6. Large format CNC (computer controlled Machining)¶

This week we worked on the large format CNC.

Group assignment¶

In the group assignment we learned about how the CNC works, safety in using CNC, and about the speed of the spindle.

Feed rate and rotation speed¶

The time consuming to cut the designs we want differs by changing the feed rate and rotation speed of the spindle.

As far as we increase feed rate and speed we would get less time? Actually, no. This is not as intuitive as it seems.

Let’s state a rule: as much material eaten by the machine as we finish faster. How much material eaten by the machine is considered by the volume of the sawdust, and the sound of the operation.

For feed rate, as we go faster as we get bigger sawdust and more noise. That means it would finish in less time. For rotation speed, as we spin faster as we get smaller sawdust. Aha! It means it eats less material. So, to take less time we decrease the rotation speed.

Test¶

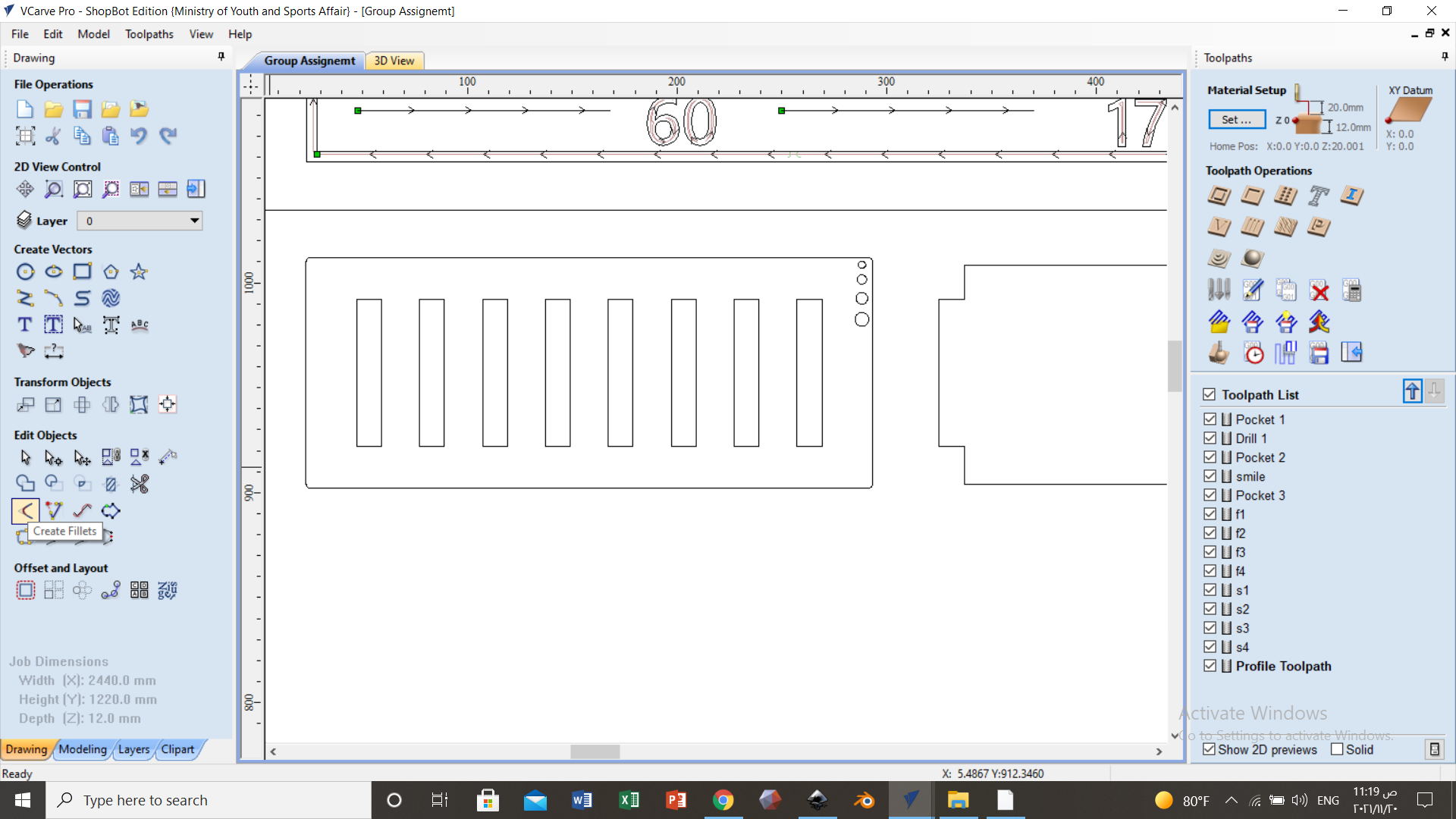

We designed it to test the features of the CNC machine.

