6. Large format CNC (computer controlled Machining)¶

Group work¶

For the group work we learnd about the saftey (I will menshiond it in my individula work) and about the machine it self.

We learned about the feed rate and the Rbm,and how they can affect the sizes of the chips and the texture of the piece.

This is the link for our group work:

individual work¶

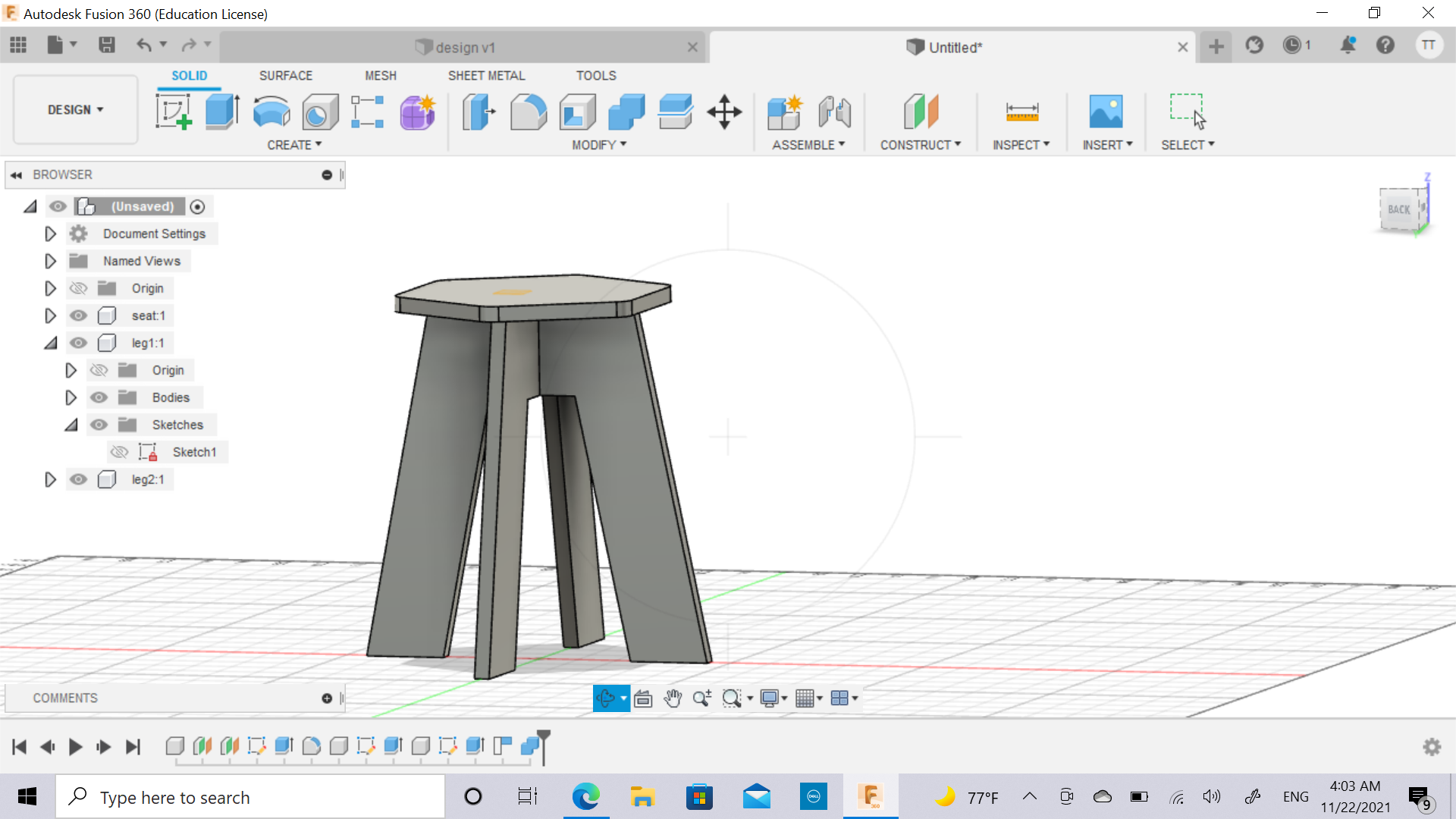

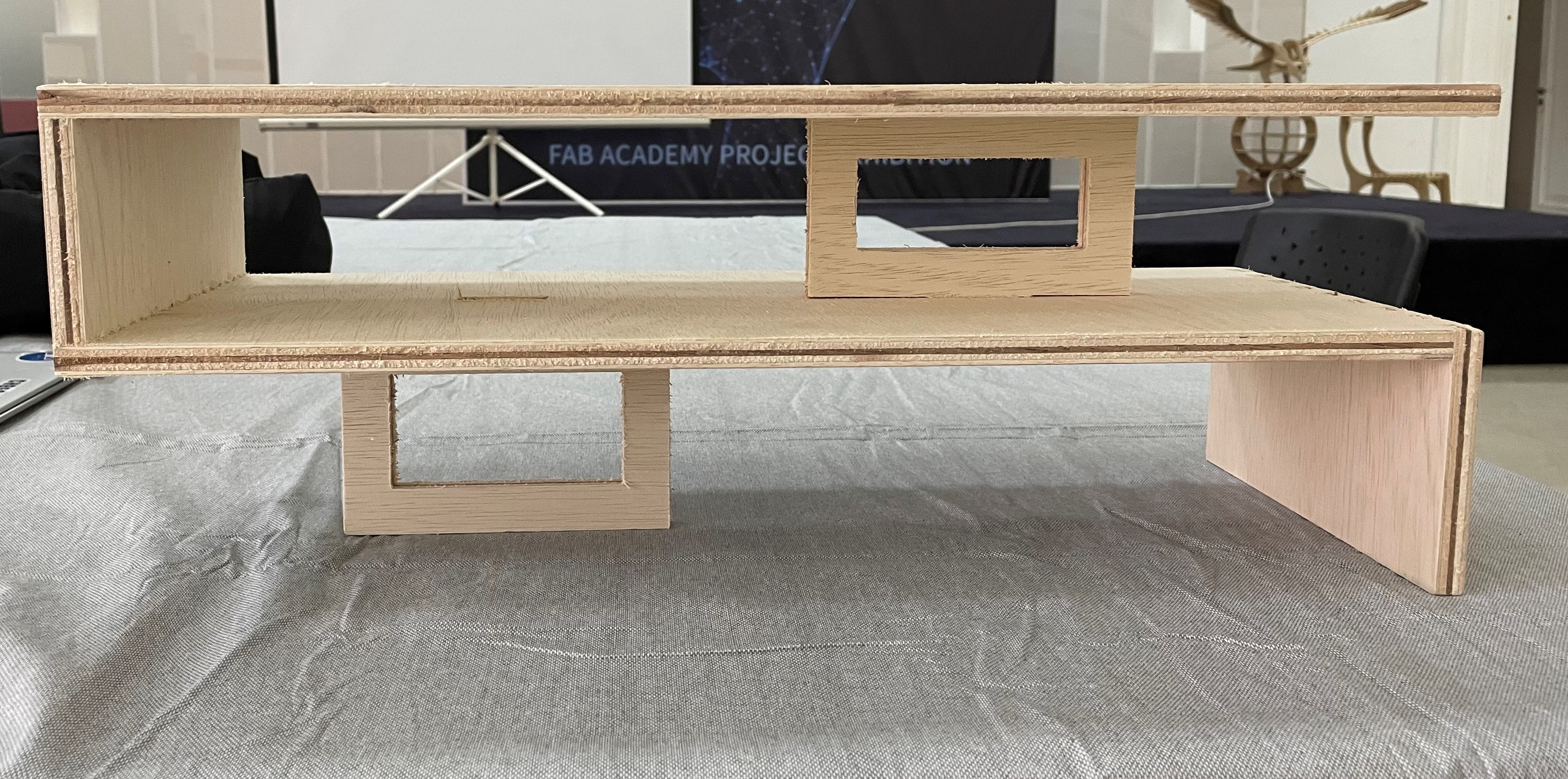

I designed a simple chair to cut it in the CNC.

