Sustainable Habitat Educational Lab (SHEL)¶

Research¶

Executive summary:¶

A smart modular comfortable mobile space that motivates the user to be more creative while being energy efficient and built-in consideration of vernacular design. The process of building it will be experimental based on material, process, and design research.

Problem Statement:¶

- Lack of practical experience in universities in building an actual smart space.

- Lack of a mobile smart space solution based on the Bahraini conditions such as weather and materials.

- Optimize designs and explore other materials options.

Learning outcomes :¶

- Experiment with a variety of materials and processes to test their limitations.

- A method of data acquisition about the status or parameters of the space Implement.

- It will help architecture and electrical students to learn the practical aspect of building mobile smart space solutions.

Goals and Objectives, Deliverables:¶

Cover the Exterior with 4 Experimental panels and test them based on different test variables such as ( Thermal Insulation, recyclability, water resistance, and cost) comparing them in a table.

Key elements in the project¶

User: The is artists that needs isolation to boost thier creativity and work in an inspiring environment or a researcher or even a scientist that is doing experiments.

Comfortable: Being able to create the ” Homy ” atmosphere by trying to stimulate the 5 senses, and creating a warm atmosphere, Where the user would be able to be at a state where it would help him/her to be more creative or productive.

Mobile space: Being able to move the space comfortably anywhere you want.

Experimental: Having the flexibility that lets us to test and experiment our panels by going through rapid prototyping cycles. Moreover test our IOT devices in an independent room that is located far from the control station.

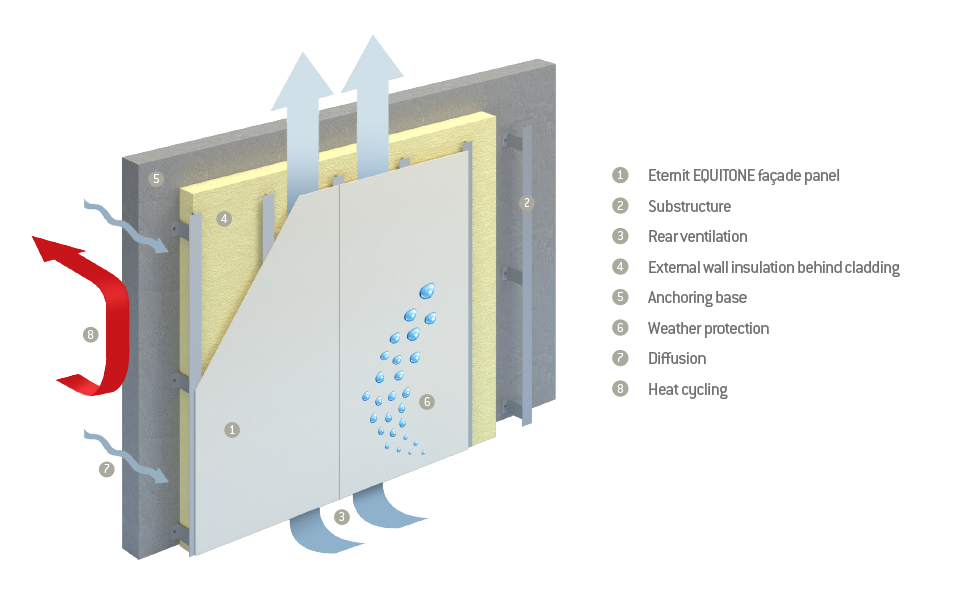

Vernacular design: is characterized by its reliance on needs, construction materials, and traditions specific to its particular locality. Can be achived using local raw available sustainable materials such as palm trees leafs. Rear-ventilated facades with rainscreen cladding achieve considerably smaller heat losses in the winter as well as reliable heat protection in the summer. In addition, they have a positive influence on the sound-insulating effect of the outer wall: the degree of sound insulation is increased. Additionally, due to the system, techical fire protection requirements can be fulfilled in line with building laws.For more information click here

Smart: Buildings benefit from advanced sensing and controls, IOT systems, systems integration, data analytics, and energy optimization to actively reduce energy use and demand while improving occupant comfort, health, productivity, and facility resilience.

Energy effecient: “Vernacular design includes” Being effecient in terms of electricity consumbtion and thermal isolation. This can be achived by designing the mobile space shape and using certain materials. Moreover using sensors to monitor the consumbtion and heat loss in the system to help optomize the preformance.

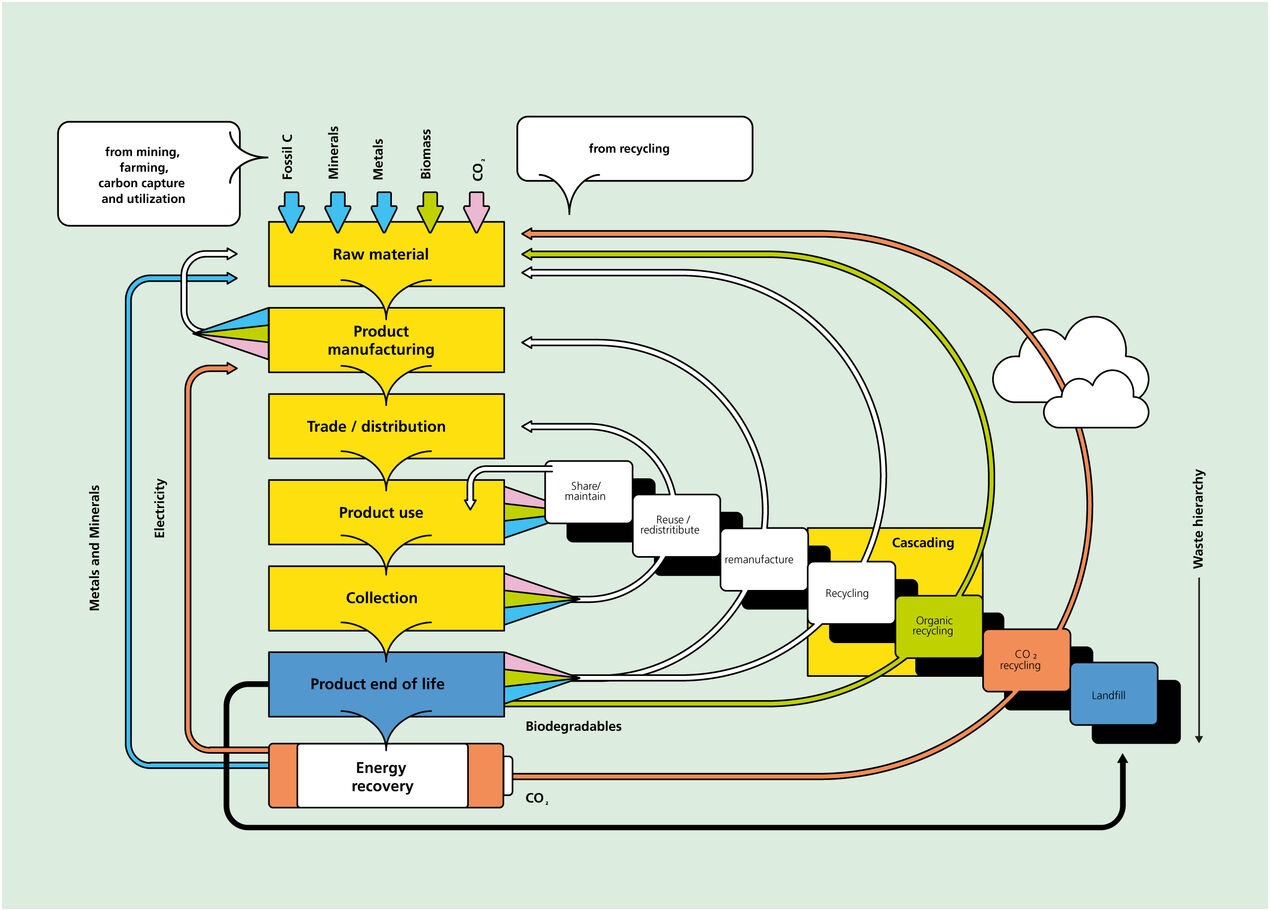

Environmently friendly: “Vernacular design includes” Building the panels based on biodegradable and enviromently friendly materials.

