5. 3D printing and scanning¶

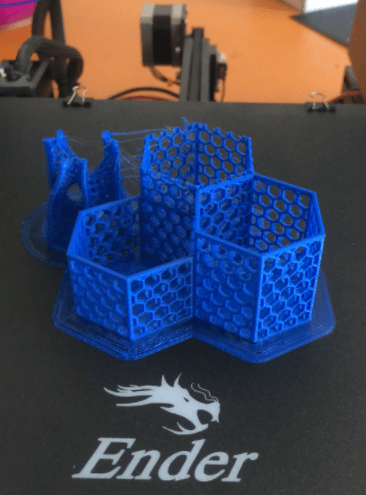

This week I worked on scanning objects using the Qlone application and I have scanned myself by SKANECT. I worked with my group on printing a 3D design using the 3D printer called Ultimaker2+ as well as we explored Ender and Prusa. I have designed a smiley 3D design with Fusion360 software and printed it.

Group Work¶

We have printed two 3d designs, documented by Weaam Ajoor

Click here

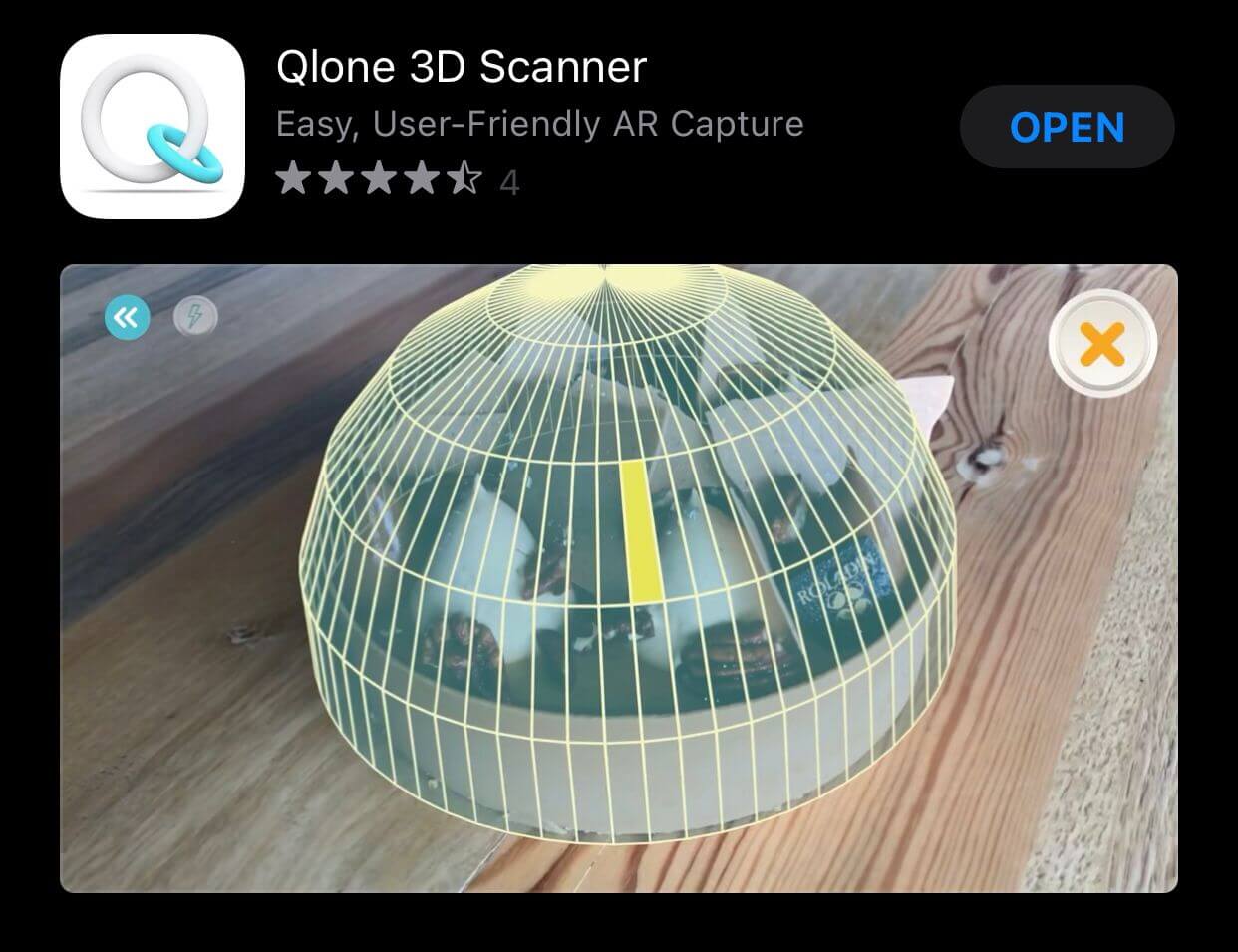

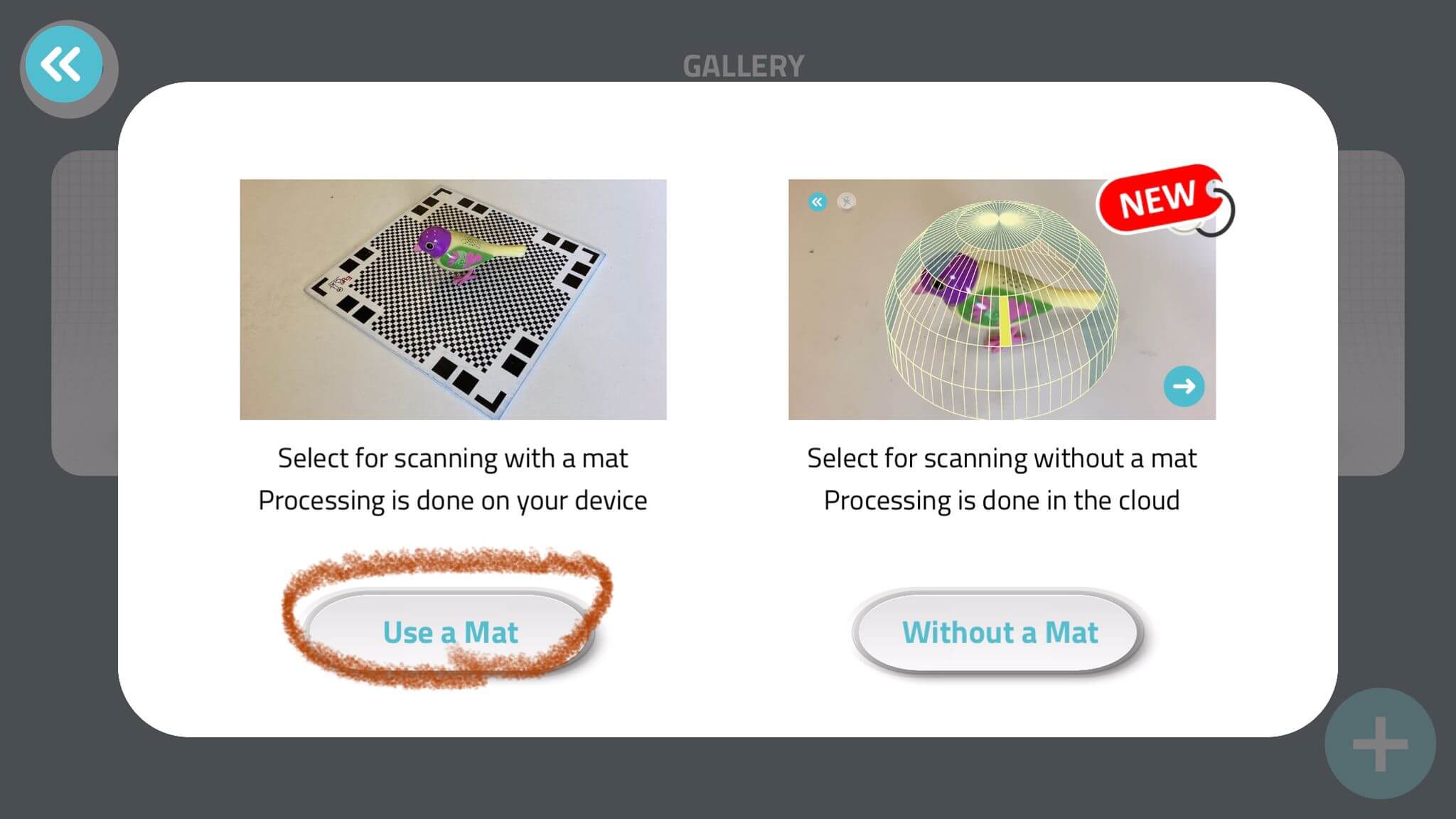

Qlone¶

Qlone is a super great application that allows you to scan fast and done in real-time on your device, it includes AR View, so you can beam your 3D models back into the real world! And even magically animate them automatically.

Click here to download Qlone

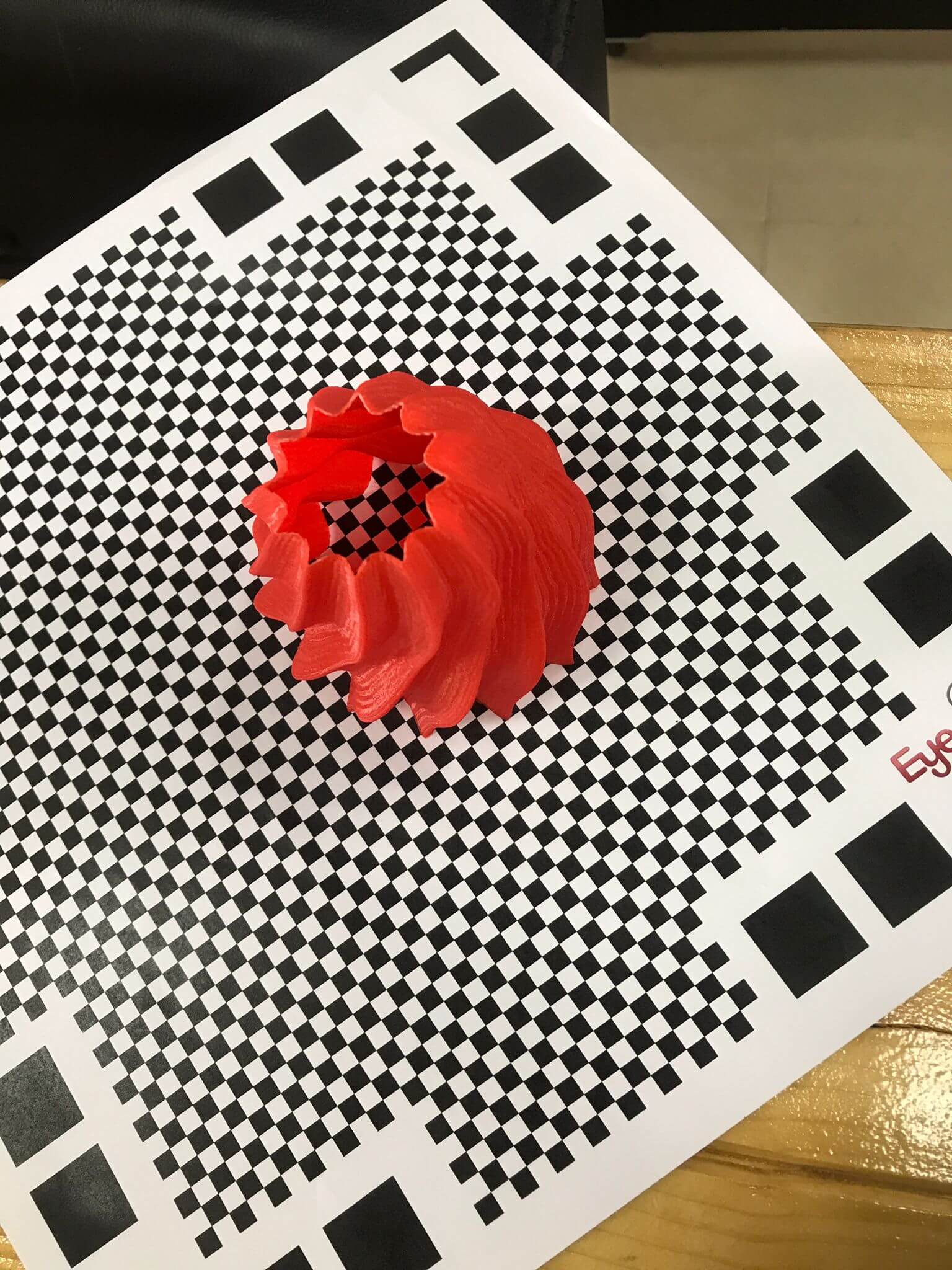

Scanning is super easy, just place your object in the middle of the mat and the AR dome will guide you through the scanning process.