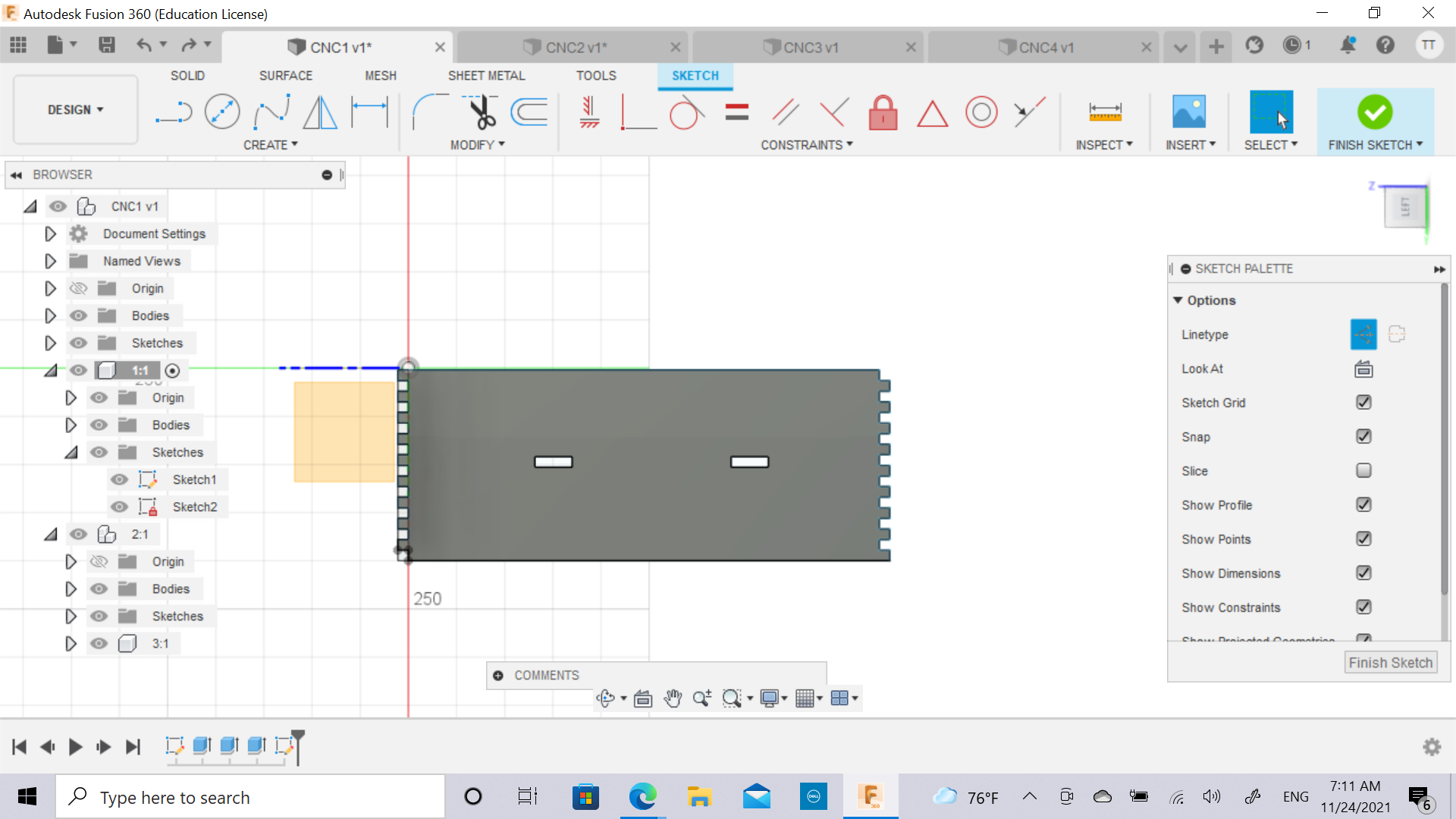

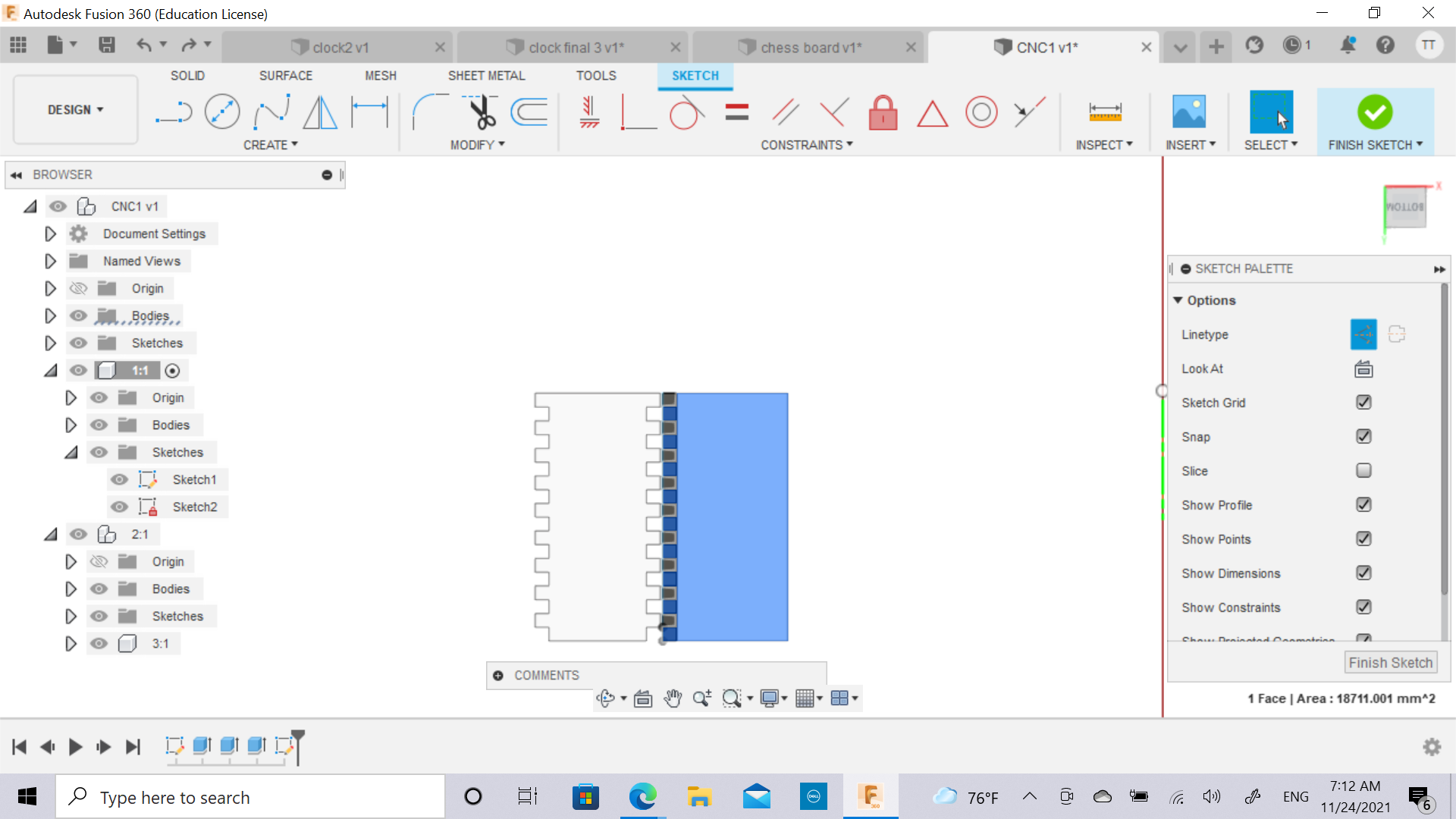

These are the steps that i’ve made in fusion 360.

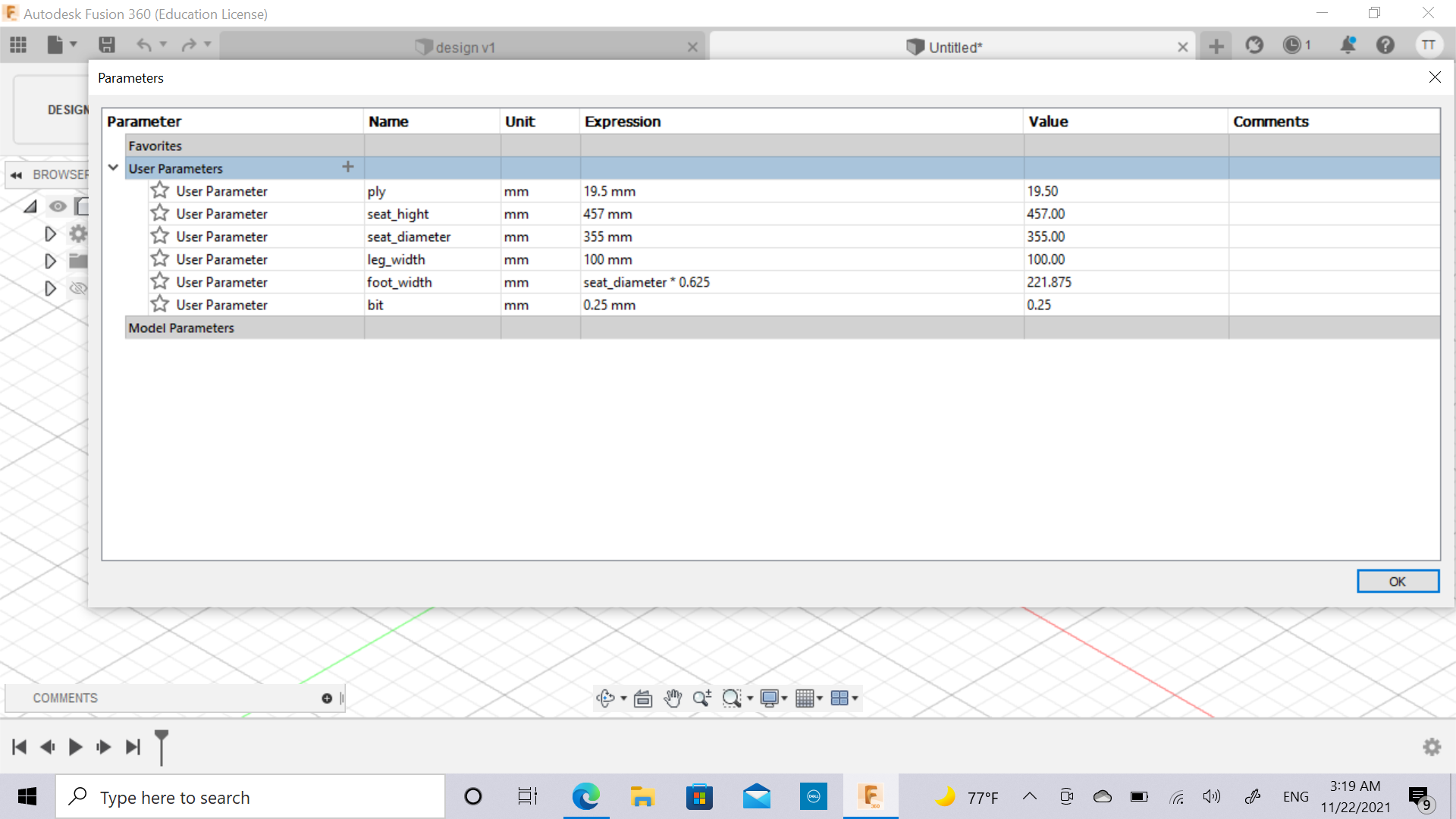

First i set up the parameters.

