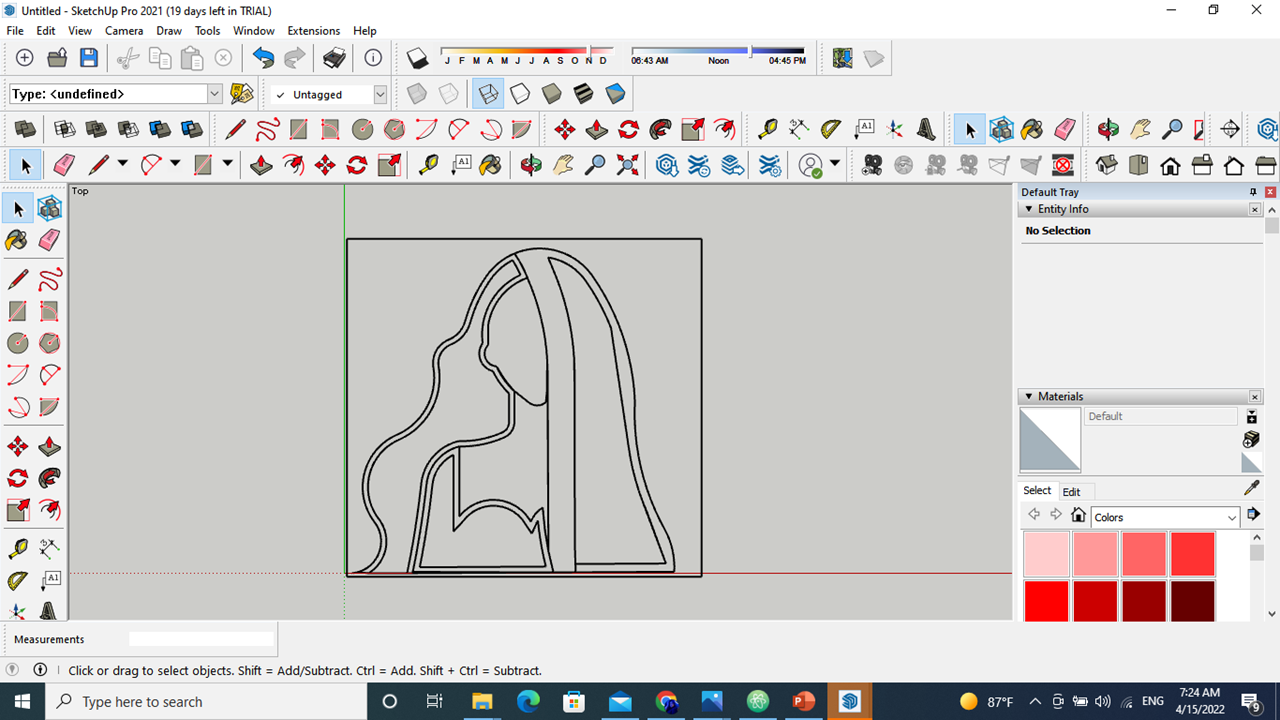

starting of making the mold need a design and for my design i design a traditional woman that wear a traditional clothes

