8. Moulding and casting¶

This week I worked on molding and casting.

Group work¶

For the grop work:

First the instructor showed us a different material and we choose one to try it for the molding process.

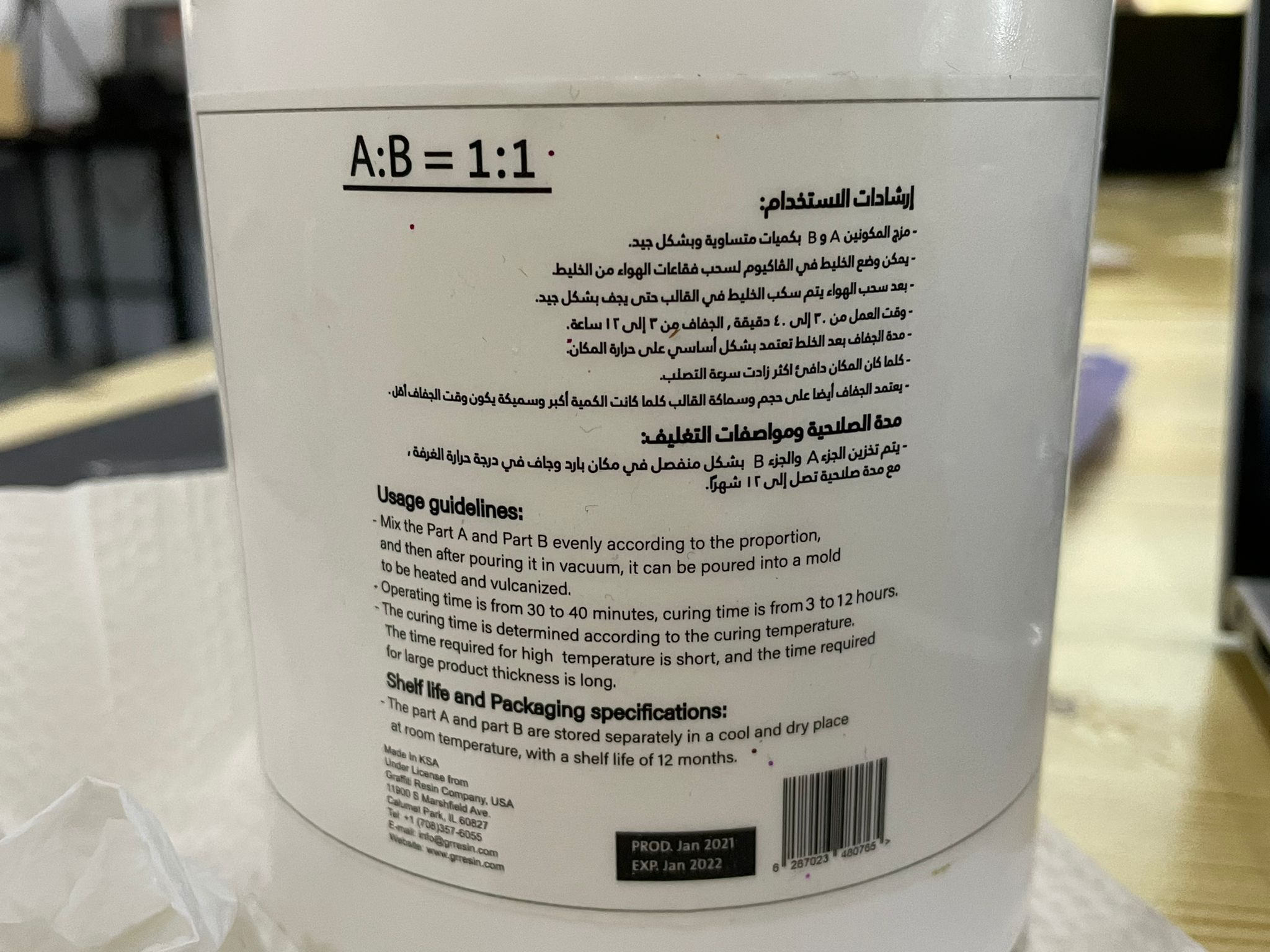

Which is this material, it called selicon (Rubber):

There is two of them, A and

I read the instructions to start the process.

Also, i rea about the warnings like: i should wear a gloves.

Furthermore, the ration is 1:1 and we need a scale to measure the amount.

Firts of all, we got a scale and put on it a plastic cup, then we put the scale into zero.

After that, I measue put A material for 16 gram and then B material for 16 gram and i mixed them.

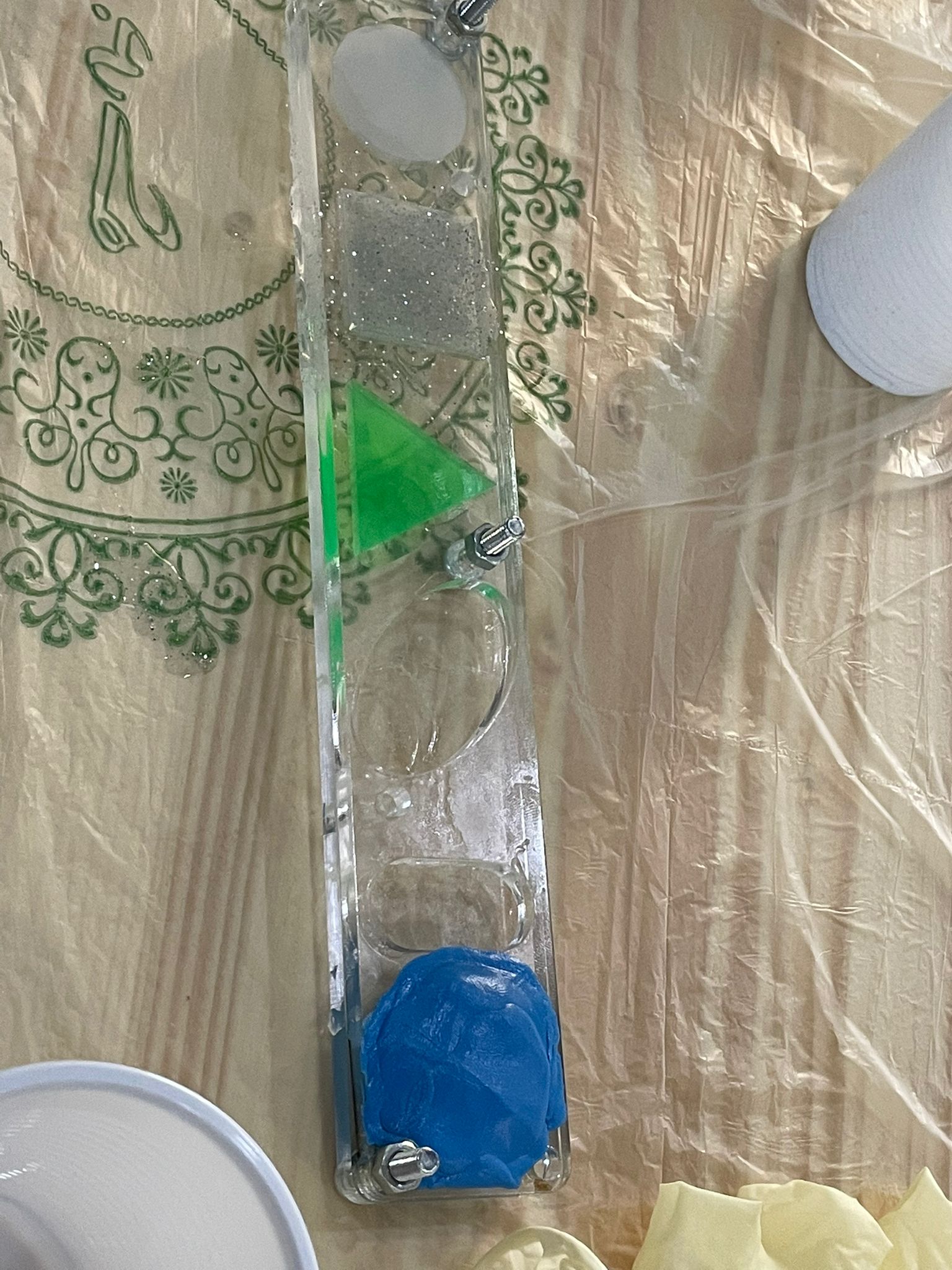

After that, I put it in this tray.