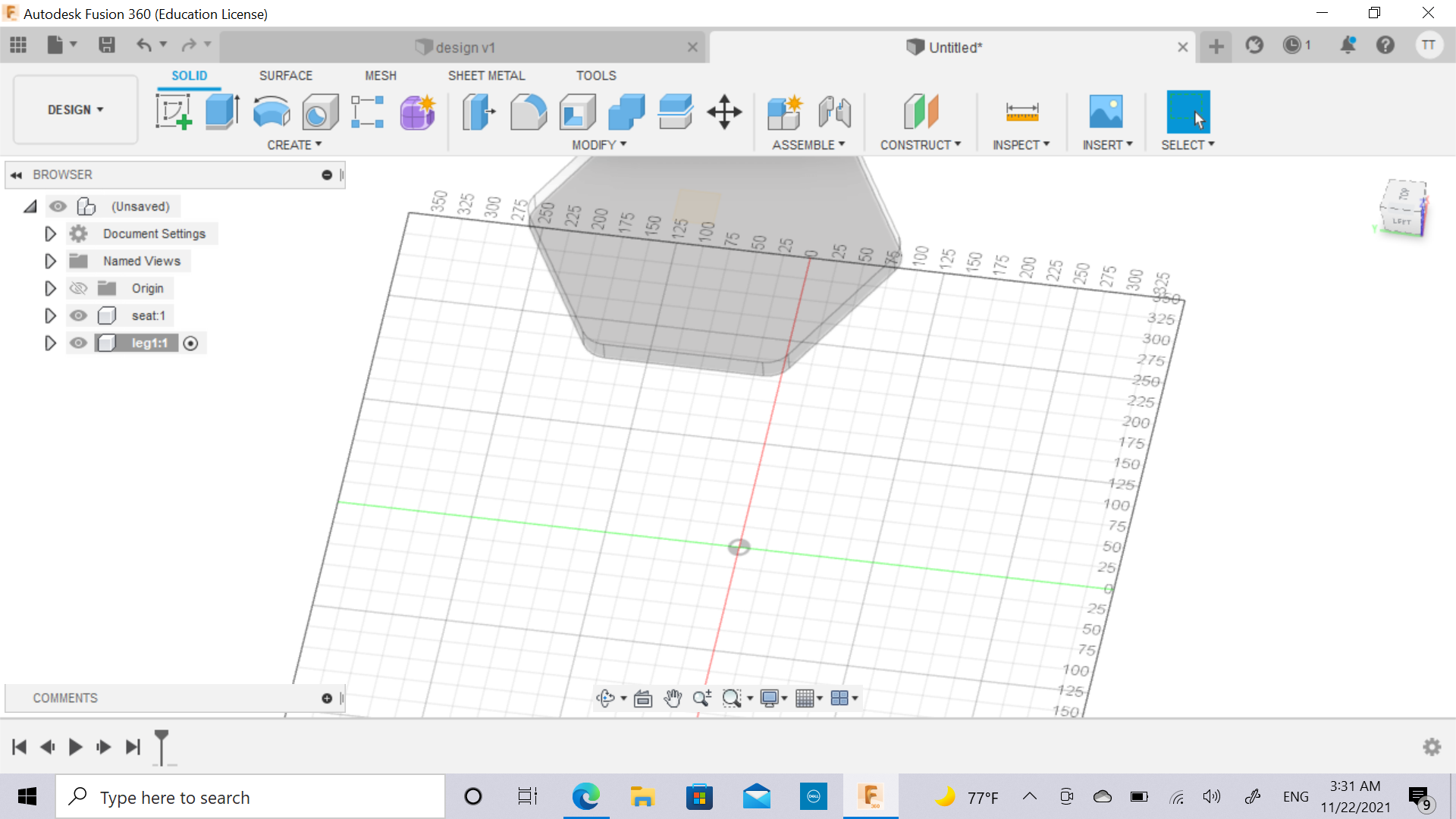

I create the base of the seat

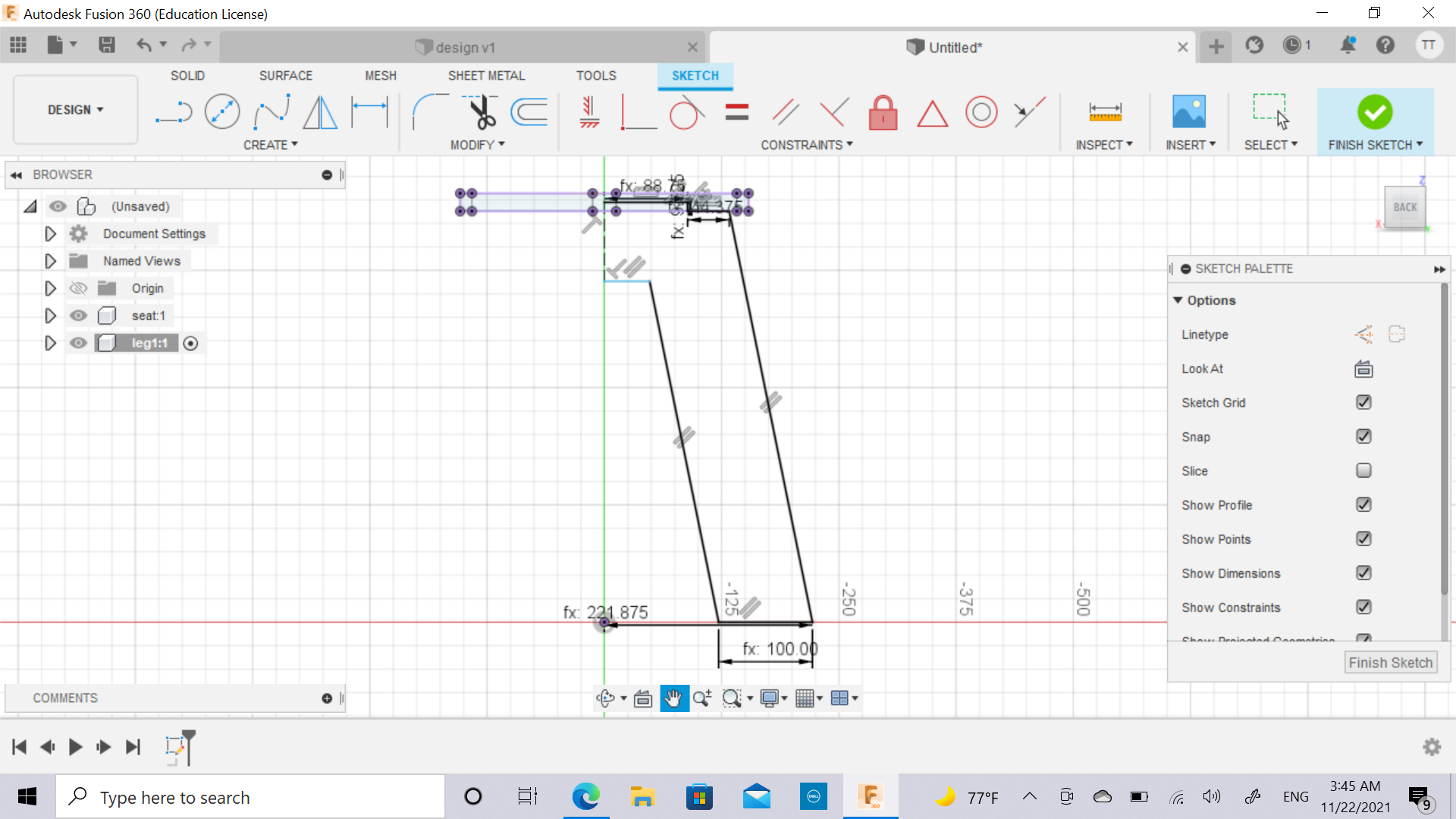

I draw the leg

I edtrude the leg and made another one.

This is the shape that i ended up with

Then, I tried to do another shape.

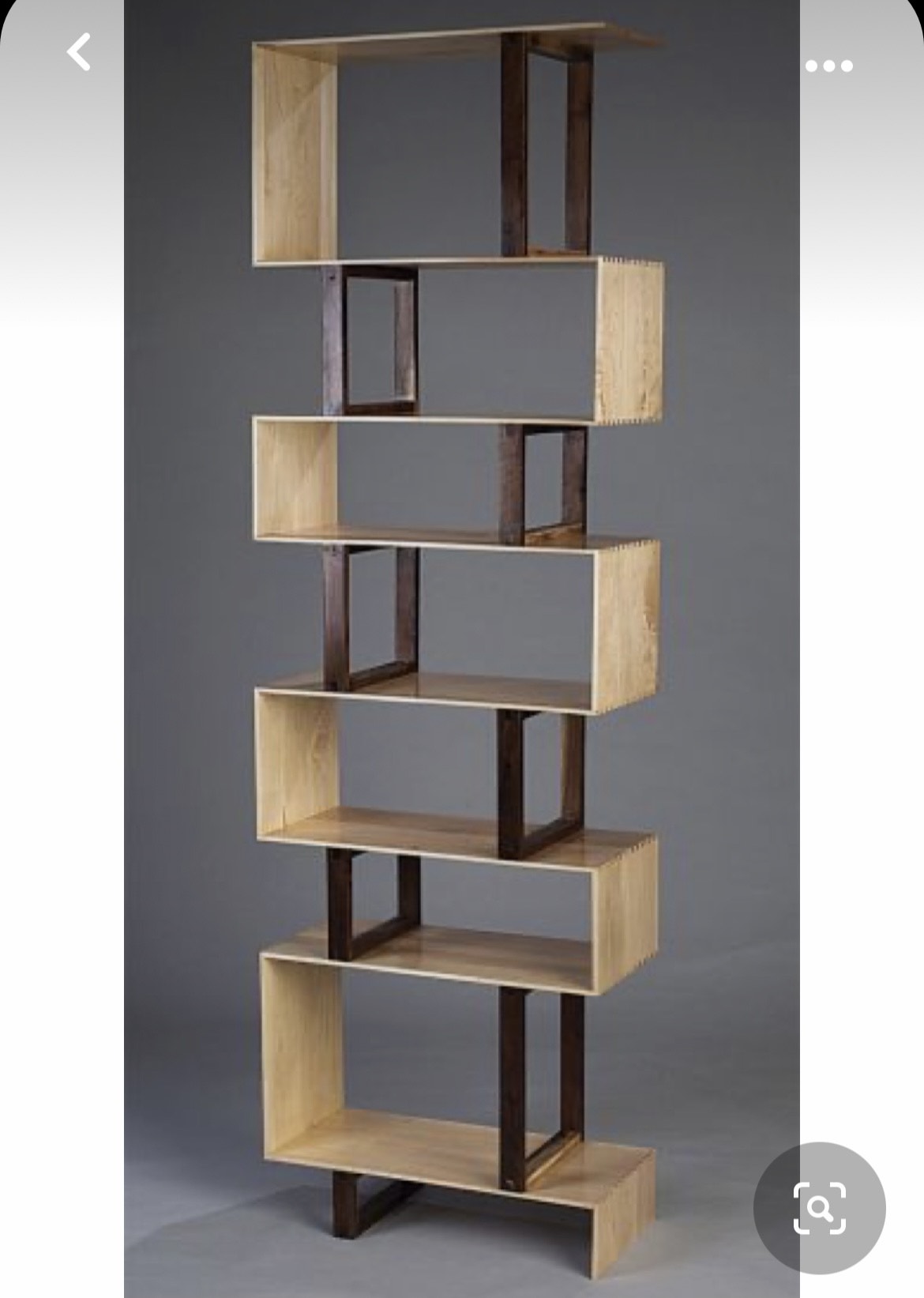

I inspired my design from this picture.

