3. Computer Controlled Cutting¶

Introduction¶

This week we were introduced to computer-controlled cutting, laser cutting, and vinyl cutting. However, we had to master the basic definitions at first.

Digital Fabrication: a type of manufacturing process where the machine used is controlled by a computer and the most common forms of digital fabrication are:

a. Subtractive Manufacturing: the proccess that removes or cuts away material to create parts such as 2D cutters (more waste).

b. Additive Manufacturing: the process that creates an object by adding multiple layers such as 3D printing (less waste).

Group Assignment¶

For the group assignment, we had to characterize the laser cutter’s focus, power, speed, rate, kerf, and joint clearance. Every two students were responsible to search for a different topic, my colleague Sara and I searched about joint clearance.

Joint Clearance¶

Joint Clearance is one of the most significant elements to create a parametric press-fit construction kit. It is the size of the opening which works as a joint between two pieces.

To get the proper joint clearance, a design that looks like a hair comb with different sizes of spacing between the teeth was created, as shown in the pictures below.

Results¶

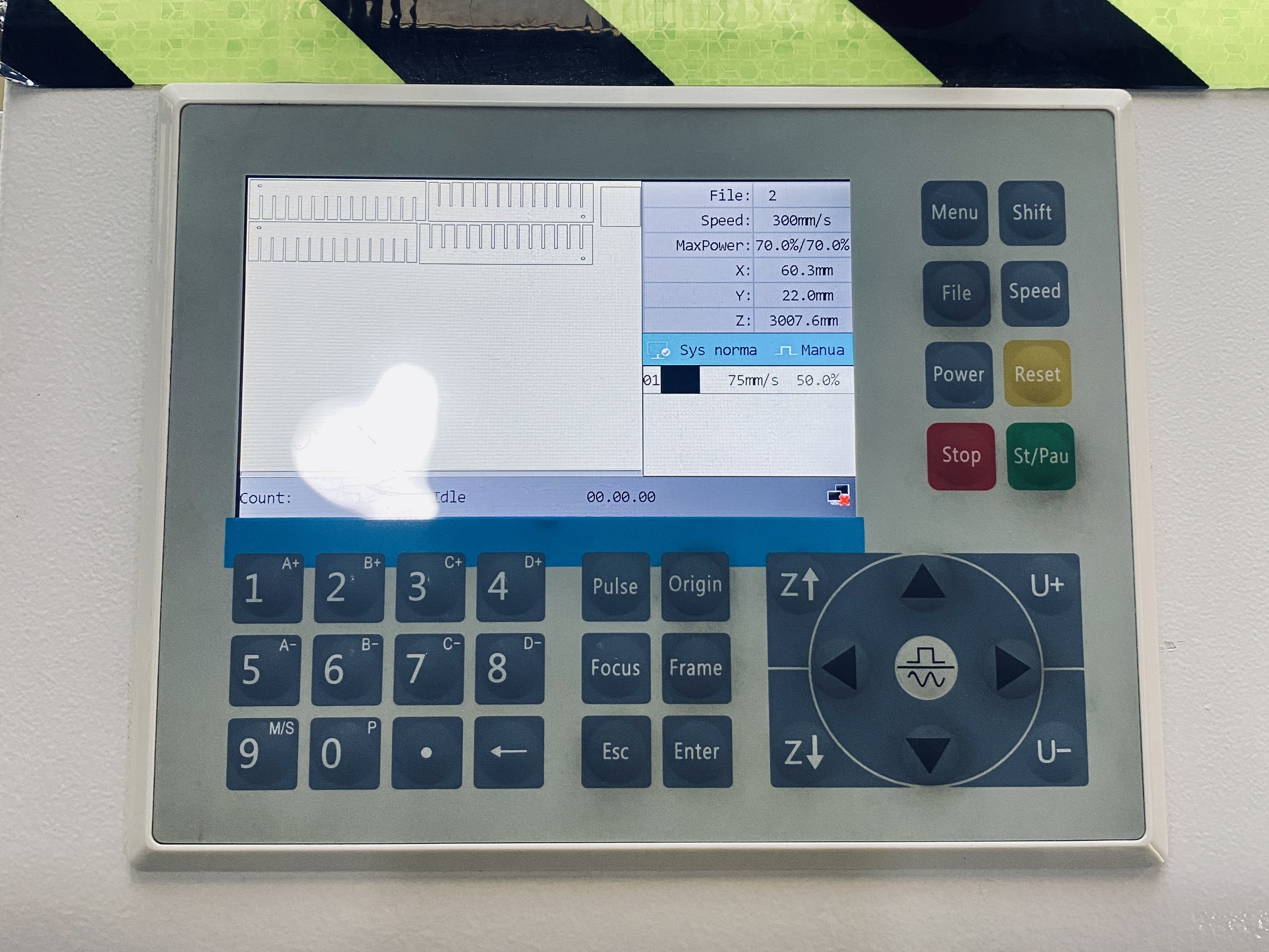

We ended up as a group having these settings for the laser cutter:

- Focus: 8 mm

- Power: 50%

- Speed: 75

- Joint Clearance: 2.2 mm

(For more information about the group assignment, refer back to my colleagues Noor and Sakeena’s websites)

Personal Opinion¶

It would be better if we did the tests together to upgrade our understanding of the laser cutting machine characteristics.

Individual Assignments¶

Laser Cutting¶

2D Model¶

First of all, I searched for laser-cutting ideas on Pinterest taking into consideration that the design/object is a parametric press-fit construction kit and can be assembled in multiple ways.