This material is good to form a mold.

Here some other students works with different materials:

individual WORK¶

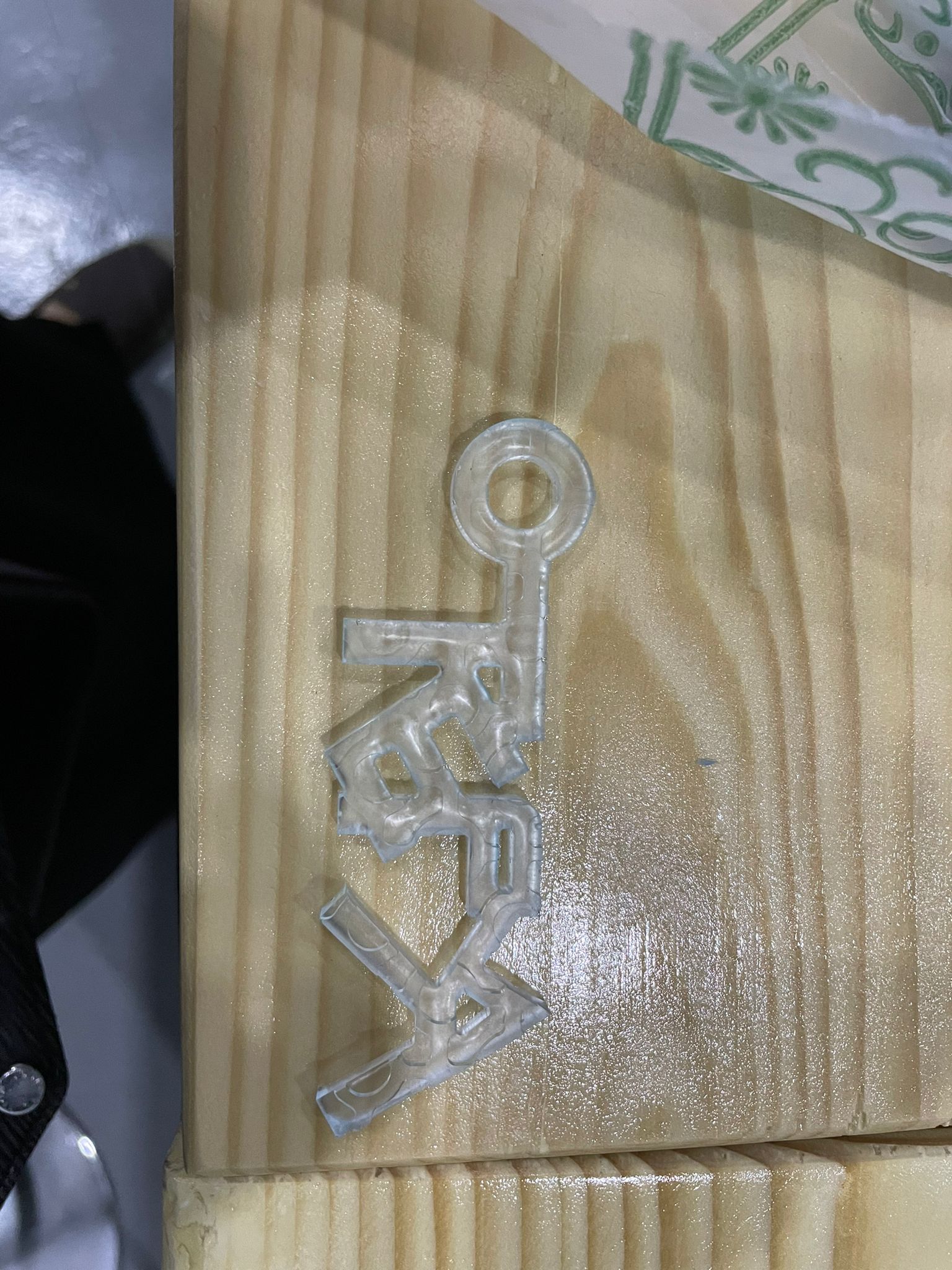

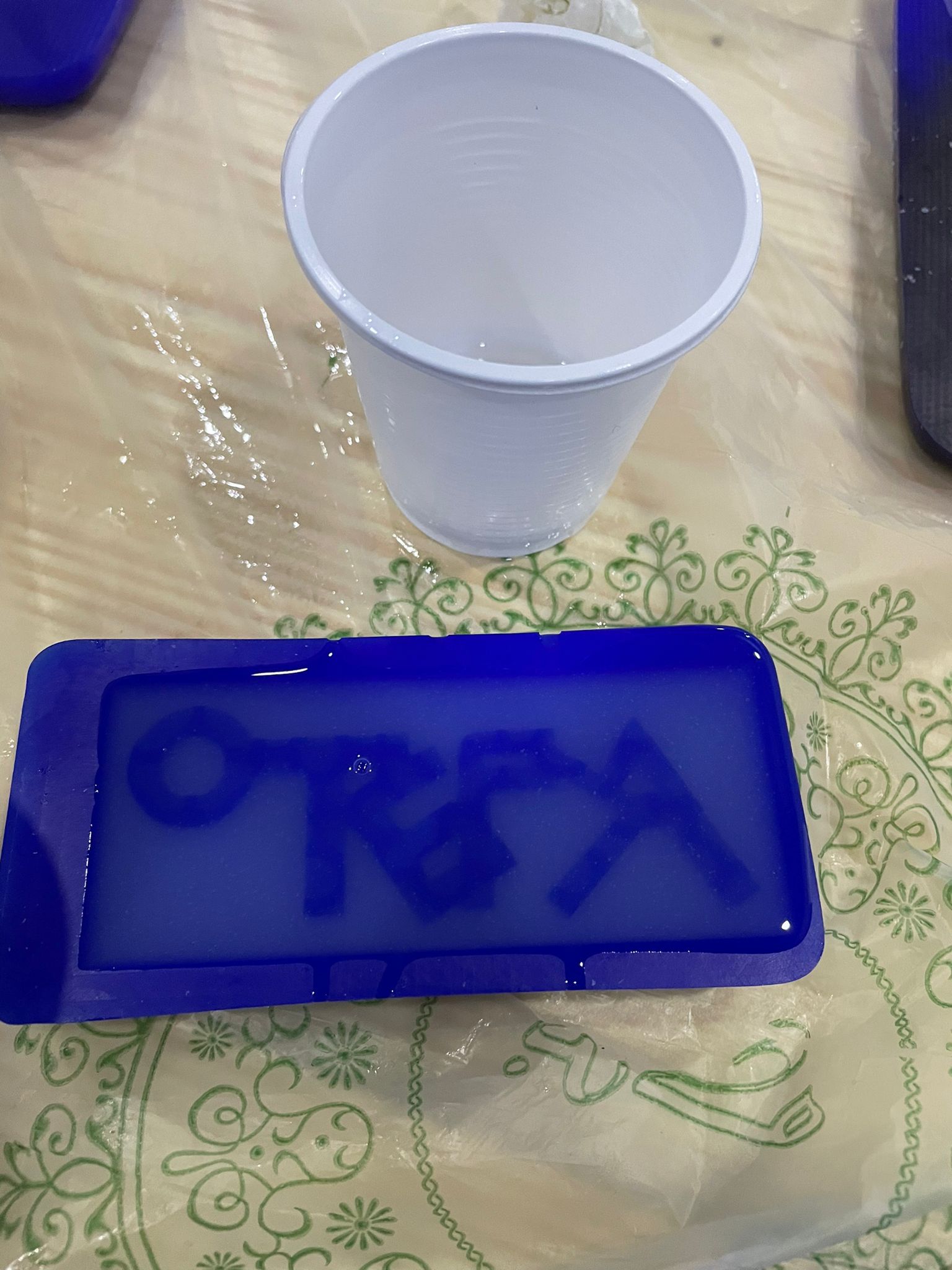

I used a design that i did it befor for a key chain .