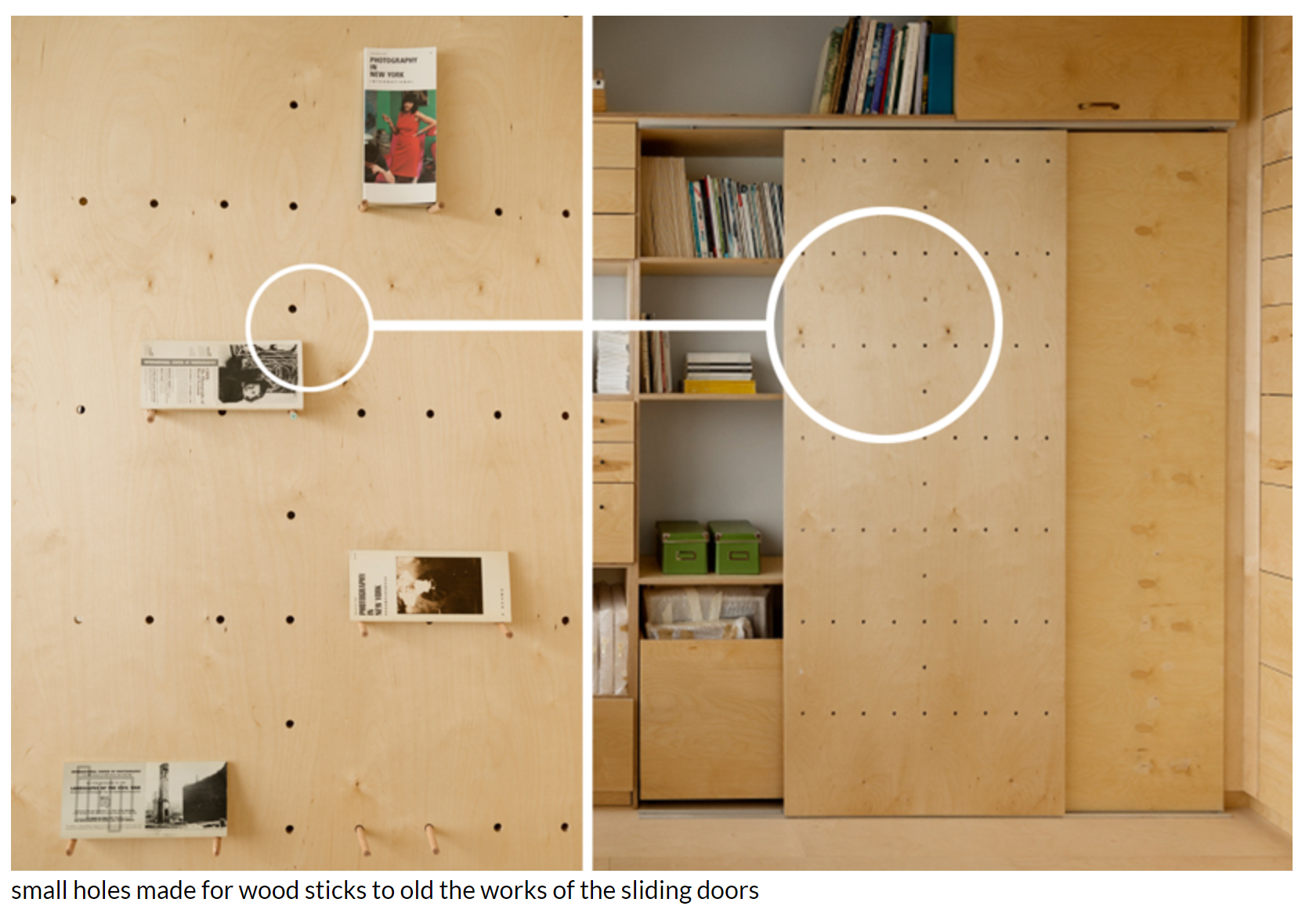

Modular: The use of modular design interior with the aim to maximize the functionality of the shell while also maintaining as much of open space inside, as the open space would be used by the users themselves to their liking.

Strategy of working and methodolgy¶

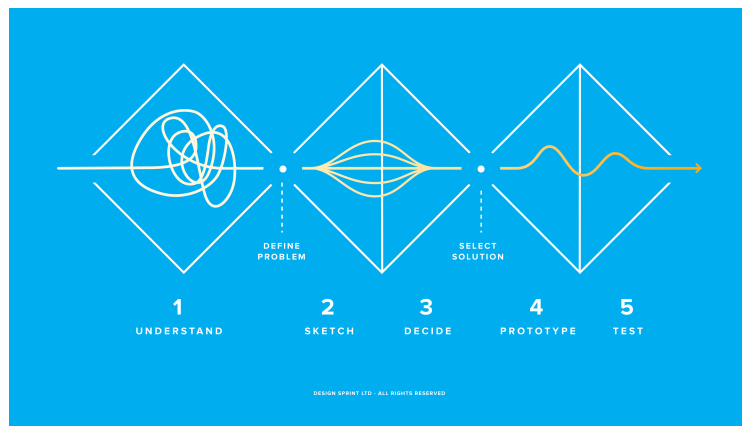

As this project is a continuous learning experience the methodology will be a set of experiments based on previous research papers then applying them in a small prototype each week, then scaling it to the actual size to be used in space using the design thinking process.The approch is going wide on reserch and options then narrowing down the options in an iterative cycles.

Product life cycle material flow¶

¶

¶

Weather conditions in Bahrain:¶

Bahrain weather conditions during the year ( When it is humid, hot, cold, sun direction, wind direction, Angles for Solar-Responsive Design ) Tuesday, July 5, 2022 8:22 PM

Bahrain features an arid climate.[2] Bahrain has two seasons: an extremely hot summer and a relatively mild winter. Click Here

The weather :

Hot months : April to October.

Cold months: February to January.

The coldest month is January.

The winter period is (changeable).

Wind:

During June and July (strong northwesterly winds).

Winter: winds alternate mainly between (southeast) and (northwest).

Two type of wind :

Shamal (northwest).

Qaws (southwest) “hot and dry” blows from the south.

• On average, the most wind is seen in December.

• On average, the least wind is seen in September.

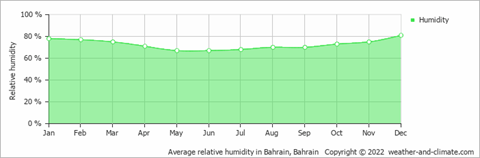

Humid:

The least humid month is June (31.7%).

The most humid month is January (58.7%).

• On average, December is the most humid.

• On average, May is the least humid month.

• The average annual percentage of humidity is: 73%.

Passive solar heating:

Passive solar design helps in reducing the ener cost by applying a design solusion to the shape for example having a window at a sertain angle helps in heating the space in the winter by letting the sunlight enter and in the summer preventing the direct sunlight to enter to help in cooling the space.

• North would have least wind and mostly help in creating a shead.

Conserving Energy¶

It is the process that includes the use of a smaller amount of electrical energy to obtain the same product or service through rationalization by carrying out a set of procedures and means aimed at reducing energy consumption and improving the efficiency of its use without affecting the level of performance, and this is done through the use of the energy efficiency label issued About the manufacturers and installers of electrical appliances.

Examples :

-

Using energy-saving lamps: they save between 25% and 80% of electrical energy, and last 3 to 25 times more, and they have different types, such as: incandescent halogen lamps, compact fluorescent lamps “CFL”, and LED lamps “LED”. The use of a

-

programmed thermometer: a device that is programmed to automatically stop, reduce, or raise the temperature in empty rooms or where people are sleeping, without the need to manually control the air conditioning or heating system, which saves energy.

-

Purchasing energy-saving devices: These devices often have a higher purchase cost, but their operating costs are lower than traditional devices in the long term, ranging from 9% to 25%.

