4. Laser Cutting¶

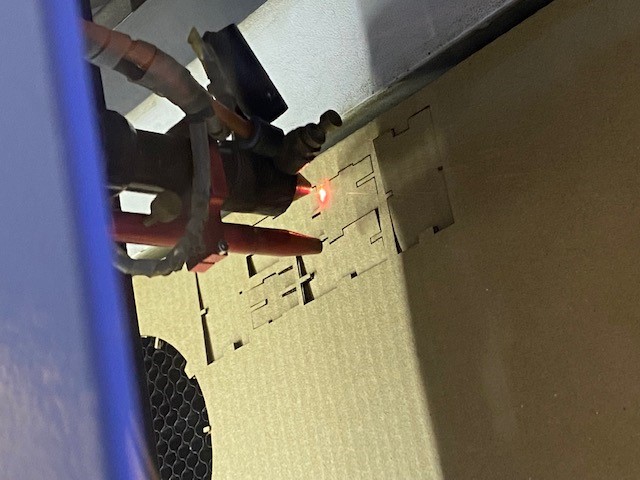

in this week we learned about laser cutting and the multiple characterization like focus, power, speed, rate, kerf, and joint clearance. also we leaned how to operate the laser cutting machine the safe way because it is very dangerous due to causing an injury or fire in the workshop. we were divided into multiple groups and each group have two partners that Research about the characterization of laser cutting. Focus laser cutting is the topic that we research about for my group, we leaned that focus laser cutting needs to be accurate and to check everything before executing so the cut will be as neat and clean as possible. also, the closeness of the laser to the object effects the result of the cut because if the laser is far from the object, the laser will not cut the object but it will reheat it which can lead to reshaping the object depending on its material. plus, the object must be placed on a surface to elevate it so the laser can cut it.

Group Assignment¶

for this week we were divided into groups and each of us searched about the characteristics and features of the laser cutter. for more details please check out this link: Group Assignment