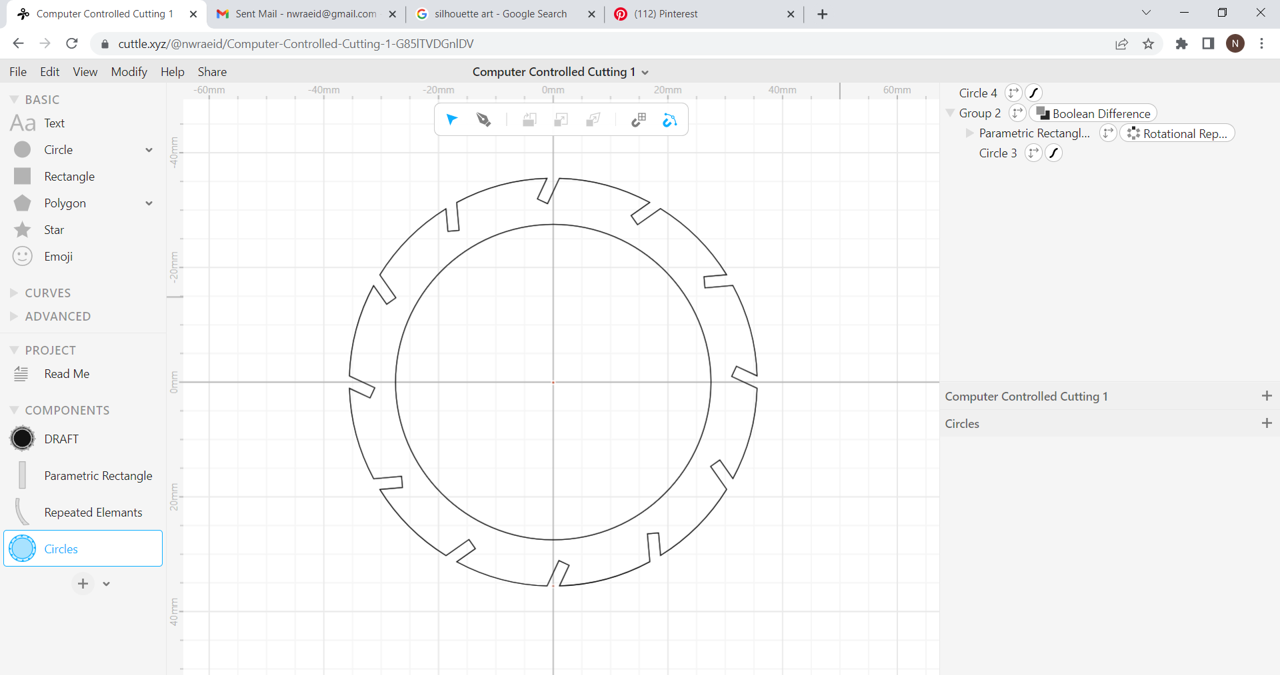

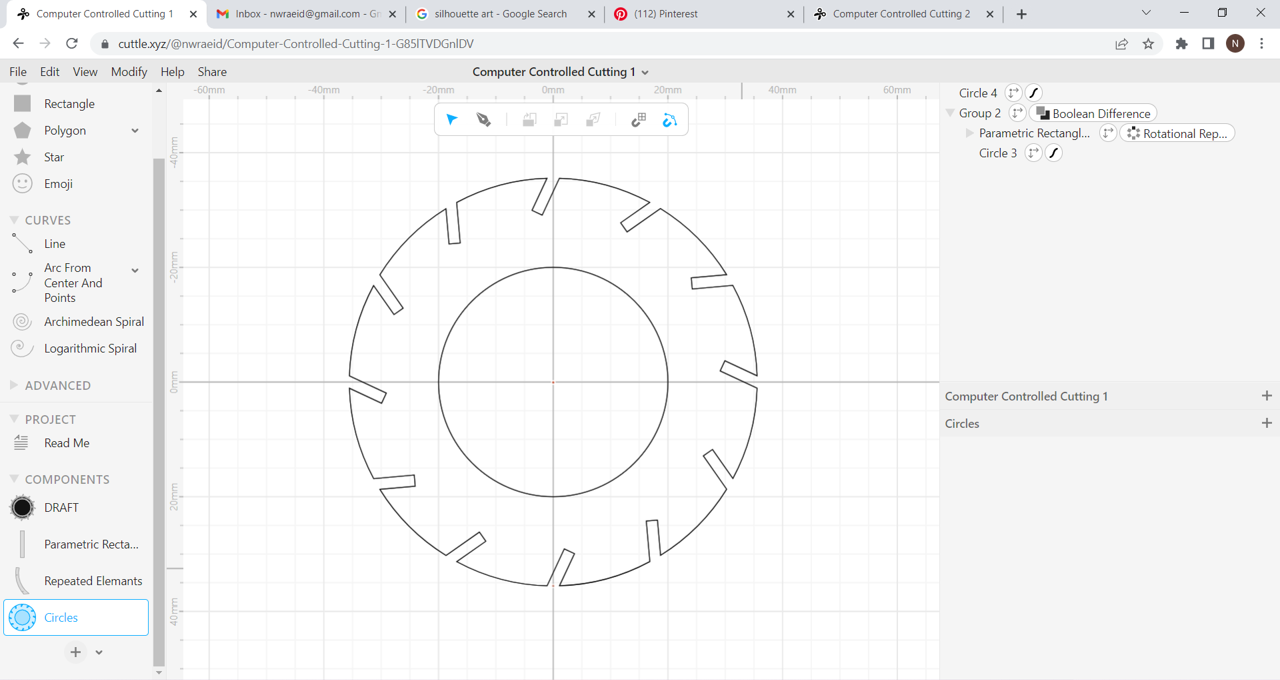

After that, I started to design the 2D model using Cuttle software. Here, I dragged two circles and placed them on top of each other. Each one has a different diameter.