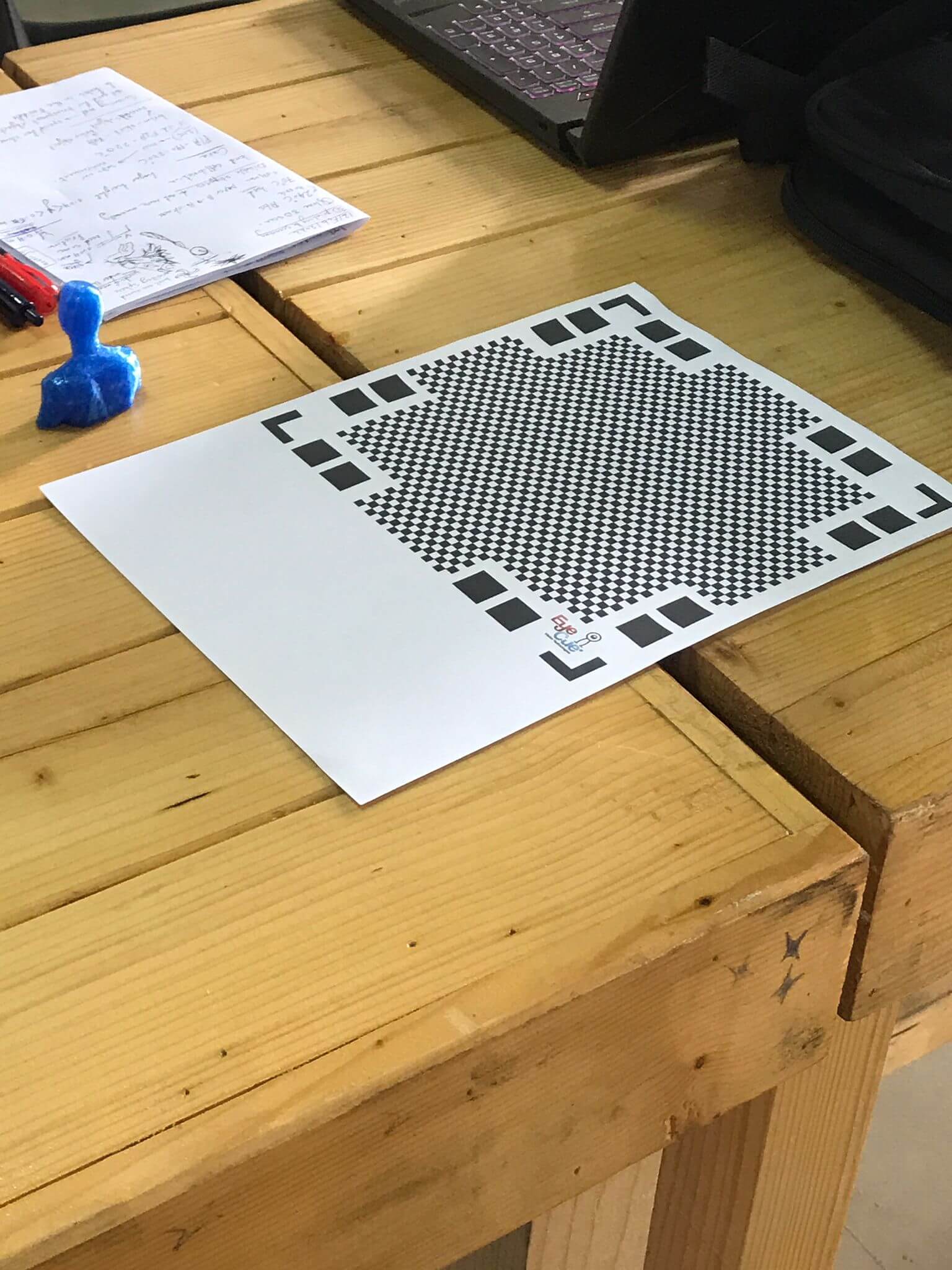

We use a mat when we are working with Qlone to enable Qlone to recognize the design

We use a mat when we are working with Qlone to enable Qlone to recognize the design

