6. Large Format CNC (Computer Controlled Machining)¶

Introduction¶

This week we learned about Computer Controlled Machining (CNC) theoretically and practically and each student ended up with a production of a piece of furniture. So, what is CNC? And how does it work?

Theoretical Part¶

CNC¶

CNC stands for Computer Numerical Control. It is a computerized manufacturing process in which pre-programmed software and code control the movement of production equipment. It is an ideal example of a subtractive type of machine with huge waste.

CNC machine is the largest machine in Fab Lab and its usage range from a small piece of furniture to architectural constructions.

Drill Bits¶

By the use of the drill bits, the CNC machine eats away the material with the guide of the programmed design.

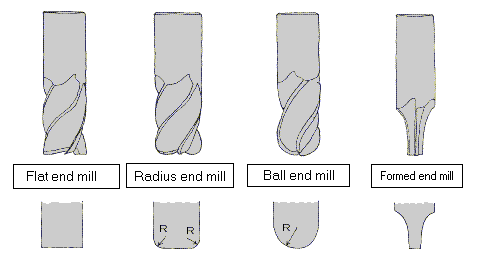

There are a variety of drill bits and each one of them is used to produce different types of cuts (as shown below). However, we do use the flat end mill bit in the Fab Lab.

Feed Rate¶

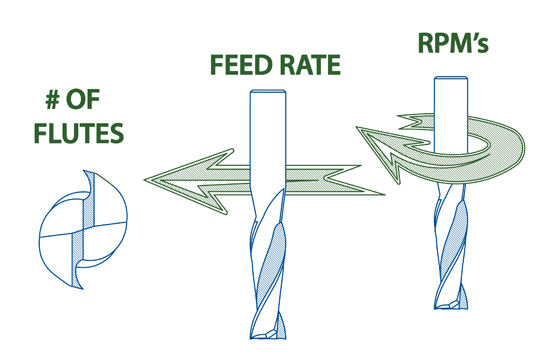

“It is the speed at which the cutter engages the part and is typically measured in units/minute.”

RPM¶

It is the revolutions per minute of the cutter or workpiece.

Notes:

- “Cutting speed and feed rate are often considered as a pair because of their combined effect on the cutting process.”

- Chip load and sound level are great indicators of the feed and speed of the machine (large chips = loud sound = high speed and vice versa).

Toolpath¶

“It is the path through space that the tip of a cutting tool follows on its way to producing the desired geometry of the workpiece.”

Joints¶

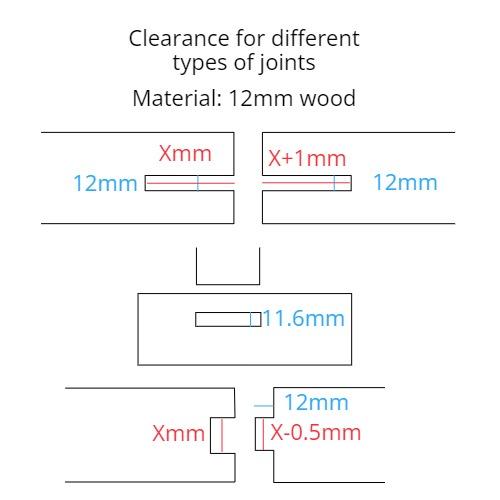

There are many different types of joints, and the following picture shows 3 types of 90 degrees clearances with their dimensions that work with 12 mm thick wood sheets.

T-bones and dog bones are great joint solutions that the CNC machine can provide for such above joints (90 degrees clearance).