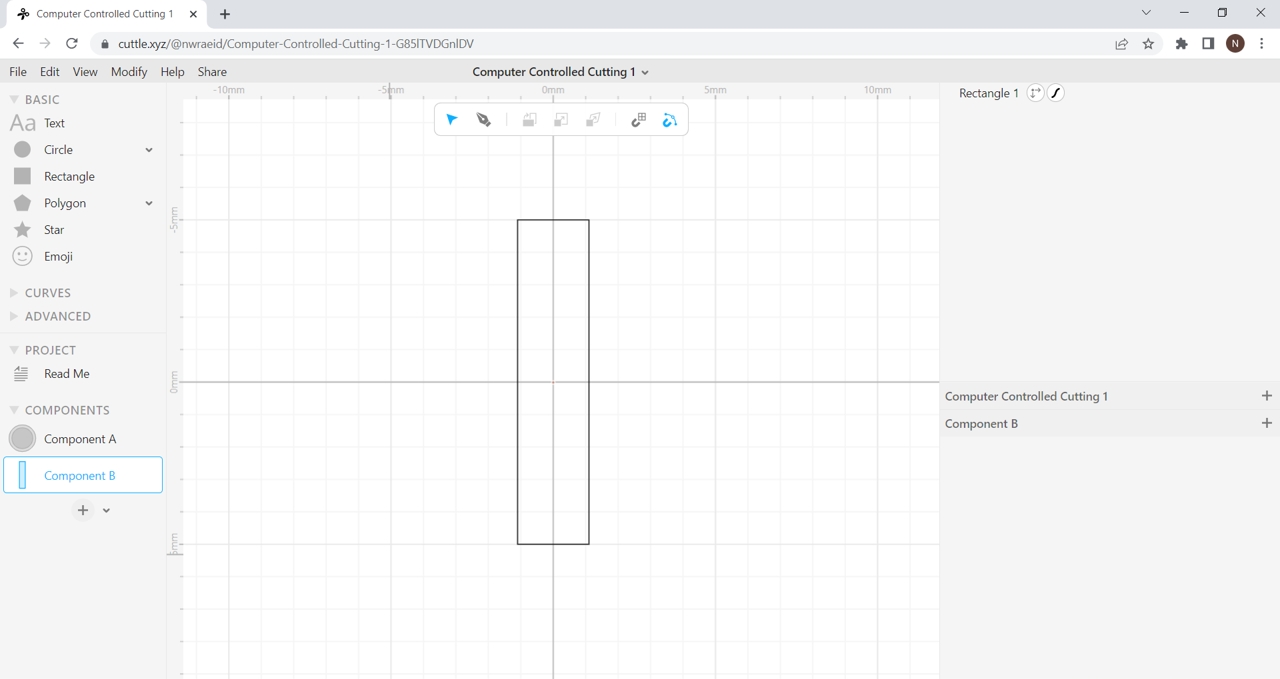

Then, I dragged a rectangle (2.2 x 15mm) into a new component and used it as a parametric element.

Next, I dragged the rectangle component into the circle component and I used the “Rotational Repeat” and the “Boolean Difference” modifiers to create the below shape.

Last but not least, I dragged two lines and two arches from three points to make this element.

After laser cutting a test for my design and as you can see here, I decreased the size of the inner circle in order to increase the thickness of the shape and make it stronger as it will be holding 12 pieces later on.