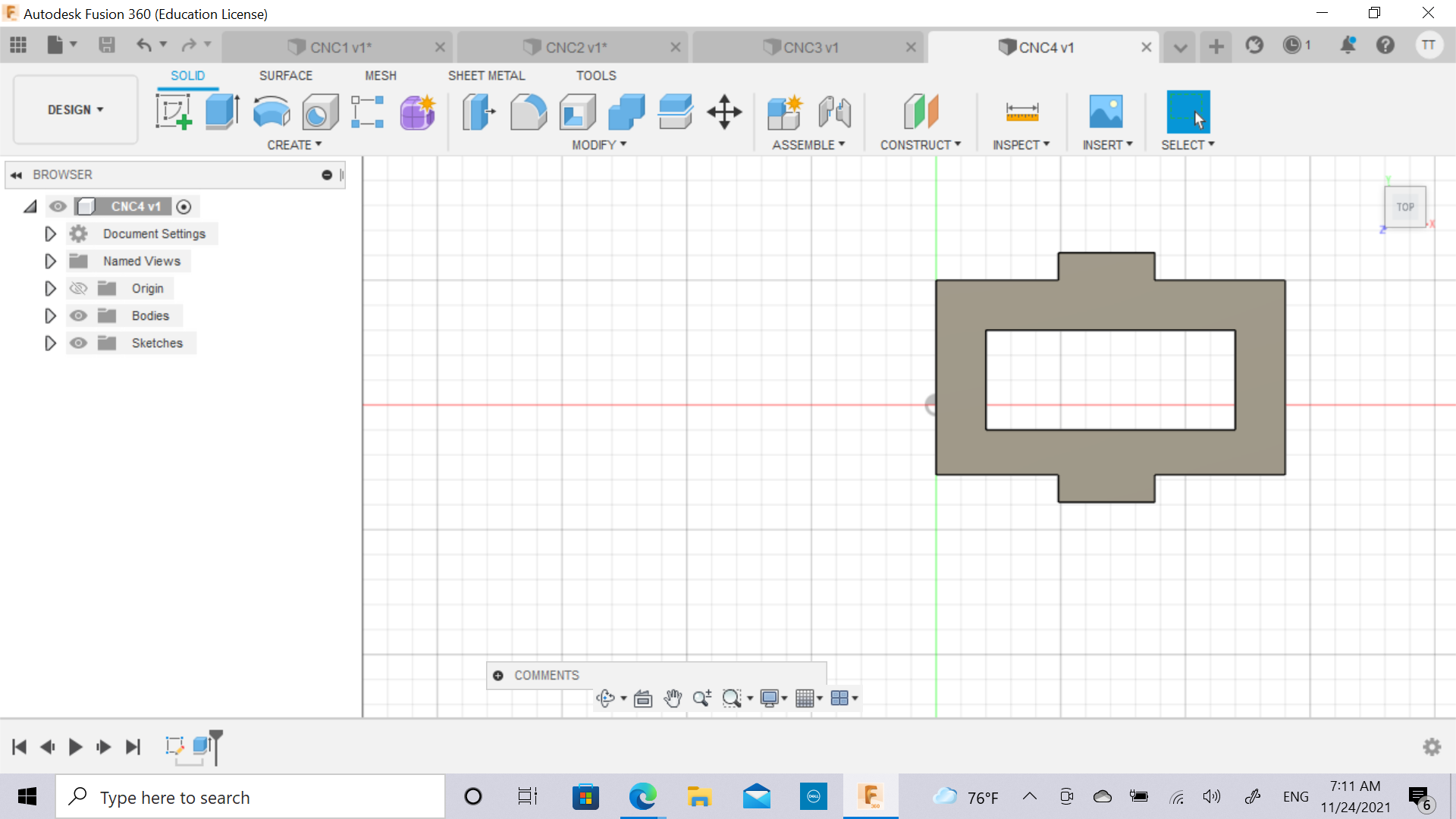

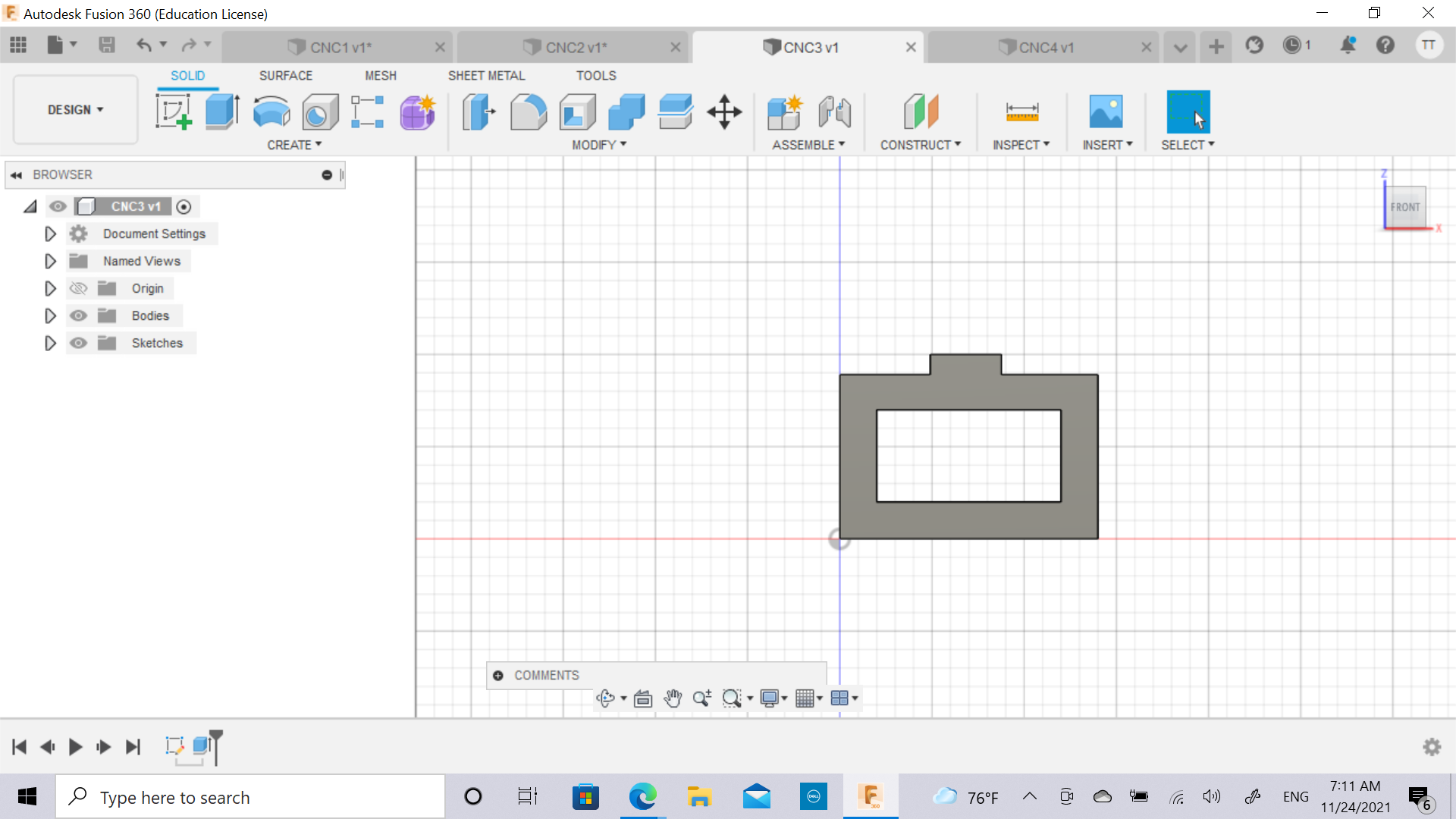

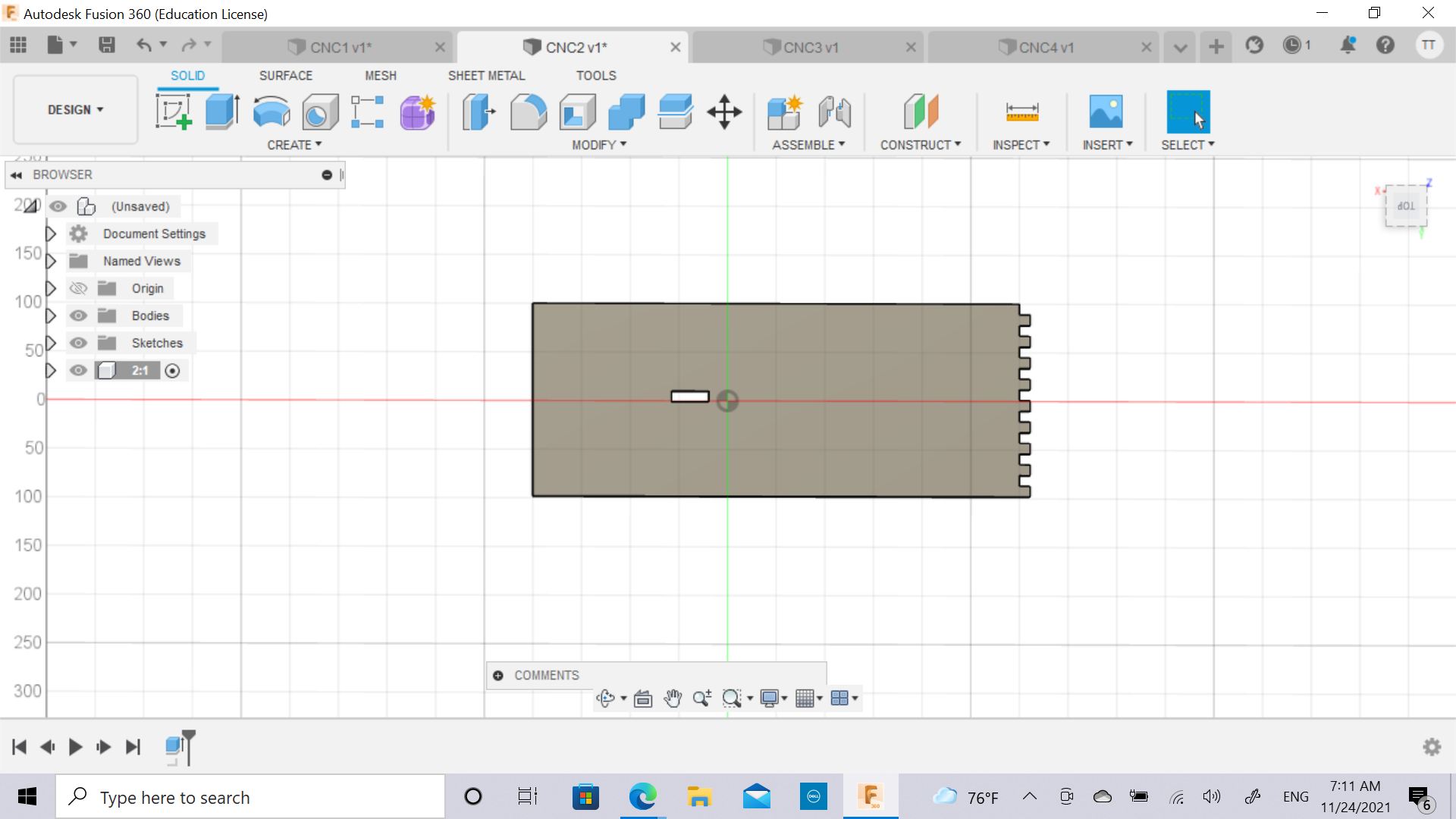

These are the pieces that i create