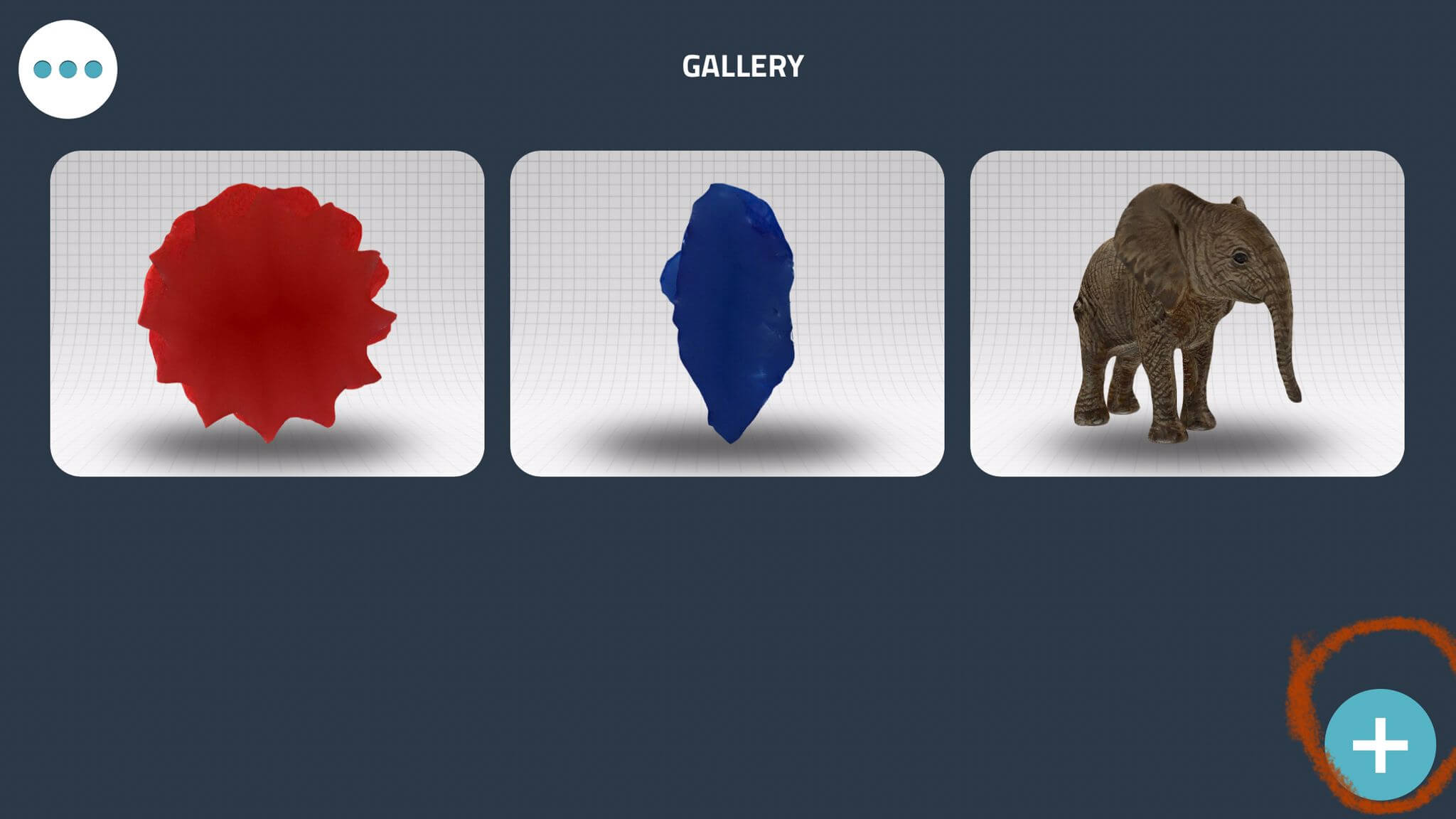

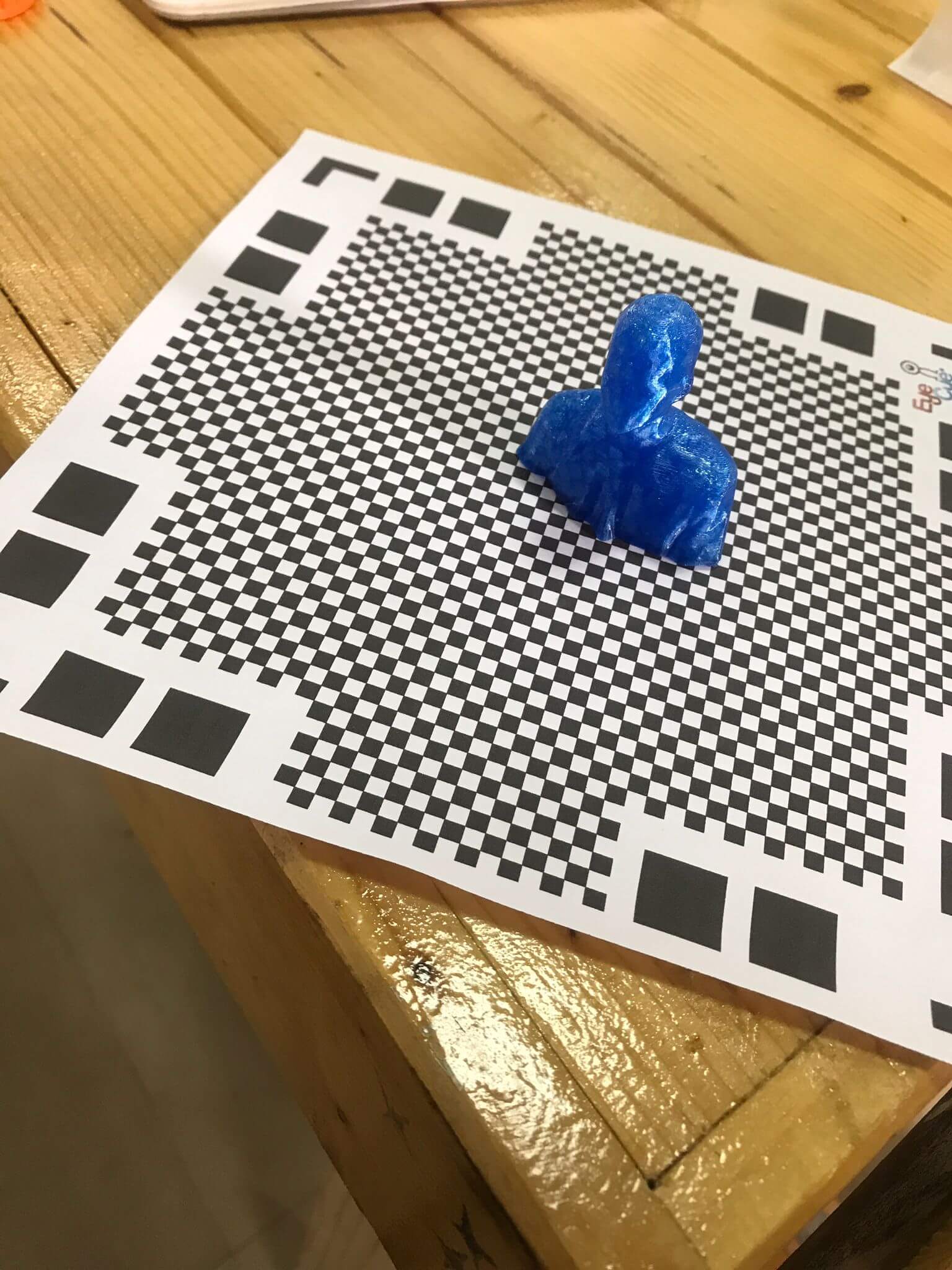

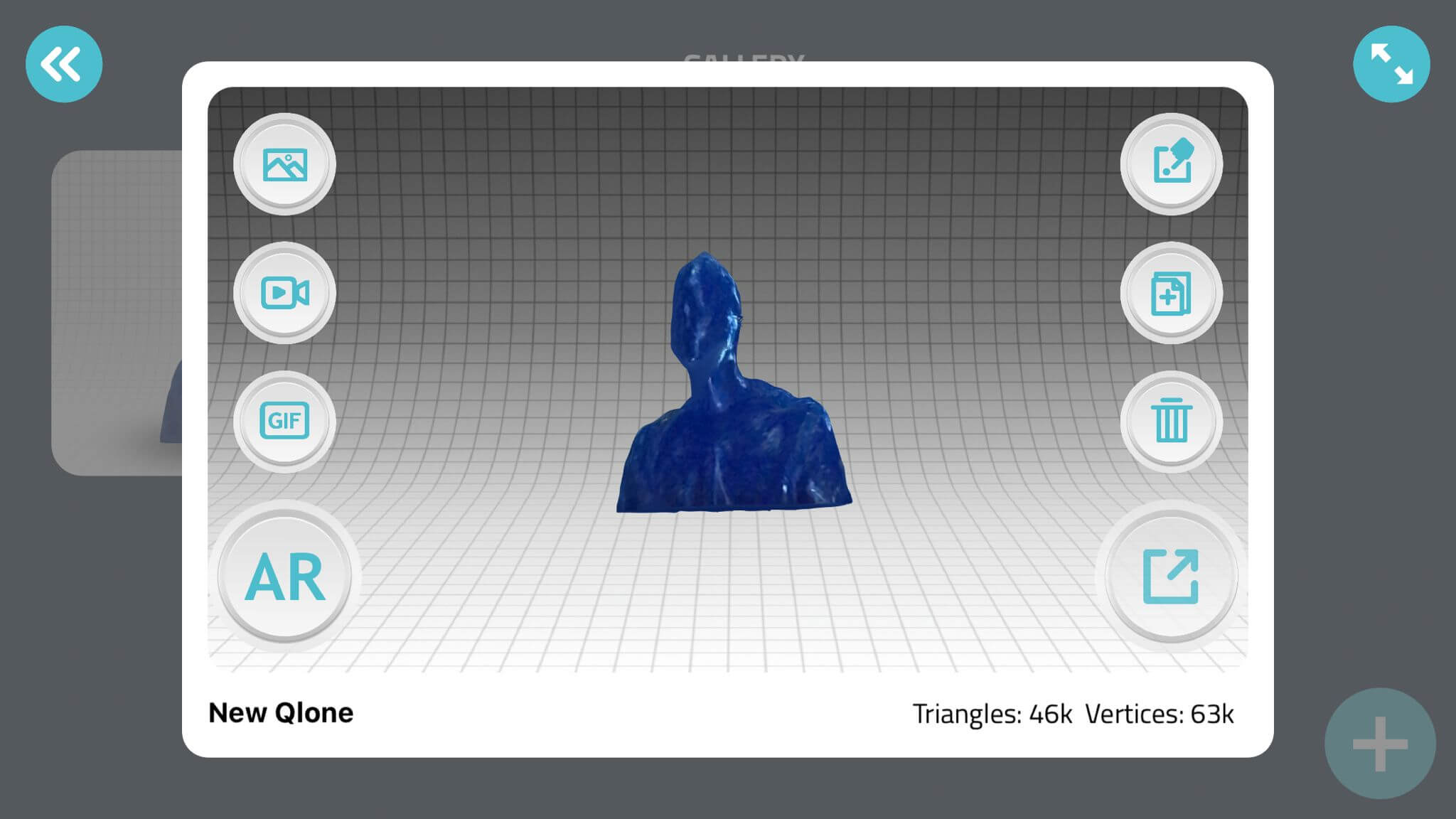

I choose a human head and shoulder design to make my first try on the application

I choose a human head and shoulder design to make my first try on the application

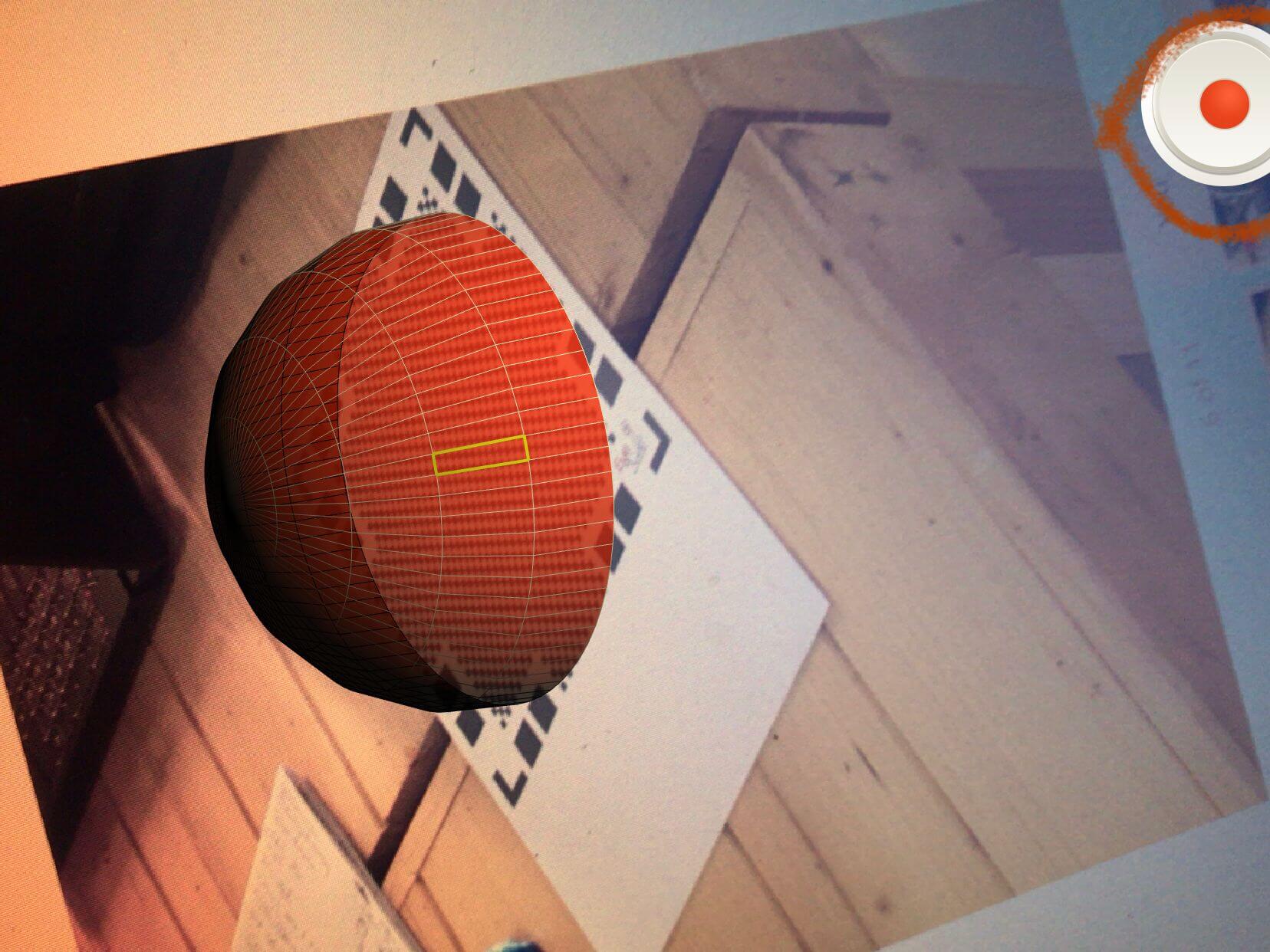

While scanning make sure that you include the four edges of the mat in the camera, as well as you have to turn around your 3D object or to move the mat gently to fill the dome-shaped until it disappears.

While scanning make sure that you include the four edges of the mat in the camera, as well as you have to turn around your 3D object or to move the mat gently to fill the dome-shaped until it disappears.