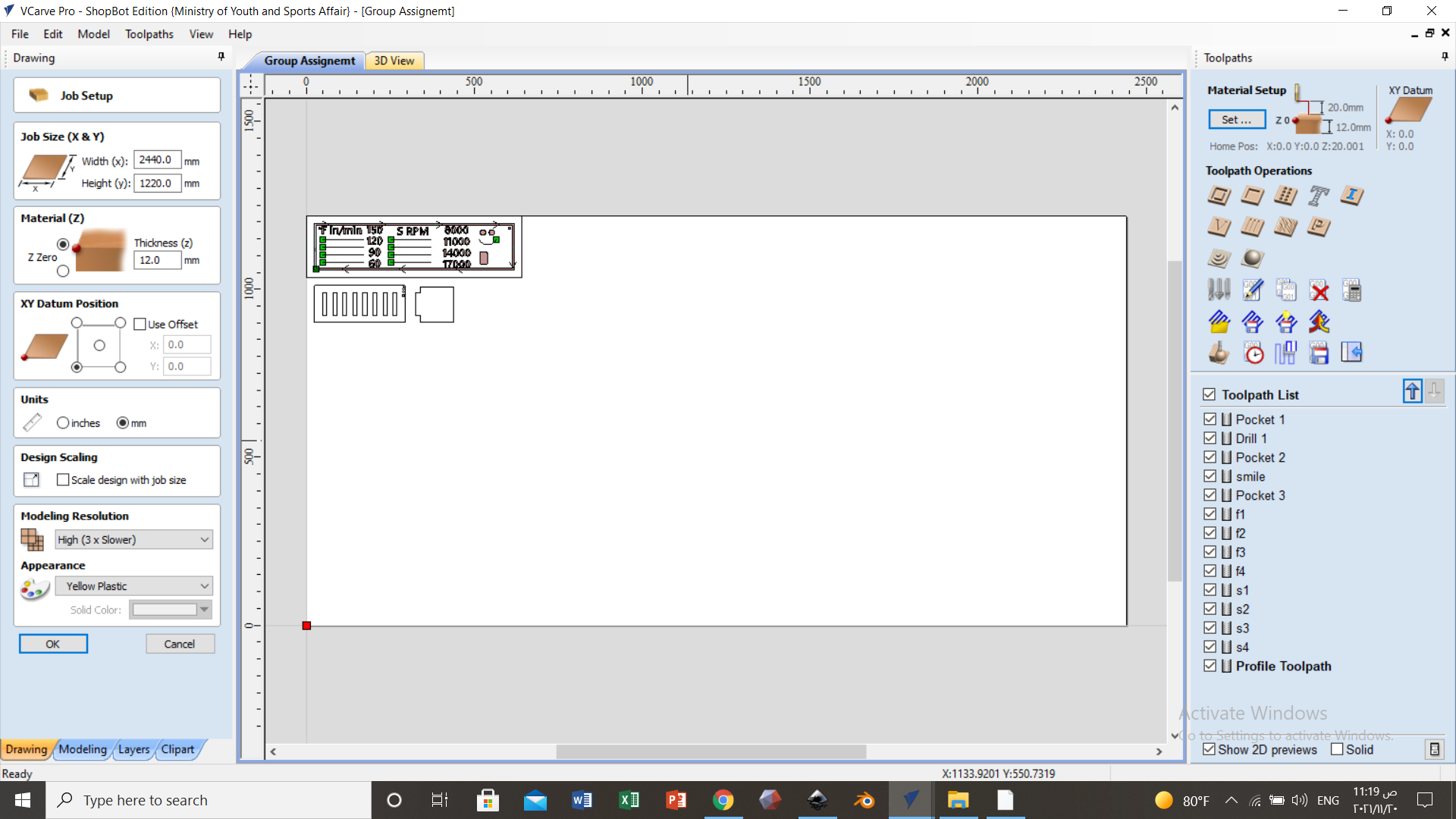

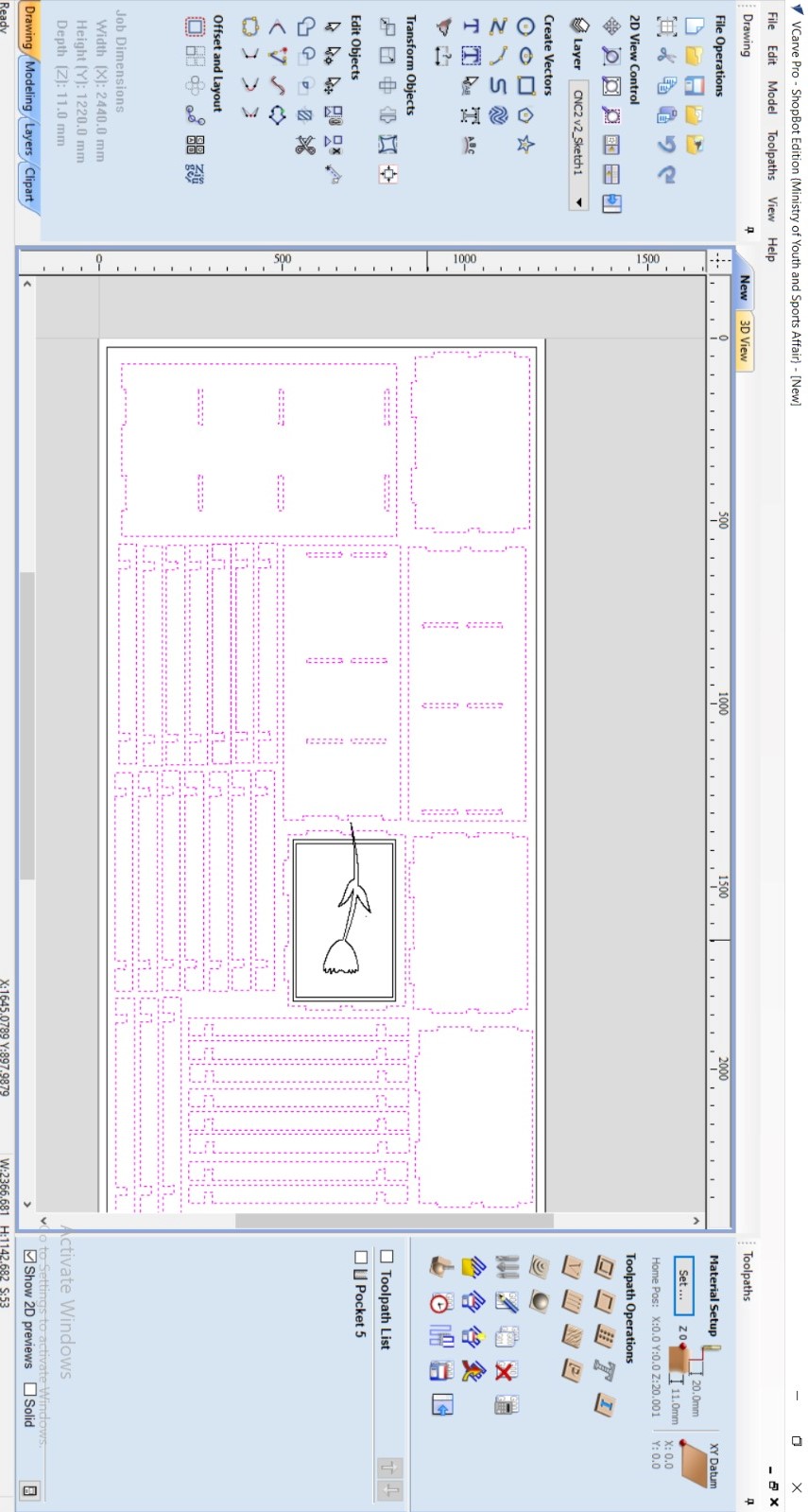

By using Vcarve software to edit the toolpath.

The test we designed is to check the effect of changing feed rate and speed on the final result. And also we designed a press-fit test.