in SketchUp

the final result

the final result

1

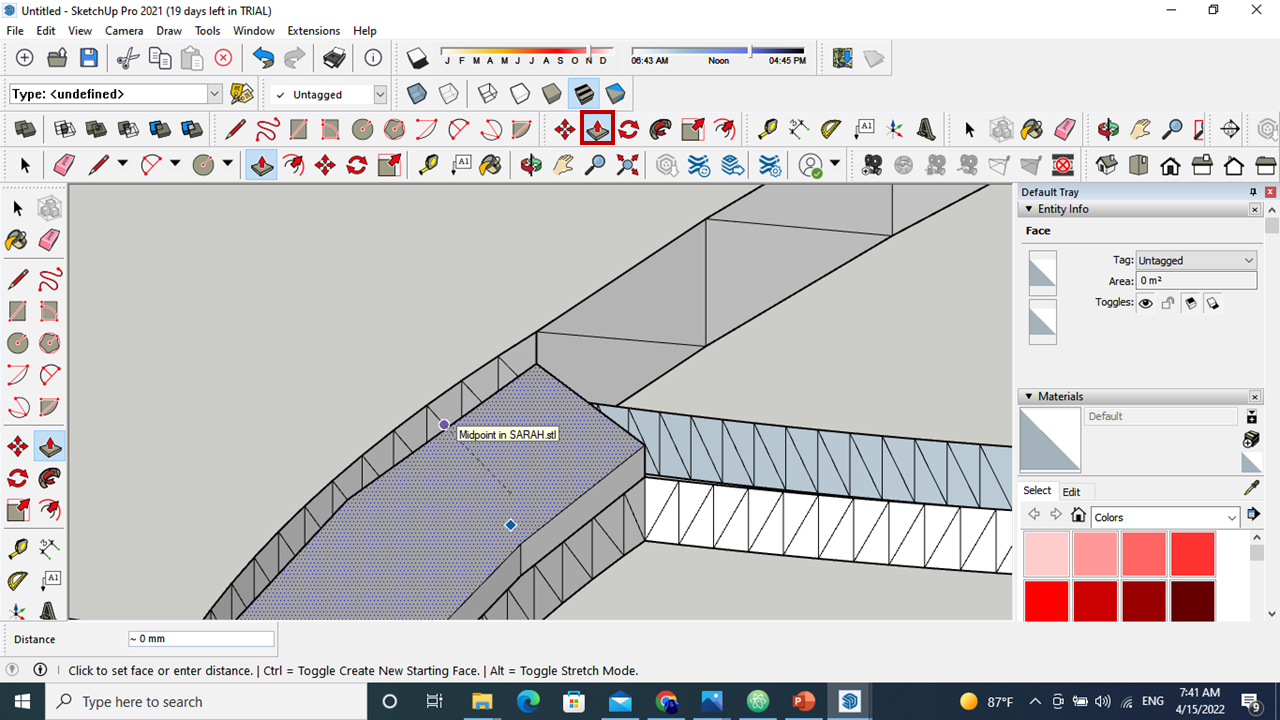

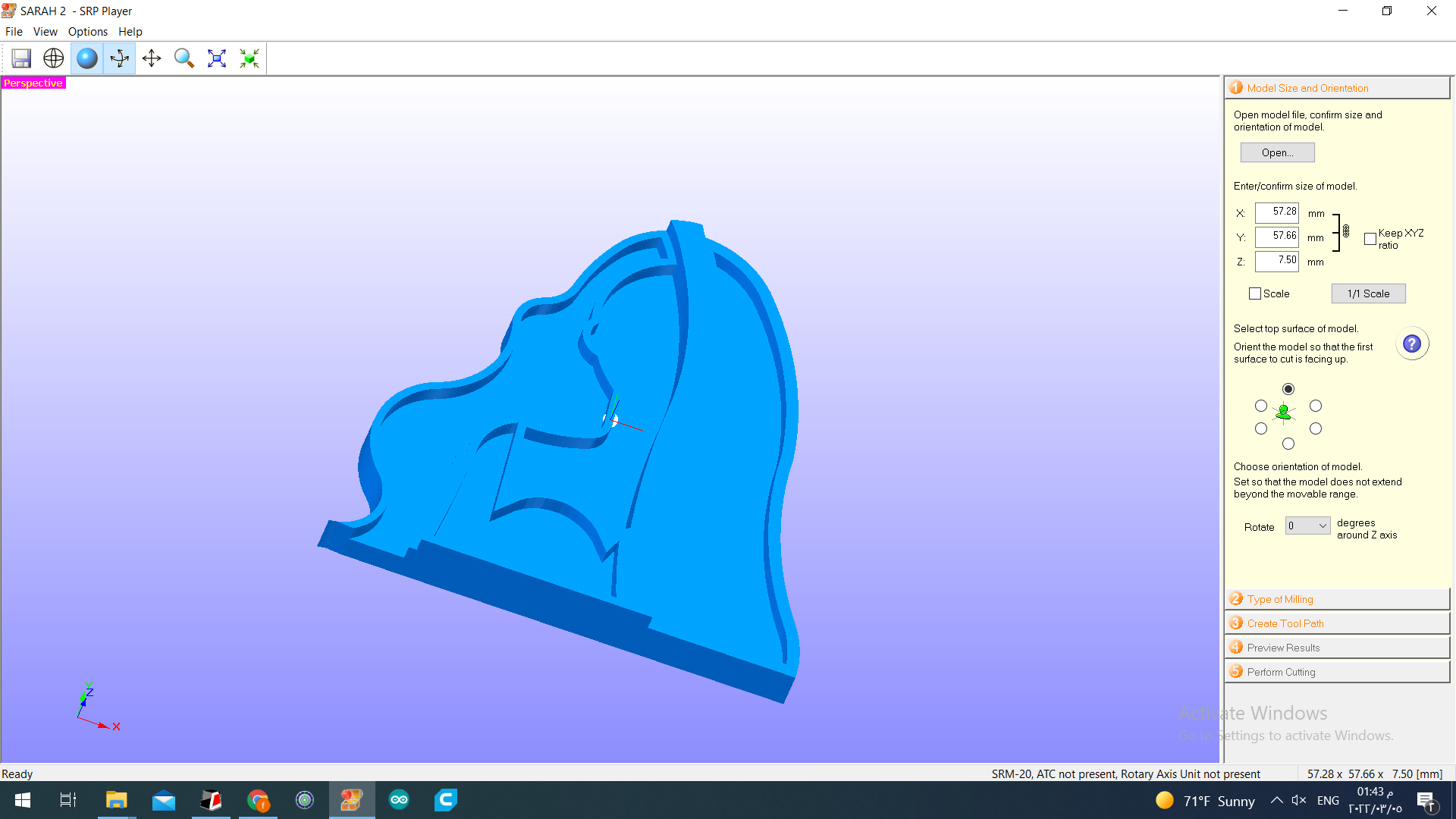

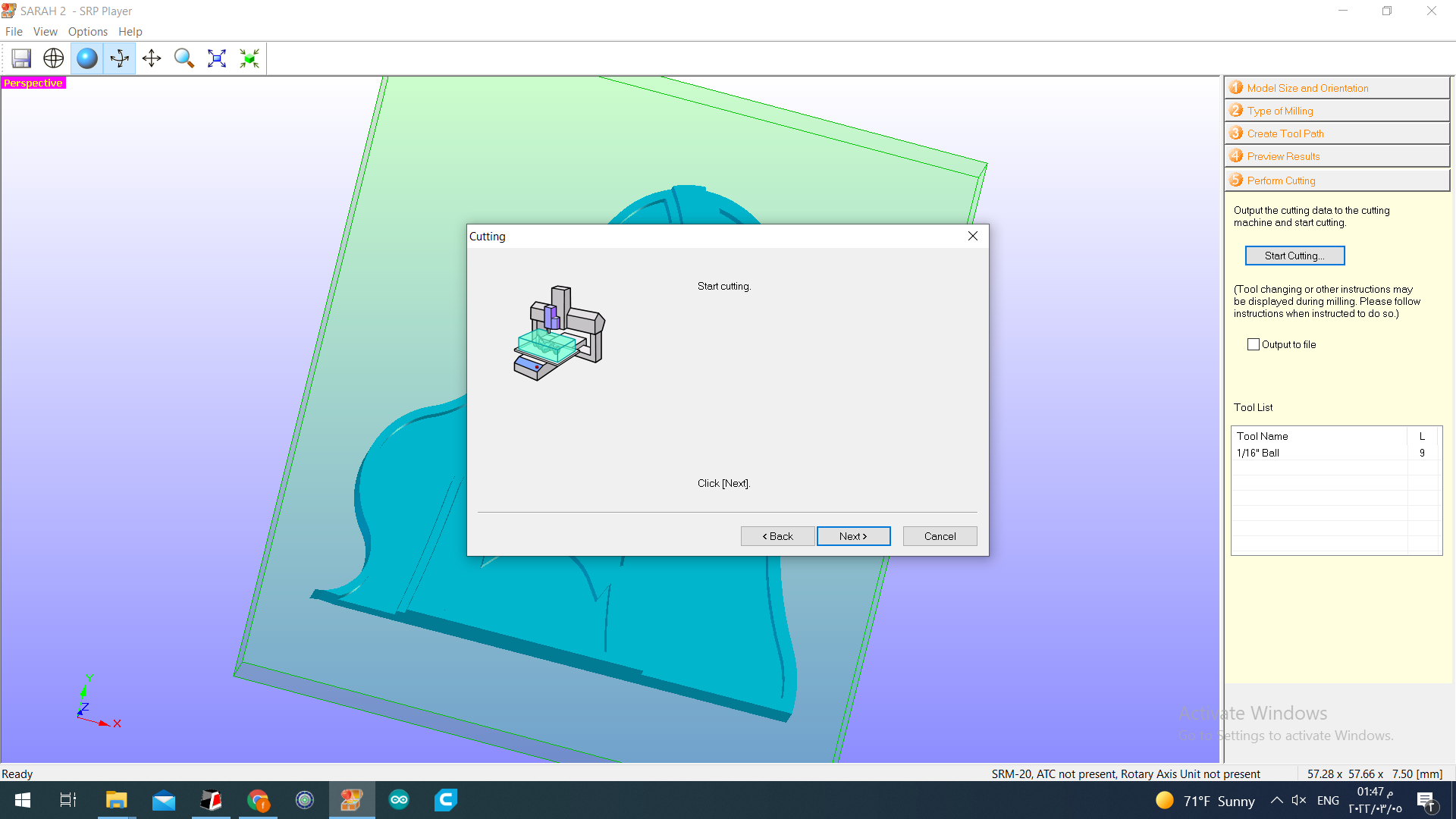

add it in the software that was used to edit the settings of the miling machine before cutting. called (0Robo-Albar)