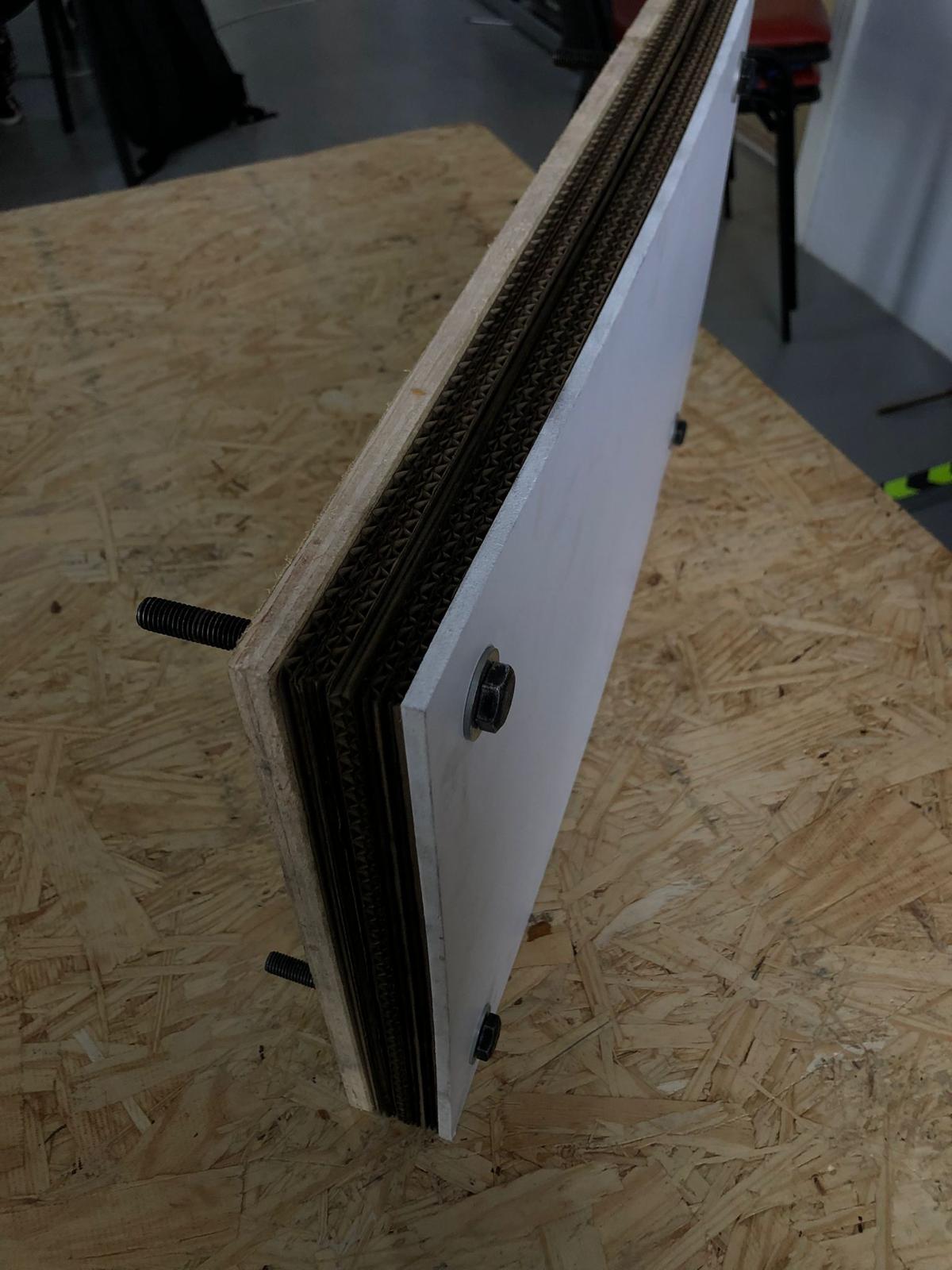

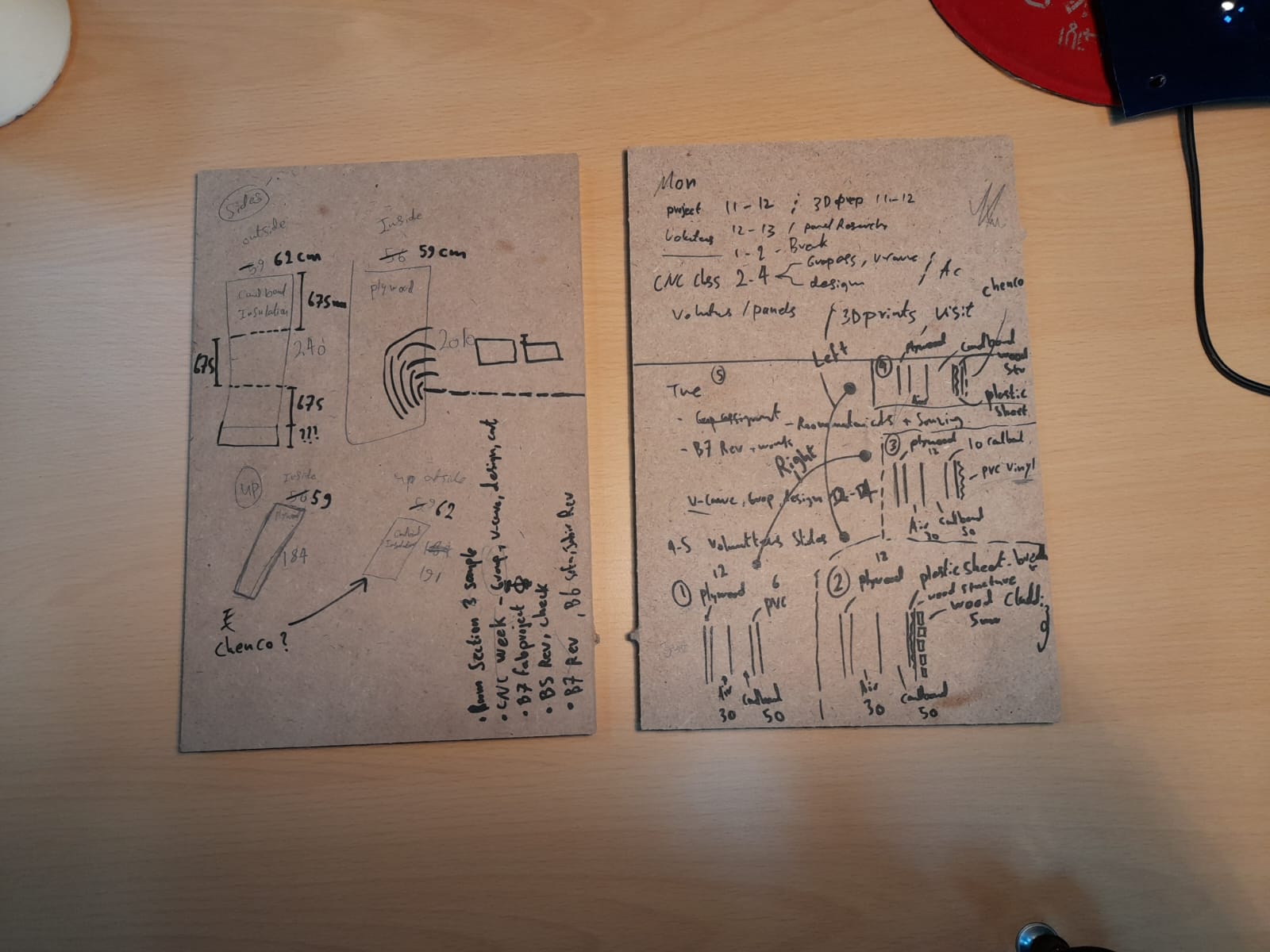

Creation of 1st panel prototype¶

Combined of our initial research, we have reached that our first panel and first type of materials we would like to test are PVC, Carboard and Plywood. the reasoning behind these material is that we wanted to acheive what we initailly stated in the summery while adding other factors like availibity and within FabLab reach to manufacture a panel with said material.

External Layer¶

The choice of material for the external layer was PVC as it check most of the boxes in our mind, as it is waterproof, cost effective, available, easily recyclable.

The thickness of the PVC in this panel is 6.7 milimeters

Middle Layer (Insulation Layer)¶

For insulation we have decided to choose Cardboard as it is a great insulator, highly flexible, light weight and cost-effective.

The thickness of the Cardboard in this panel is 2.5 centimeters

The thickness of the Cardboard in this panel is 2.5 centimeters

Interior Layer¶

As for the interior layer we chose plywood, as it is sturdy and high impact resistant.