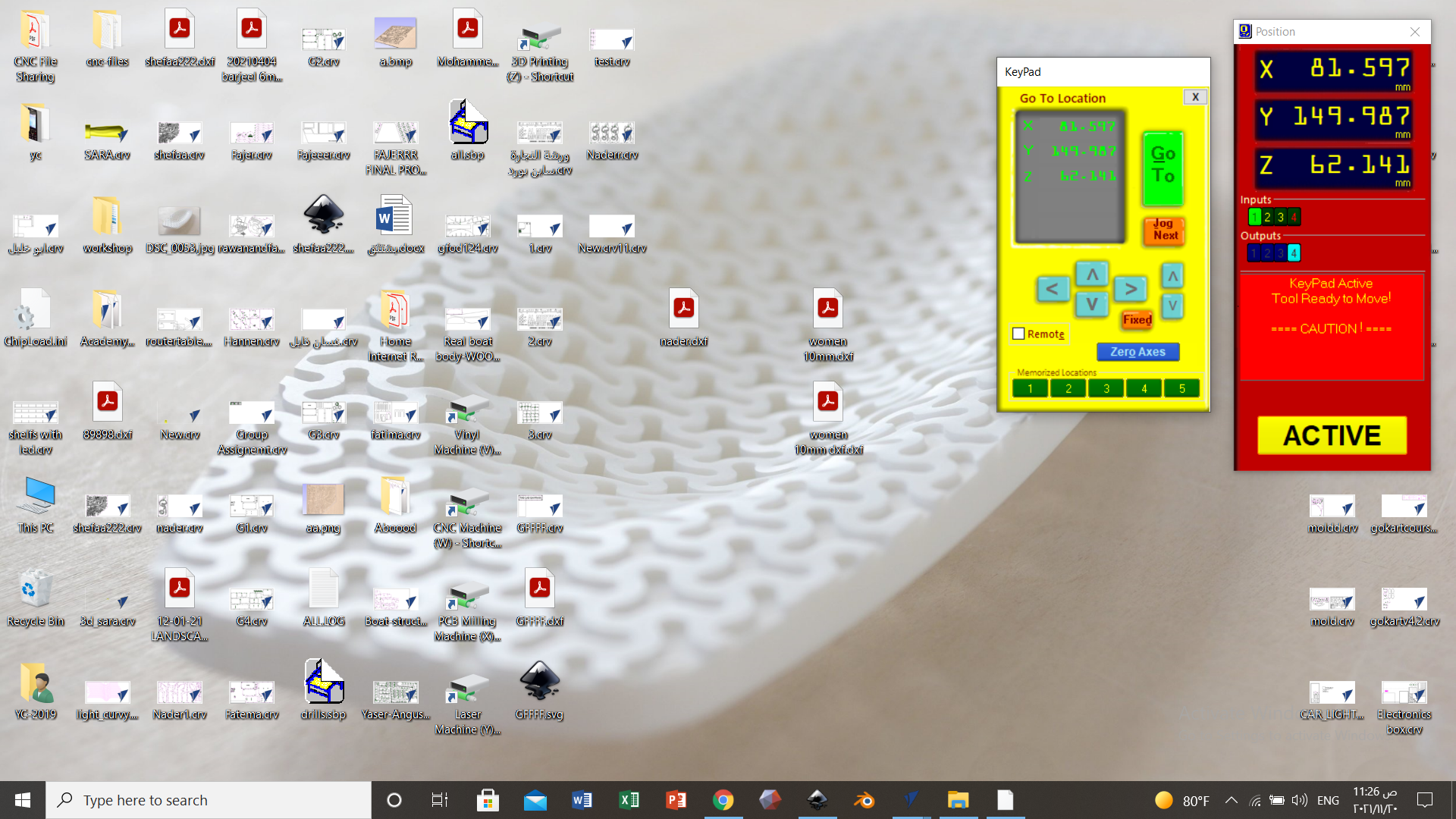

After finishing and editing the origin, it is time to be safe and start the machine:

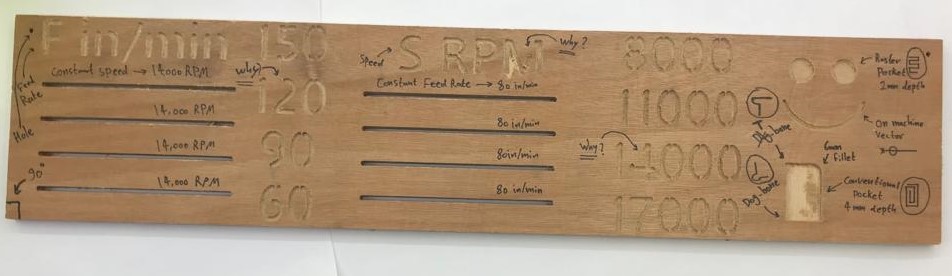

The result is here:

We have to discuss it a little bit.