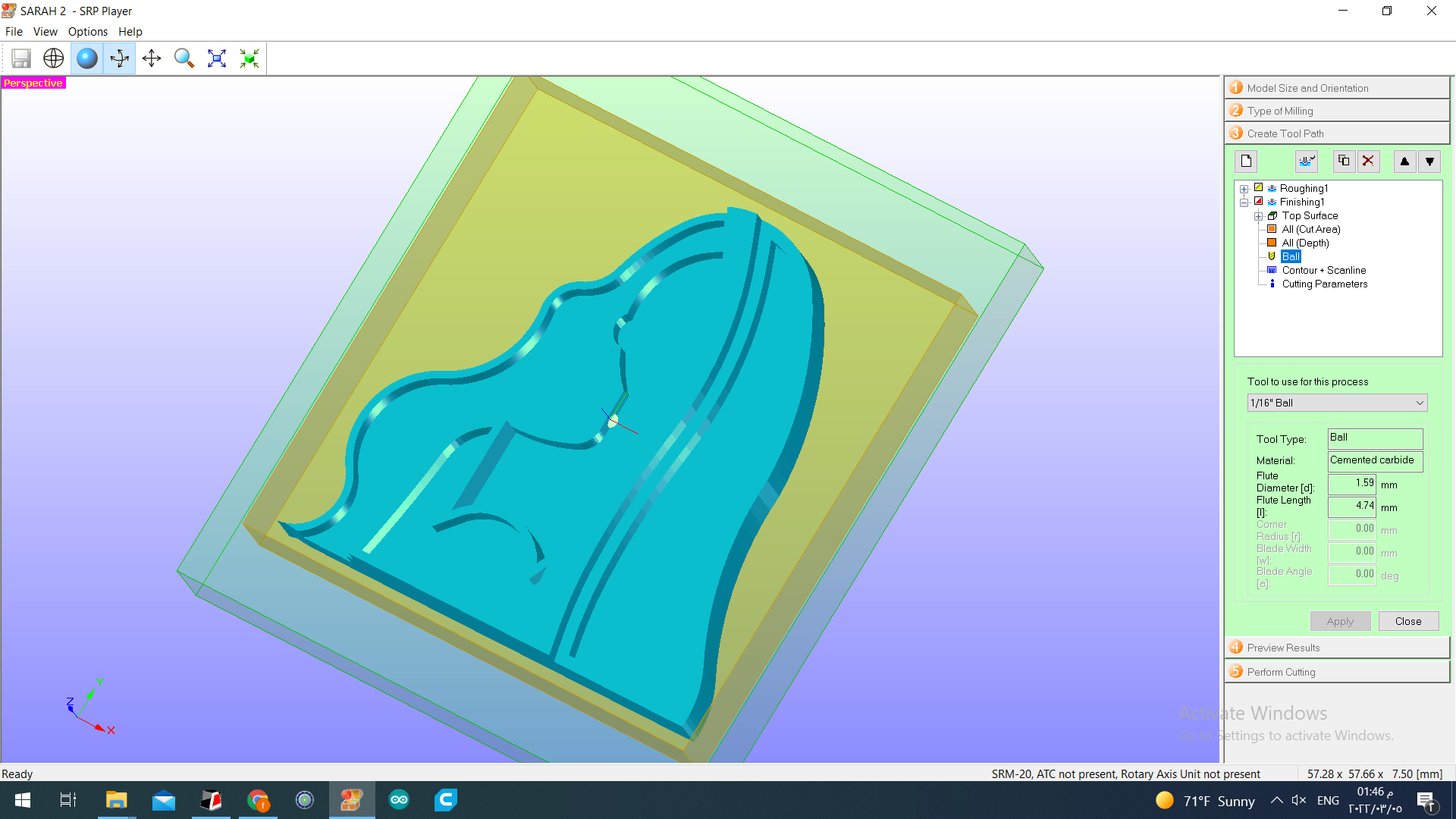

2

as the settings bar showed in the right side of the program there is some option to sit it first is the dimension of our models in the following settings