Preview the design below in 2D ^_^

Cutting¶

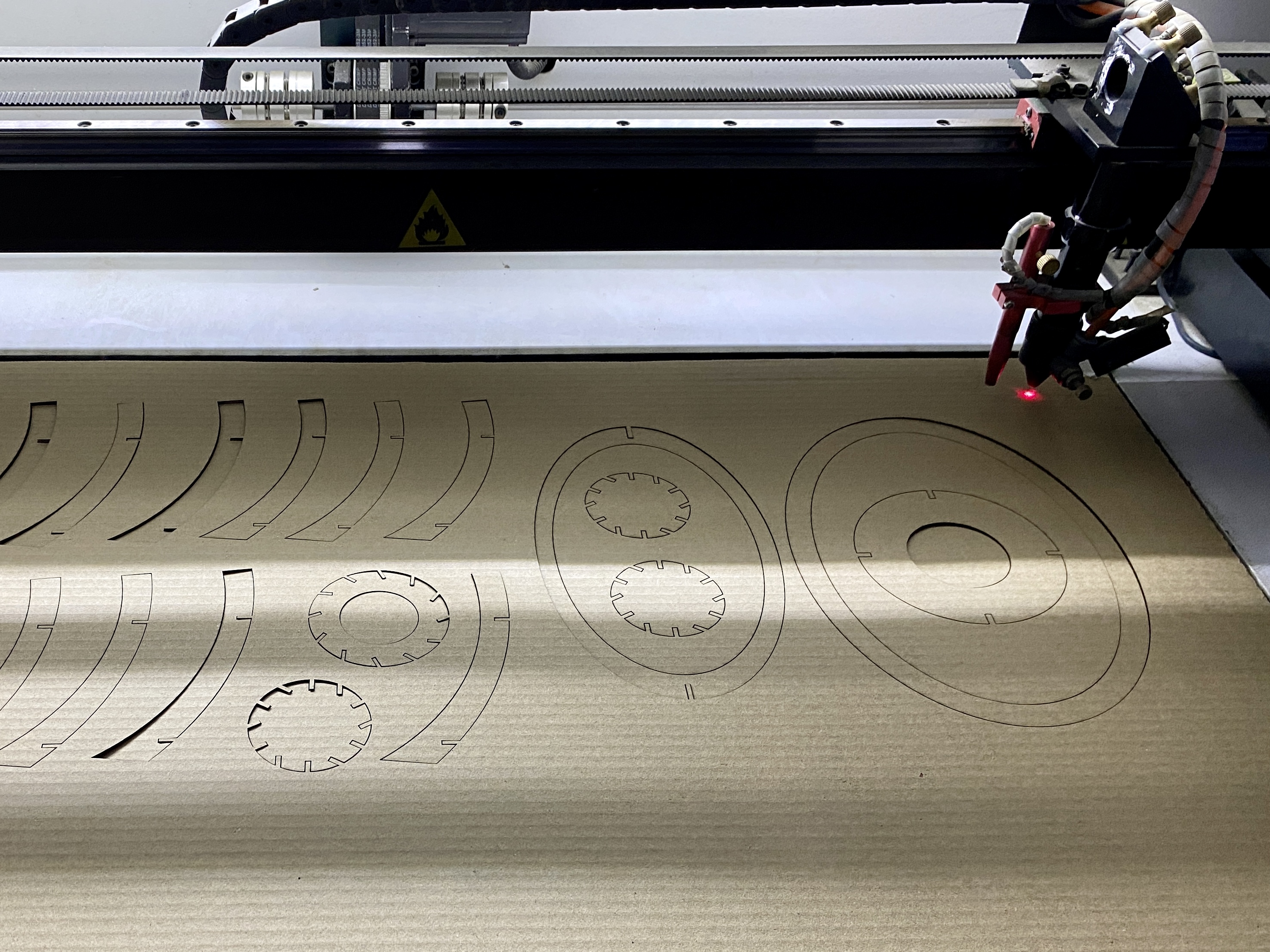

This is a shot while laser cutting the design.

Results¶

I ended up having this parametric press-fit construction kit which can be assembled in multiple ways as you can see below.

Way 1

Way 2

Way 3

Personal Opinion¶

- The below circle was missing in the design (way 1), as for that it was not balanced and stable enough.

- I think placing the parametric rectangle in a diagonal way was not a good decision, as it was difficult to join the pieces with each other and simultaneously it affected the rigidity of the whole object.