Vcarve¶

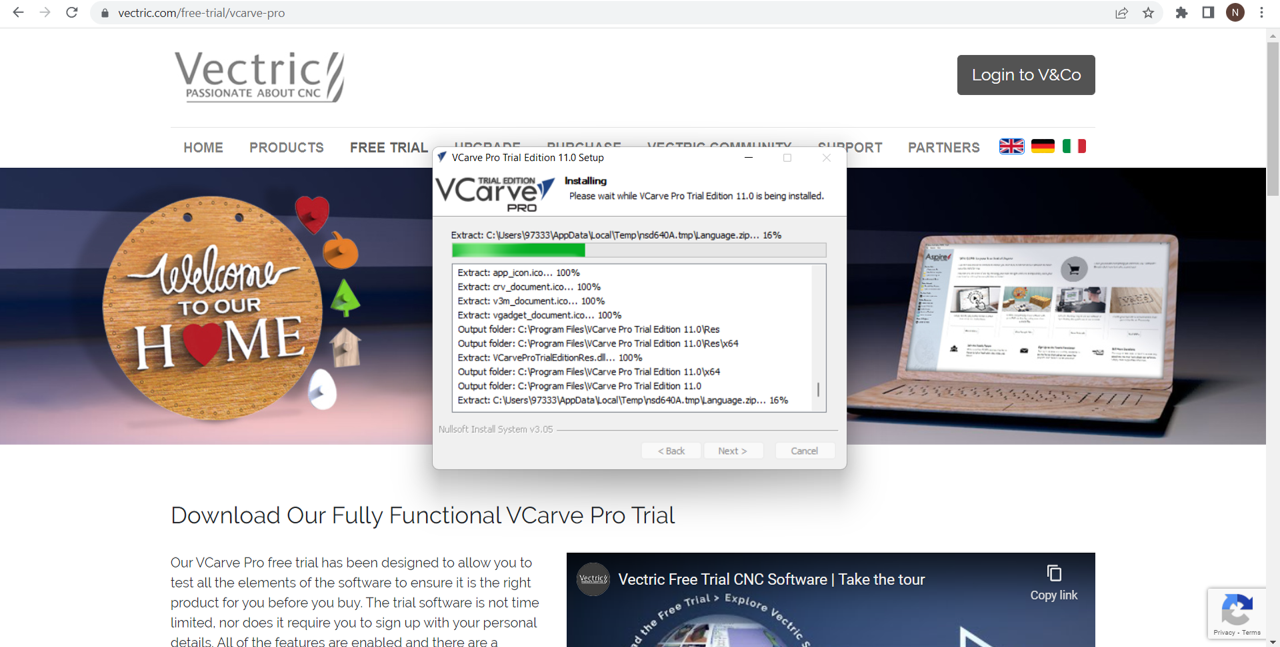

Vcarve provides a powerful but intuitive software solution for creating and cutting parts on a CNC Router. The pro version of it gives you the power to produce complex 2D patterns and a lot of execlusive features and tools. As for that, we were asked to download it (free trial).

Click here to download the Vcarve.

Extra Notes¶

- The lab will provide you with a full wood board (4 x 8 ft.) for your design.

- Fixing the sheet/board with screws is essential to secure it.

- Try your best to make your design parametric, as it will save your time and effort in case of errors.

Practical Part¶

Group Assignment¶

For the group assignment, we were asked to test runout, alignment, speed, feeds, and toolpaths of the CNC machine. The following picture gives you a brief description of what we did:

Click here for more information and details about the group assignment.

Individual Assignment¶

Idea¶

Since we were required to produce a child-theme piece of furniture that we would be donating to a charity eventually, I started by collecting pictures from Pinterest as you can see below.

Then, I decided to make a multi-use piece of furniture that serves children from different age groups, and simultaneously something easy to design as it was my first time designing with Fusion 360 and dealing with the CNC machine.

This is my choice after the approval by the instructors:

Designing¶

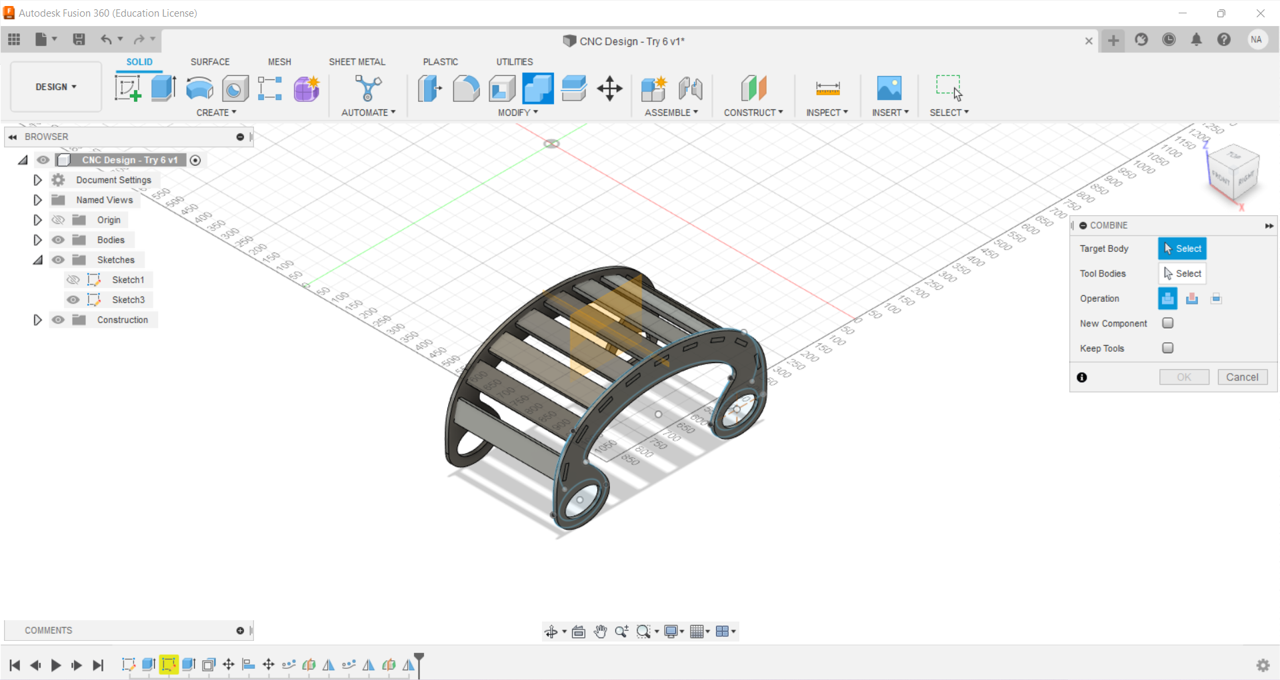

For the design, I used fusion 360 software.

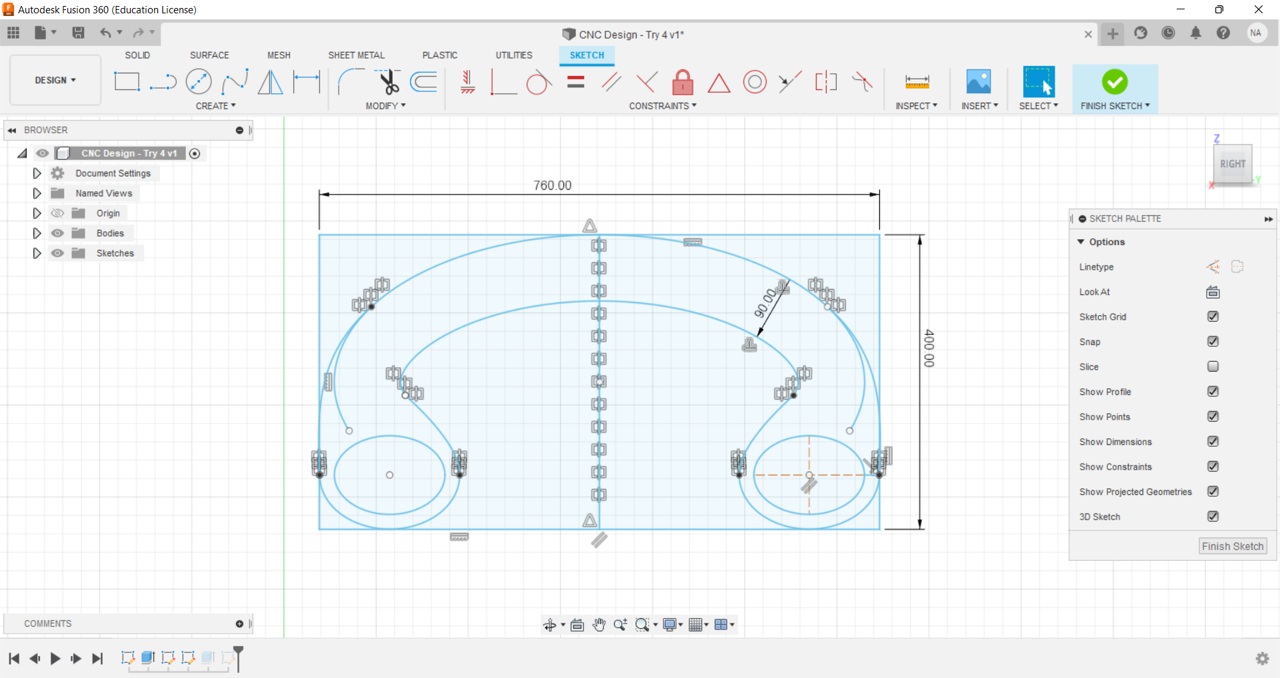

Firstly, I started by 2D sketching the two parts, putting in mind that the size of the final product is 400mm x 760 mm x 38 mm as a standard.