The thickness of the plywood in this panel is 12 milimeters

The thickness of the plywood in this panel is 12 milimeters

Final Assembly¶

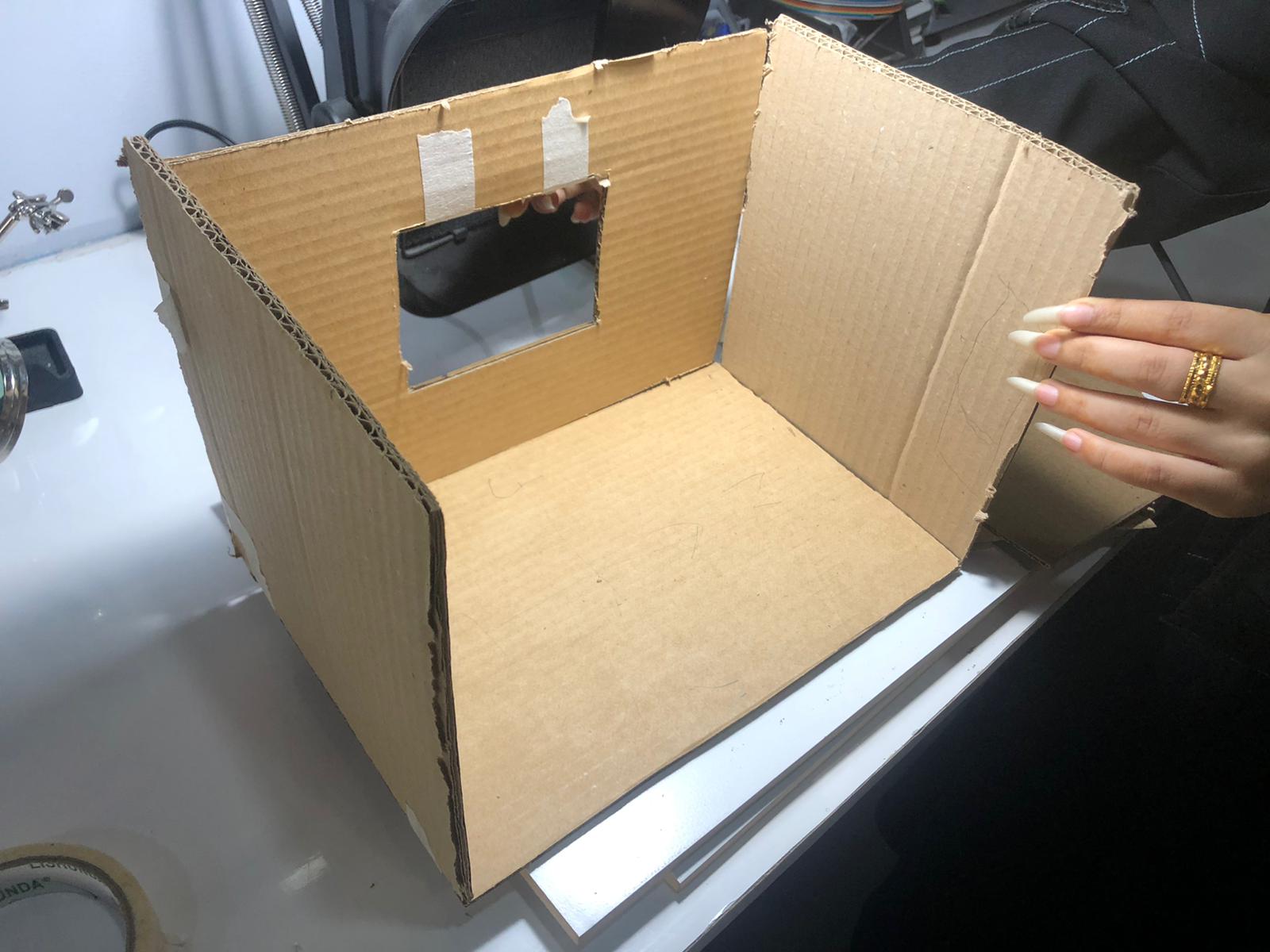

General shape exploration¶

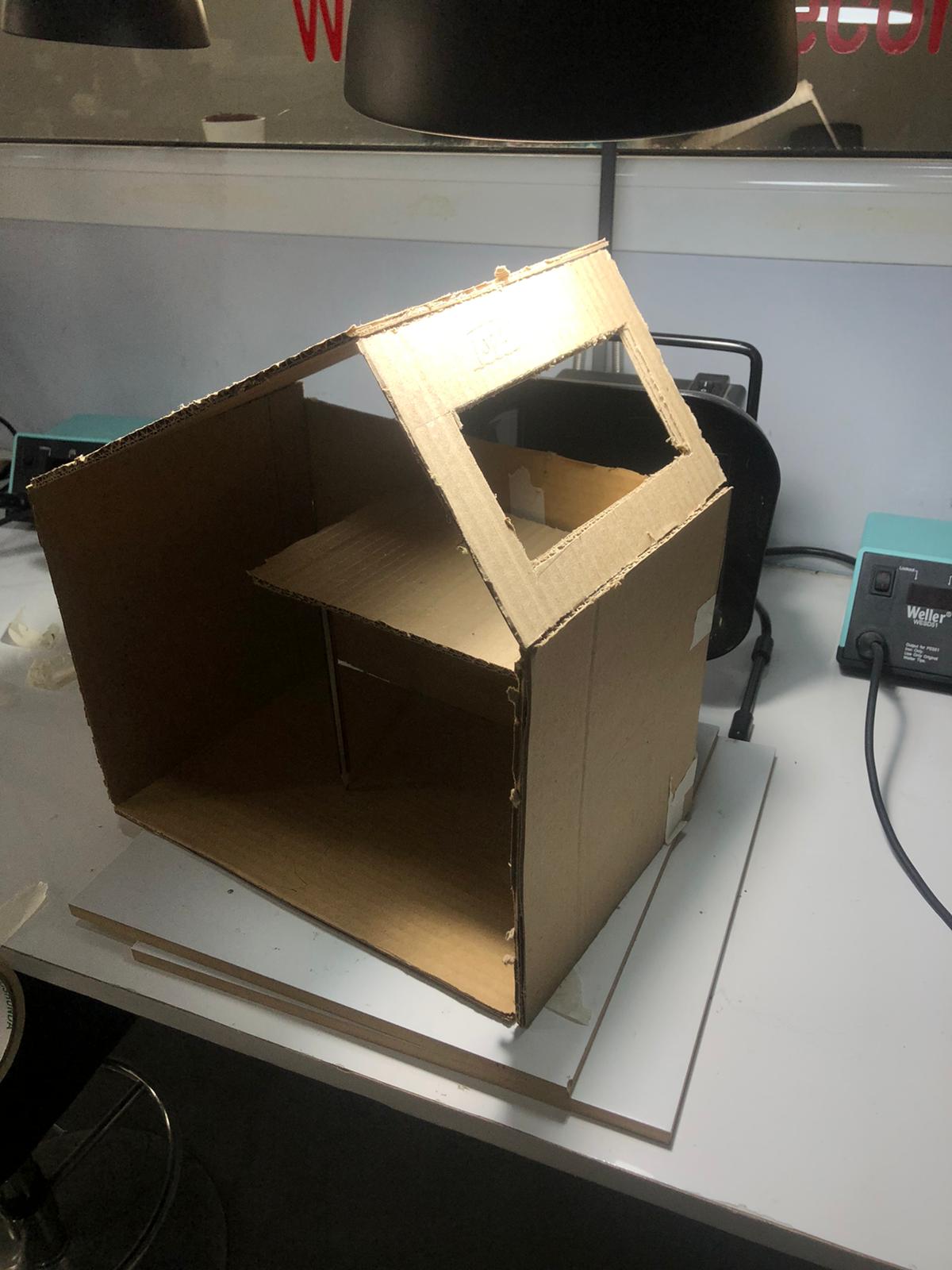

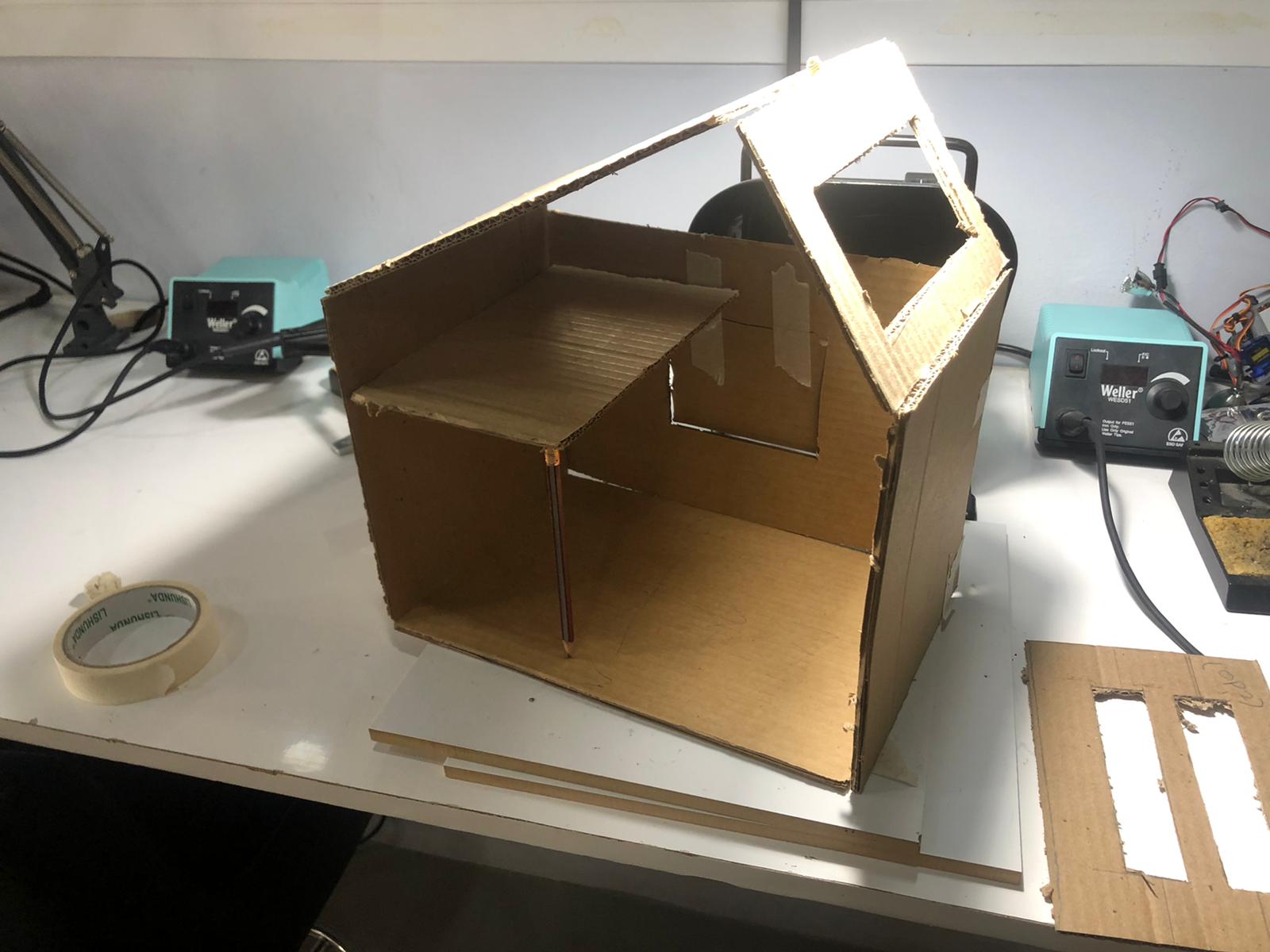

Initally we made our first prototype model with cardboard scaled down to 1:10 with two options of windows and bed position to test how would sunlight enter the SHEL when the sunlight is on a 90 degree angle (Noon). Based on passive solar design

Roofless

1st option Bed

1st option Window & 1st option bed position

2nd option Window & 1st option bed position

2nd option Window & 2nd option bed position

How to test cladding materials?¶

What are the variables in which we will compair our panels with are they () ?

- In this video below this person use the thermal camera to test wet walls, ceilings, and construction materials.

- In this website we found 8 tests that applied on Bricks.

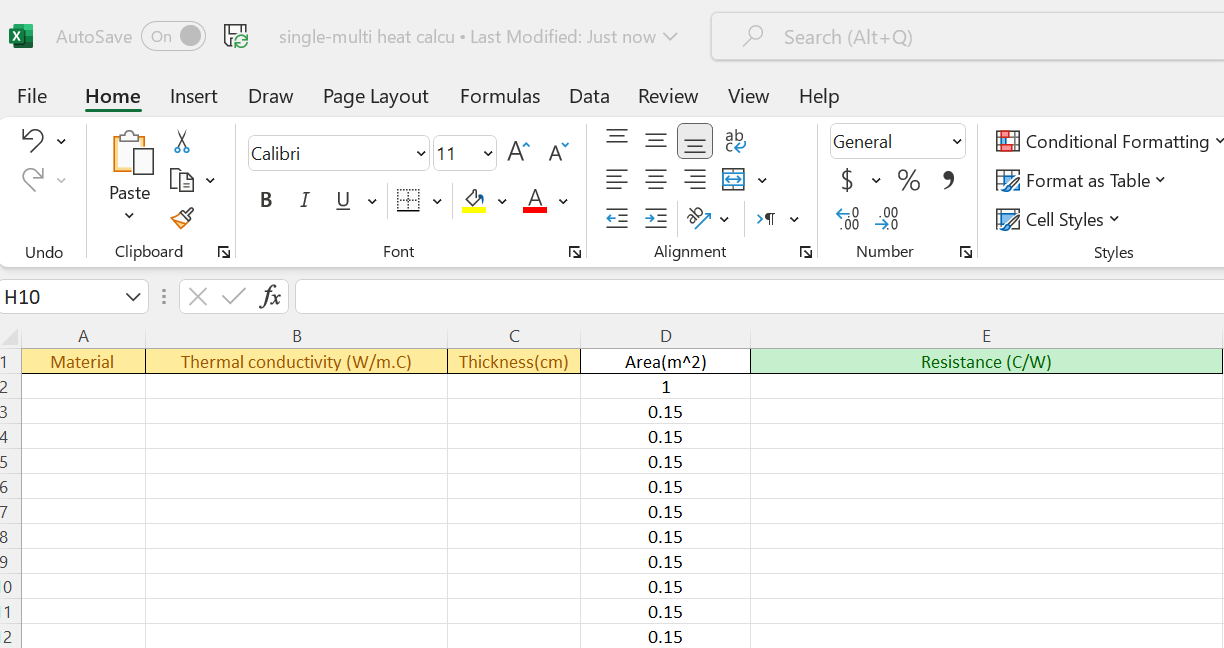

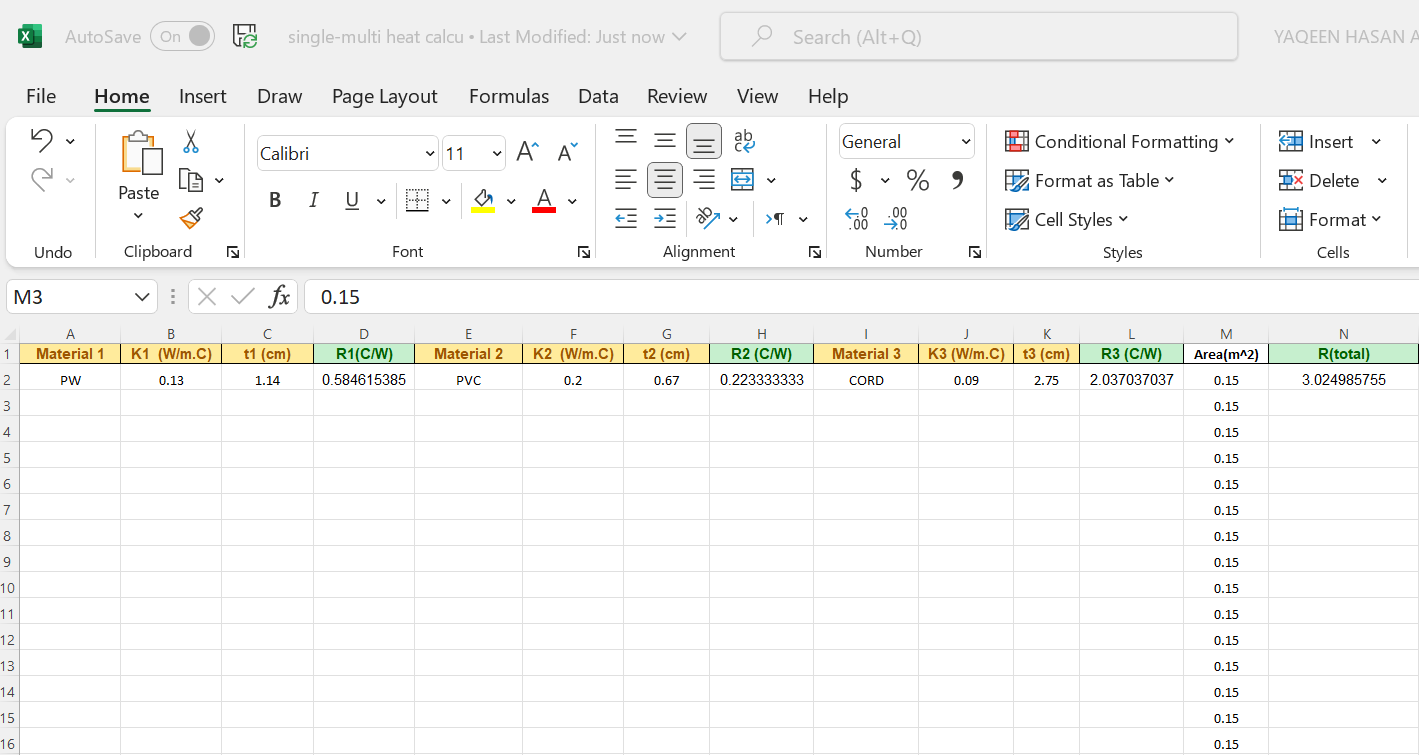

Research about “Thermal Conductivity”¶

We want to be able to calculate the thermal conductivity before creating the panel. This will help us to choose the best panel before spending time in designing and fabricating the panels.

- First, We found the formula “Thermal Conductivity”:

- Then we try to calculate the thermal conductivity manually also by using excel for one layer.

- For multi layer.

- where K is constant for the materials:

Plywood: 0.13 W/(m·K).

Cardboard:0.05 to 0.12 W/(m·K).

PVC: 0.2 W/(m·K).

-

The important part of this research to take a look for the conditions in Bahrain during the thermal conductivity and the materials that can we use also some calculation.

-

We found this PDF book Thermal Insulation In Bulidings there is a lot of equations and forms that may helps us to find the specific heat transfer. Created by Bahrain sustainable energy authority.

-

Some useful resources:

Link 1 Created by Bahrain ministry of work.

Link 2.Created by Bahrain Ministry of municipalities affairs and agriculture.

Link 3 Created by Bahrain electricity and water authority.

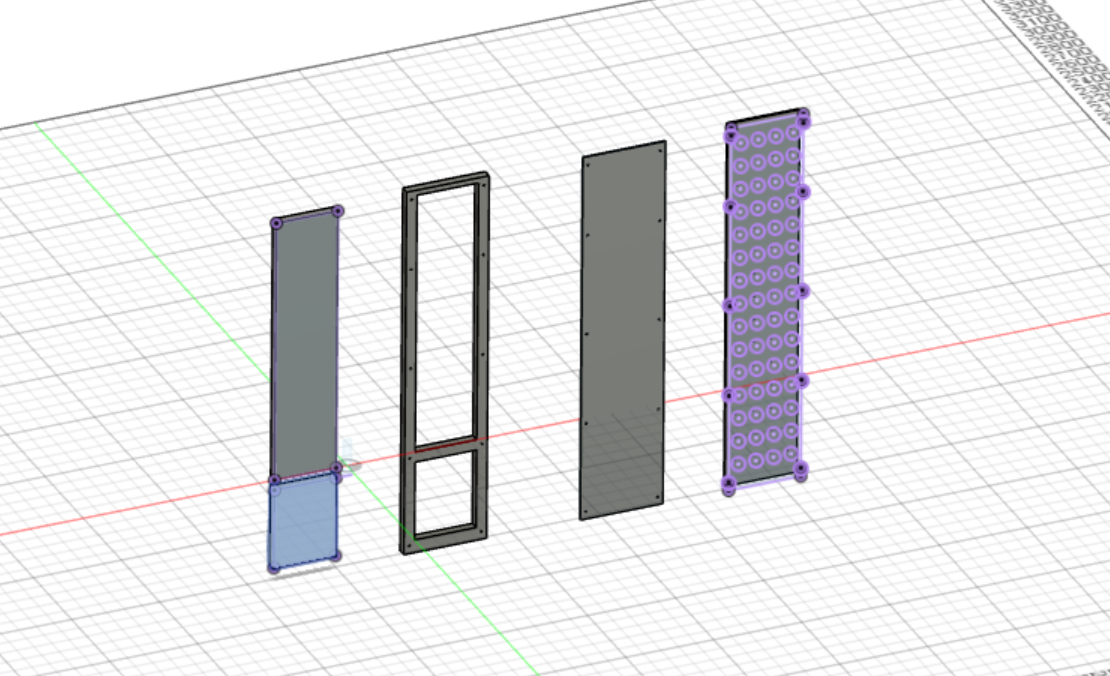

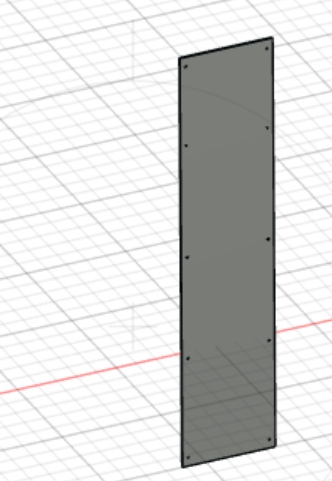

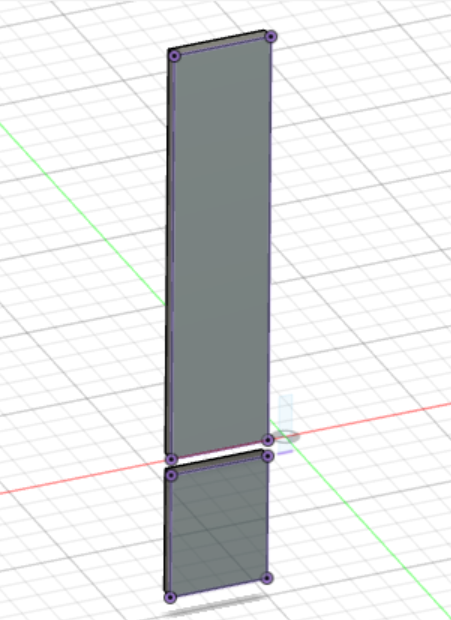

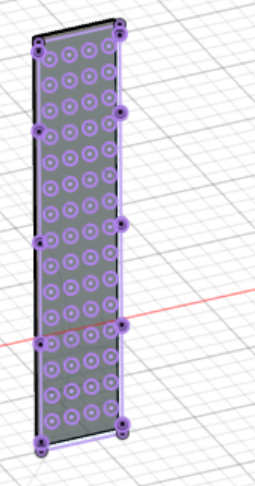

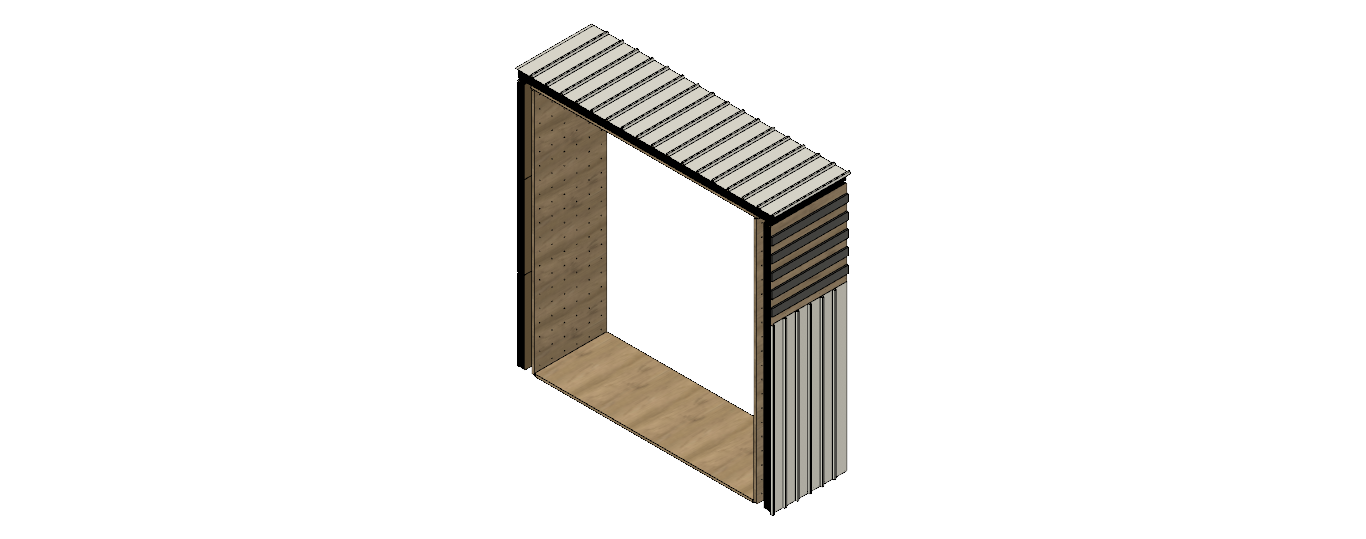

Test Panel design¶

-

After that we started designing a panel using fusion360:

-

The three layers.