I wish i had more time to make it taller and added more shelves.

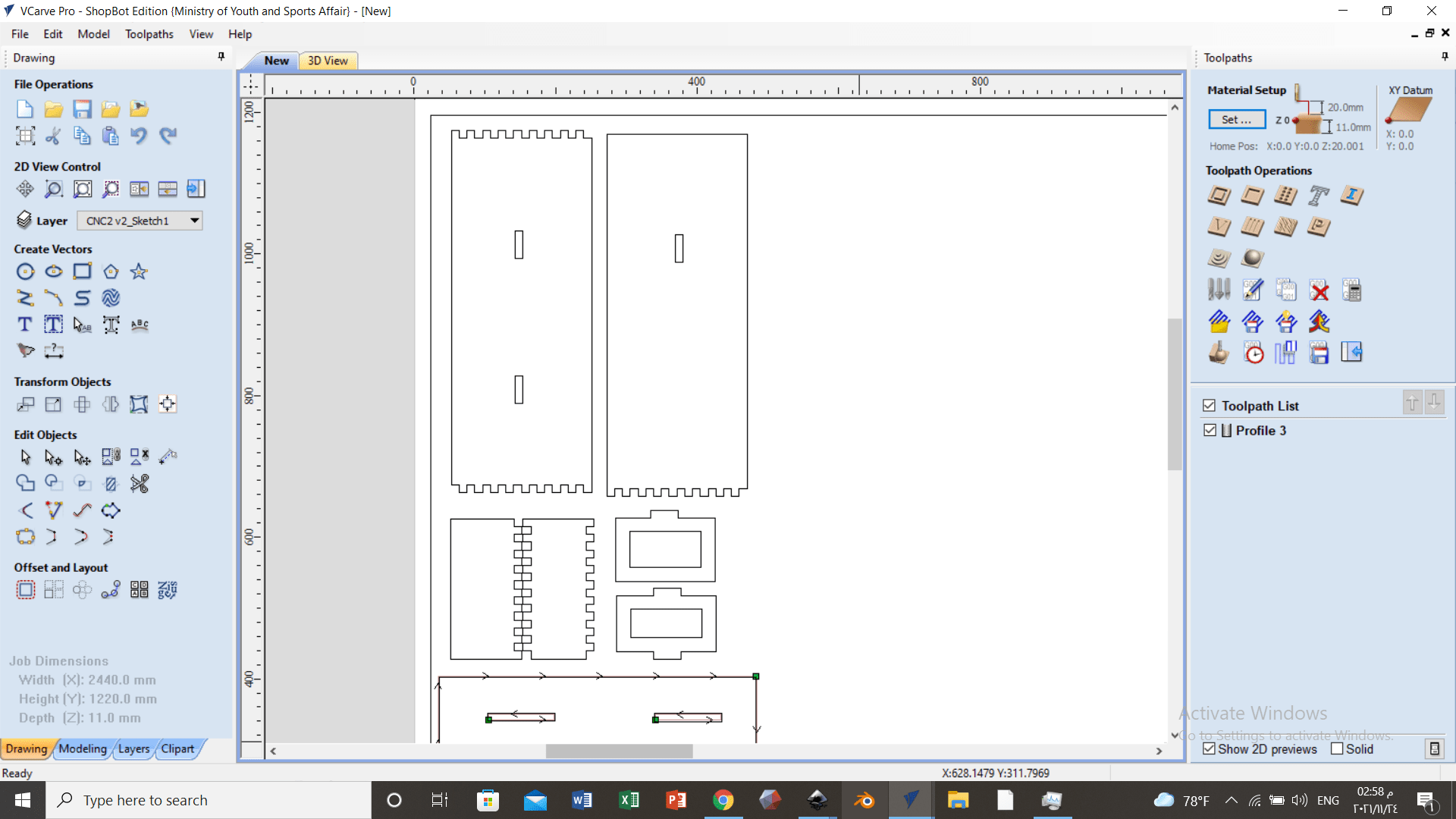

so i completed the piece and i went to the computer of the CNC machine.