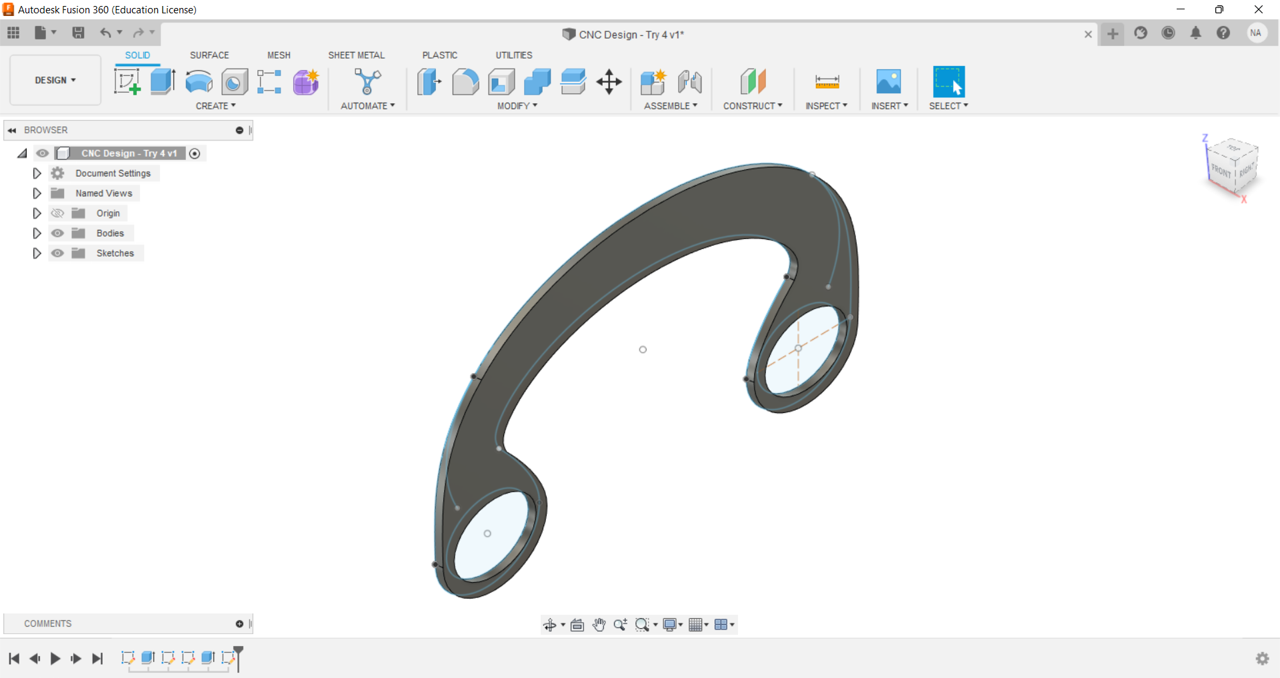

Secondly, I ended the sketch and used the Extrude tool in order to give them a thickness, which is the thickness of the wood that I will be cutting my design on it later on (12 mm).