3

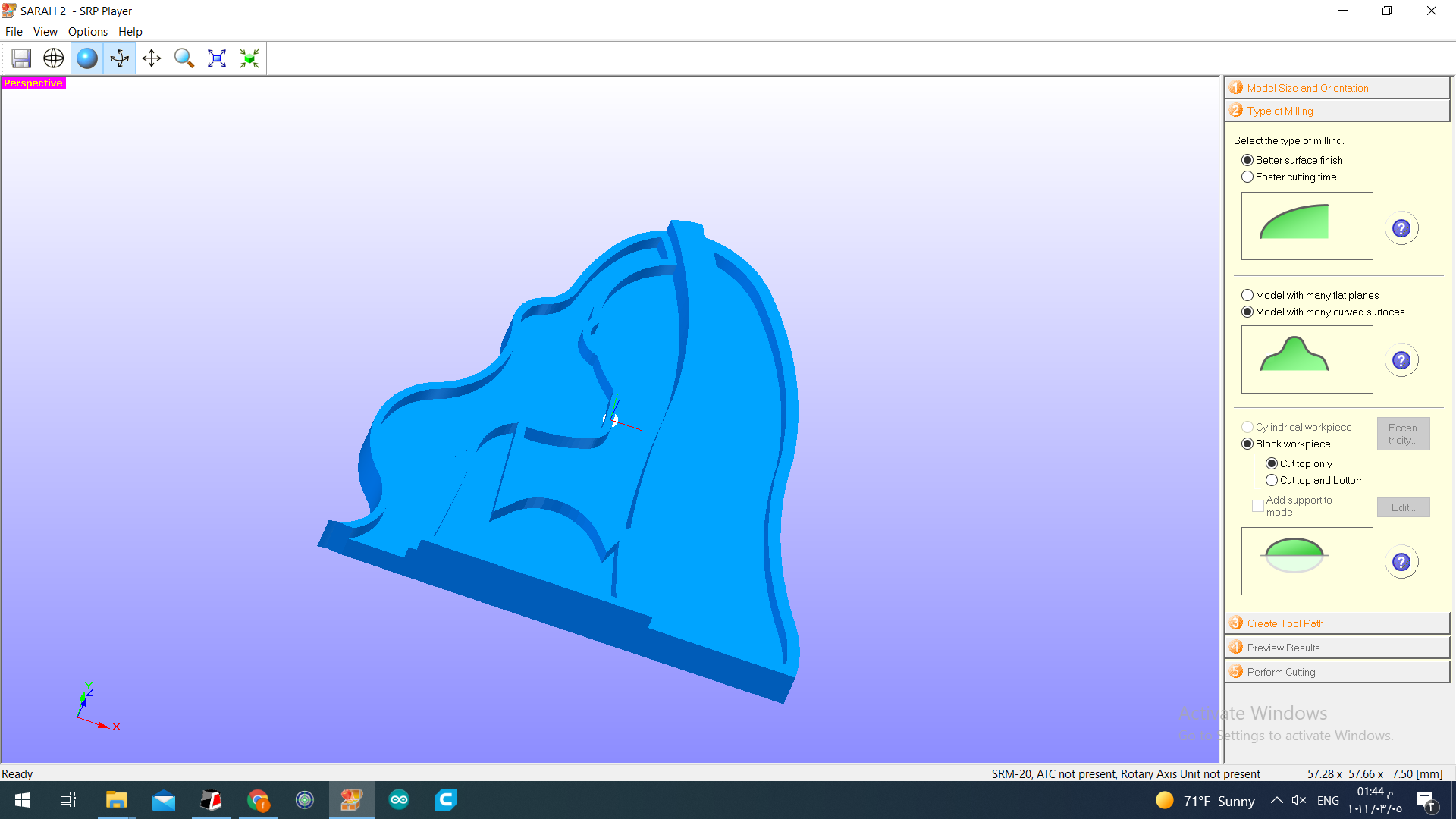

type of milling

selecting butter surface finish

for the edge finishing

and we have a we have a curve finishing we chose the many curve surface

and choosing to cuttings direction that is on the top or bottom

3

type of milling

selecting butter surface finish

for the edge finishing

and we have a we have a curve finishing we chose the many curve surface

and choosing to cuttings direction that is on the top or bottom

as you can see on the deferent finishing

as you can see on the deferent finishing

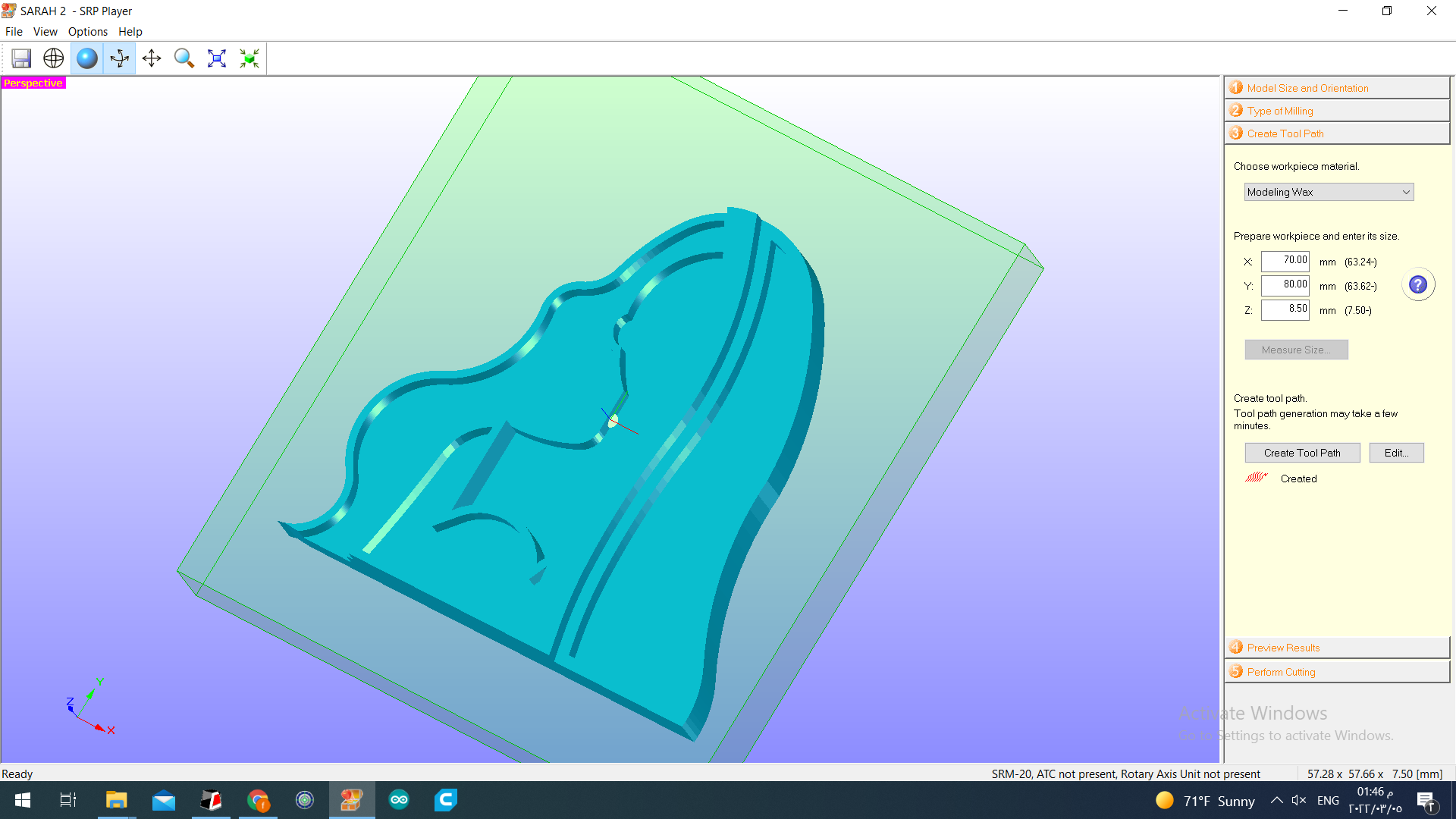

choosing the material type that we will be used which is the wax

choosing the material type that we will be used which is the wax

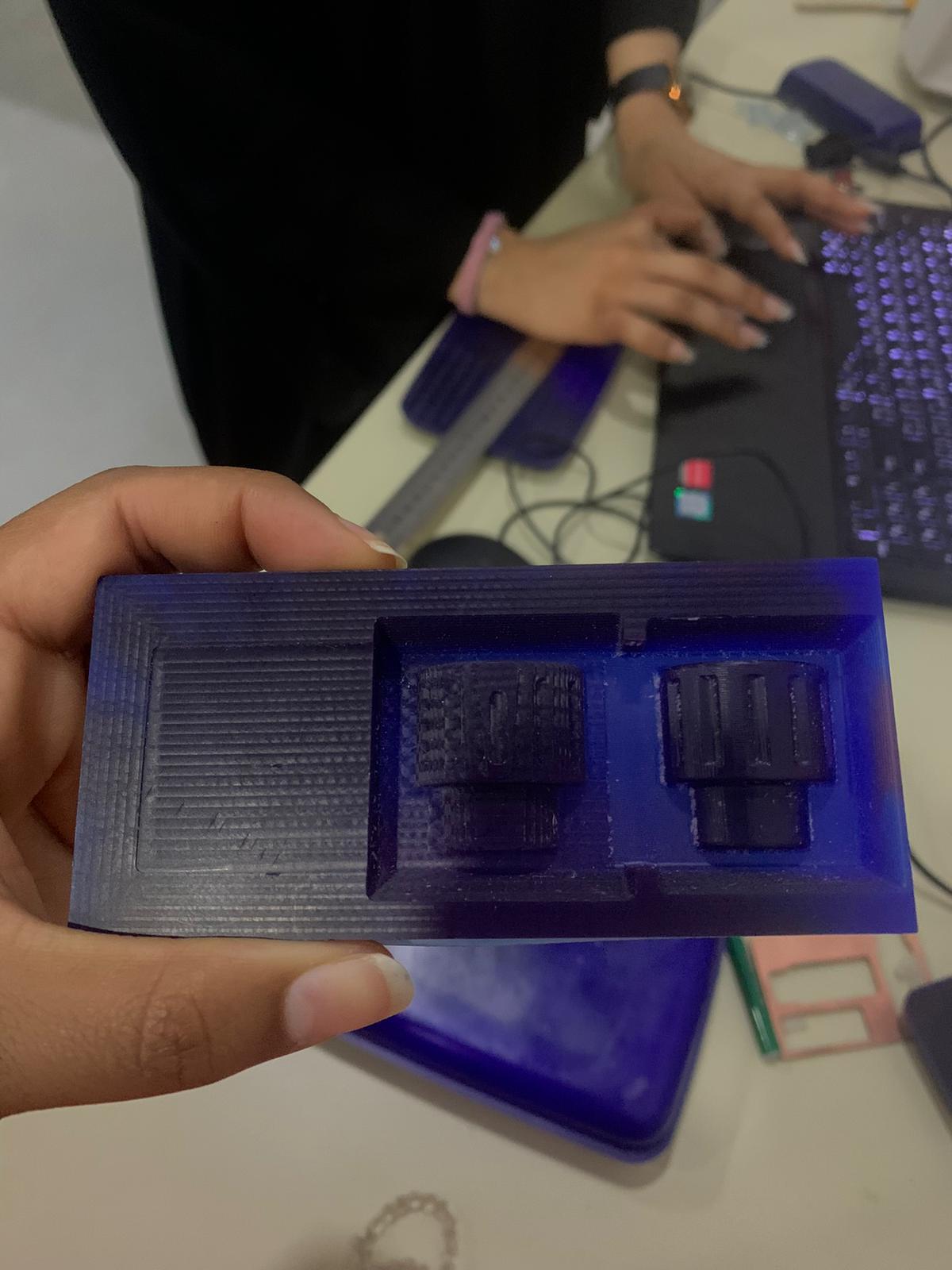

the material that used

the material that used

the toolpaths sitting is about the balling like the speed of the balling and the ball size .

the toolpaths sitting is about the balling like the speed of the balling and the ball size .