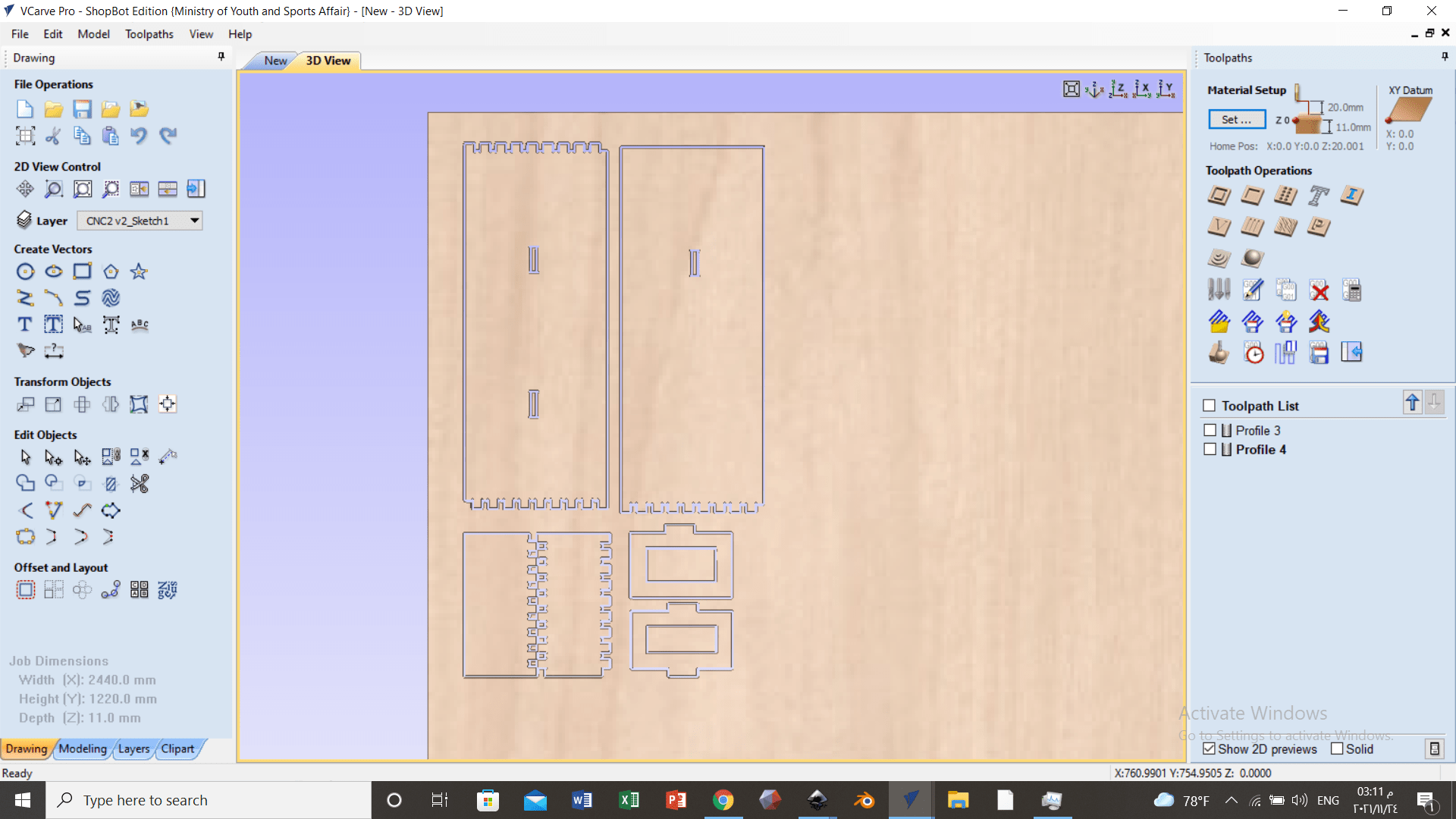

First, i added all of my pieces

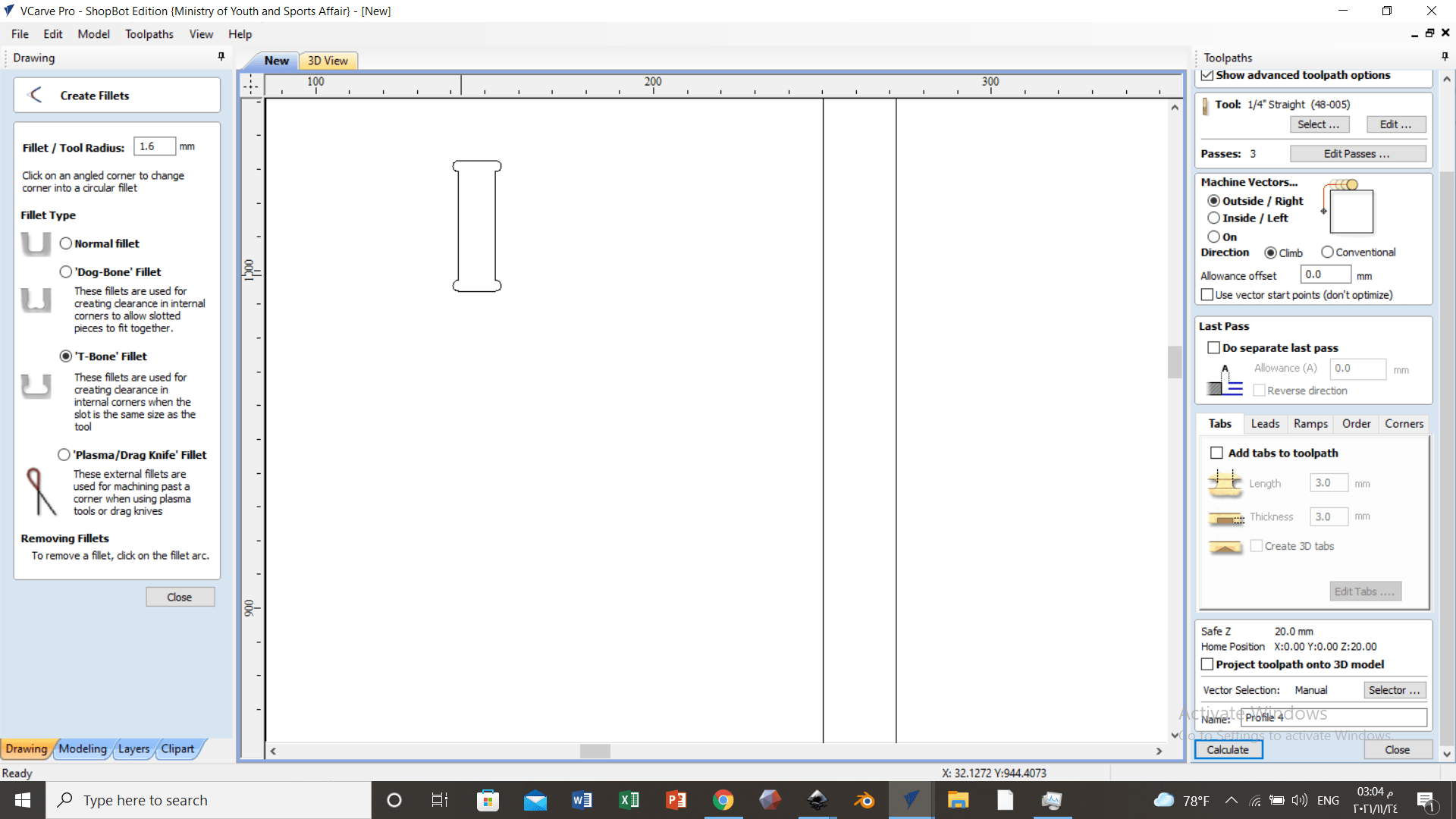

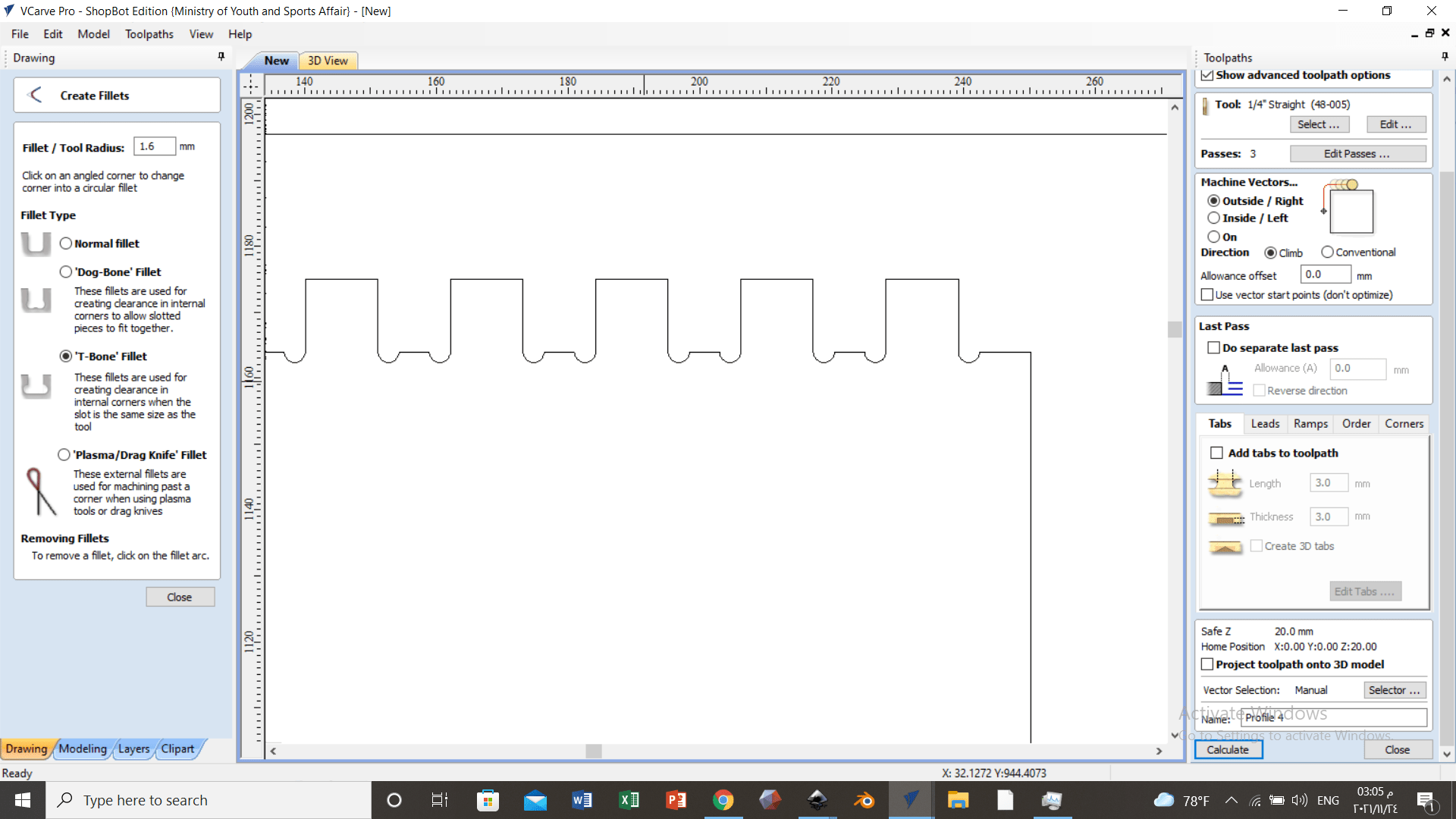

I added the T bone

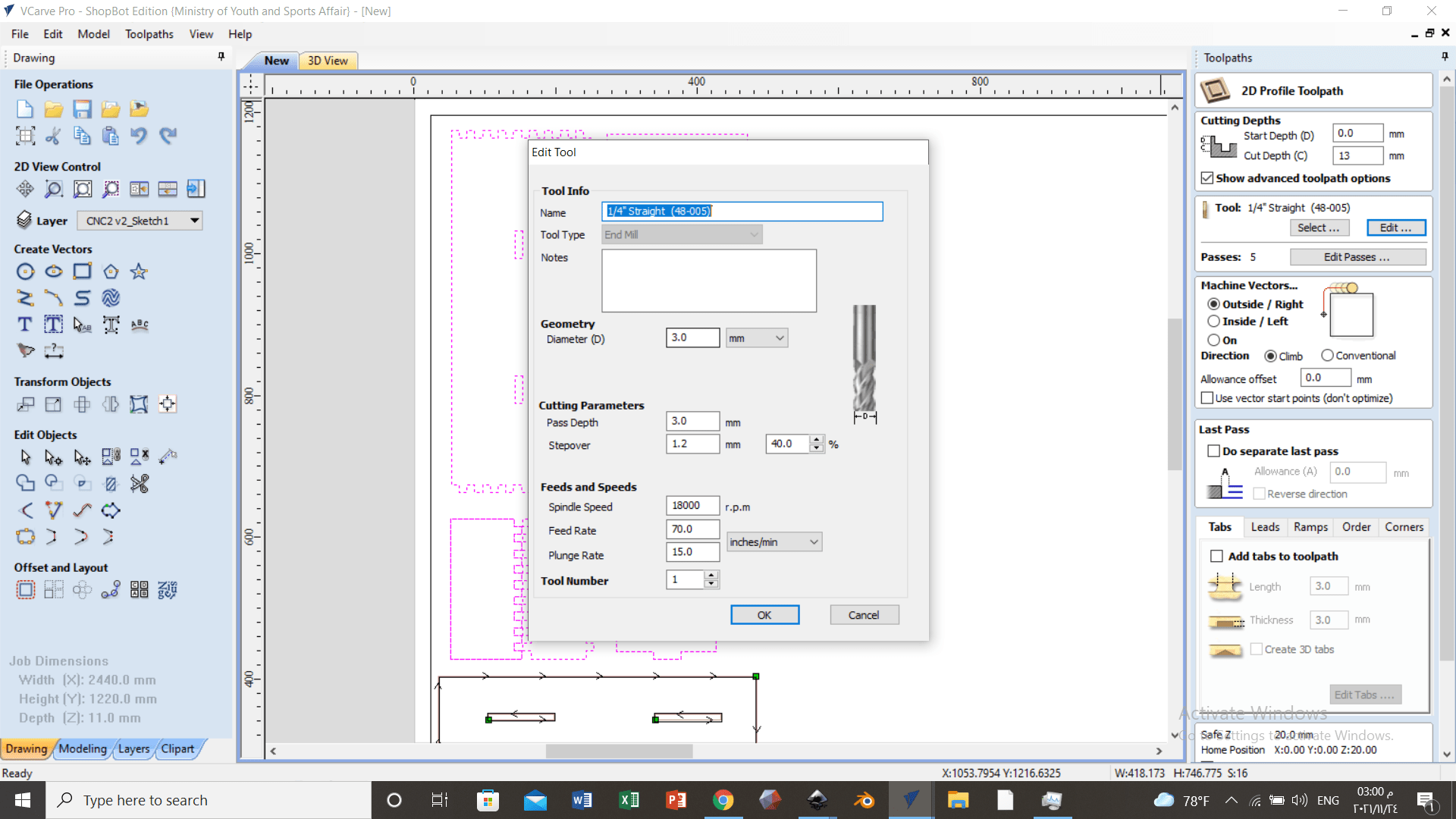

I entered the diameter of the bit and the speed, Feed rate.