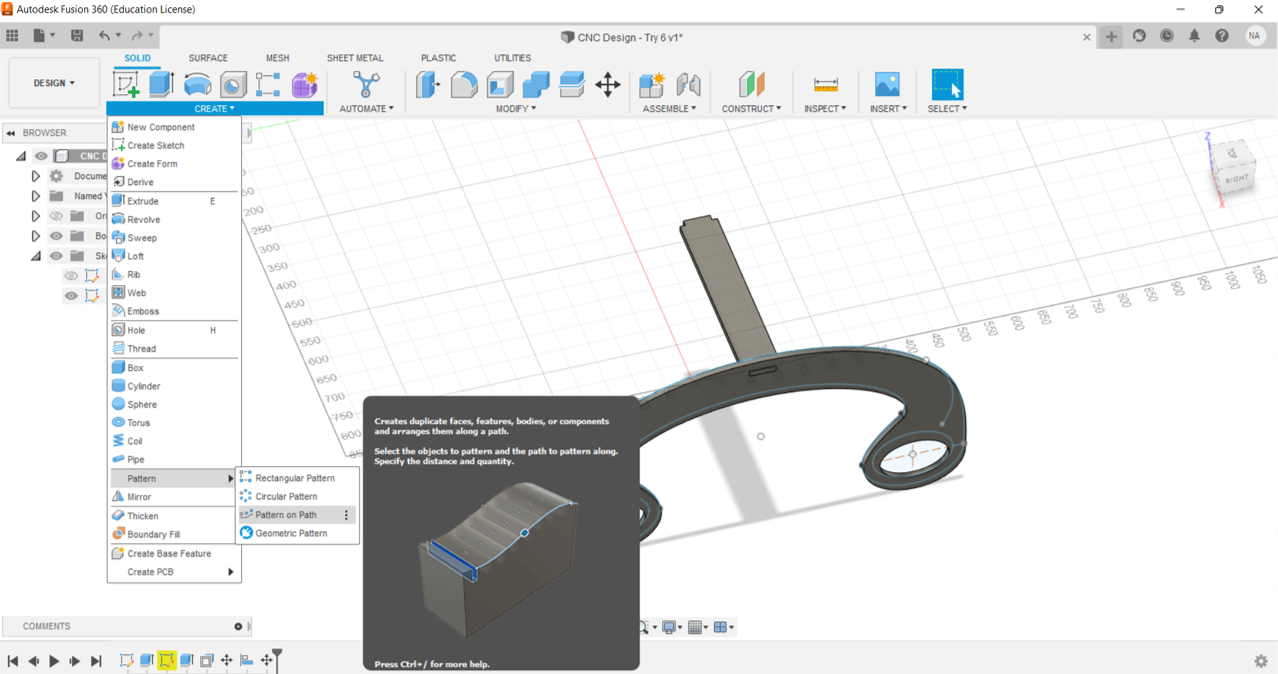

Thirdly, I joined the two parts together using the Move tool. Also, I used the Pattern on Path tool to repeat one of the parts over the other as shown below.

Last but not least, I created a plane in the center using the Construct tool and then mirrored the second part through it to the other side. In addition, I used the Combine tool which creates the holes wherever required as it reads all the parts as one.

Lastly, I saved each part of the design separately as .dxf files.

Click here to dowload the first piece of the design and Click here to dowload the second piece of the design.