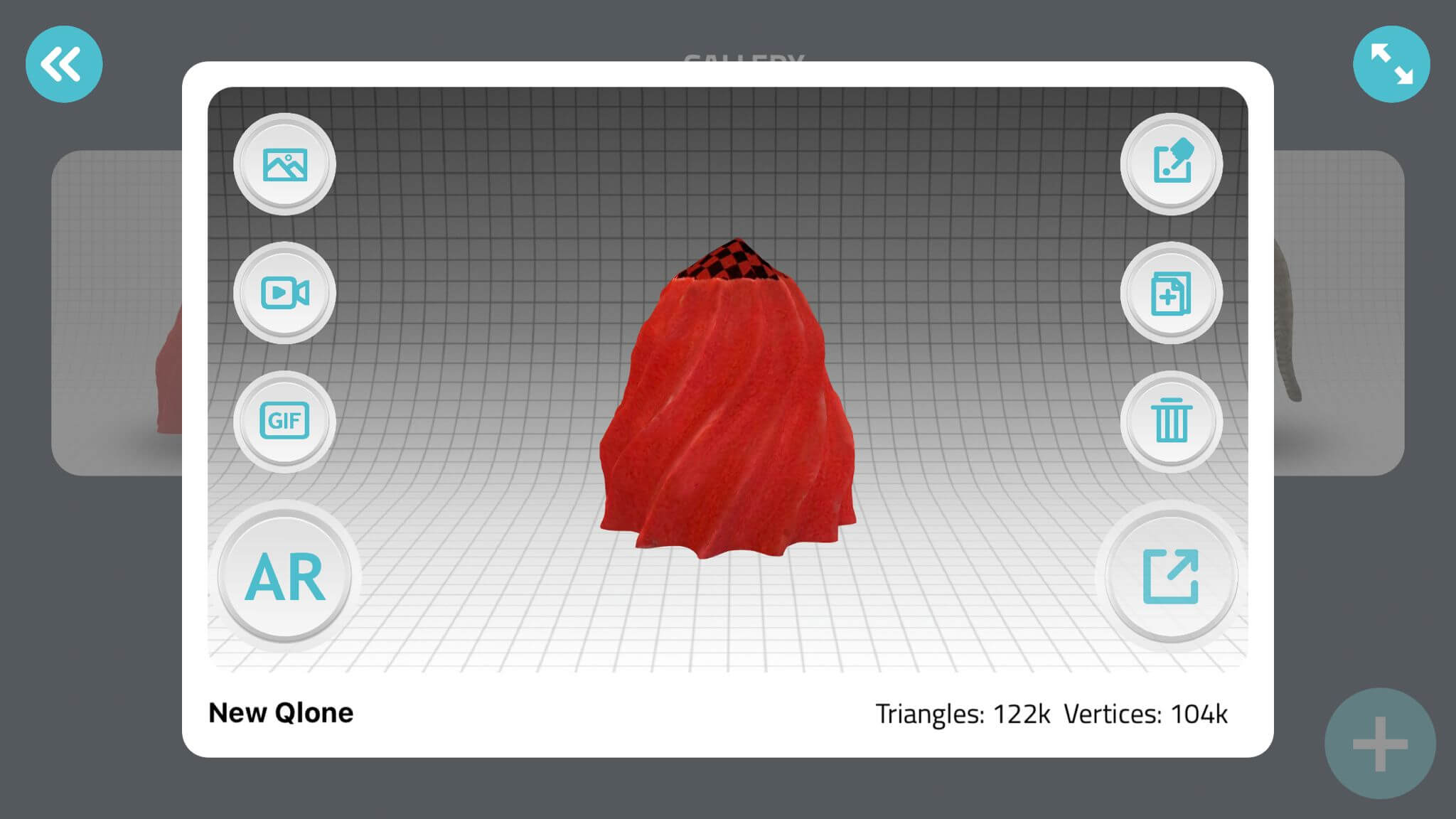

It has scanned perfectly. Here is another try

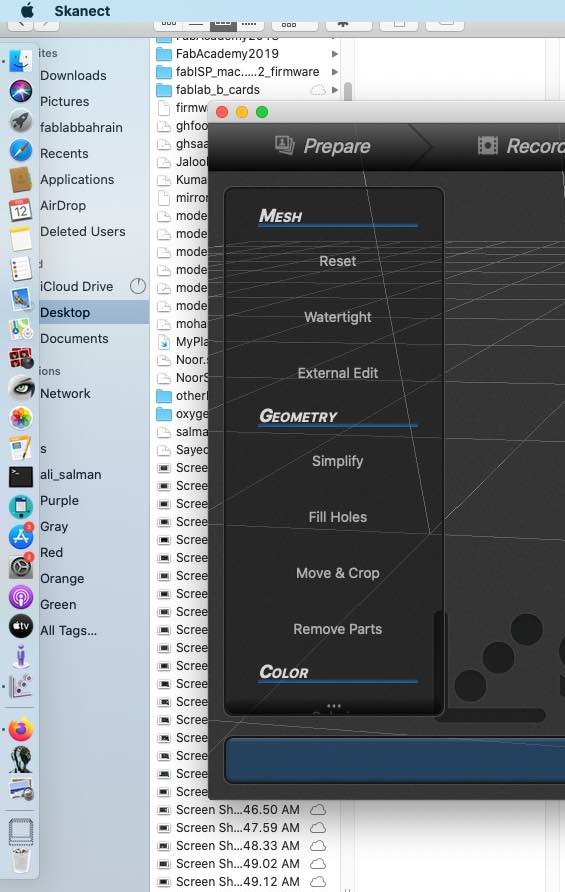

Skancet¶

Skanect allows you to capture a full-colour 3D model of an object, a person or a room affordably. Skanect transforms your Structure Sensor or Structure Core depth sensor into a low-cost 3D scanner able to create 3D meshes out of real scenes in a few minutes.

Click here to get skancet

Using XBOX360 has three 3d depth sensors and an RGB camera. XBOX360 has a stand to allow you to rotate in front of it freely and flexibly, as well as you can stay constant, and another person rotate the XBOX360 gently around you.

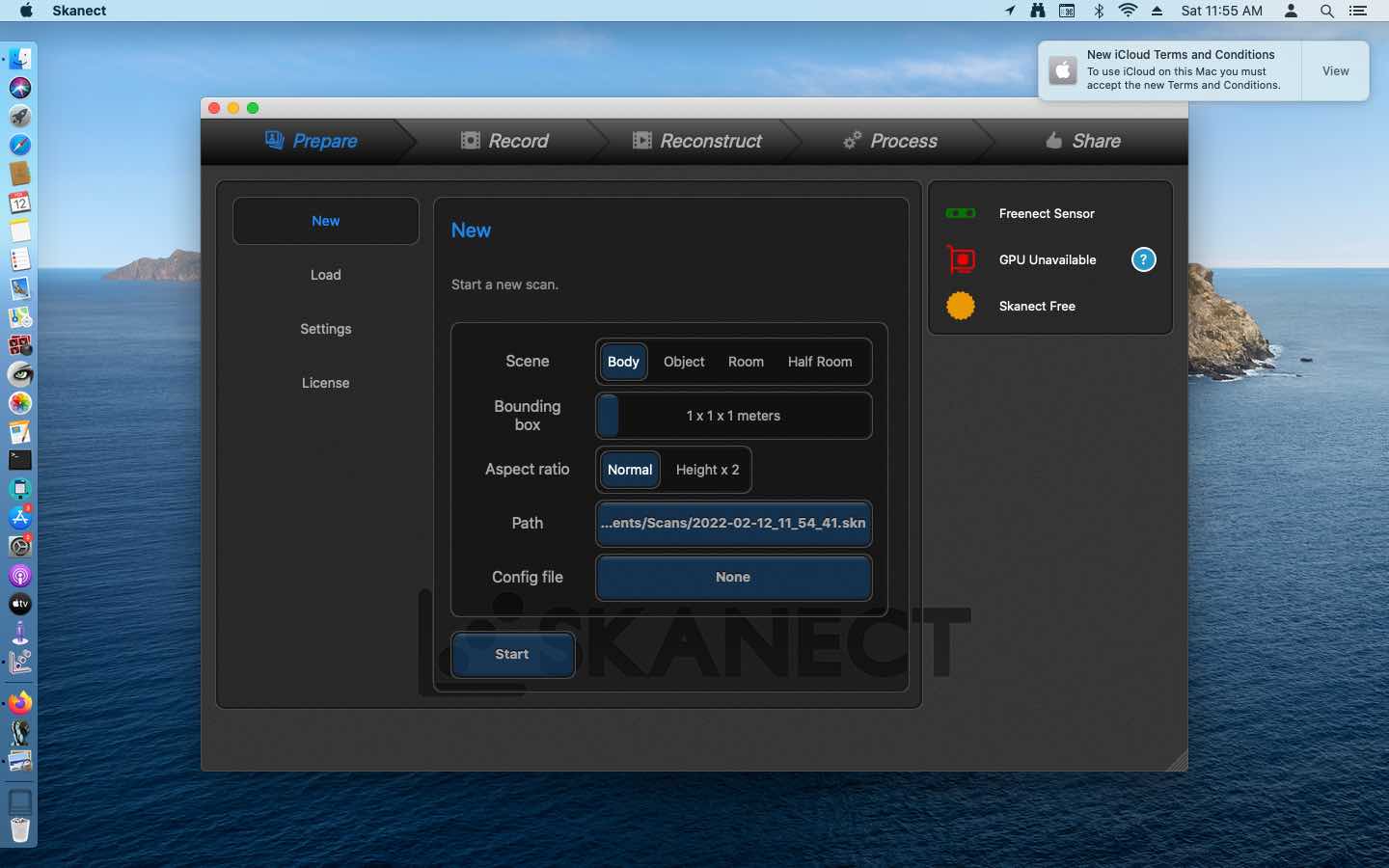

Before scanning, you have to adjust the setting so XBOX 360 can recognize the scanned object, while I will scan myself so I chose the body

Before scanning, you have to adjust the setting so XBOX 360 can recognize the scanned object, while I will scan myself so I chose the body

Here is my final result, noting the hole on top of my head because XBOX 360 take the shape on one moving axis,so I filled that hole through the setting -> Geometry -> fill hole

Here is my final result, noting the hole on top of my head because XBOX 360 take the shape on one moving axis,so I filled that hole through the setting -> Geometry -> fill hole

Choose fill hole.