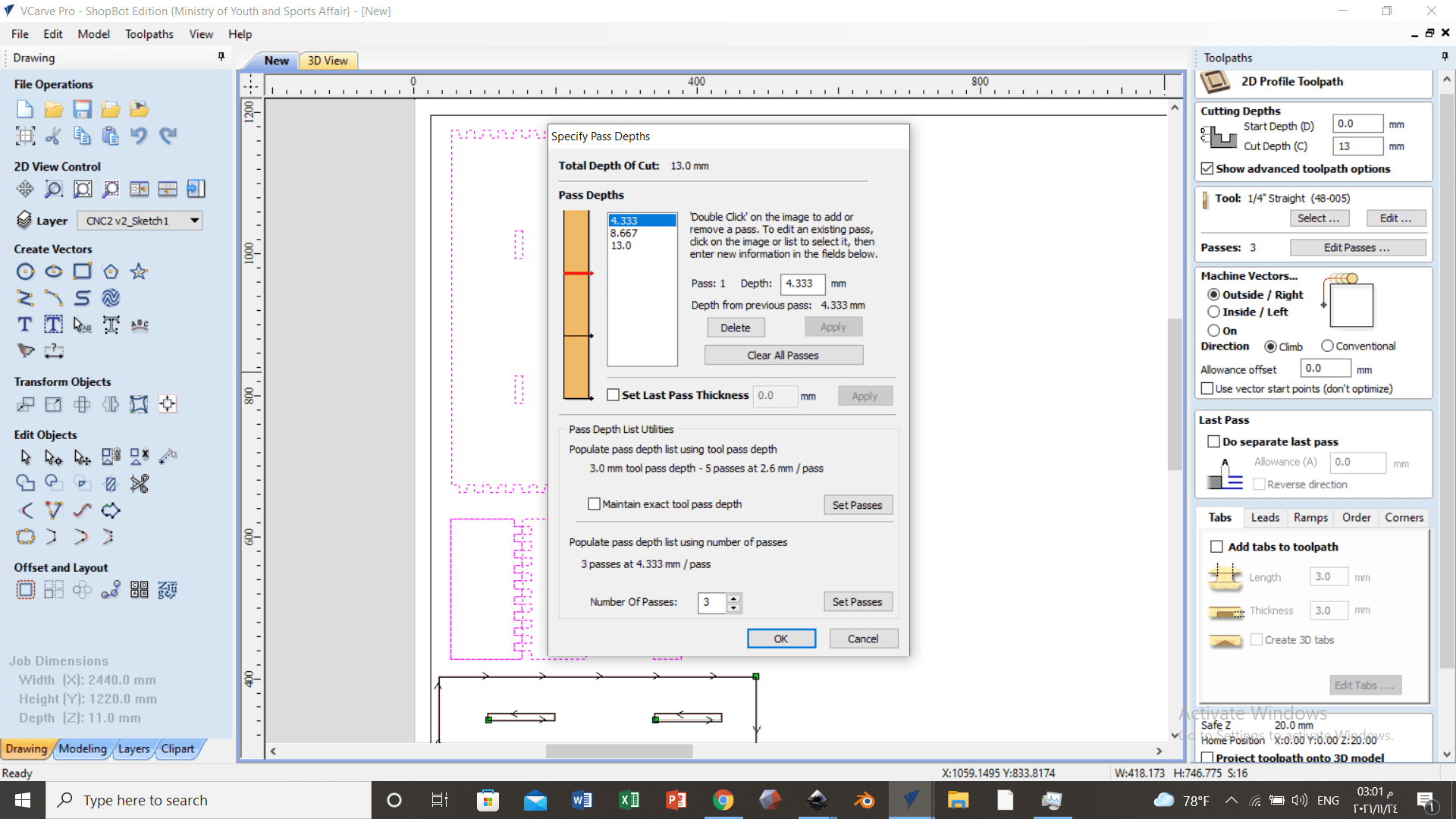

The thickness was 11 mm but we set the depth of the cut to be 13 mm to make sure that it will cut through.

Also I set the machine to pass three time.

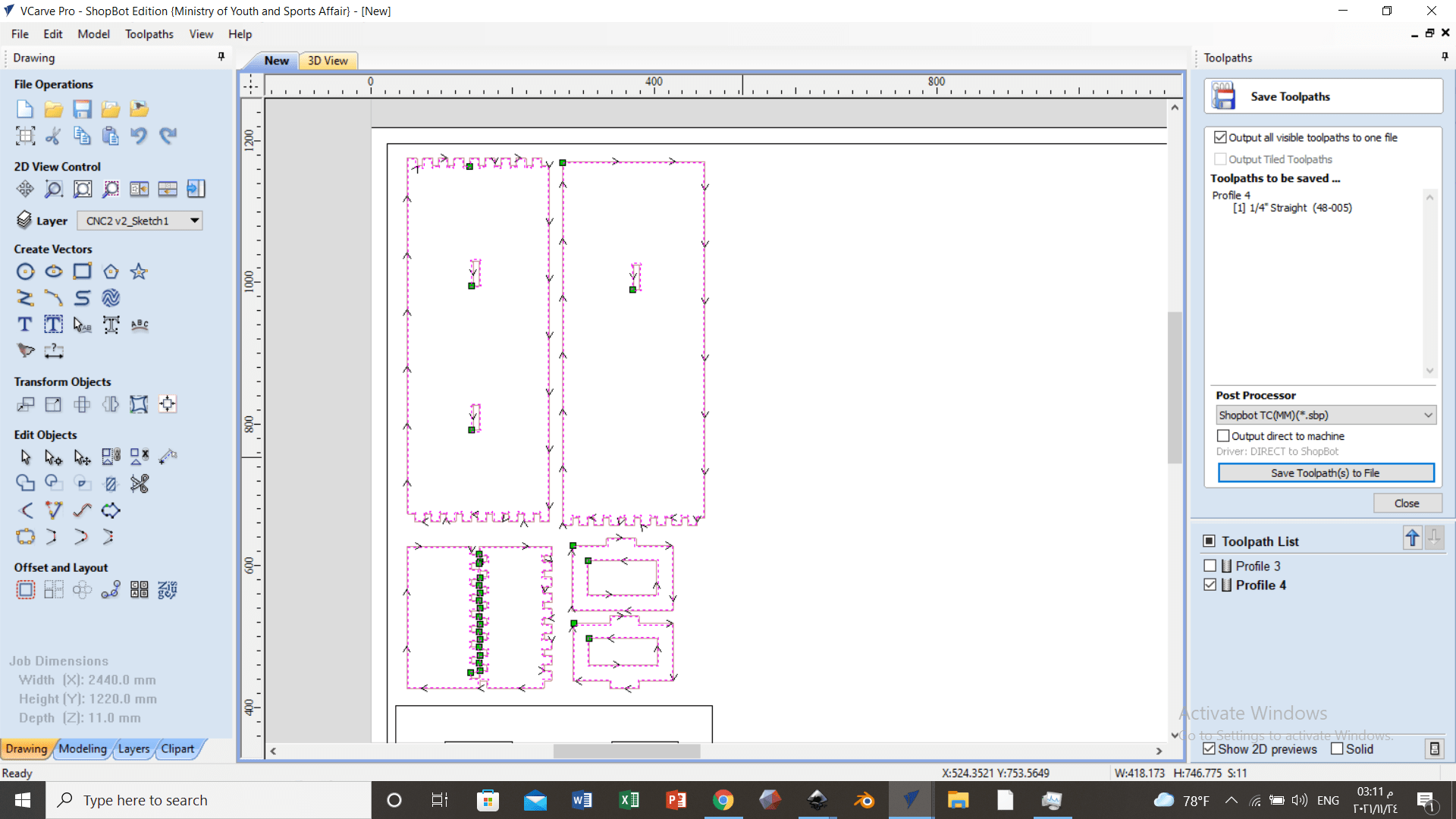

I reviewed everything and set it to be ready.