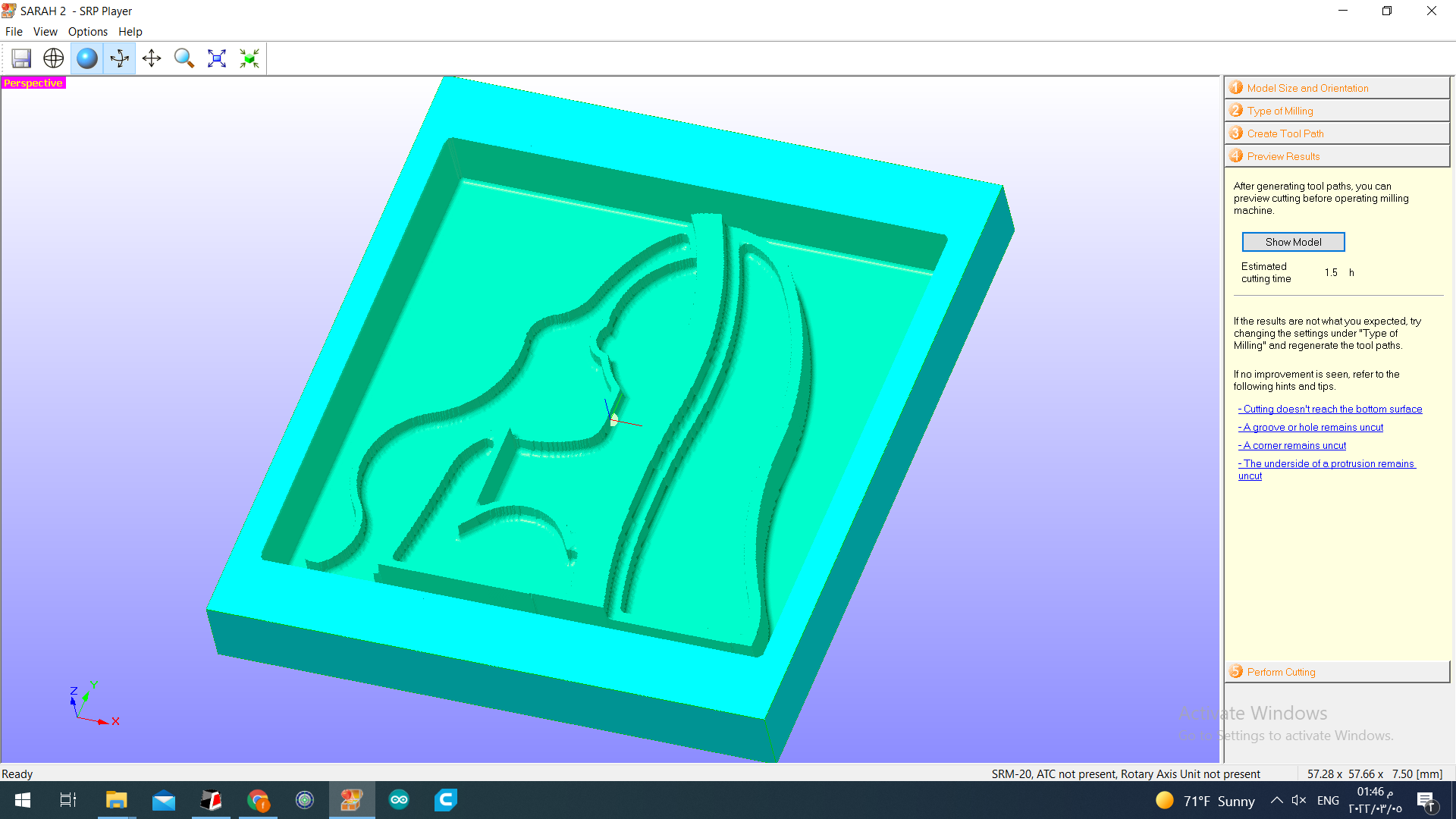

showing the estimation result time for the cut

showing the estimation result time for the cut

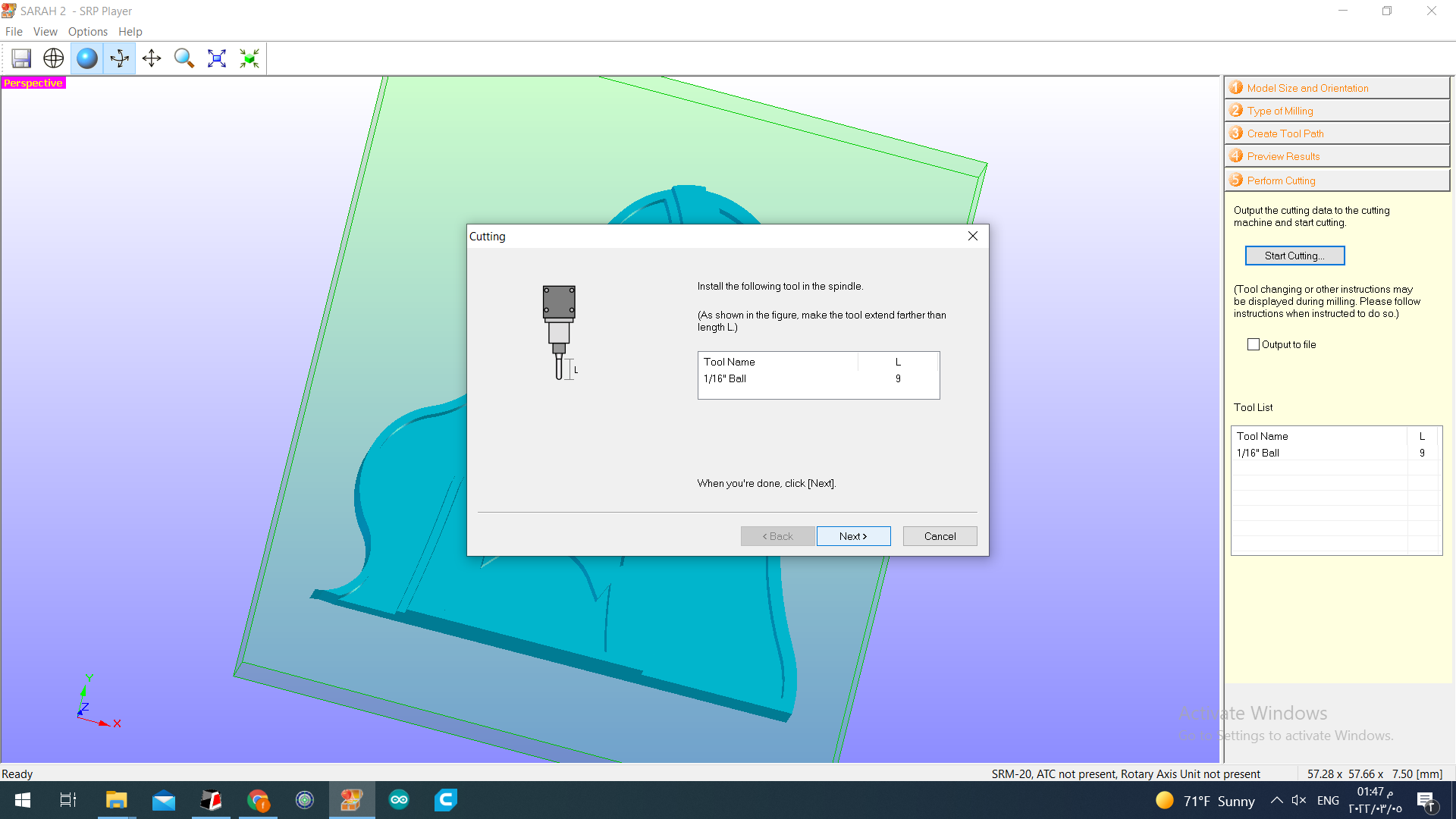

installing the balling

installing the balling

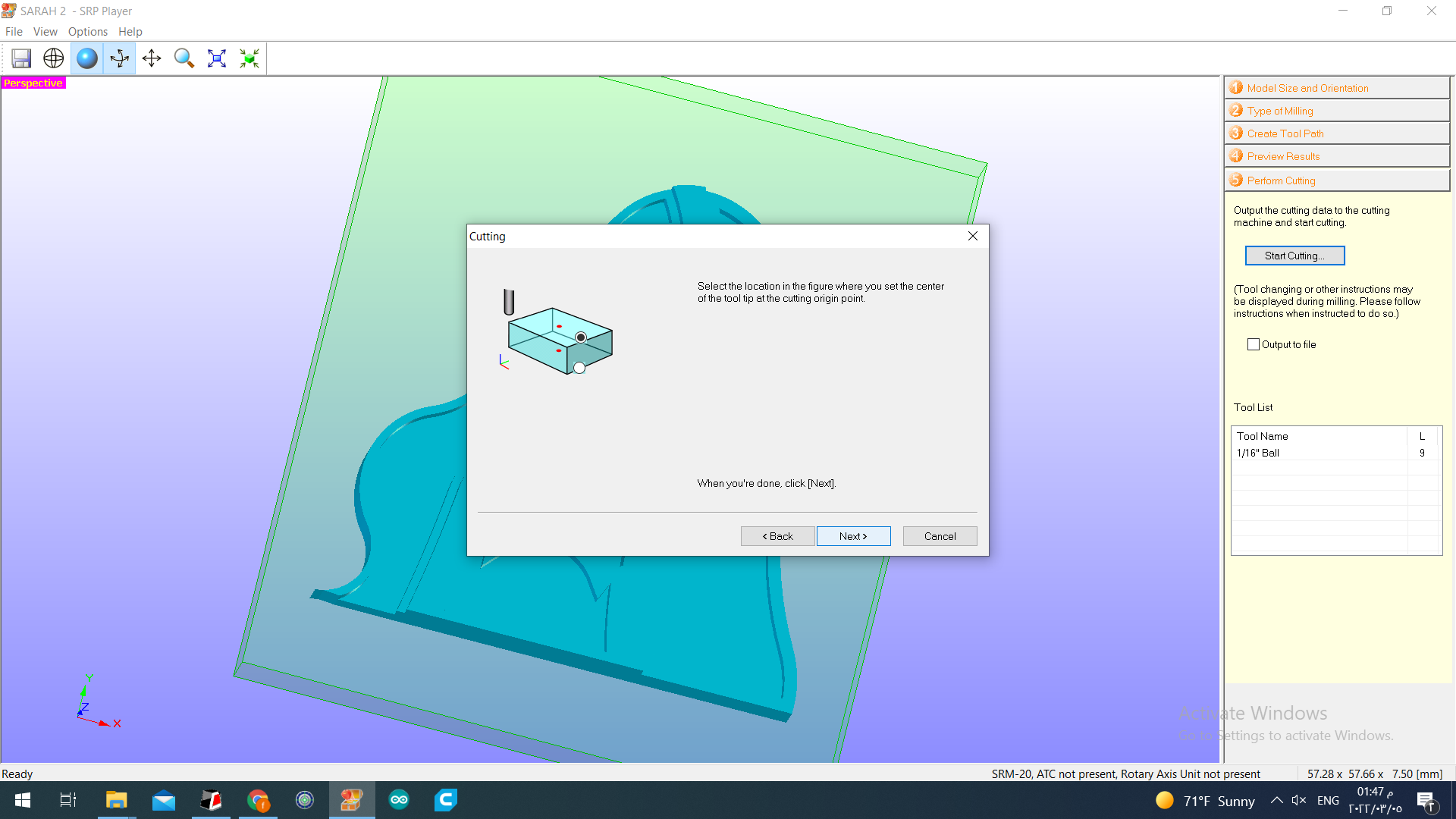

selecting the location of the center of the tool tip at the cutting origin point

selecting the location of the center of the tool tip at the cutting origin point

and start cutting

and start cutting