and i added this pattern above

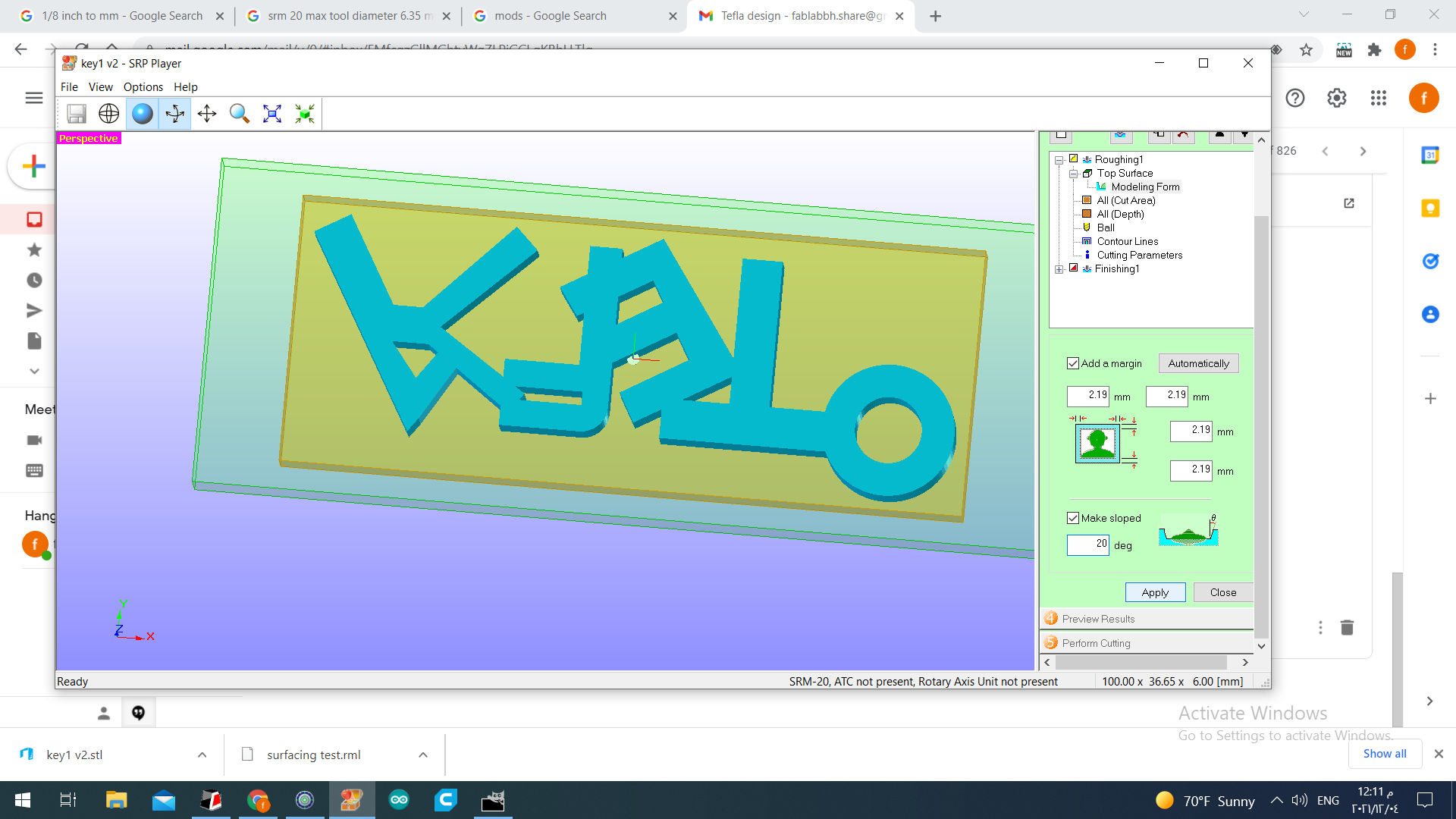

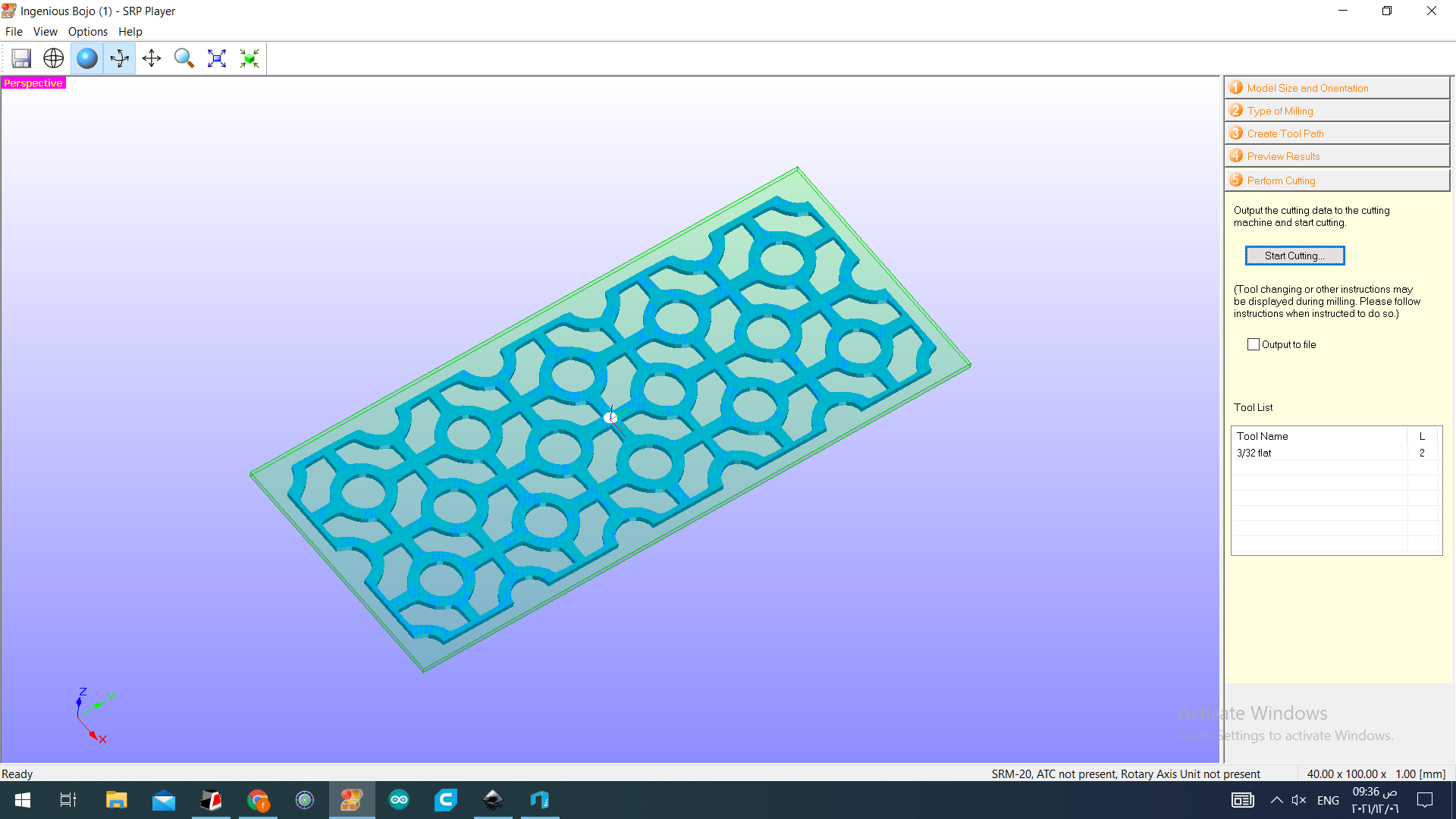