Vinyl Cutting¶

Process¶

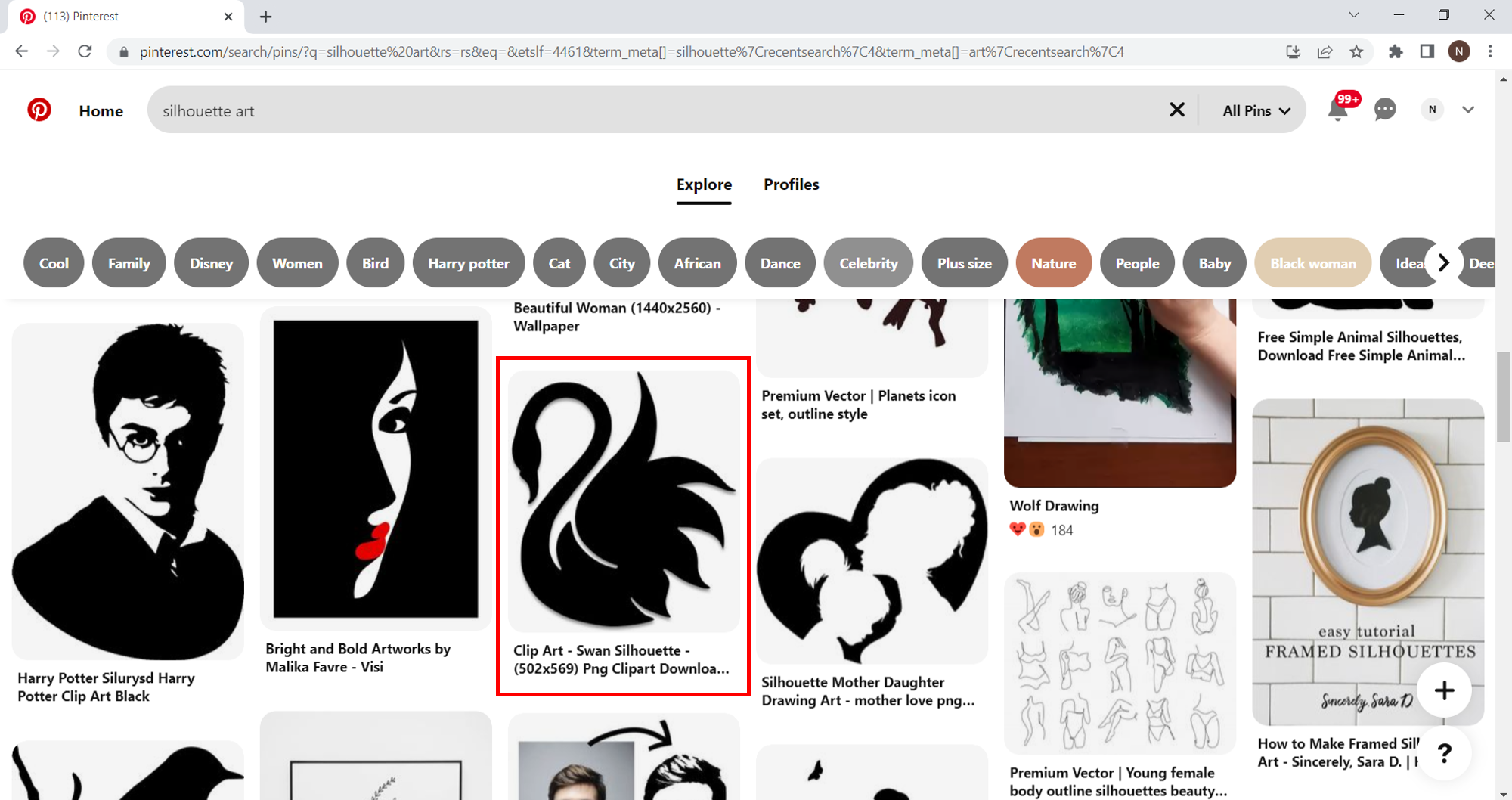

First, I searched on Pinterest for “Silhouette Art” and I chose this bird.