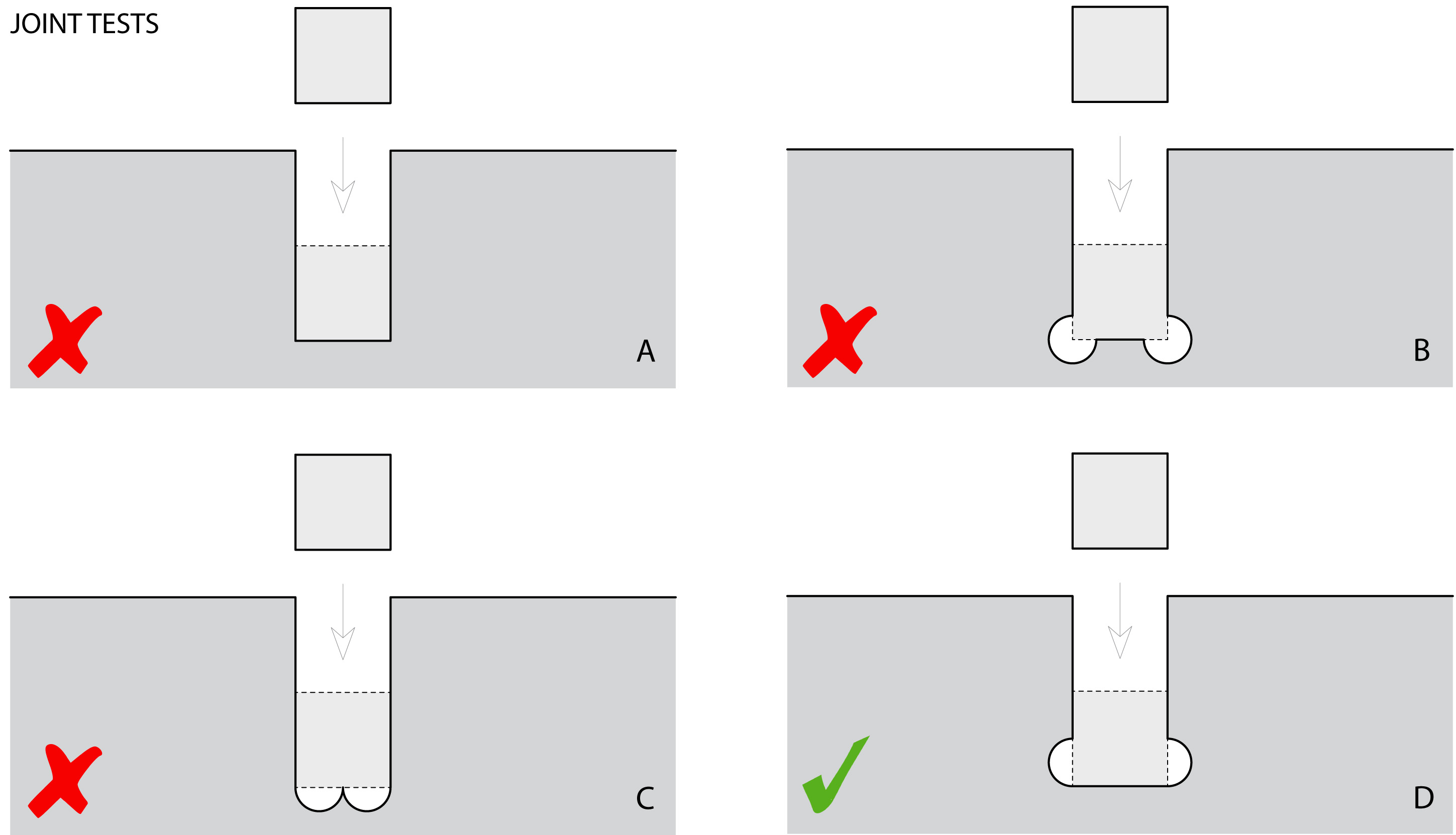

Notice that, we have to make what is called dog-bone shape at the inner corner. That prevent us from the left un-cut material due to spindle’s diameter.

You can notice some parts of the numbers is not cut properly. This refers to that, the width of the toolpath there was smaller than the diameter of the spindle. So the software doesn’t allow the spindle to go there. This can be solved by choosing a proper spindle and editing your design.

Limitations¶

We should say that, CNC is a powerful machine, but it has limitations. It’s a 2.5 D machine, that means it is not fully free to make 3D designs as 3D printers. It can only engrave along the z-axis.

Another thing is that your precision is related to the diameter of the spindle you are using. For example, you cannot operate the machine on a design contains some 2mm details if the spindle’s diameter is 4mm.

Due to spindles, you cannot go with highly feed rate without any limits. You are restricted with the strength of the spindle and the material you are cutting. If so, the spindle will breaks and it’s fragments flies away. So be careful!

Safety¶

We should wear safety glasses to protect your eyes from flying fragments. Also don’t forget to protect your ears by soundproof headset.

Other things you must do is to wear suitable footwear and ensure that you raise the sleeves of your clothes.

When the machine is working, make sure that you are behind the flashy line in the ground.

There’s also an emergency stop button, if anything wrong happen you can stop the machine right away.