I went to the machine to adjust the sittings .

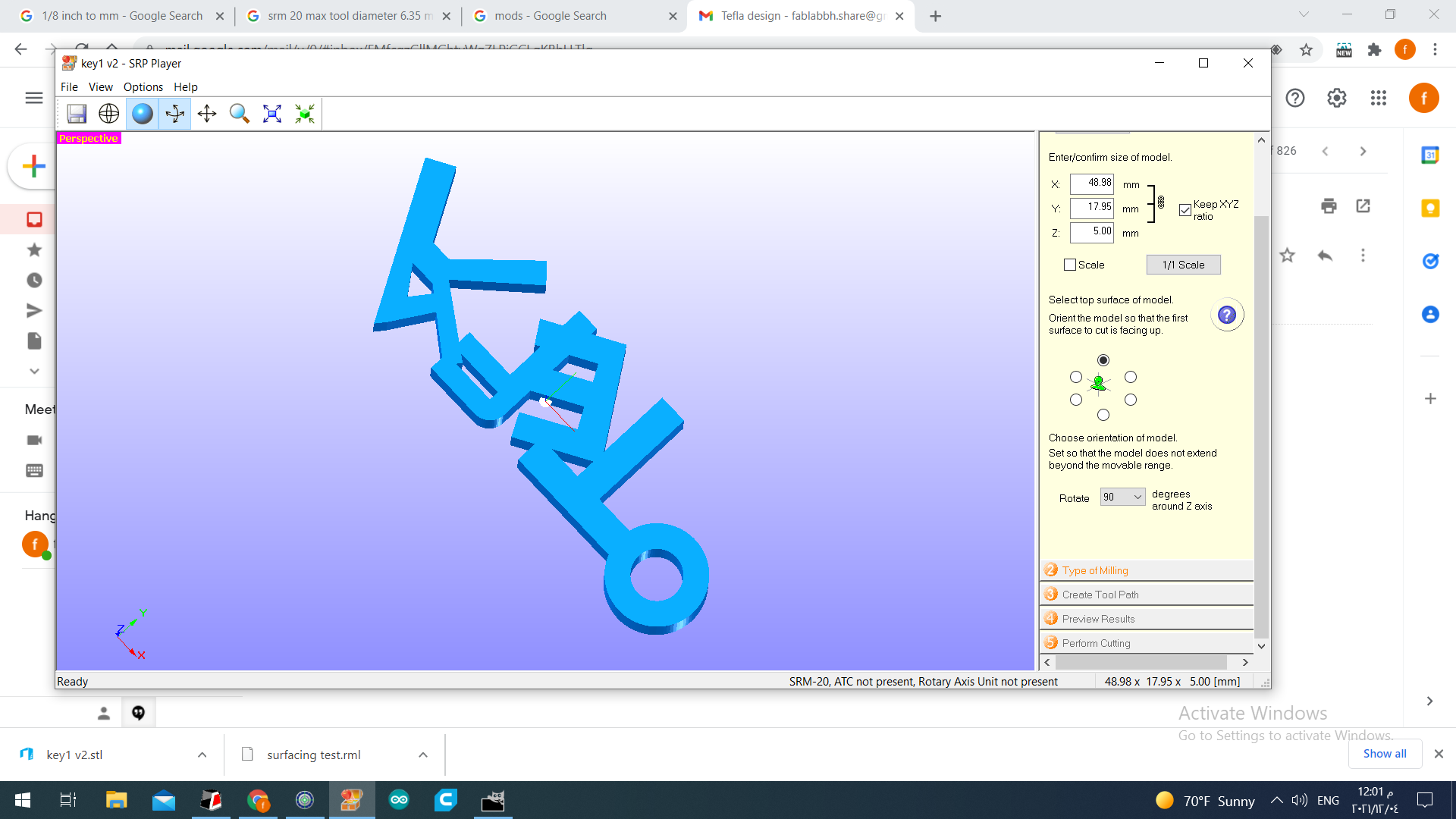

I uplod the foldar and set the directions (oriantation)