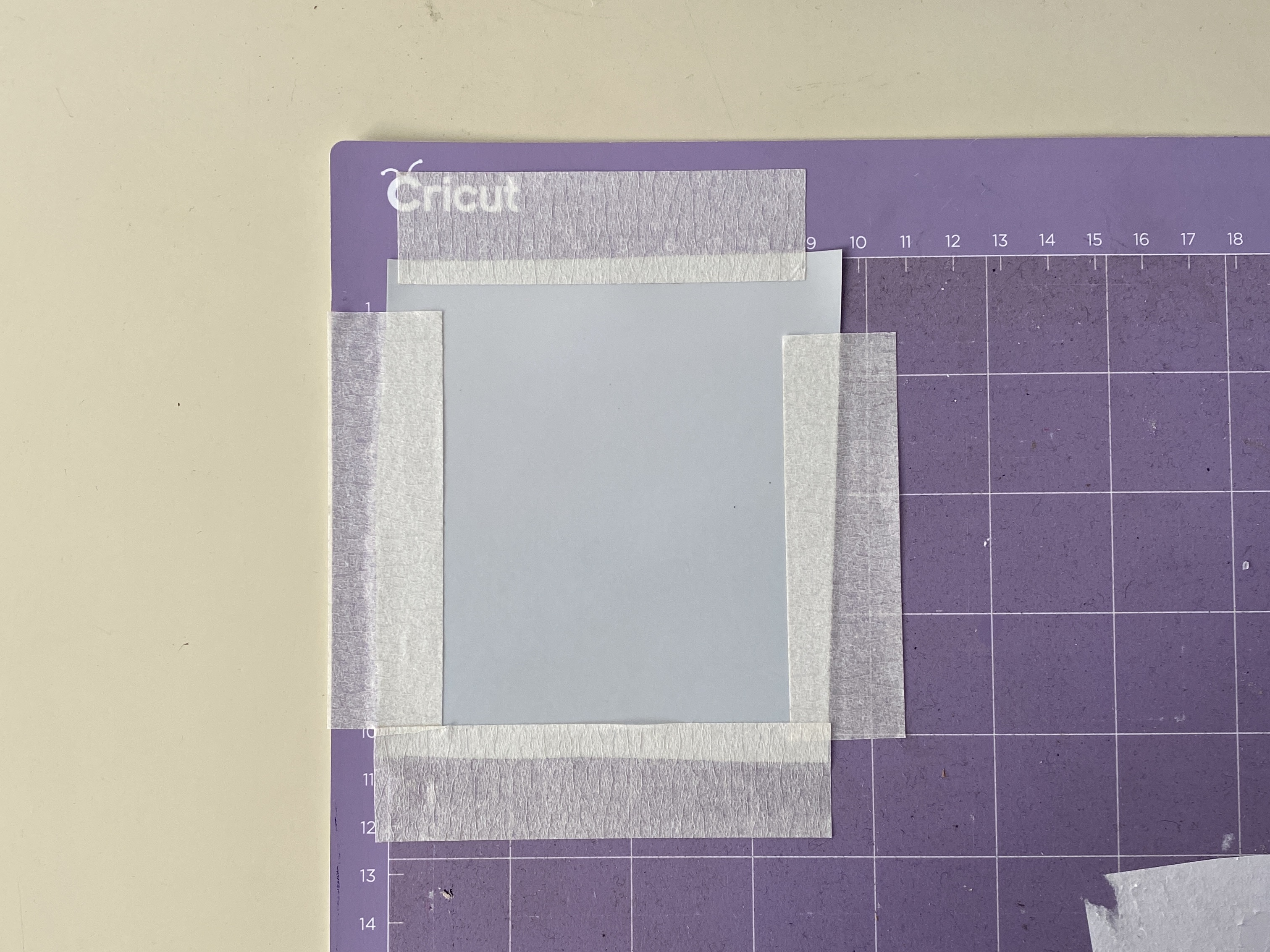

Second, I chose Iron-on as a base material to cut the bird on it. Then, I stick the material on the top left corner of the Cricut mat and I put it in the Cricut machine.