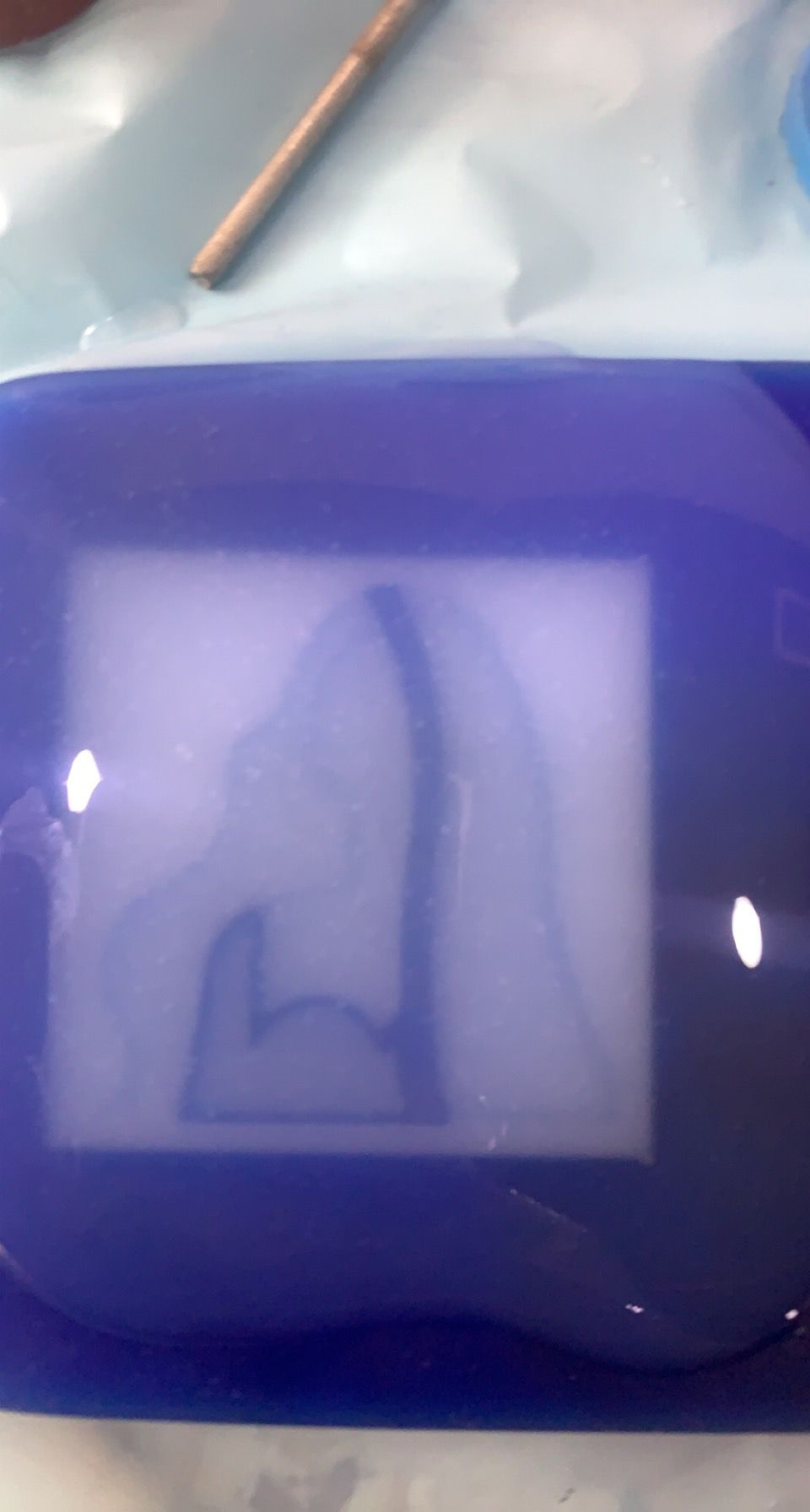

the final result

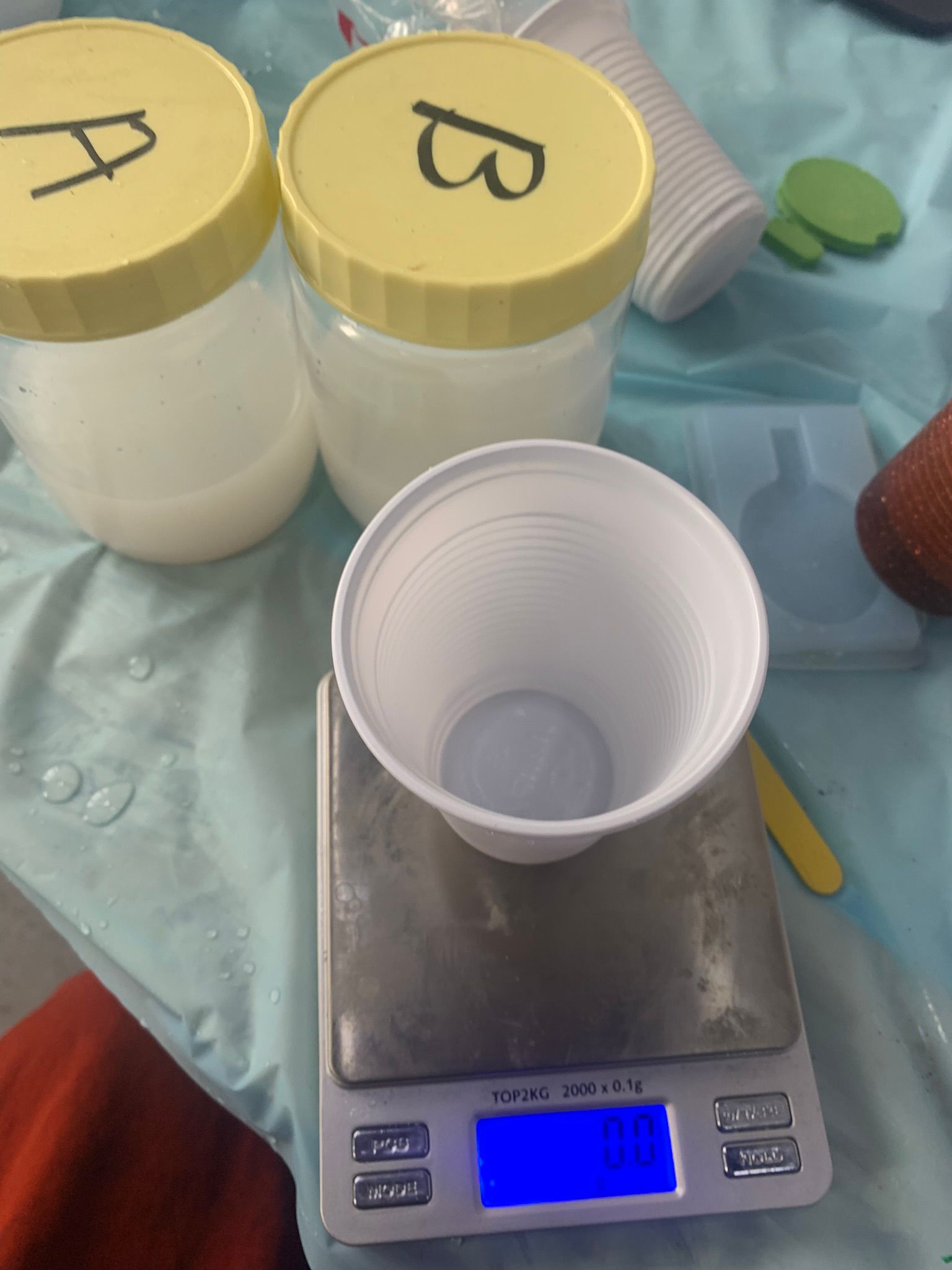

start with to create the silicon

| about | description |

|---|---|

| cure time | 2h to 10h |

| work time | 15 min |

| mix ratio | 1 to 1 A and B |

| cured material state | fixable |

adding 40 gram A and 40 gram B

and pure it on the mold

and pure it on the mold

after its get dry

after its get dry

the final result

the final result

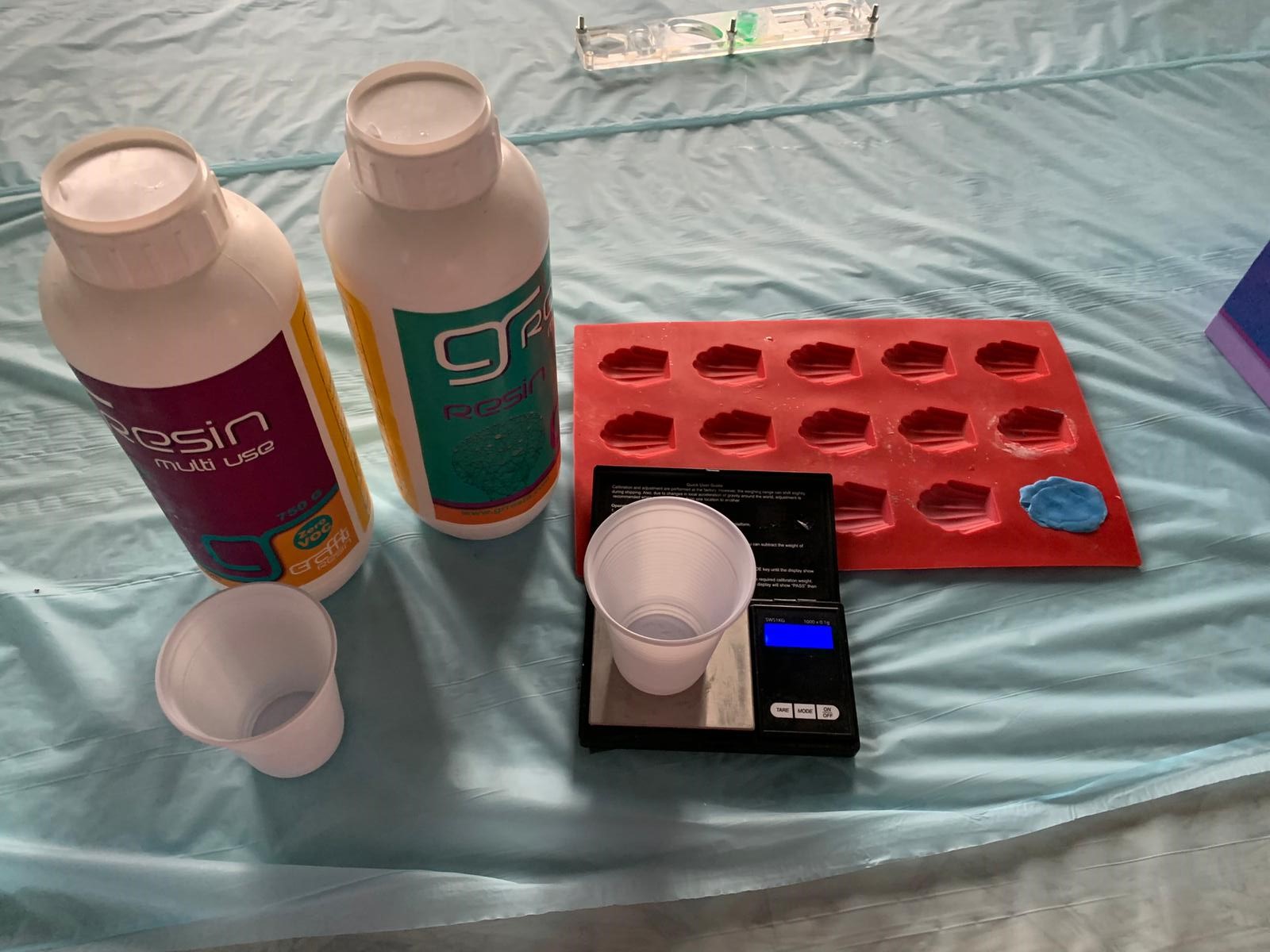