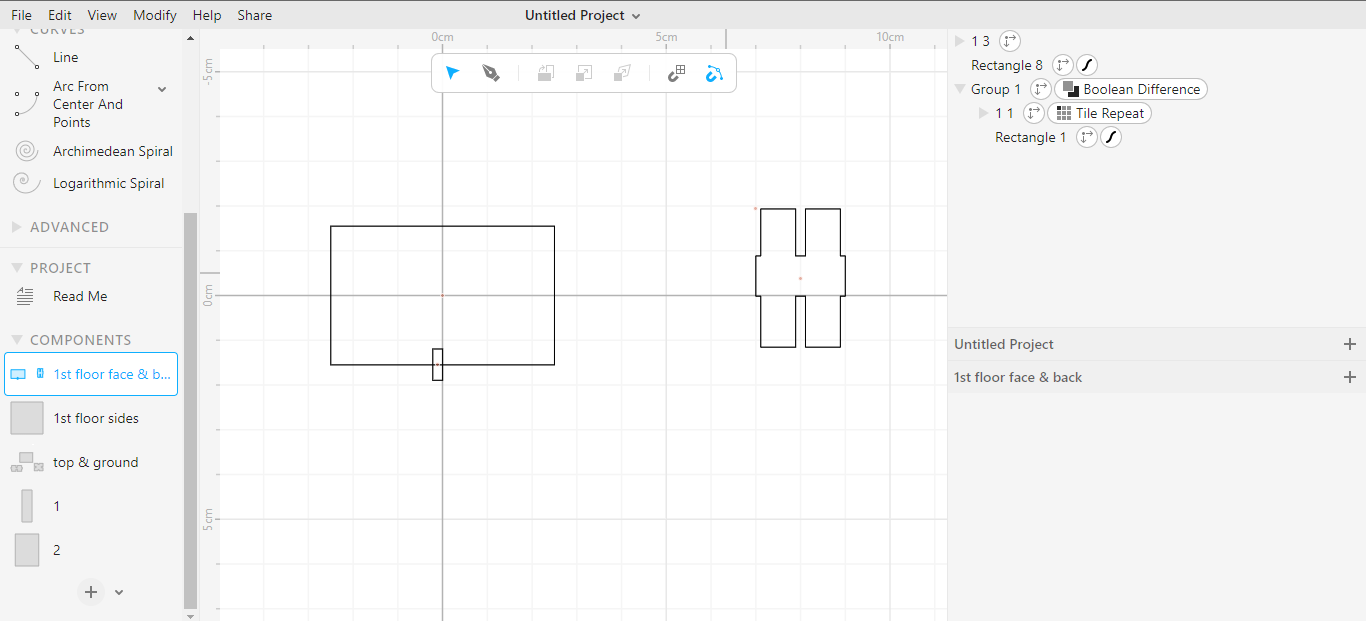

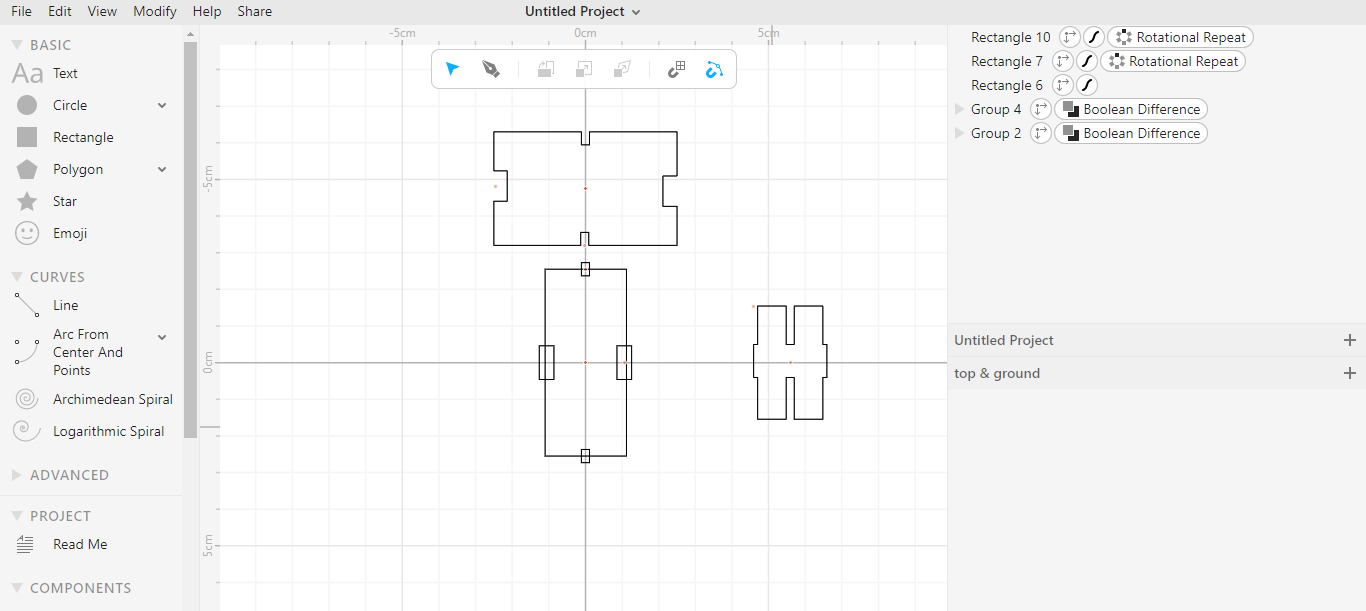

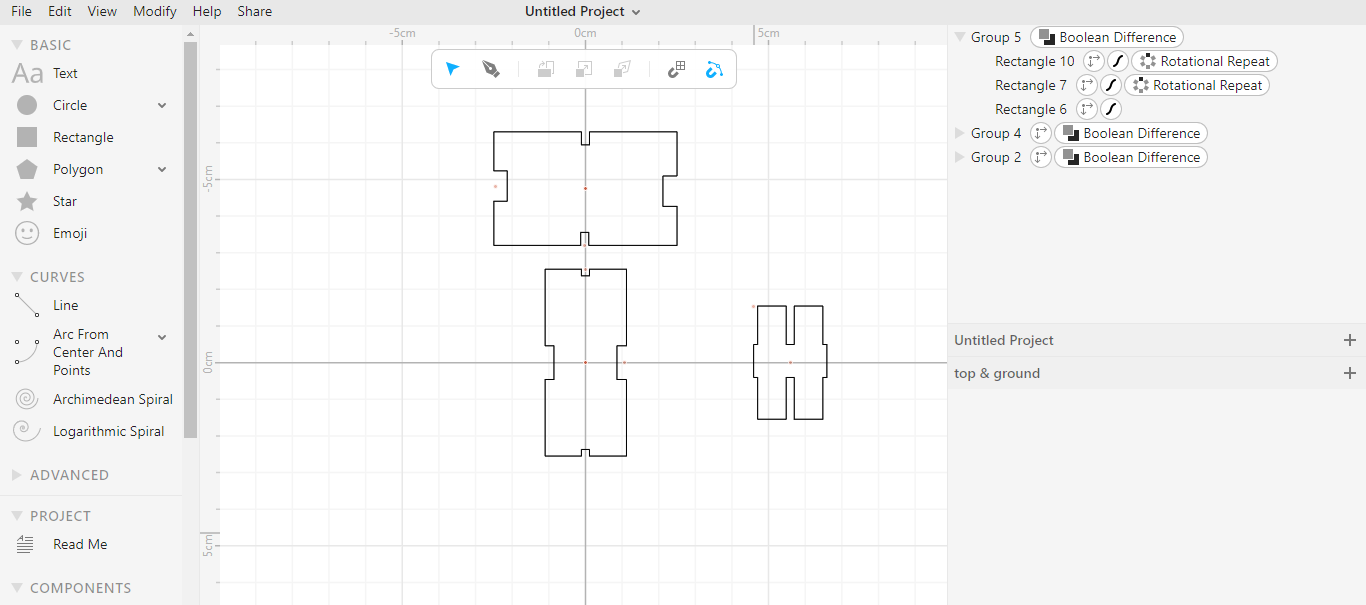

Parametric press-fit construction kit¶

parametric press-fit construction kit is cutting pieces on laser cutter using any material you like (I used carton) to construct a structure that you like with the pieces, the pieces can be designed on any 2D or 3D software so i used cuttle because i find it easy and includes a variety of tools to design the pieces, plus there is a tutorial to teach you how to use the software which was very helpful. parametric press-fit construction kit is a cool exercise that requires the use of imagination, creation and construction. for my design i tried to make a bridge with pieces that are shown below.