So the problem solved

3D Printing¶

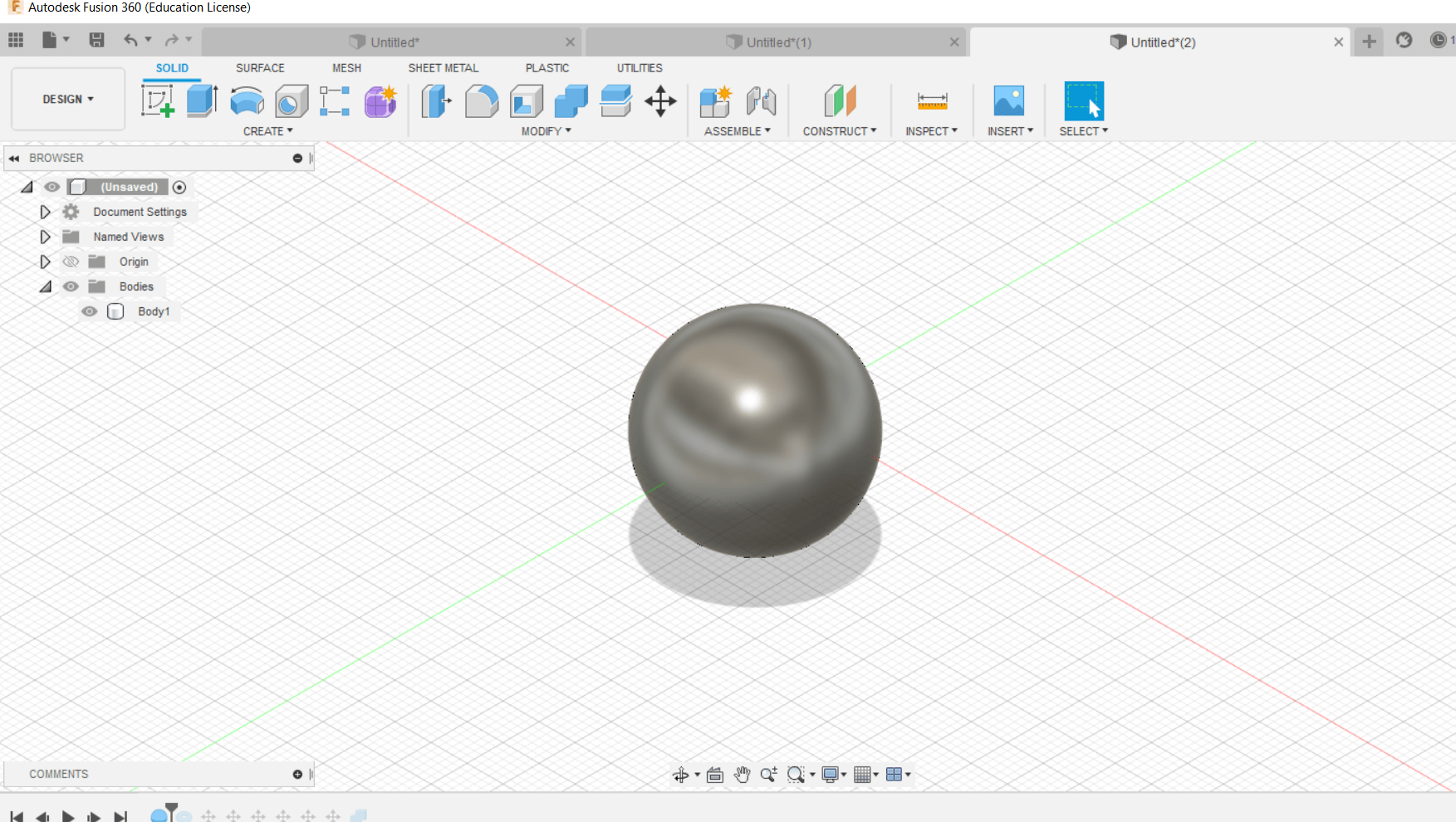

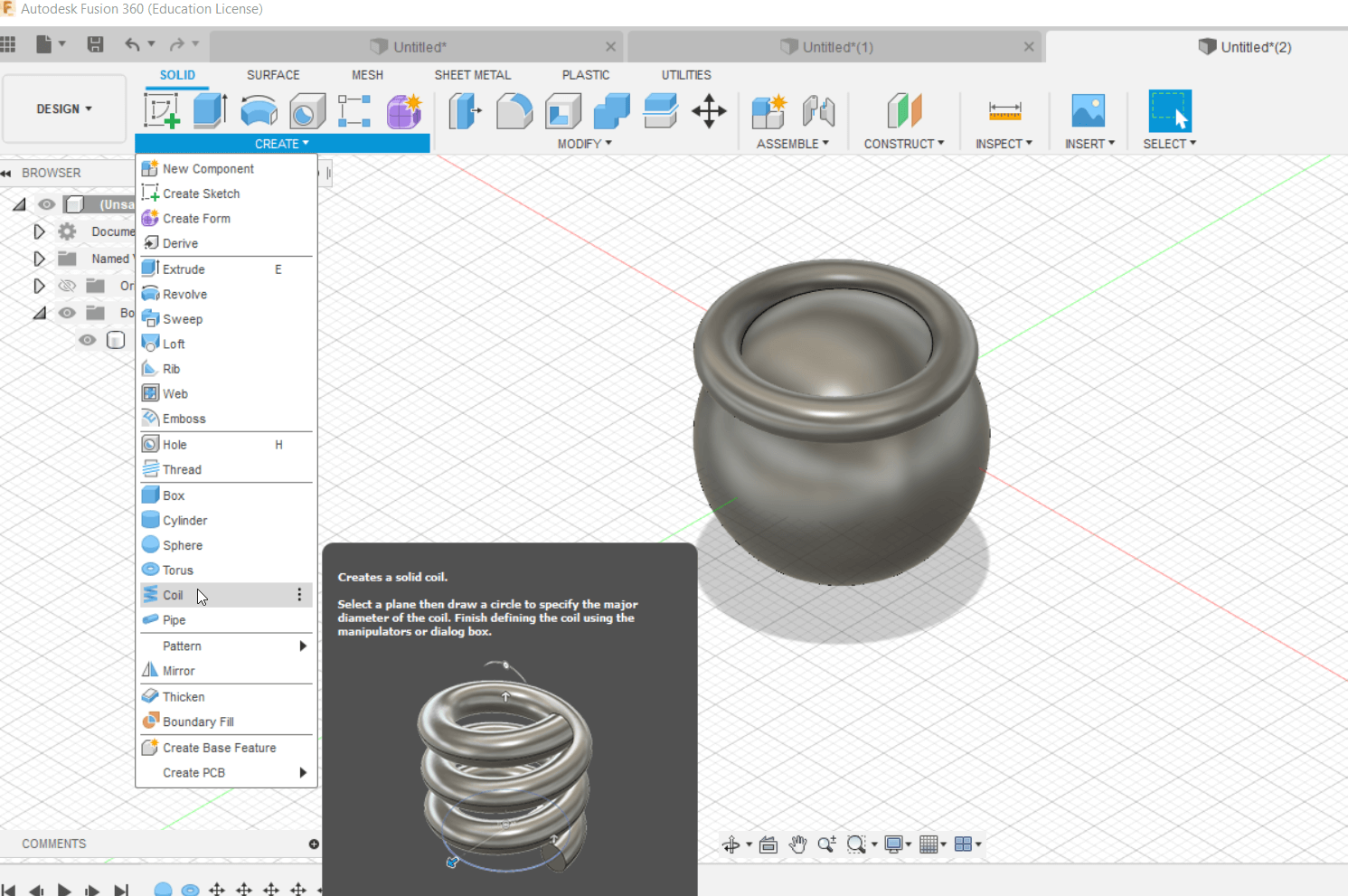

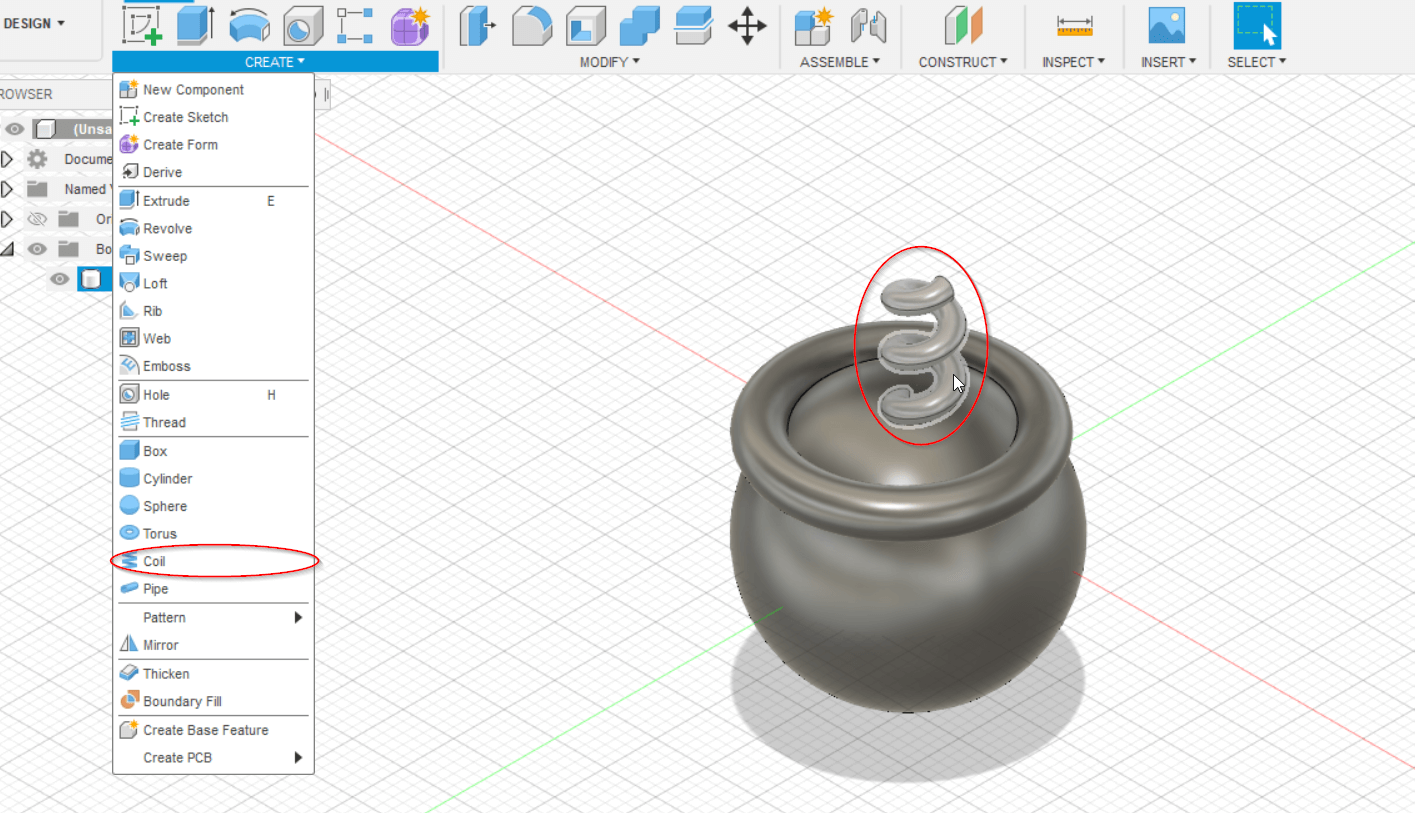

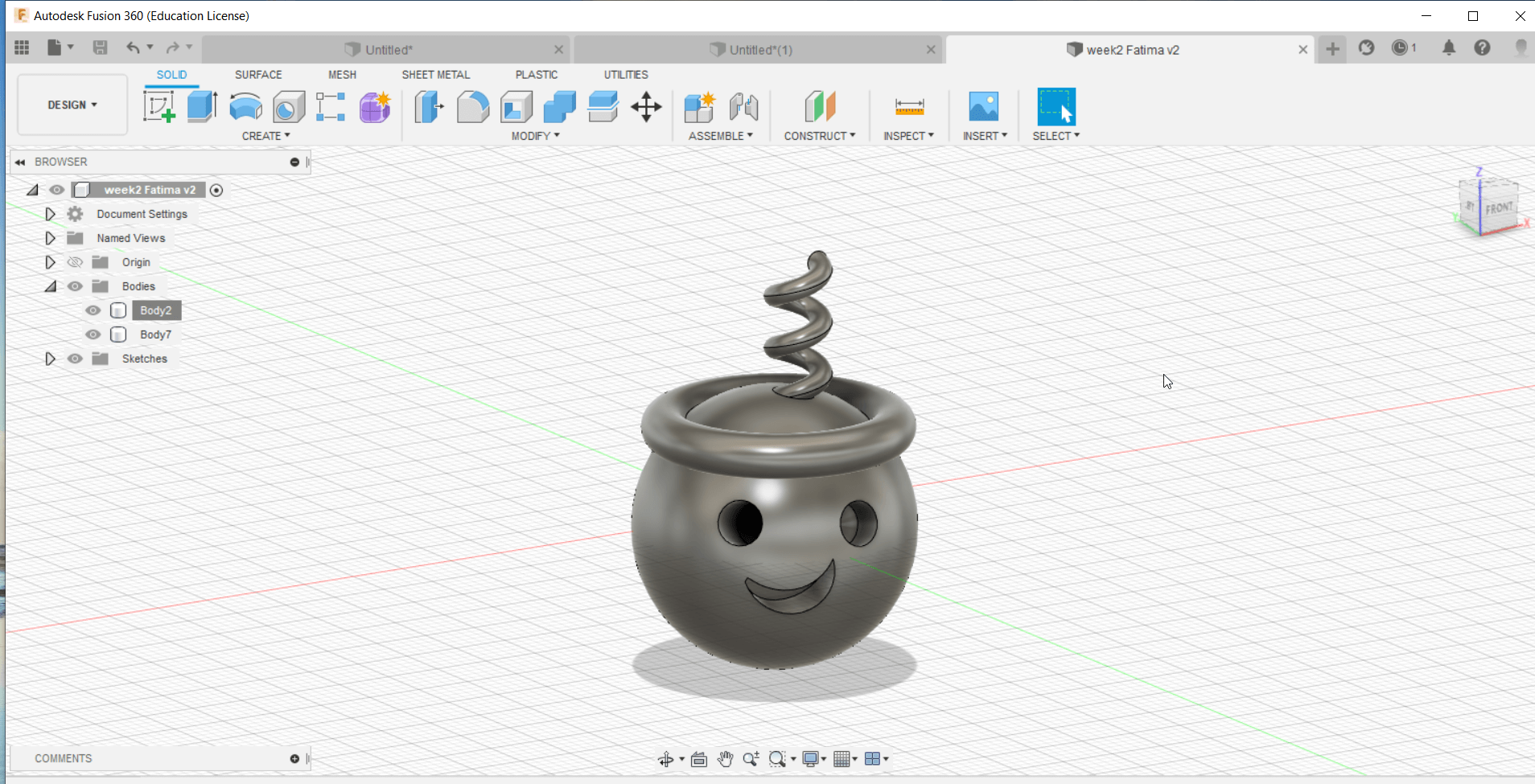

I have printed my first design using the Fusion360 software UltiMaker 3D printer