Preview the CNC model below in 3D ^_^

Click here to download Fusion 360 file ^_^

Cutting¶

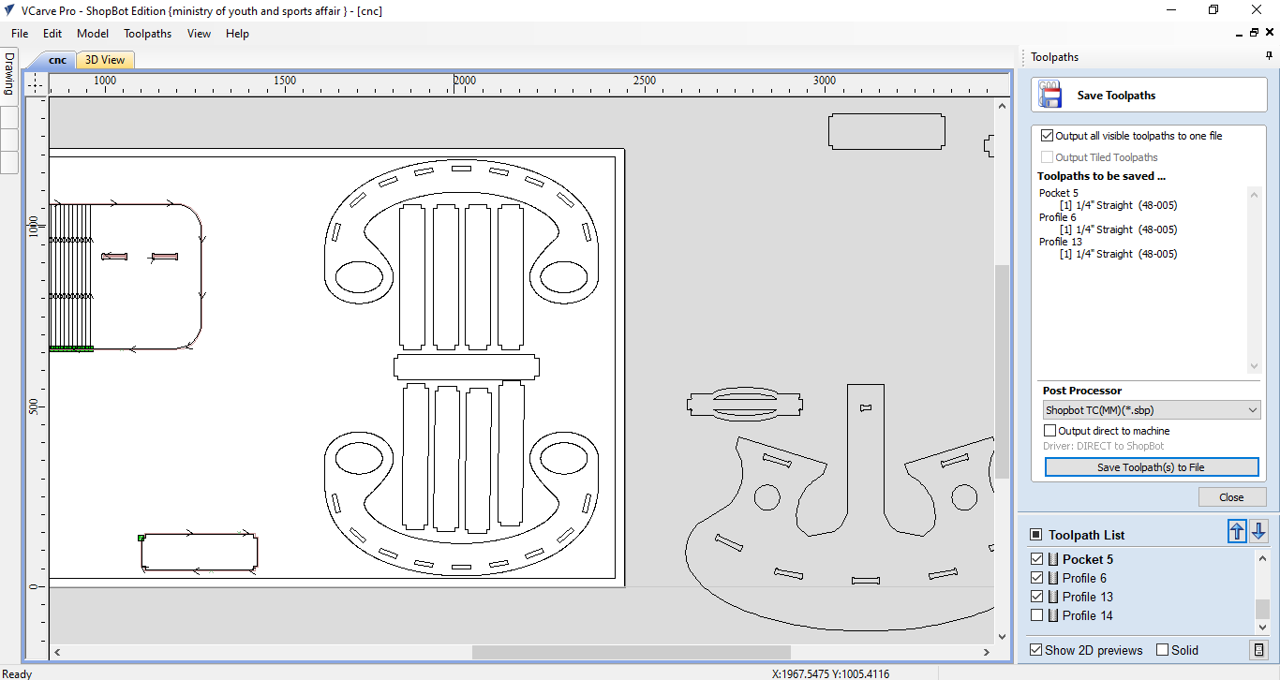

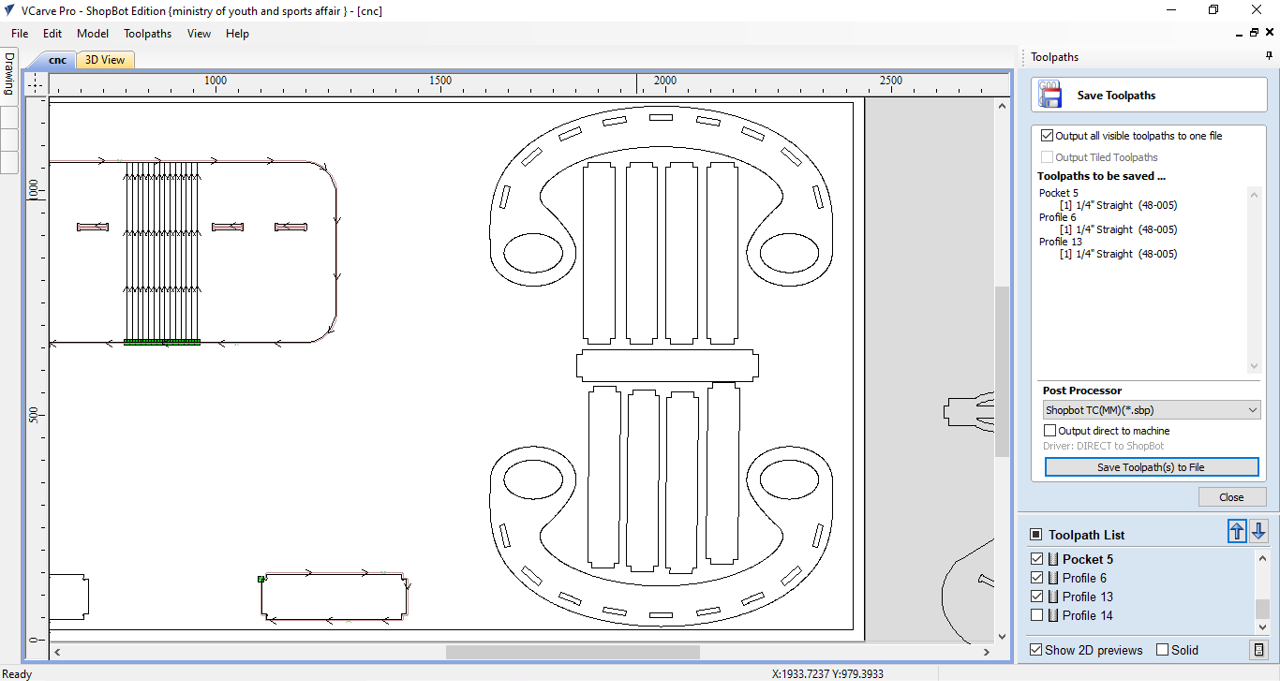

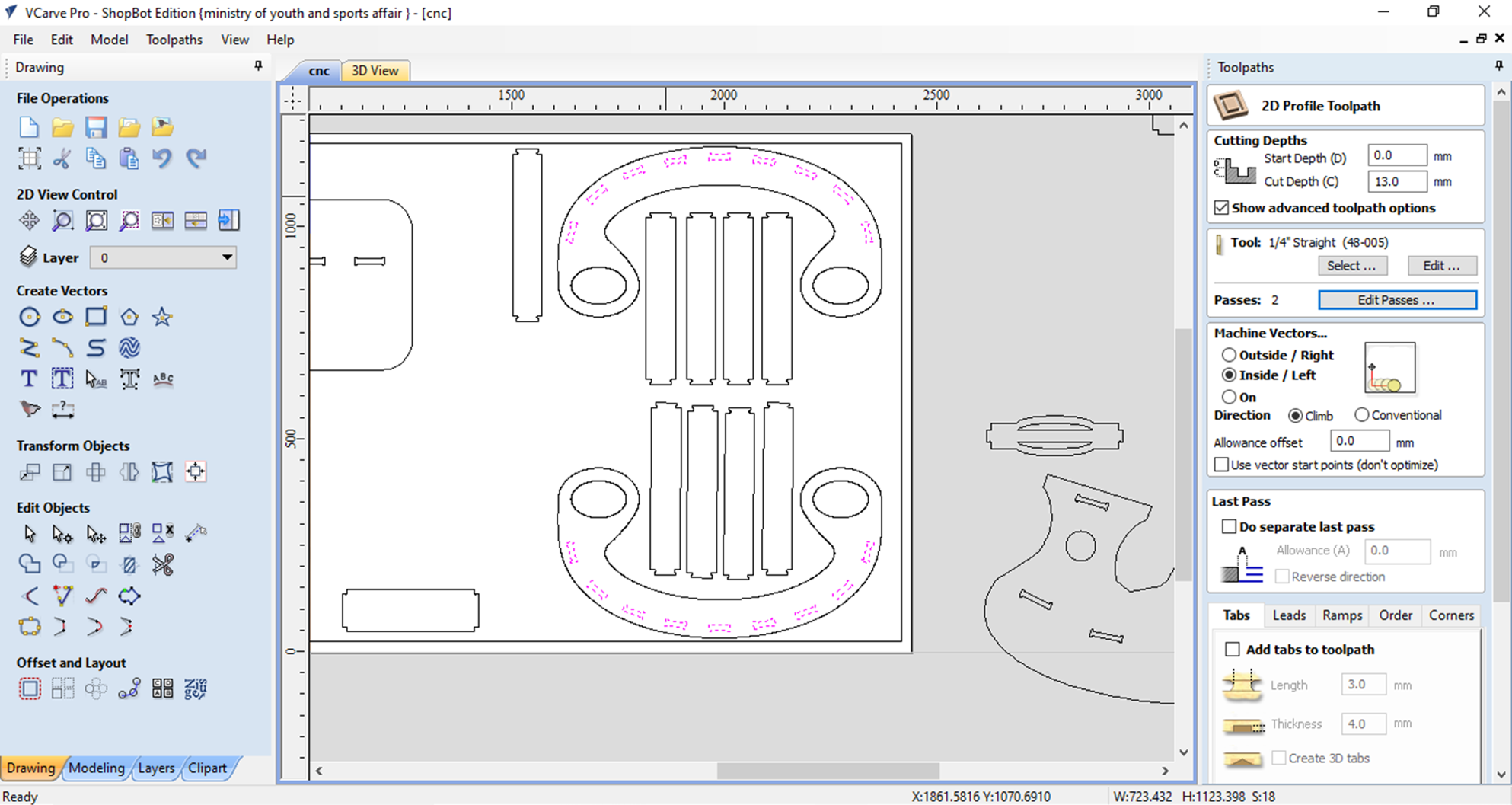

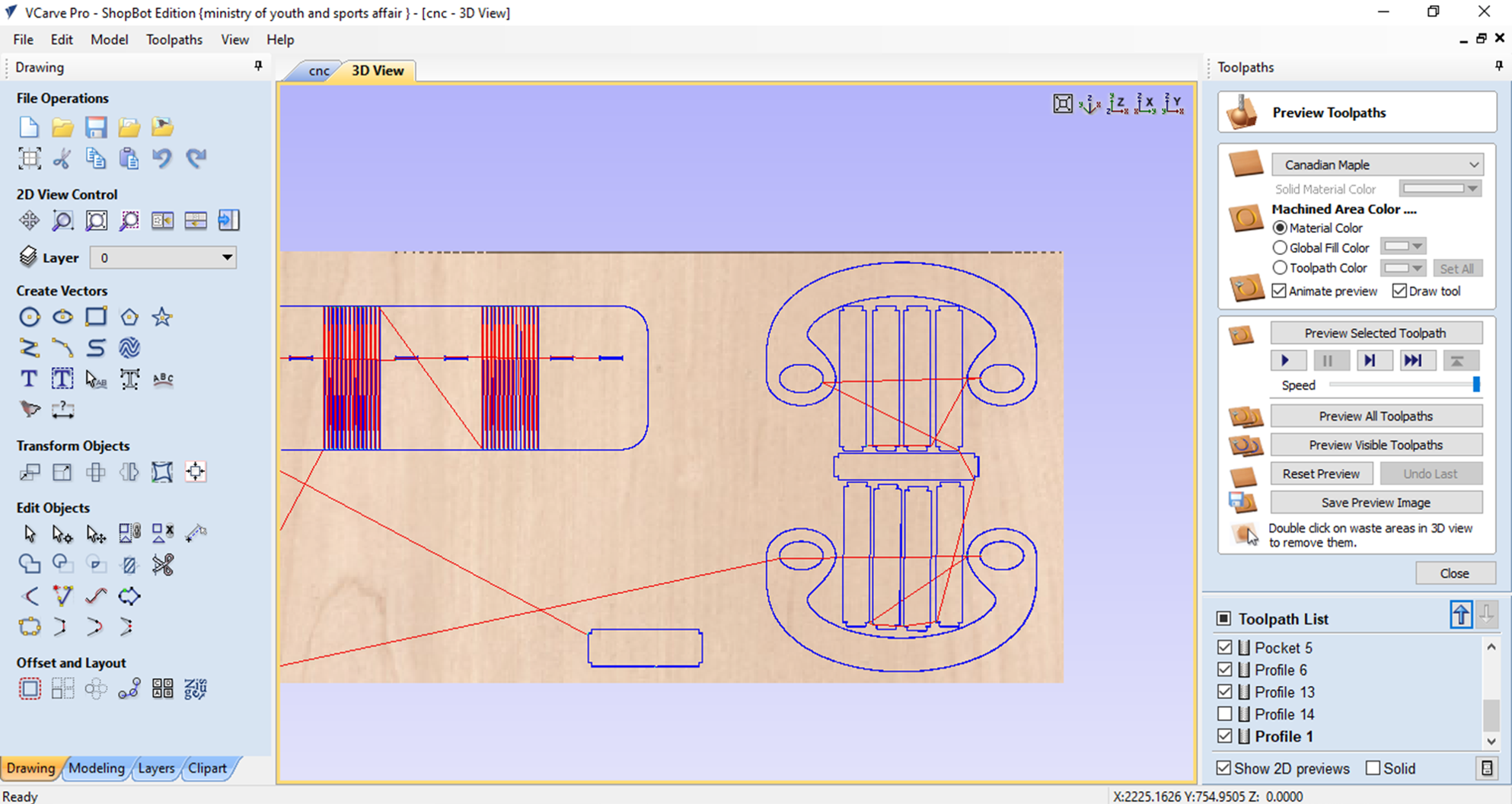

For cutting, I opened the design files in the Vcarve software in order to set them as you can see in the following pictures.

This video was captured during the cutting process.

Sanding¶

After the cutting process, I had to sand and clean the wood pieces as the CNC machine does not cut it 100% neat, and to do so, I used sanding papers, a metal file, and an electric sanding machine.

Assembling¶

For assembling, I used a mallet to join all the parts together.

Final Result¶