Note: “Iron-on fabric has a glue backing that melts into another fabric when it is applied with heat.”

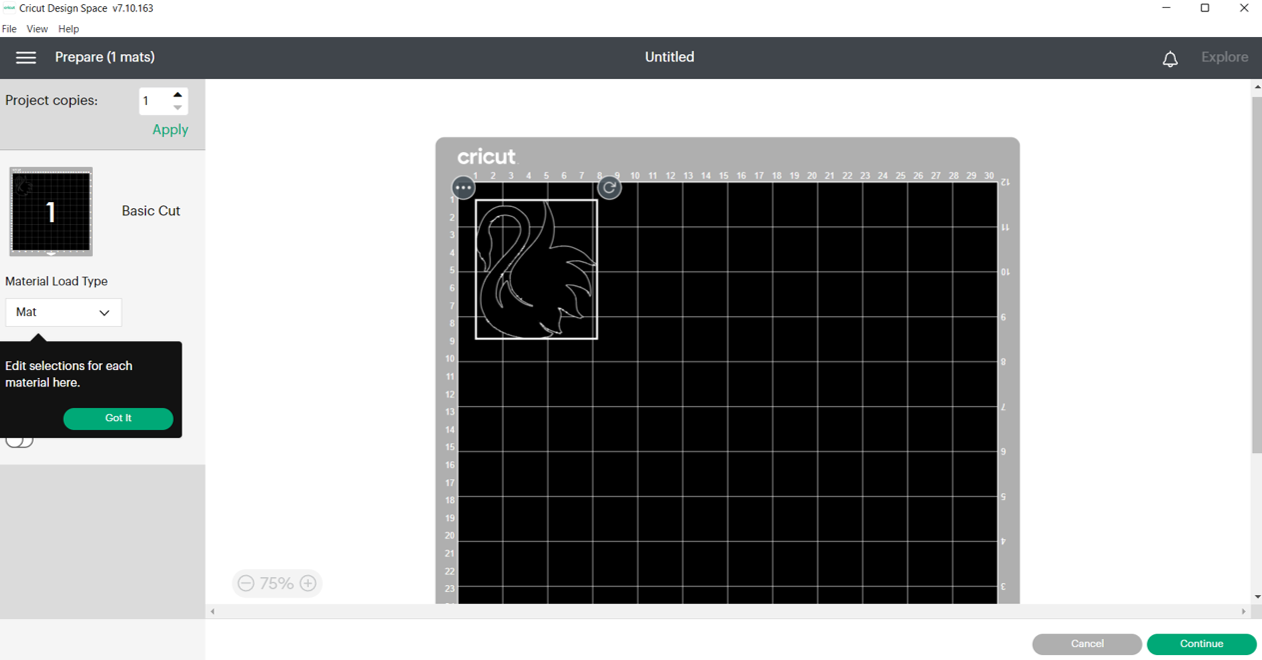

Third, I imported the bird image into Cricut Design Space Software. After that, I modified the scale with reference to the mat grid, set the required settings, and prepared it for cutting.

Finally, the cutting process started and I got the final result by removing the extra material around the bird.

Results¶

Now it is ready to be applied to fabric using the iron!

Personal Opinion¶

- I like that there is a variety of materials that can be used within the same machine and each material has a different application.

- The process was very smooth and rapid which is really good.

- The size is limited within the size of the mat.

References¶

Rapid Direct. (2022). Additive Vs Subtractive Manufacturing: What Are the Differences. [online] Available at: Click Here [Accessed 12 Jun. 2022].

Pinterest. (n.d.). Download and share clipart about Clip Art - Swan Silhouette, Find more high quality free transparent png cli… | Bird silhouette art, Silhouette art, Bird silhouette. [online] Available at:Click Here [Accessed 15 Jun. 2022].

Wikipedia. (2021). Iron-on. [online] Available at: Click Here [Accessed 15 Jun. 2022].