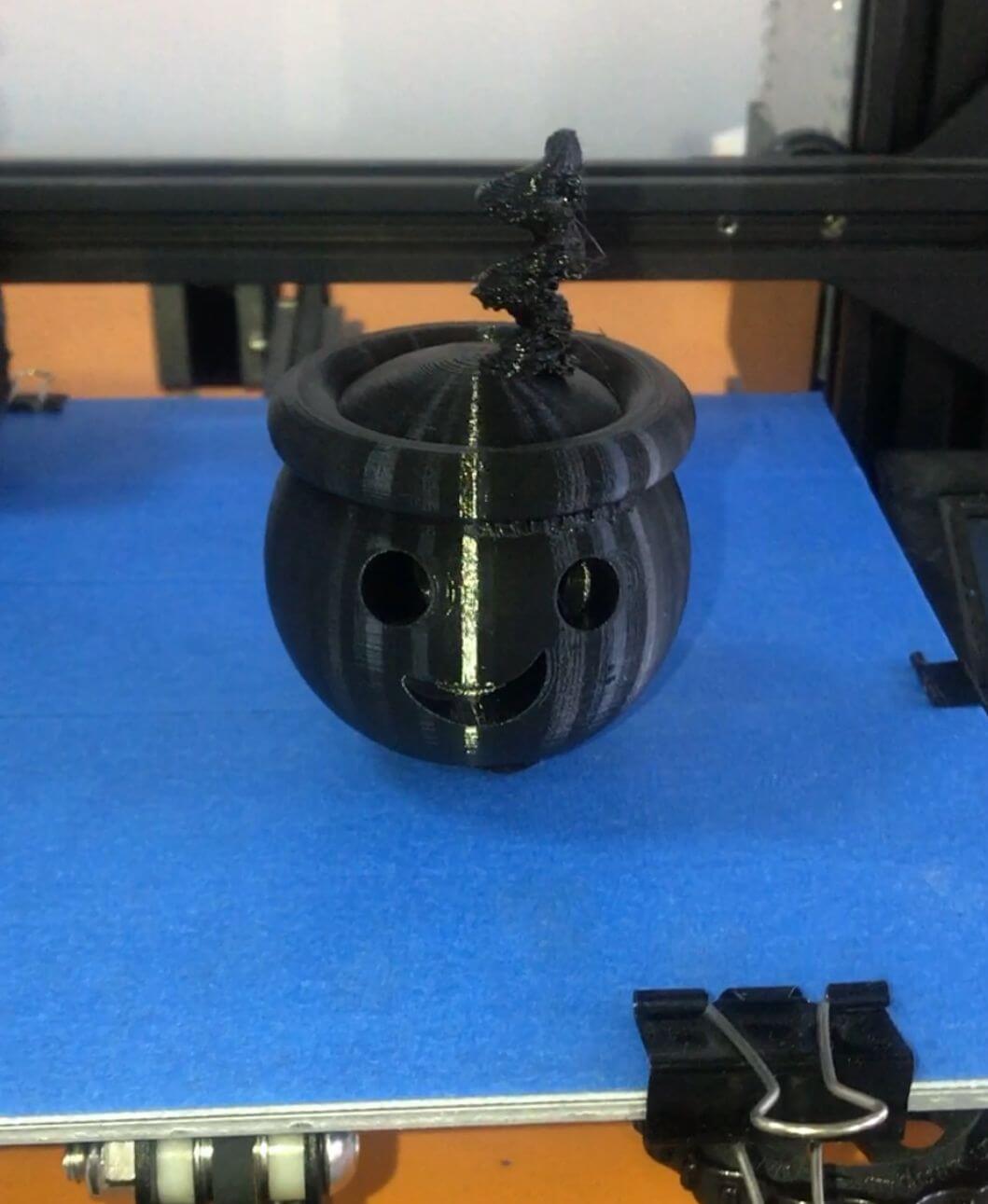

I chose a happy sphere masterpiece design

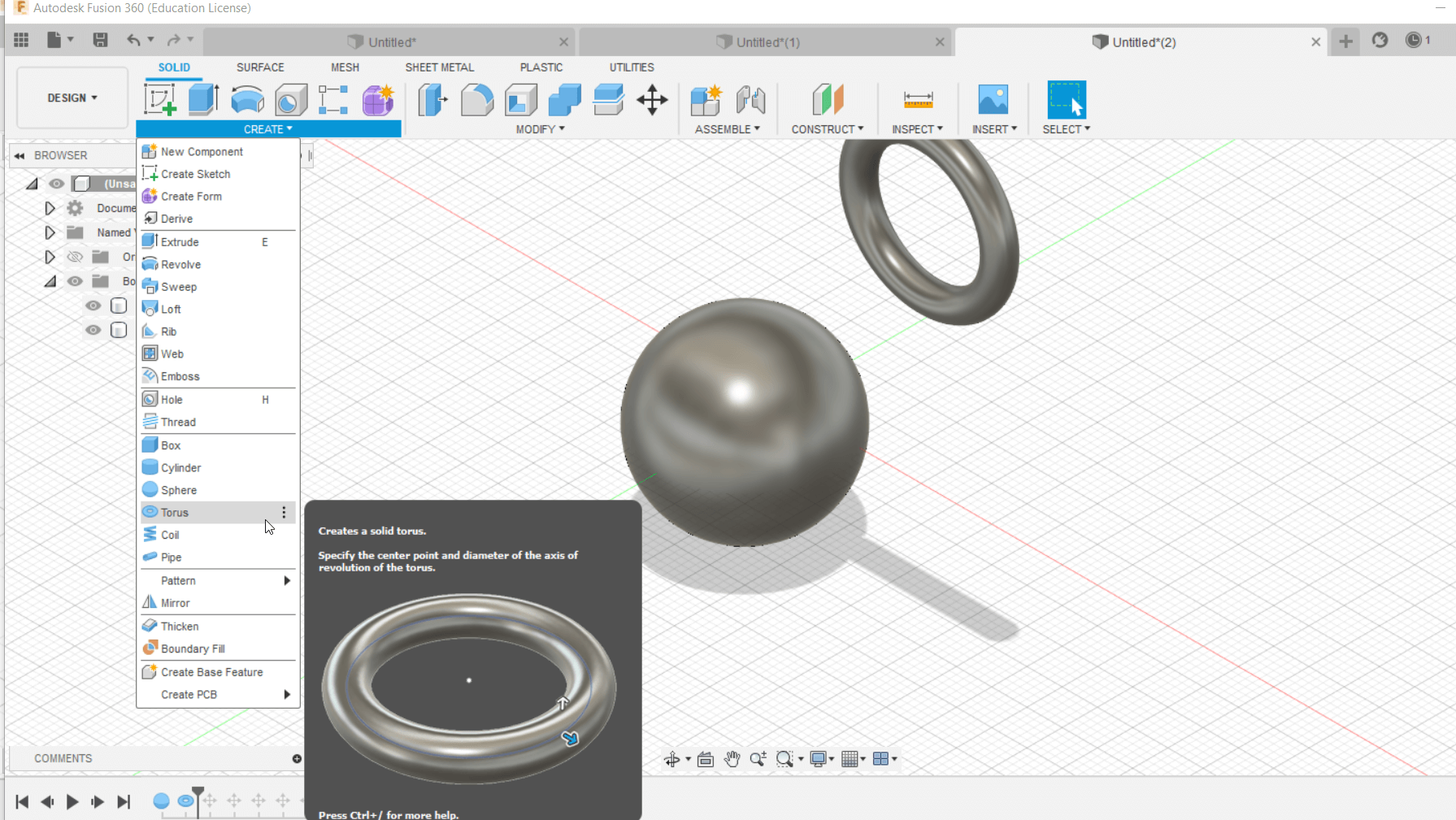

So I drag a sphere from the built-in components [solid -> create -> sphere], I put it on the desired location while I can move it by [Control + M]