Individual assignment¶

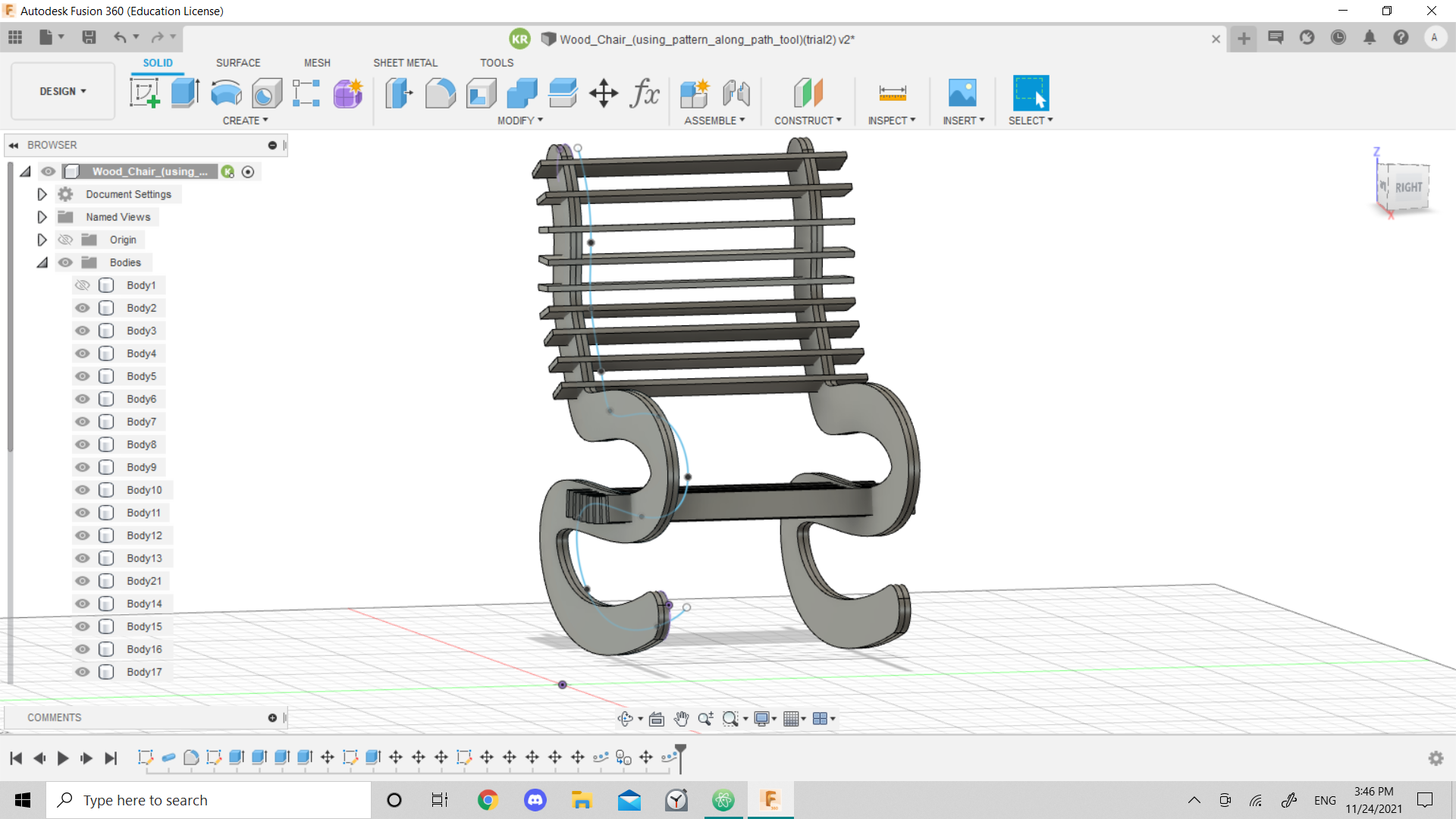

I work with Sayed Ali in designing our chair and cutting it through CNC.

This is what we did:

We made this chair through 5 steps:

1. Designing.

-

Toolpath editing.

-

Cutting by CNC.

-

Sanding.

-

Assembling.

Design files:¶

Click here to see how we did it in details.