- External Layer : PVC.

Middle Layer “Insulation Layer” : Cardboard.

Interior Layer : Plywood.

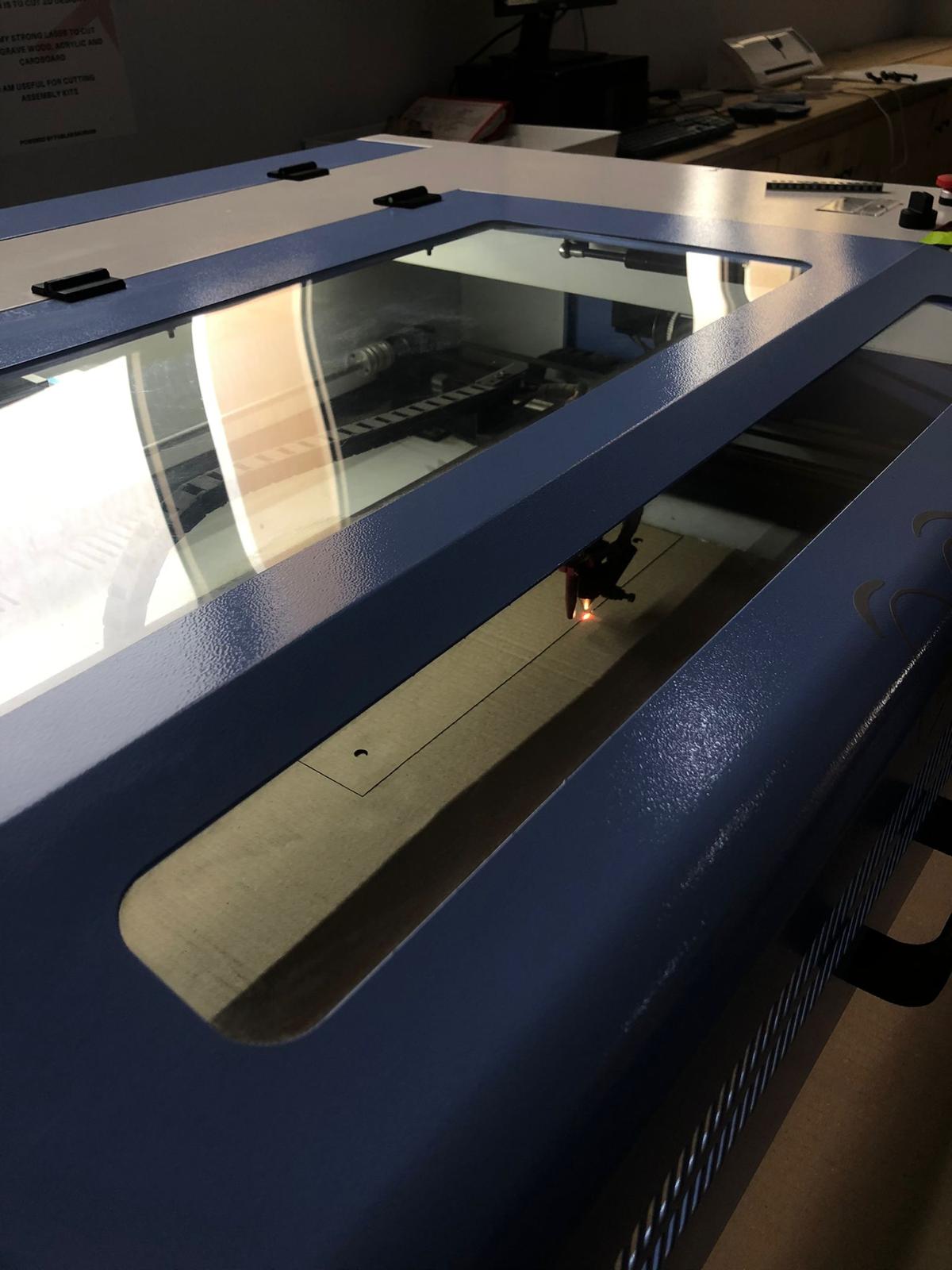

Test Panel fabrication¶

- Start to cut the interior layer

4 panels prototypes¶

The layers plan with thickness based on this paper Click Here

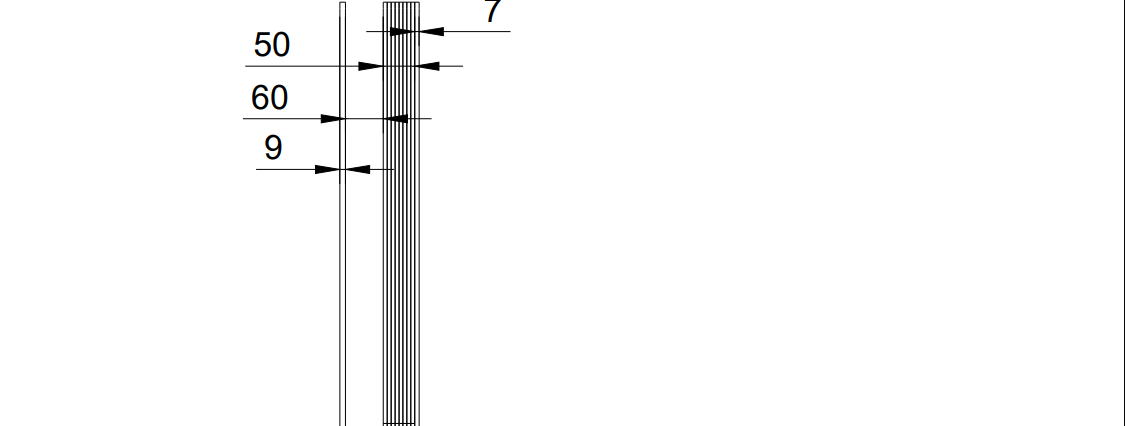

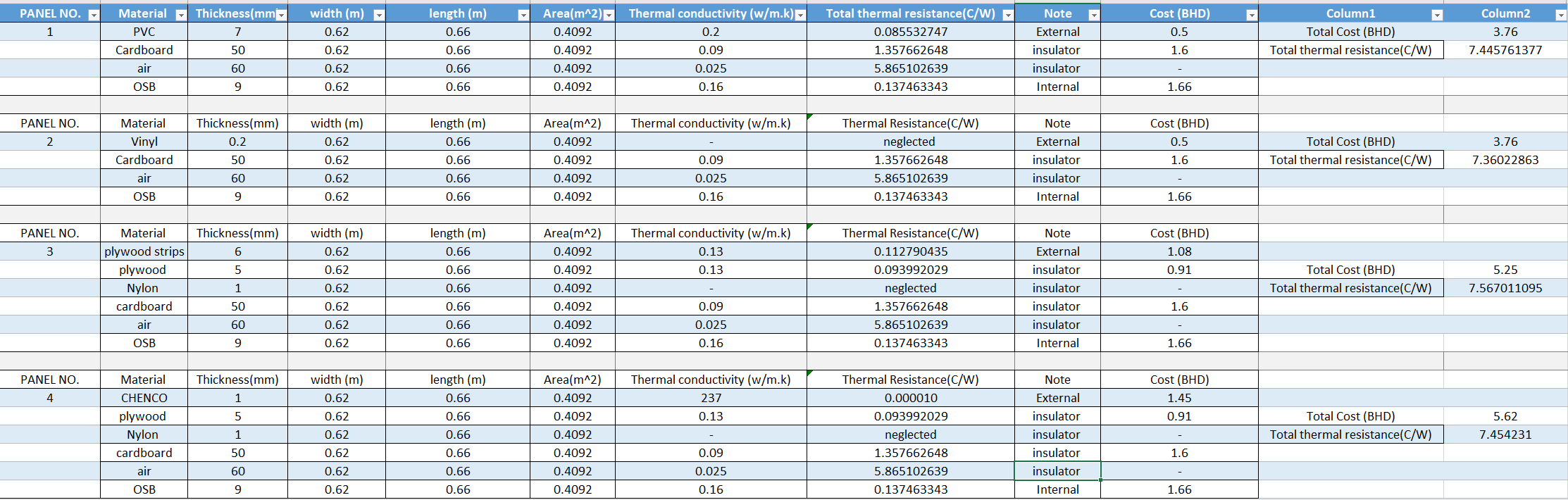

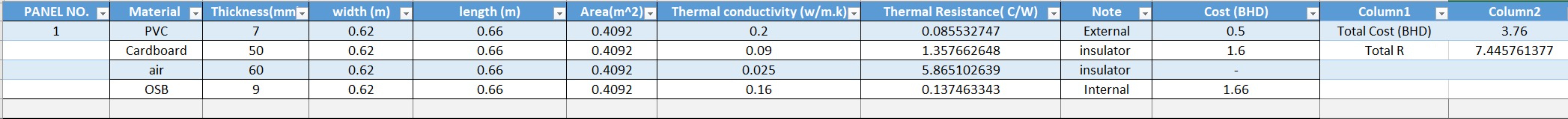

Panel Number 1:¶

the panel consist of the following material:

PVC with thickness of 7mm,

Cardboard with thickness of 50mm,

an air gap with 60 mm,

an OSB With thickness of 9mm.