This is the final result after the assembling process and fortunately it was successful from the first time. Indeed, it can be used in multiple ways depending on the surface that it is grounded:

Firstly, in this position, it can be used as a cradle by adding a piece of fabric and also rocking playing equipment.

Secondly, in this position, it can be used as a chair, table, or playing equipment that children can climb on.

Lastly, in this position, it can be used as a table for small pieces.

Personal Opinion¶

- Studying and understanding the design, dimensions, and practicality of the product in the early stages can highly affect and reduce the chance of error and failed trials.

- I wish that I increased the width of the second piece during the design so it can carry larger objects.

- I wish that I gave it a chance to be painted with a pastel color scheme so it looks more attractive and visually pleasing.

References¶

Goodwin University (2018). What is CNC Machining? | Goodwin College. [online] Goodwin University. Available at: Click here [Accessed 18 Aug. 2022].

mecsoft.com. (n.d.). Feed Rates Explained – Extend the Life of Your CNC Tools and Machines | MecSoft Corporation. [online] Available at: Click here [Accessed 18 Aug. 2022].

Wikipedia. (2020). Speeds and feeds. [online] Available at: Click here [Accessed 18 Aug. 2022].

Wiktionary. (2020). toolpath. [online] Available at: [Click here](https://en.wiktionary.org/wiki/toolpath#:~:text=toolpath%20(plural%20toolpaths) [Accessed 18 Aug. 2022].