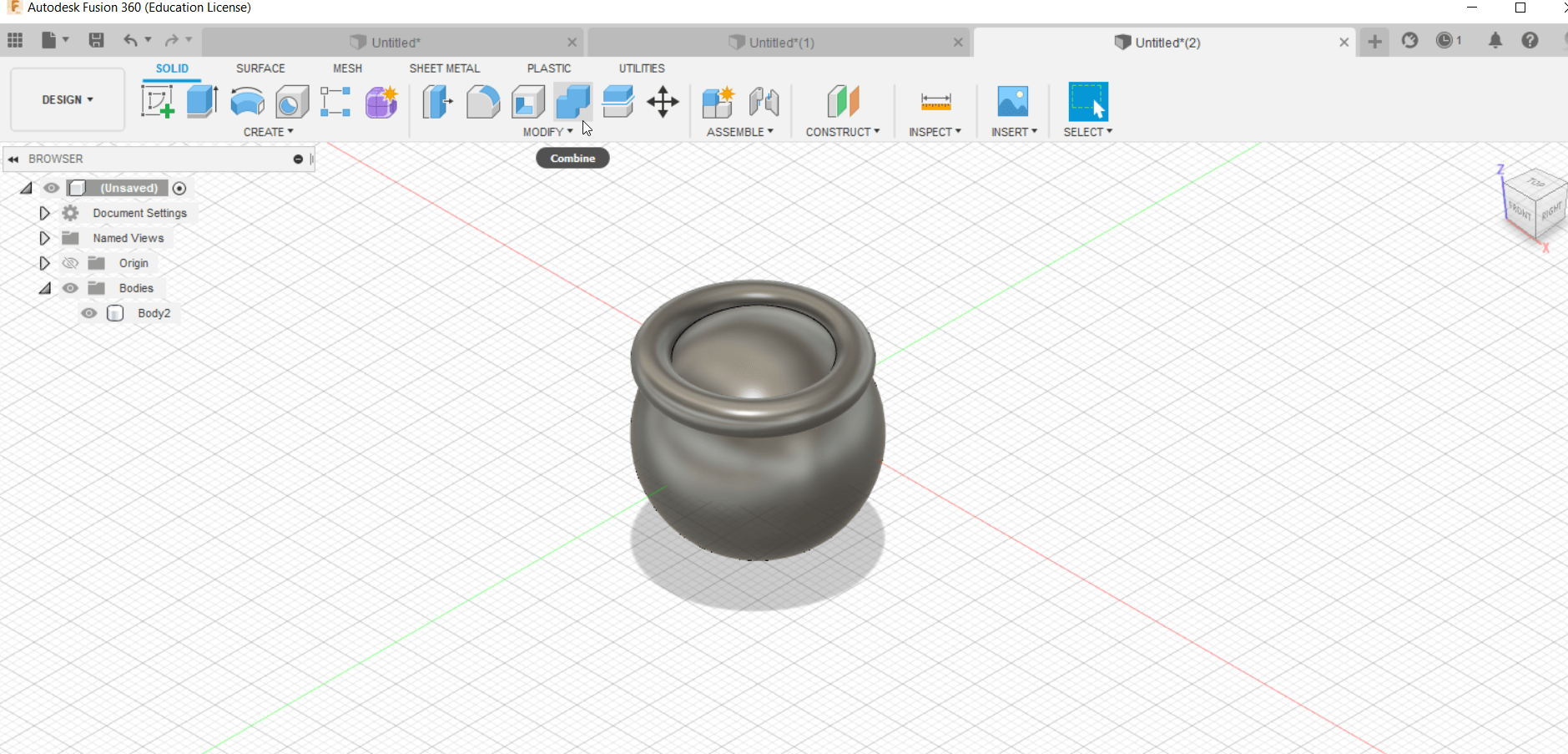

I can combined two or more components to be one body

I can combined two or more components to be one body

I have created 2 holes for the eyes and sketched the mouth as I have done in the previous Fusion360 design

I have created 2 holes for the eyes and sketched the mouth as I have done in the previous Fusion360 design