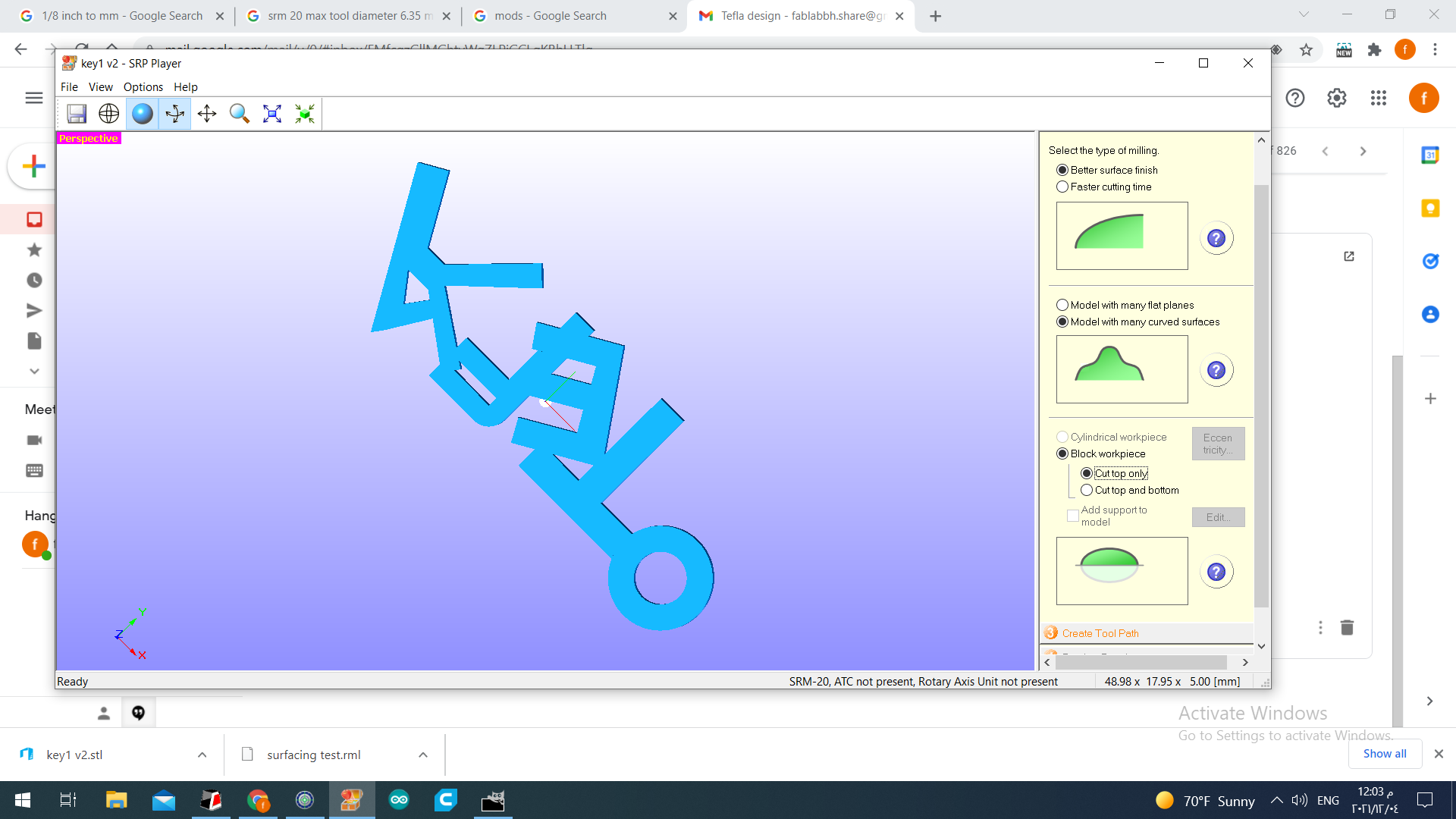

I chose the type of molding

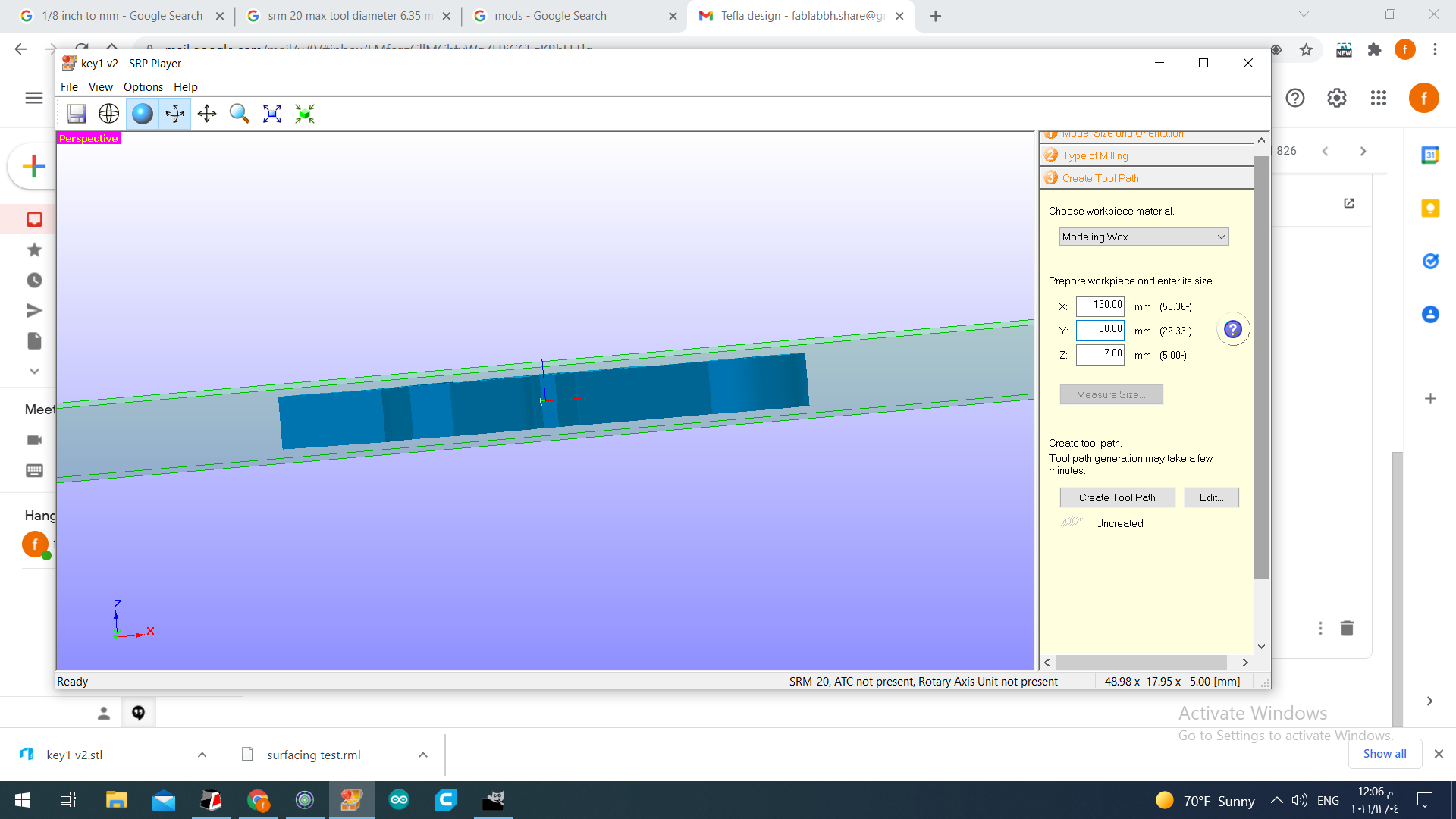

Then i create the tool path

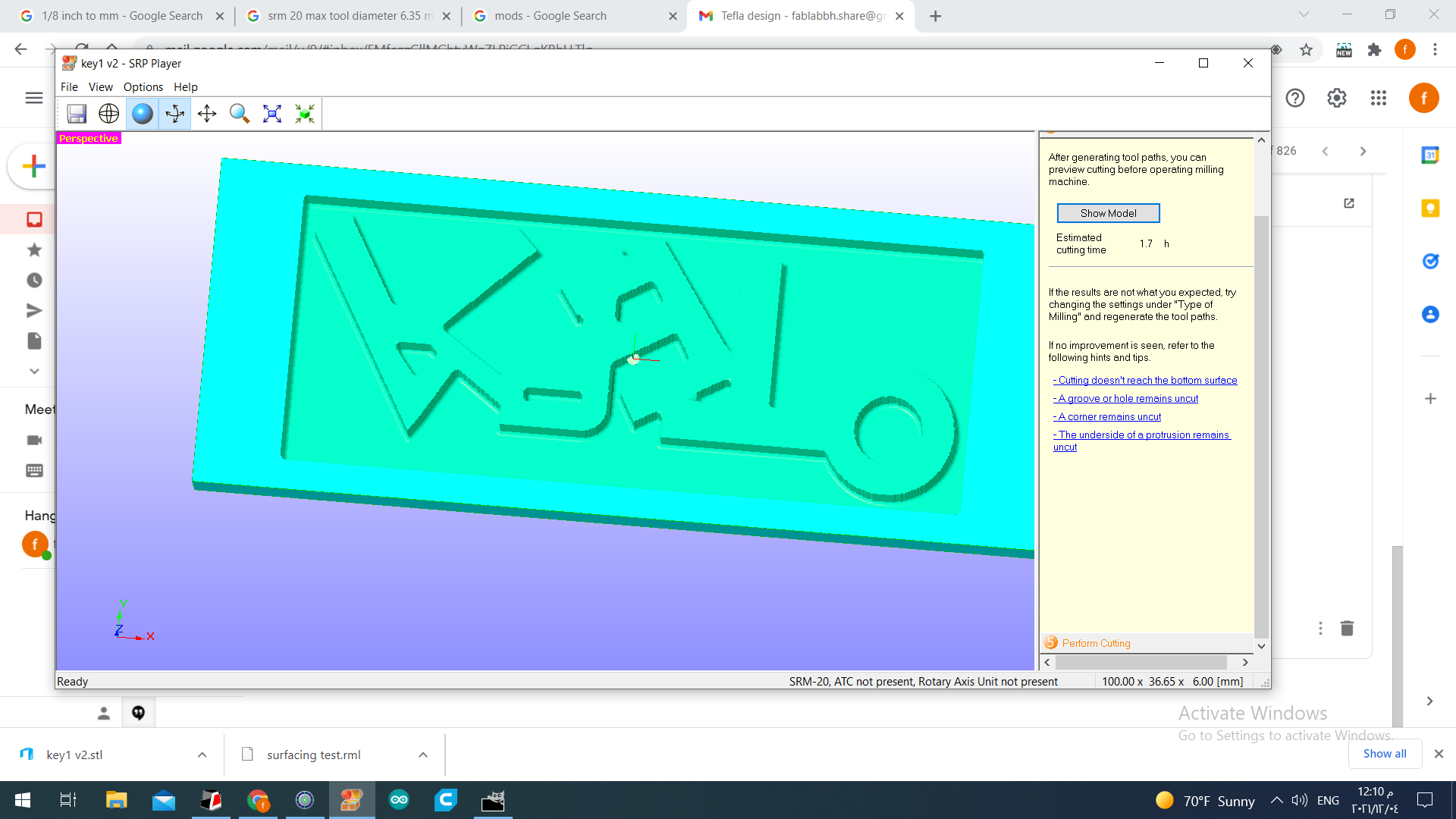

Showing the model to check everything and set everything