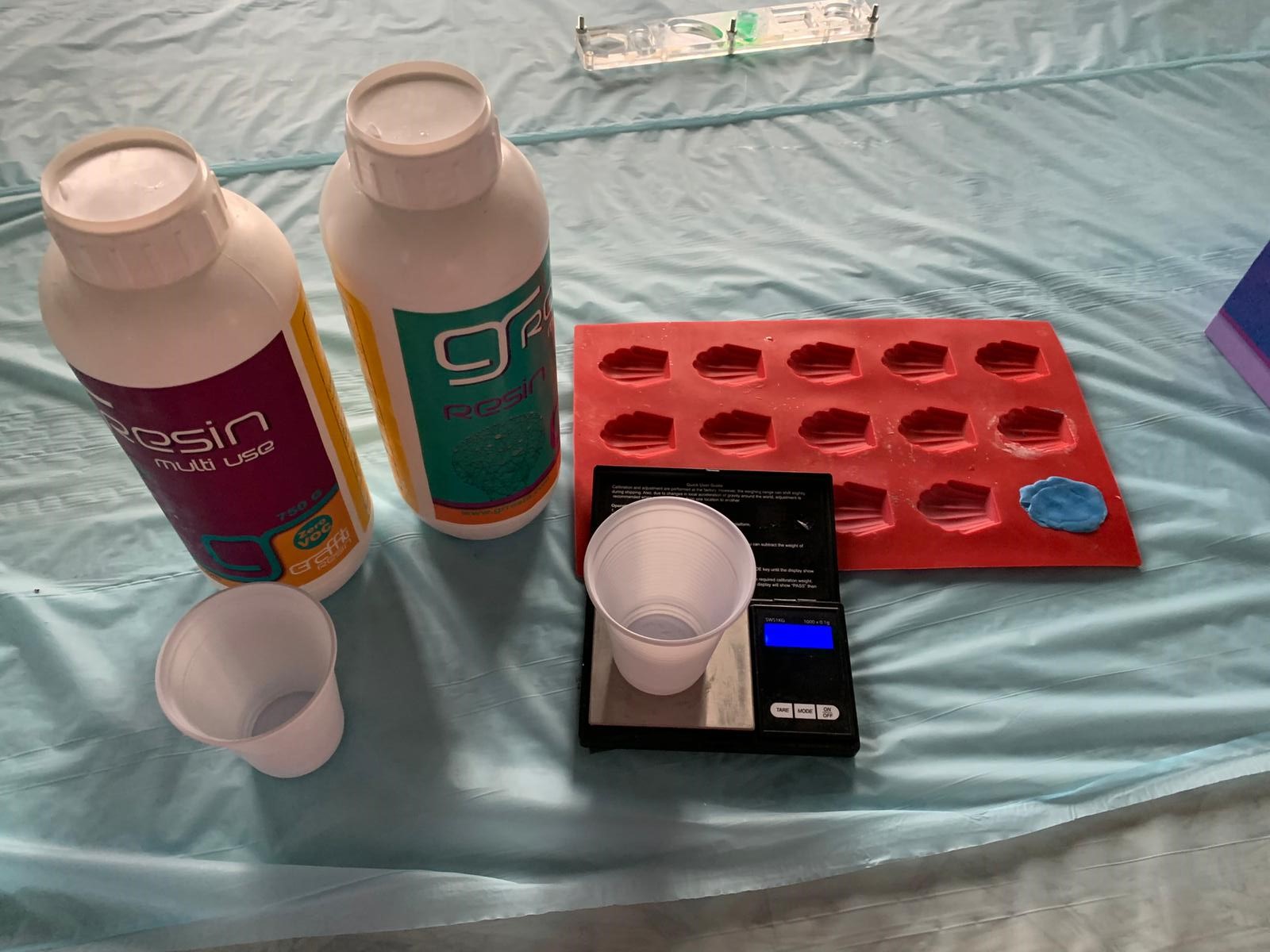

## casting

using the resin

| about | description |

|---|---|

| cure time | 24h to 72h |

| work time | 15 min |

| mix ratio | 10 gram of resin and 6 gram of hardener |

| cured material state | Solid |

Food Safe after 72hours – full cure Zero VOC odorless / Less Smell Low Viscosity Meets the requirements of the relevant FDA listing and therefore when fully cured ideal to be used in contact with food

material can be using

cup - colors - glitter - weighting scale - wood stick or plastic spoon for mixing and gloves for safety

material can be using

cup - colors - glitter - weighting scale - wood stick or plastic spoon for mixing and gloves for safety

step 1 : adding the quantity want to use by that ratio 10 gram of resin and 6 gram of hardener

step 2: add any color or decoration

step 3: mix the micture for 10 min

step 4: poring on the mold

from Youtube¶

hero shot¶