As you can see in the table the total thermal Resistance of this panel is 7.4458 C/W and the total cost is 3.76 BHD.

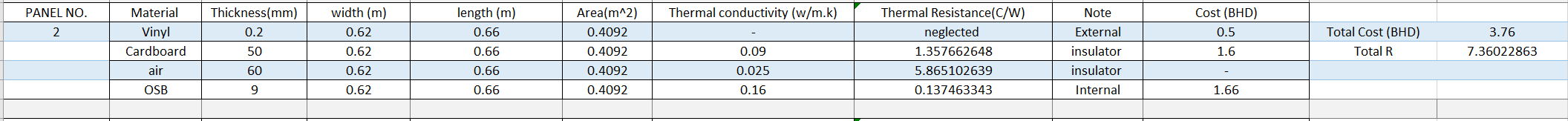

Panel Number 2:¶

the panel consist of the following material:

Vinyl with thickness of 0.2 mm,

Cardboard with thickness of 50 mm,

an air gap with 60 mm,

an OSB With thickness of 9 mm.

the panel consist of the following material:

Vinyl with thickness of 0.2 mm,

Cardboard with thickness of 50 mm,

an air gap with 60 mm,

an OSB With thickness of 9 mm.

Here the thermal resistance of vinyl was neglected to ease the caluclation.

As you can see in the table the total thermal Resistance of this panel is 7.360 C/W and the total cost is 3.76 BHD.

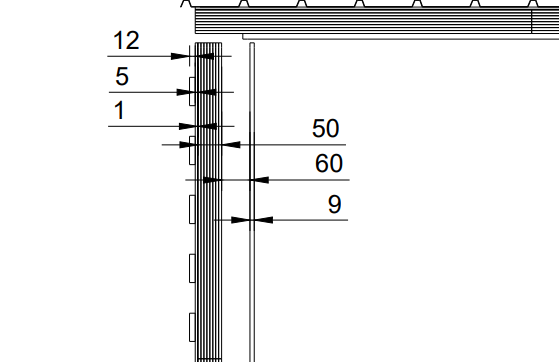

Panel Number 3:¶

the panel consist of the following material:

plywood strips of thickness 6mm,

plywood sheet of thickness 5mm

nylone of thickness 1mm,

Cardboard with thickness of 50mm,

an air gap with 60 mm,

an OSB With thickness of 9mm.

Here the thermal resistance of naylon was neglected to ease the caluclation.

As you can see in the table the total thermal Resistance of this panel is 7.567 C/W and the total cost is 5.25 BHD.

Panel Number 4:¶

the panel consist of the following material:

Chenco of thickness 1 mm,

plywood sheet of thickness 5mm,

nylone of thickness 1mm,

Cardboard with thickness of 50mm,

an air gap with 60 mm thickness,

an OSB With thickness of 9mm.

Here the thermal resistance of naylon was neglected to ease the caluclation.

Also here we considered the Chenco to be full sheet without the air gap to ease the calculations.

As you can see in the table the total thermal Resistance of this panel is 7.454231 C/W and the total cost is 5.62 BHD.

Full Assembly¶

Presenting our work¶

Full comprasion Table¶

Click here to download the excel file That calculate Thermal Resistnace

Click here to download the excel file That has a comprasion between the four panels

Comment on the results¶

The most cost effective pannels are panel 1 and 2 although panel 3 and 4 has more thermal resistance but it is extrermly small amount of difference and the reason of the higher cost in panel 3 and 4 with almost the same amount of thermal resistance is because of plywood, since plywood is releativly expensive than other materials.

future plans¶

- Explore more materials.

- Verify the calculated thermal resistance using practical experiments. For example applying heat from one side and measure the heat transmission against time using a heat sensor and a timer. We need to serch for the methods of testing the walls in terms of test variables ( Insulation, recyclability, weight, fire resistance, cost, … ).

- Compair our results against standard walls such as the ones mentioned in: Link 1 Created by Bahrain ministry of work.

Link 2.Created by Bahrain Ministry of municipalities affairs and agriculture.

Link 3 Created by Bahrain electricity and water authority.

General Action Plan during the 3 months¶

- Understand and research keywords and glossary and how to apply each “Hamad”

- History + Look for previous successful examples in energy-efficient mobile buildings “Mohammed”

- Define the problem and understand it “Mohammed”

- Bahrain weather conditions during the year ( When it is humid, hot, cold, sun direction, wind direction, Angles for Solar-Responsive Design ) “Yaqeen”

- Cladding layer’s names and functions ( Interior, Insulation, Exterior ) “Hamad”

- Optimal overall shape design of the space ( Clerestory roof angle, passive and active design ) “Hamad”

- Understand cladding materials’ properties ( Resistant to…, strength per area, weight, ) “Yaqeen”

- Experimental panel 50cm x 30cm (Prototype 1) ”All”

- List the test variables to test the cladding options “How can we compare each panel to another” ( Insulation, recyclability, weight, fire resistance, cost, … ) “Ayman”

- How to test cladding materials ( using what tools can we measure the test variables ) “Yaqeen” Accelerated weathering chamber physical room … Packages accelerated test The weather controlled room has a pump, LED, Fan, Smoke generator, heater to simulate weather https://www.techeblog.com/tempescope-is-an-actual-weather-simulator-box-for-your-home-including-rain/ https://www.oddee.com/item_99475.aspx

- Best practice for fitting the panels to the structure ( Screws or joints or … )

- Piping options inside the layers

- Different options of cladding materials Research a small scale option to test next (Prototype 2) (Sketch, Design,CNC, Laser) Observe and improve the design

- Different options of cladding materials Research a small scale option to test next (Prototype 3) (Sketch, Design,CNC, Laser) Observe and improve the design

- Different options of cladding materials Research a small scale option to test next (Prototype 4) (Sketch, Design,CNC, Laser) Comparison table to choose one option or do prototype 5

- Modify the structure shape based on the “Optimal overall shape design of the space research” (Welding and metal work)

- Scale up and fit in the structure

Fusion File¶

Excel File¶

Click here to download the excel file That calculate Thermal Resistnace

Click here to download the excel file That has a comprasion between the four panels

Resources¶

Link 1 Created by Bahrain ministry of work.

Link 2.Created by Bahrain Ministry of municipalities affairs and agriculture.

Link 3 Created by Bahrain electricity and water authority.

Link to thermal resitance calculator

BOM¶

| Qty | Description | Price | Dimensions | Thickness |

|---|---|---|---|---|

| 1 | Plywood | 13 BHD | 1220mm x 2440mm | 12mm |

| 1 | OSB | 7 BHD | 1220mm x 2440mm | 9mm |

| 72 | Cardboard | 14.4 BHD | 62cm x 66cm | 6.25mm |

| 1 | Vinyl | 8 BHD | 60cm x 15m | 0.2mm |

| 1 | PVC | 4 BHD | 122cm x 2440cm | 7mm |

| 1 | Chenco | 5 BHD | 100cm x 200cm | 1mm |

| 1 | Plywood | 5.5 BHD | 1220mm x 2440mm | 5mm |

Team Members¶

Abdulla Albaitam - Digital Fabrication Engineer - Project Leader page

Yaqeen Fardan - physicist Page

Mohammed Tawfeeq - Mechanical Engineer Page

Ayman Yunes - Mechanical Engineer Page

Hamad - Mechanical Engineer Page