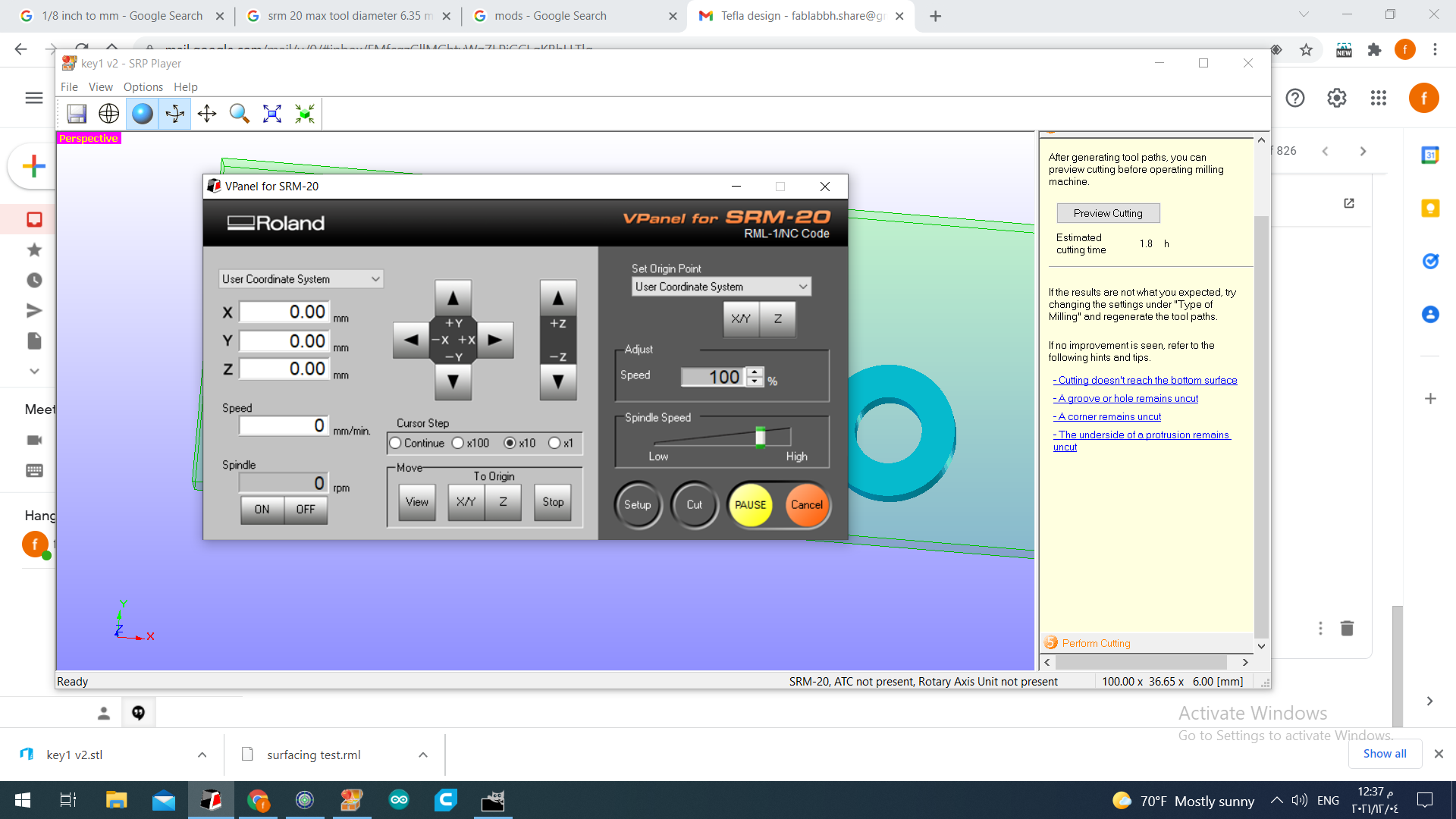

After that, we opened the machin app

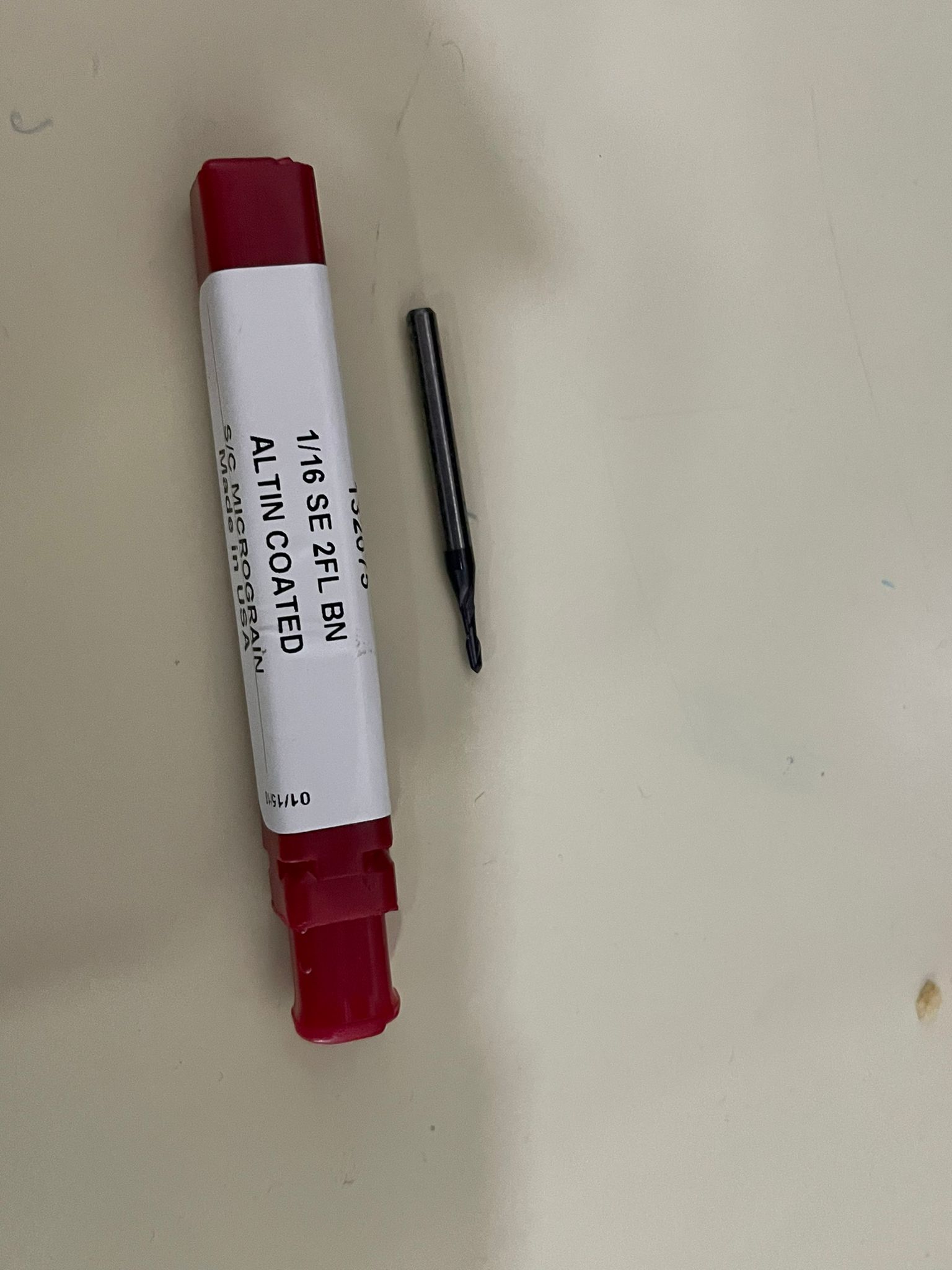

Then, we chose the pit and the location

and I added a pattern

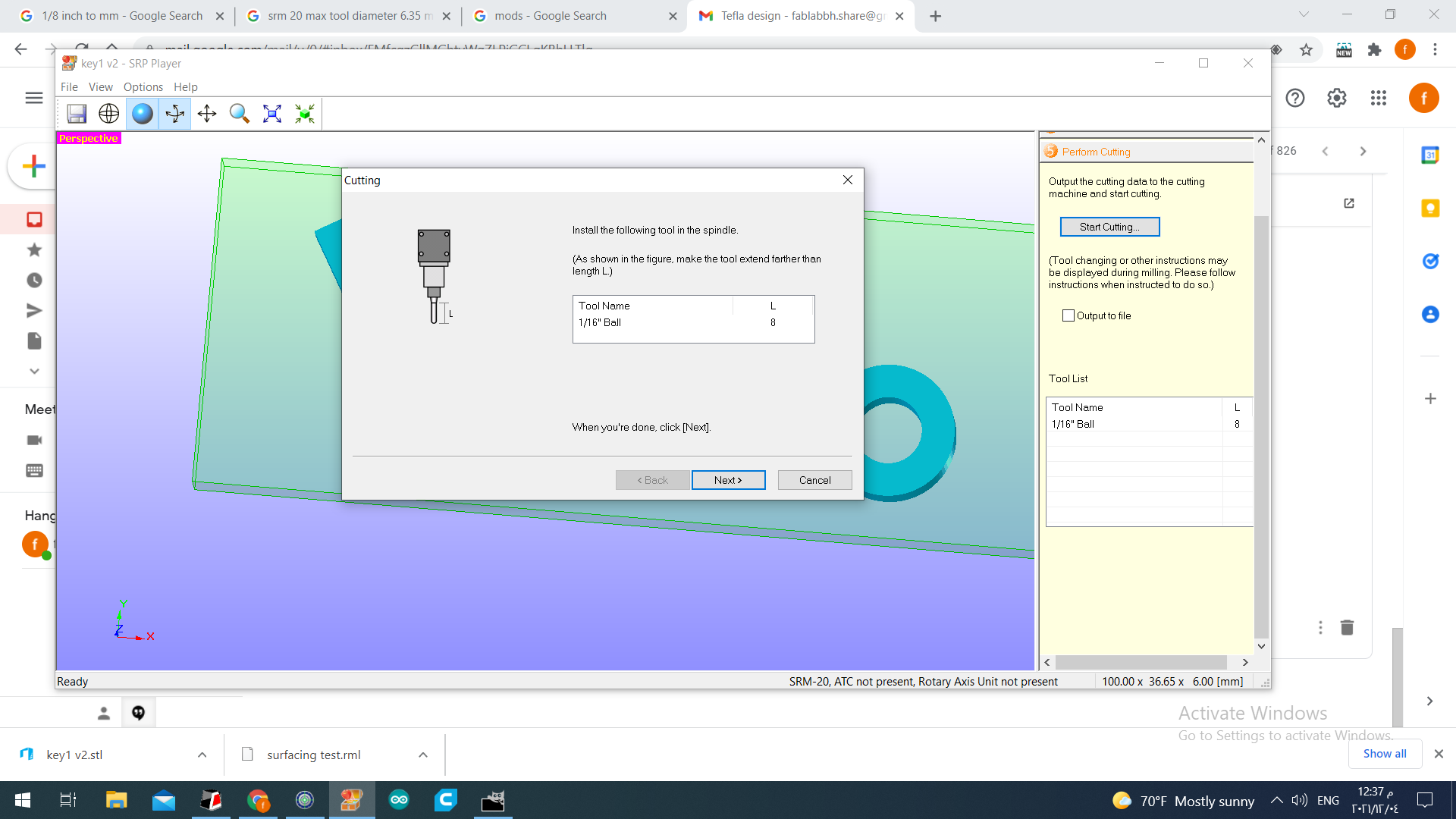