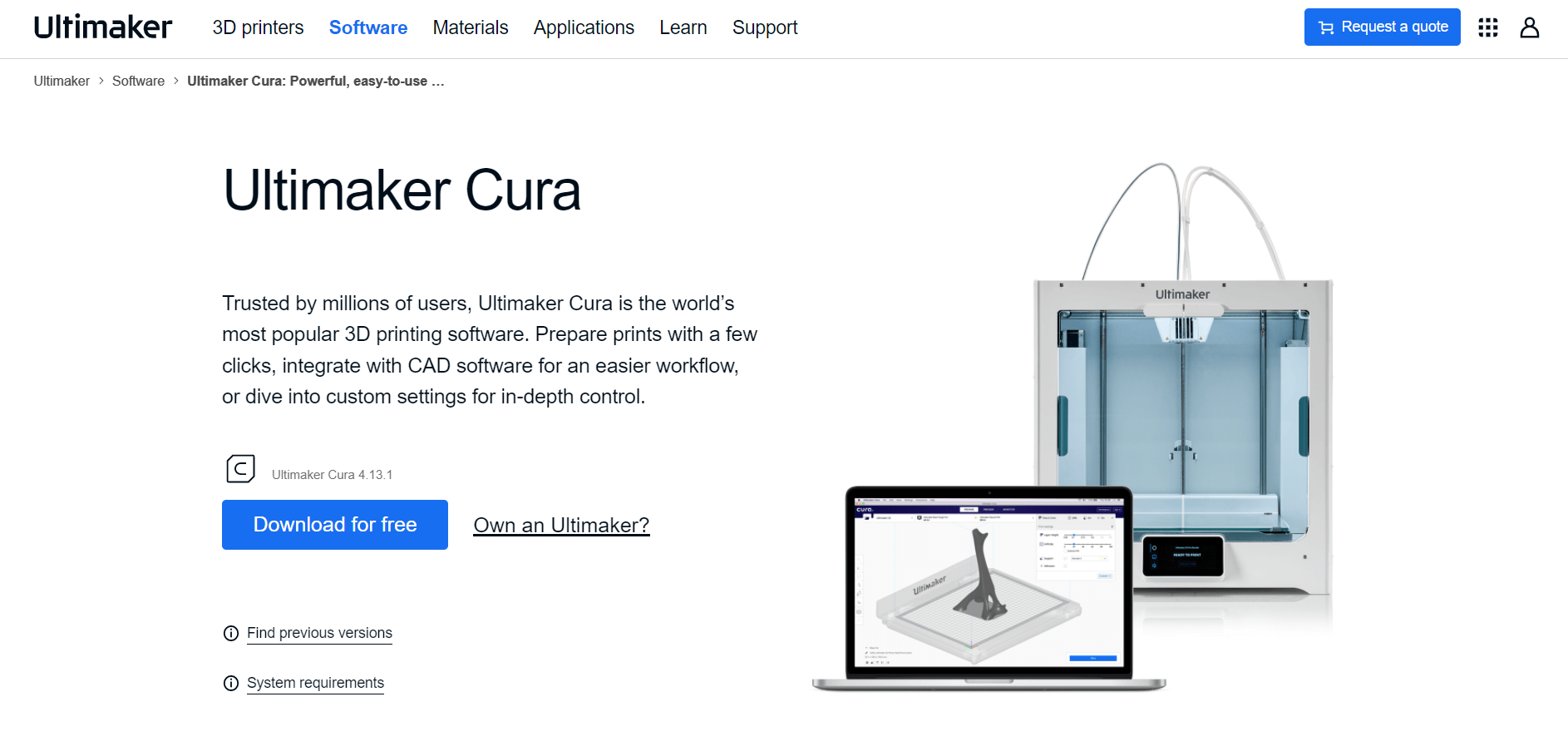

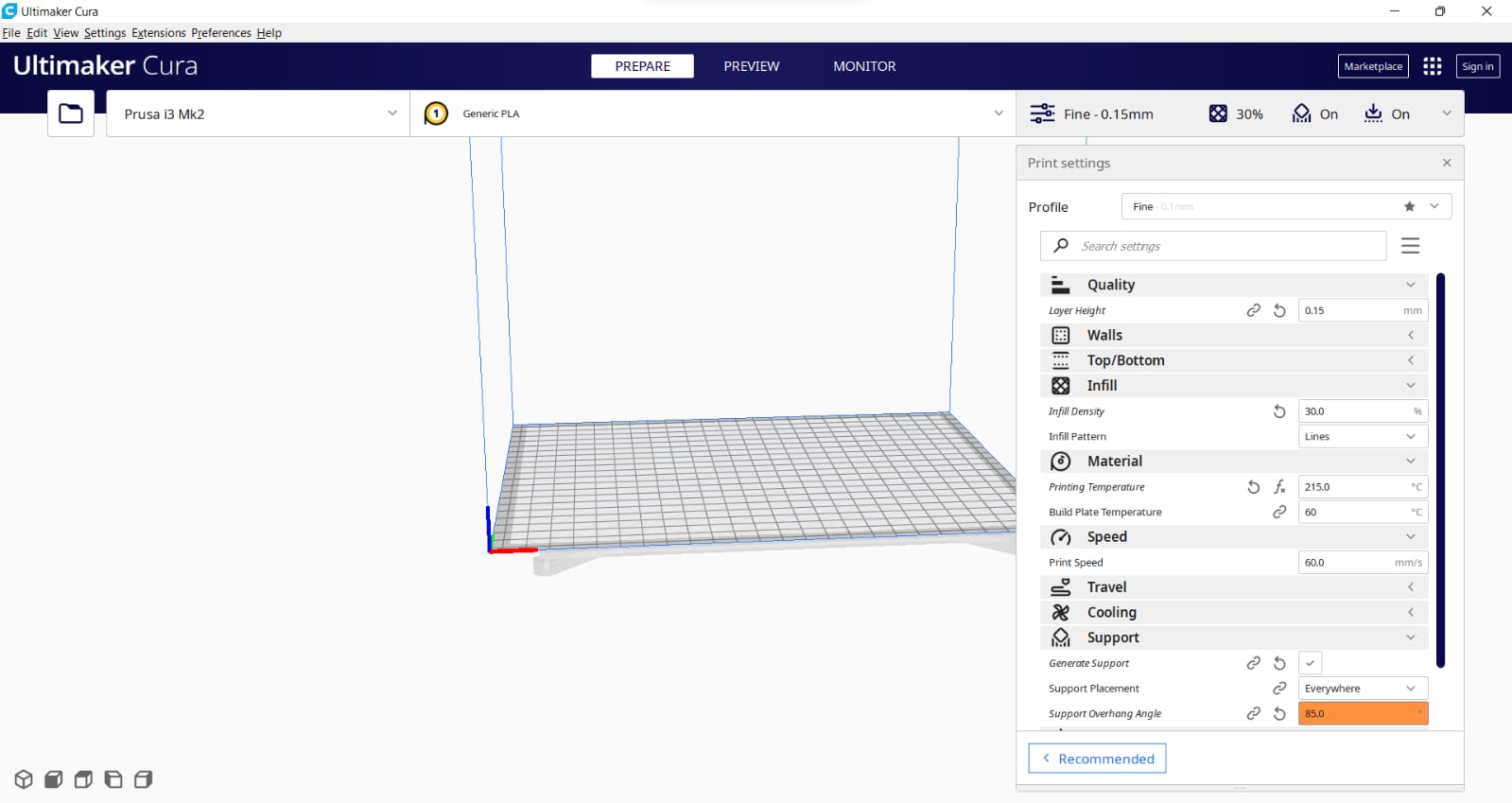

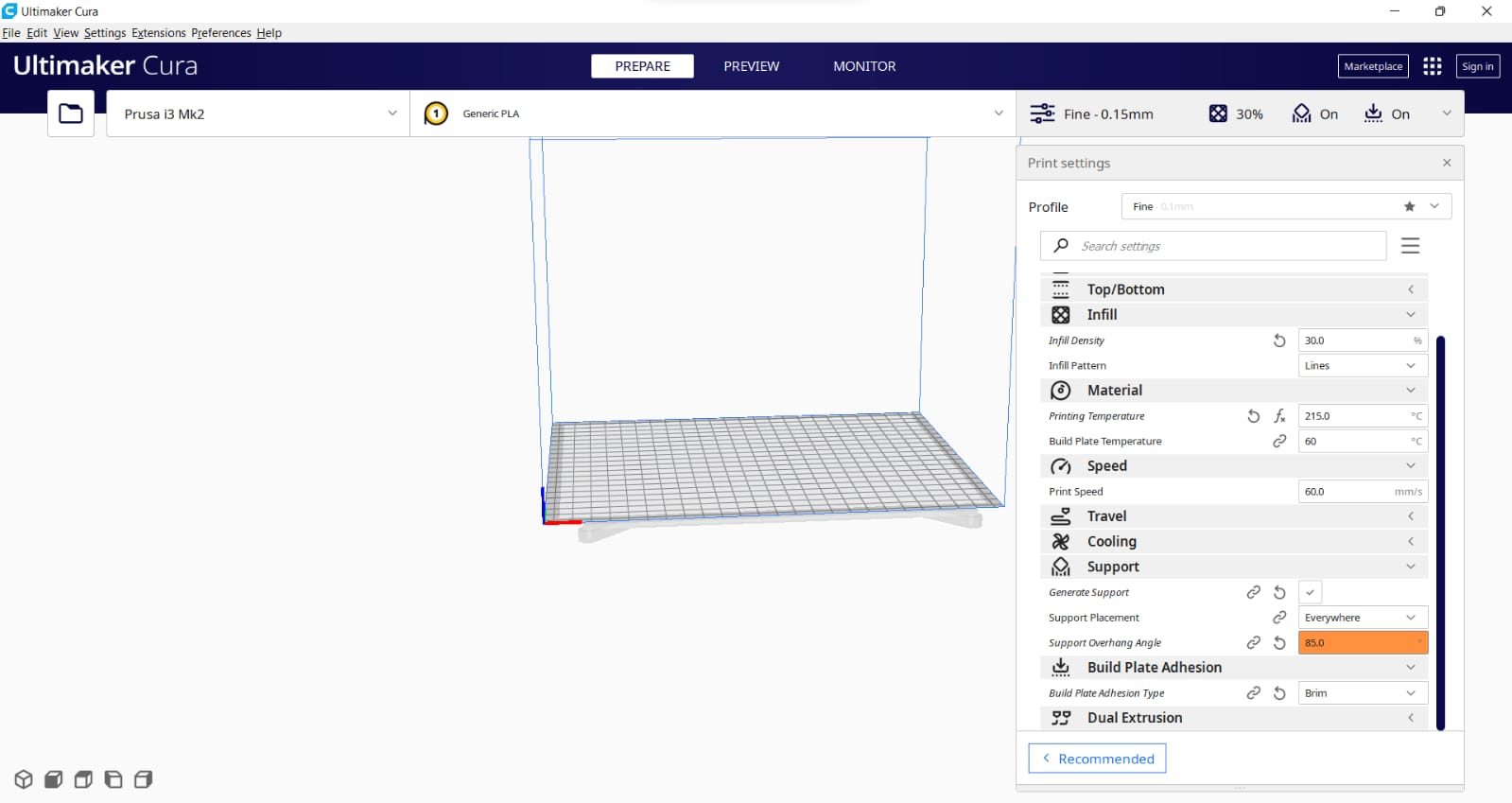

Here is the setting for cura printing

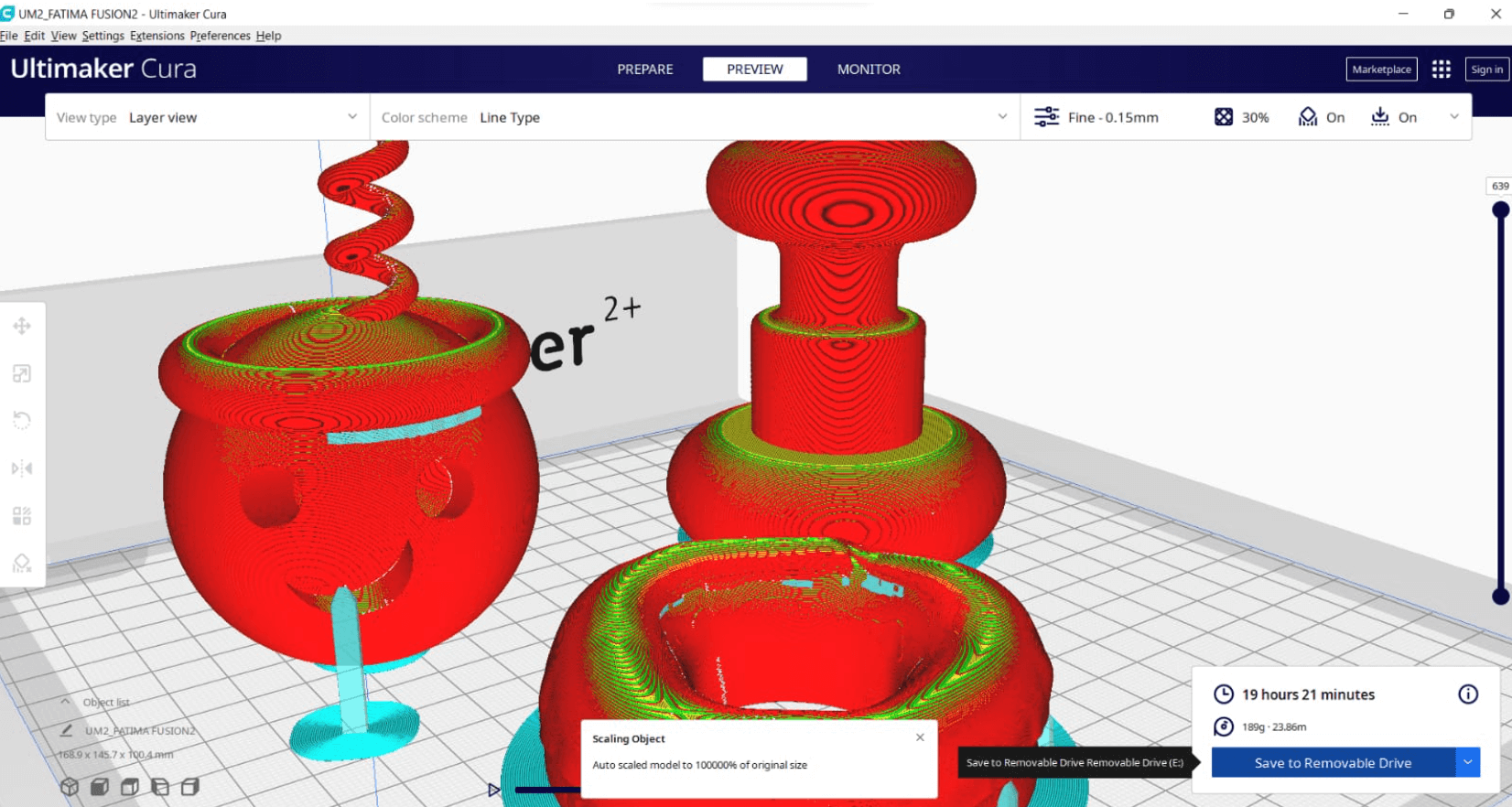

After selecting slice, the time it will take to print will appear

After selecting slice, the time it will take to print will appear

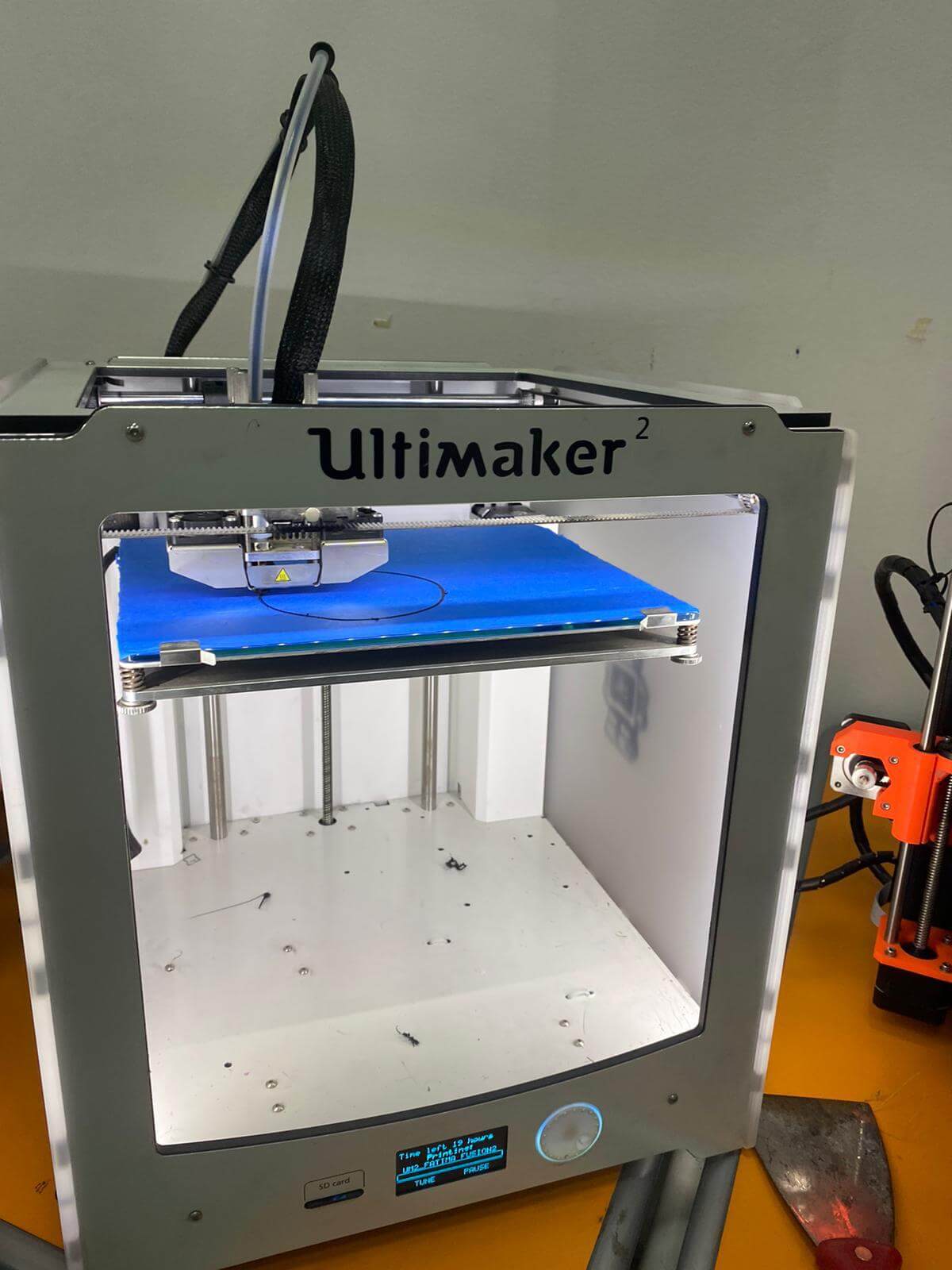

I have used UltiMaker printer, We have to insert the SD card and adjust the filament

I have used UltiMaker printer, We have to insert the SD card and adjust the filament

Hero Shots¶

what I have learned from testing the 3D printers¶

3D printers build parts from three-dimensional models, the mathematical representations of any three-dimensional surface created using computer-aided design software or developed from 3D scan data. The design is then exported as an STL or OBJ file readable by print preparation software. 3D printers include software to specify print settings and slice the digital model into layers that represent horizontal cross-sections of the part. Some 3D printers use a laser to cure liquid resin into hardened plastic, others fuse small particles of polymer powder at high temperatures to build parts. Most 3D printers can run unattended until the print is complete.

why it could not be easily made subtractively¶¶

Additive manufacturing processes build objects by adding material layer by layer, while subtractive manufacturing removes material to create parts. Both have cases where it makes sense to use one approach over the other, but additive manufacturing is the best choice to create the smiley sphere. Disadvantages of subtractive manufacturing It cannot alter the volumetric density of building material. Material wastage takes place. Process planning is mandatory (it is a laborious task that needs a lot of data). Limited capability in feature form (enclosed features cannot be generated).

Fesign Files¶

Happy Sphere Design File CAD Design file