Vinyl cutter¶

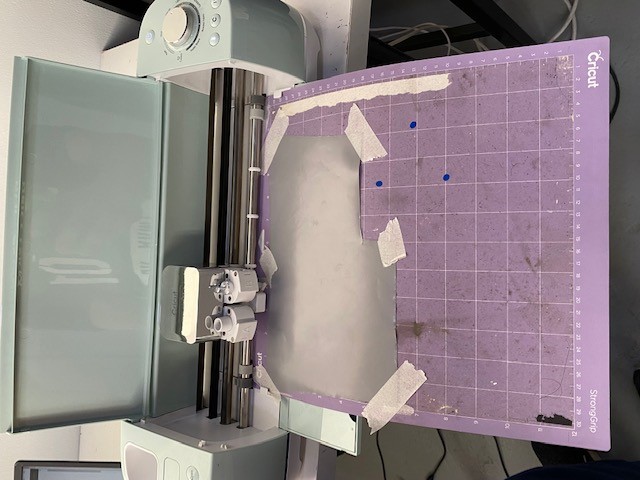

Vinyl cutter is a machine that cuts material depending on you design. Vinyl cutter works by inserting the material you want to cut in the machine and then adjusting the design and location of your design on the PC via connecting the machine program to the PC so the cut will be neat. when everything is ready design wise, just adjust the machine rotation circle to Vinyl so it knows what is the material you are going to cut and then press start.

Sticker¶

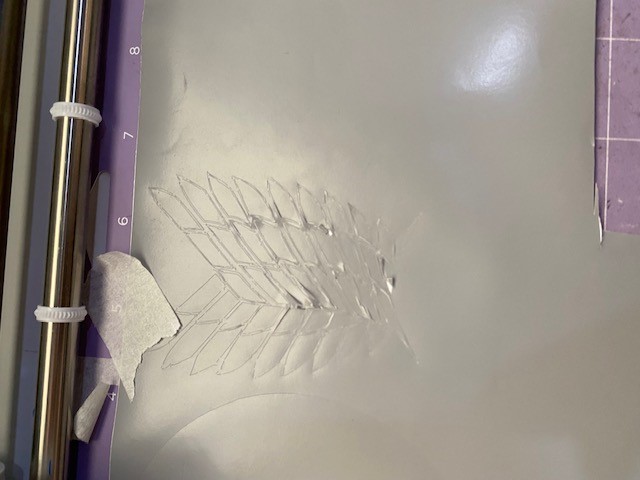

However, for our exercise we used vinyl to create stickers so i started to think about cool designs and i wanted to make a sticker of the logo of my favorite show (Attack on titan) so i searched for attack on titan logo black and white and found many designs.

but, unfortunately it was a failed attempt due to the design had many small and separated objects that was hard to remove the extra vinyl to transfer it to the sticker so my advice is to pick a design with few objects or one whole object.

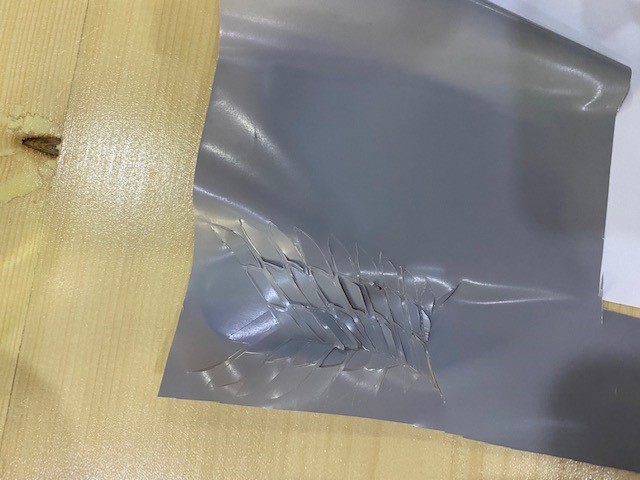

on my second attempt, i used the logo of my favorite game (god of war) which is the omega sign so i searched for god of war omega sign. thankfully, it was a success to cut and was easy to make it into a sticker.

Final Result¶

The final result was better then what i expected because the omega sign became a beautiful sticker with no rough edges or bubbles and the bridge was solid and strong enough to hold two floor bridge.