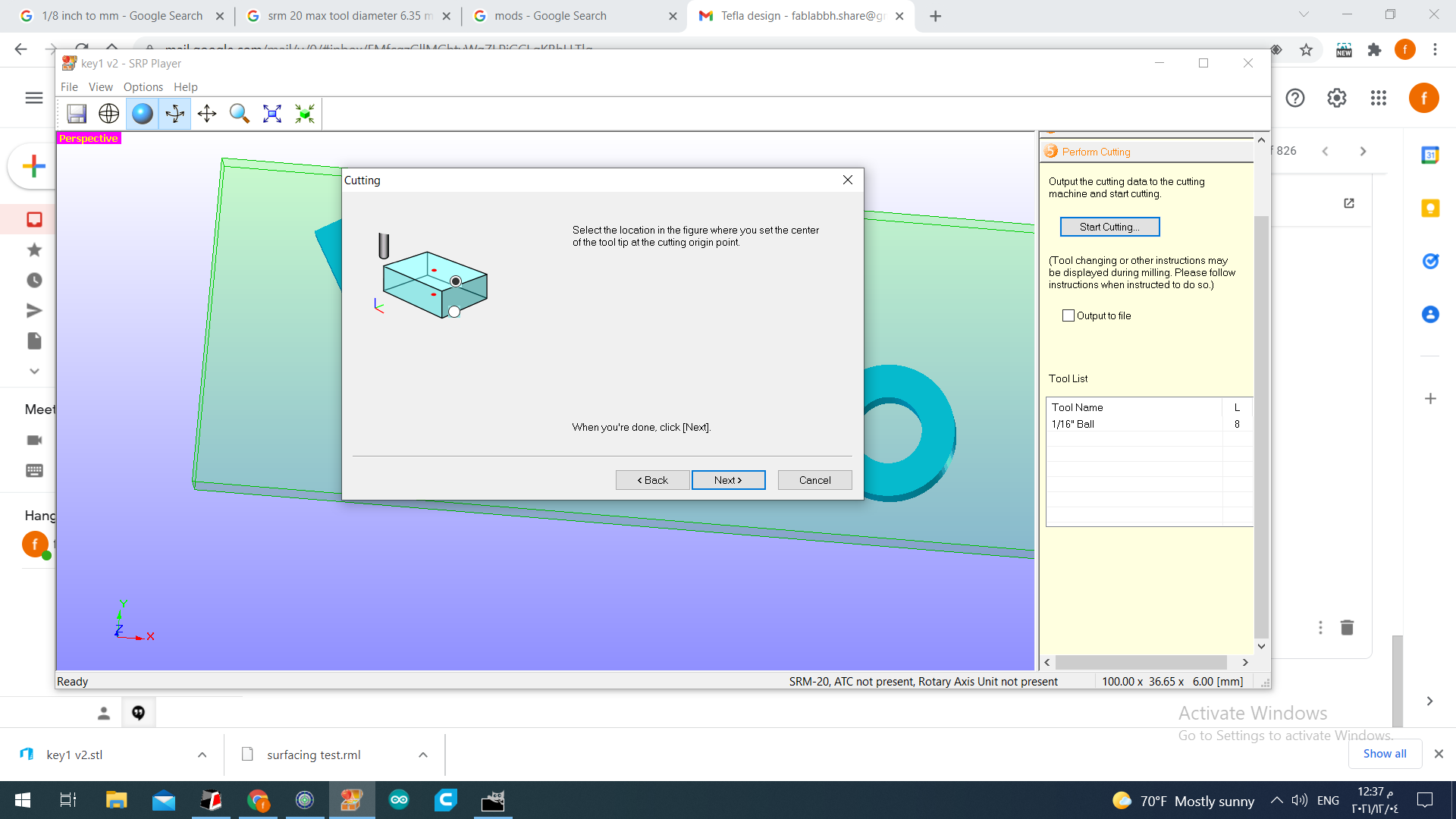

This was the pit

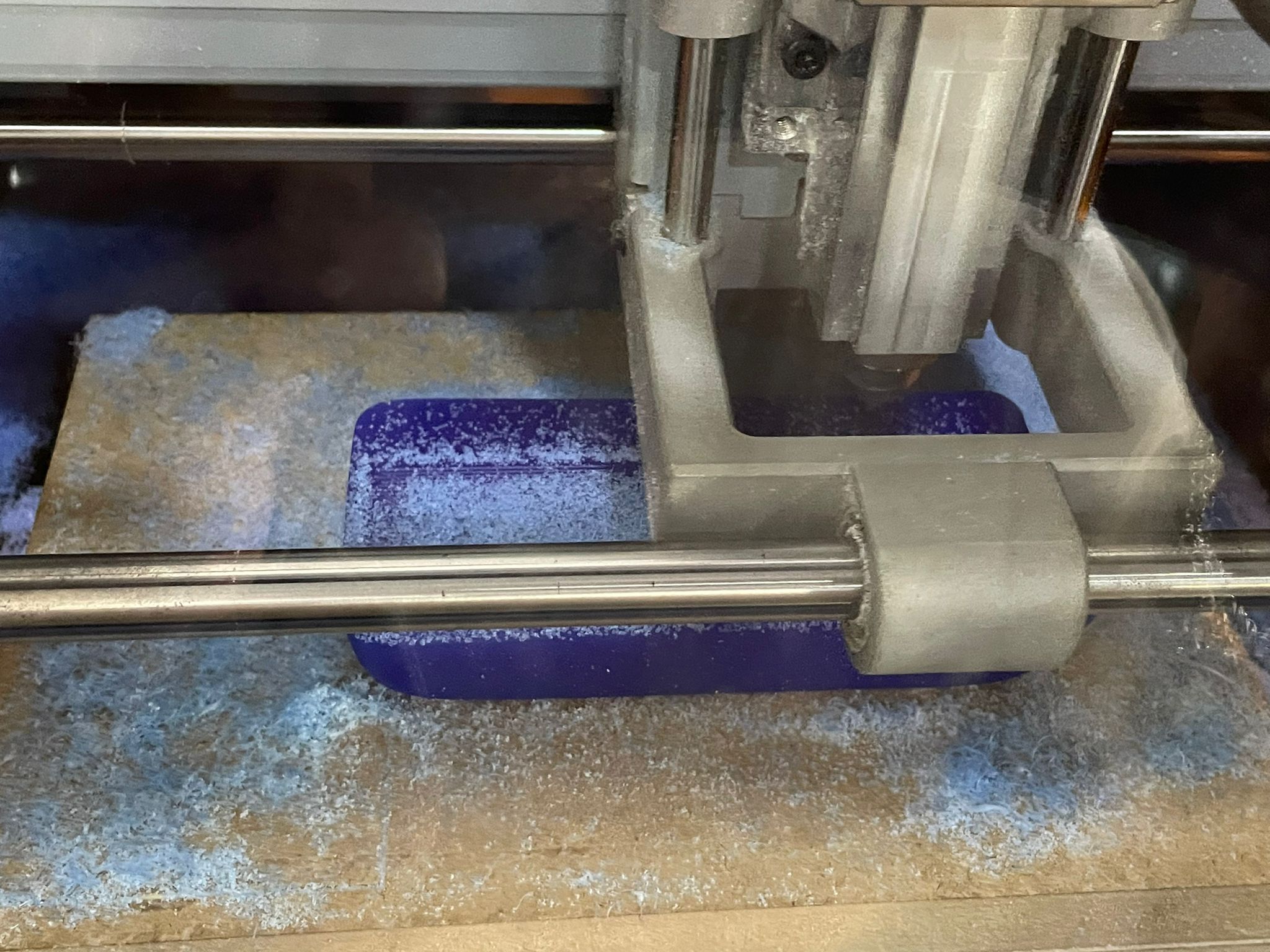

the process started

This is the result

I mixed the same material i used before for the molding and put it on my design

After waiting 1 hour of waiting this was the result.

Moreover, I used this material to make the shape that i wanted.

The ratio is 4:10

I made it by mixing the material and used a heatgun to remove the bubbles .

And finally this is the result.