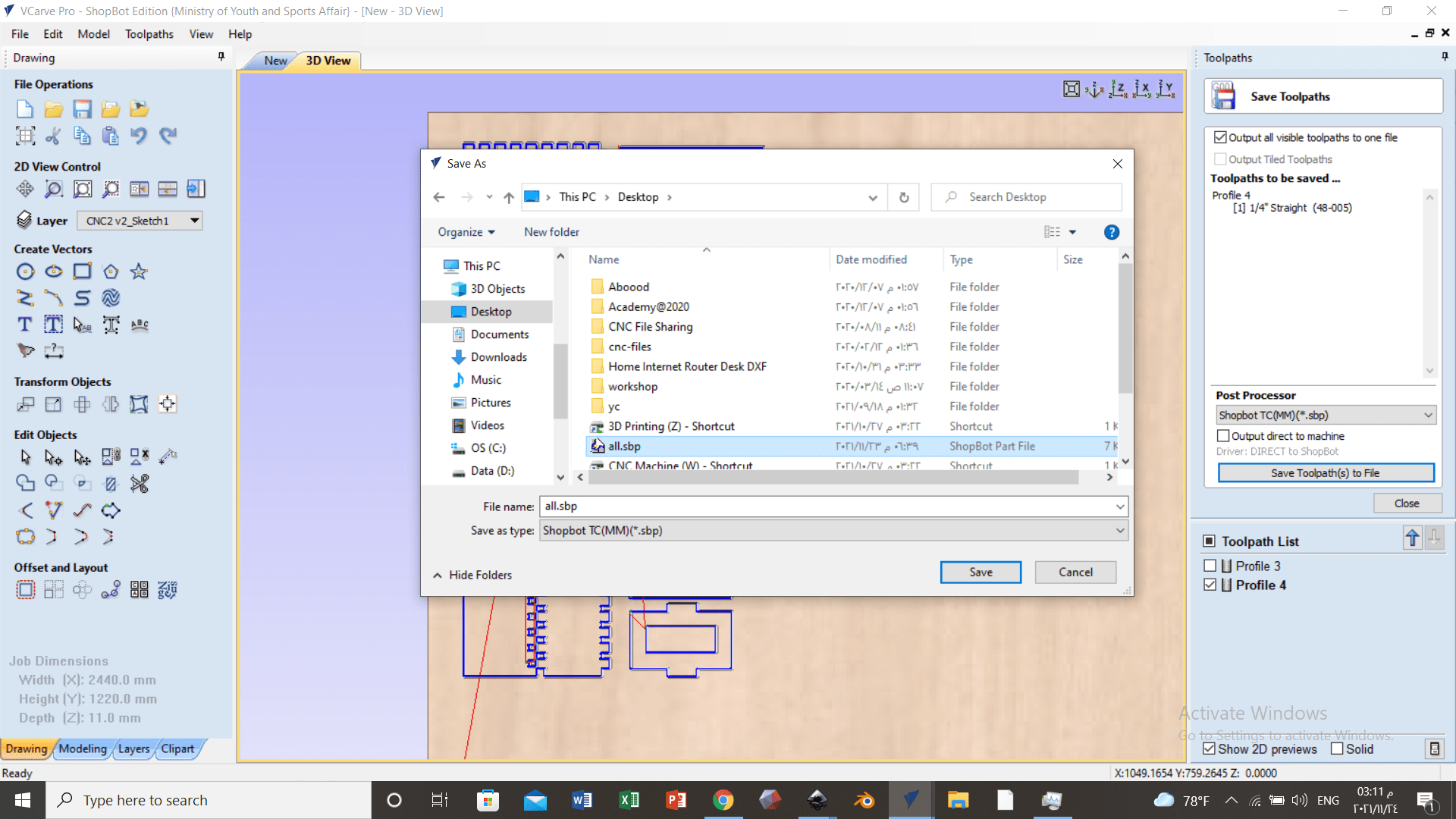

I uploaded the file

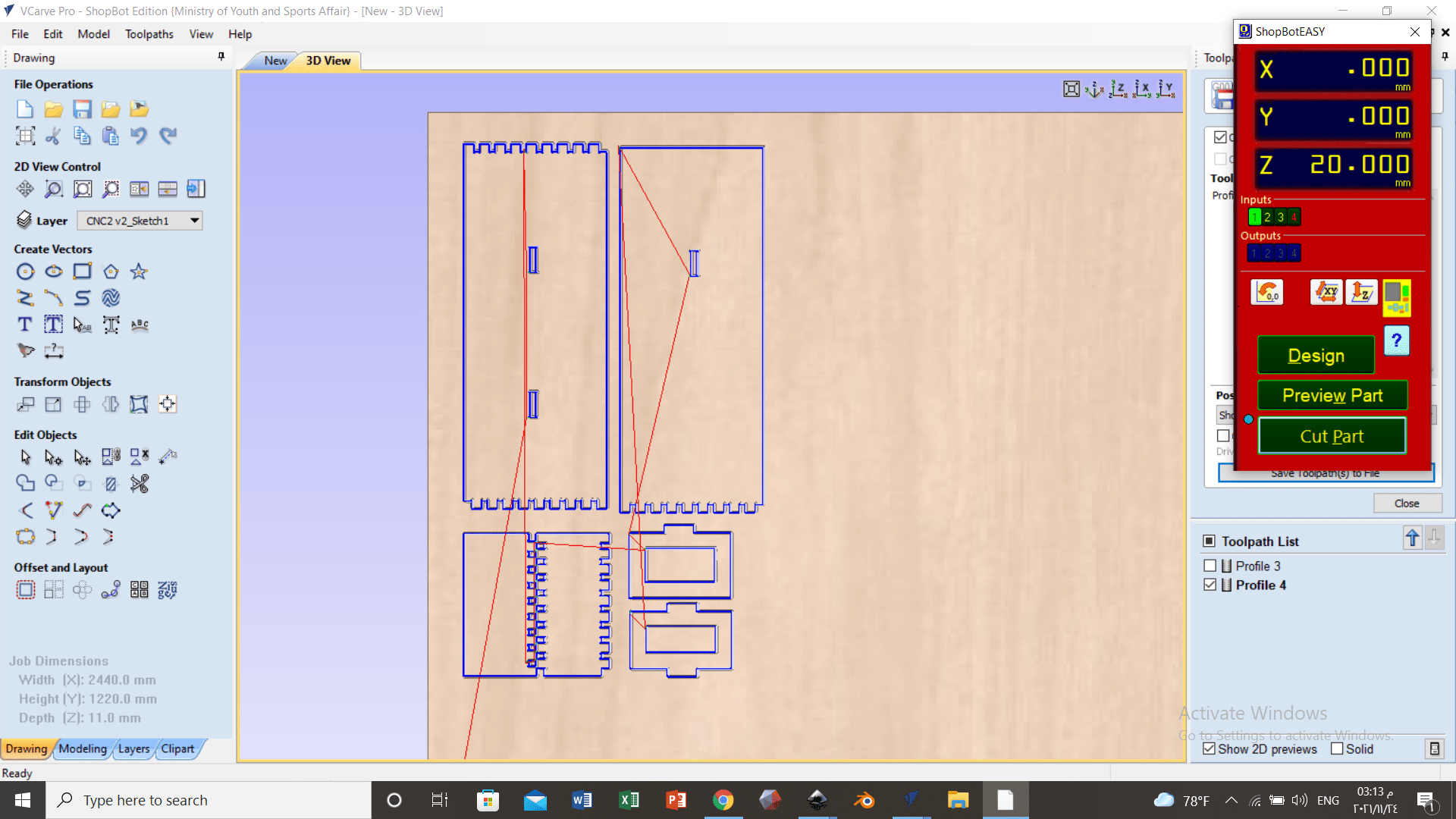

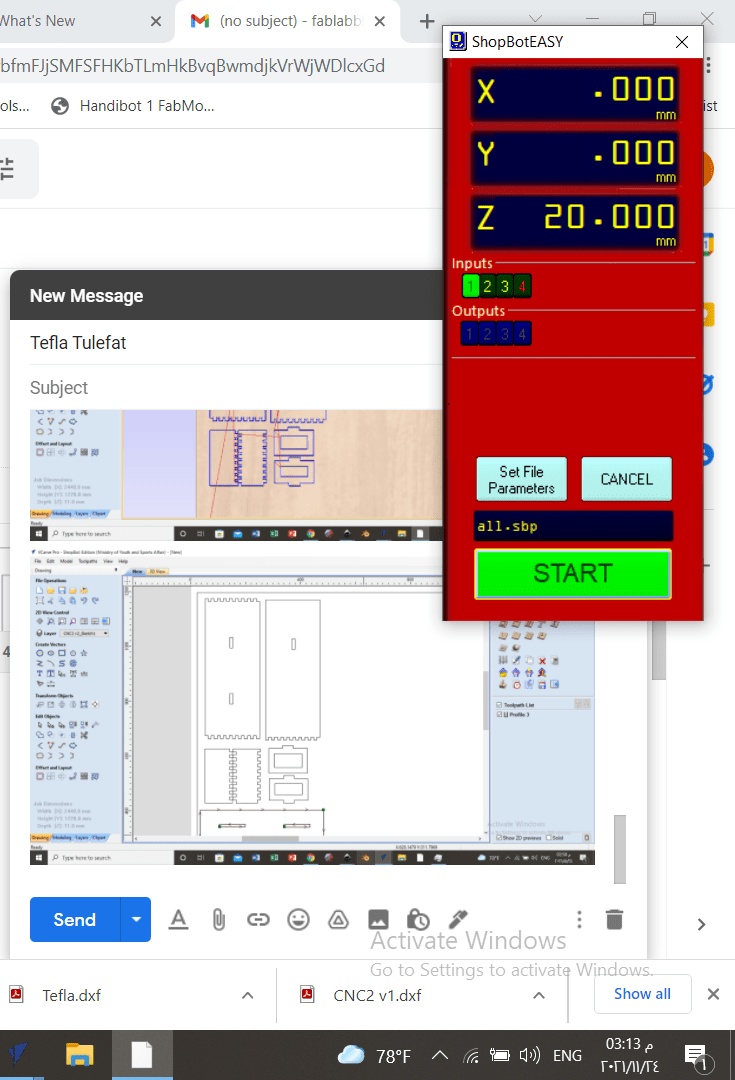

Now I went to the setting of the machine and adjust everything to start cutting.

Before we start the machine, the tutor introduced me to the safety.

-

there is a line i must stand behind it.

-

There is three method that i can stop the machine with it .

a. The red button in the machine.

b. The red button near the computer.

c. by the computer it self.

- we must wear a safety googles.

Now to start the machine:

First, I turn this to the right.

Then press the reset button, Next press start

The machine started to cut the pieces

After that, I cleaned all the pieces

And this was my final result.

These are the pieces that i’ve made in fusion 360: