8. Molding and casting¶

In this assignment, my task was to create a mold using proper materials and then cast it.

Molding¶

What is molding?¶

Molding is the process of filling a cavity (mold) using heat and/or pressure.

It used widely in manufacturing and even in our day to day life, such as, when we make ice cubes and jelly.

The main idea of molding ice cubes in our fridge is the same in manufacturing, we use heat (very cold temperature) to solidify the water and we use the mold to shape the water while it solidifies.

There are several types of molding processes, these are some of the processes that are used:

-

Compression Molding

-

Melt Molding

-

Transfer Molding

-

Injection Molding

4 Types of Molding Processes in Rubber and Plastics Manufacturing

What type of material to use?¶

The materials can vary, from silicon to thermoplastic.

In Fab Lab Bahrain we use silicon to create the mold and we use other materials such as resin, to pour it inside the cavity.

Safety for silicon¶

- Keep the container closed when not in use.

- Store it in a cool place.

- Keep it away from heat and flame.

- keep it out of reach of children.

For more information visit our group assignment link

Steps to create the mold¶

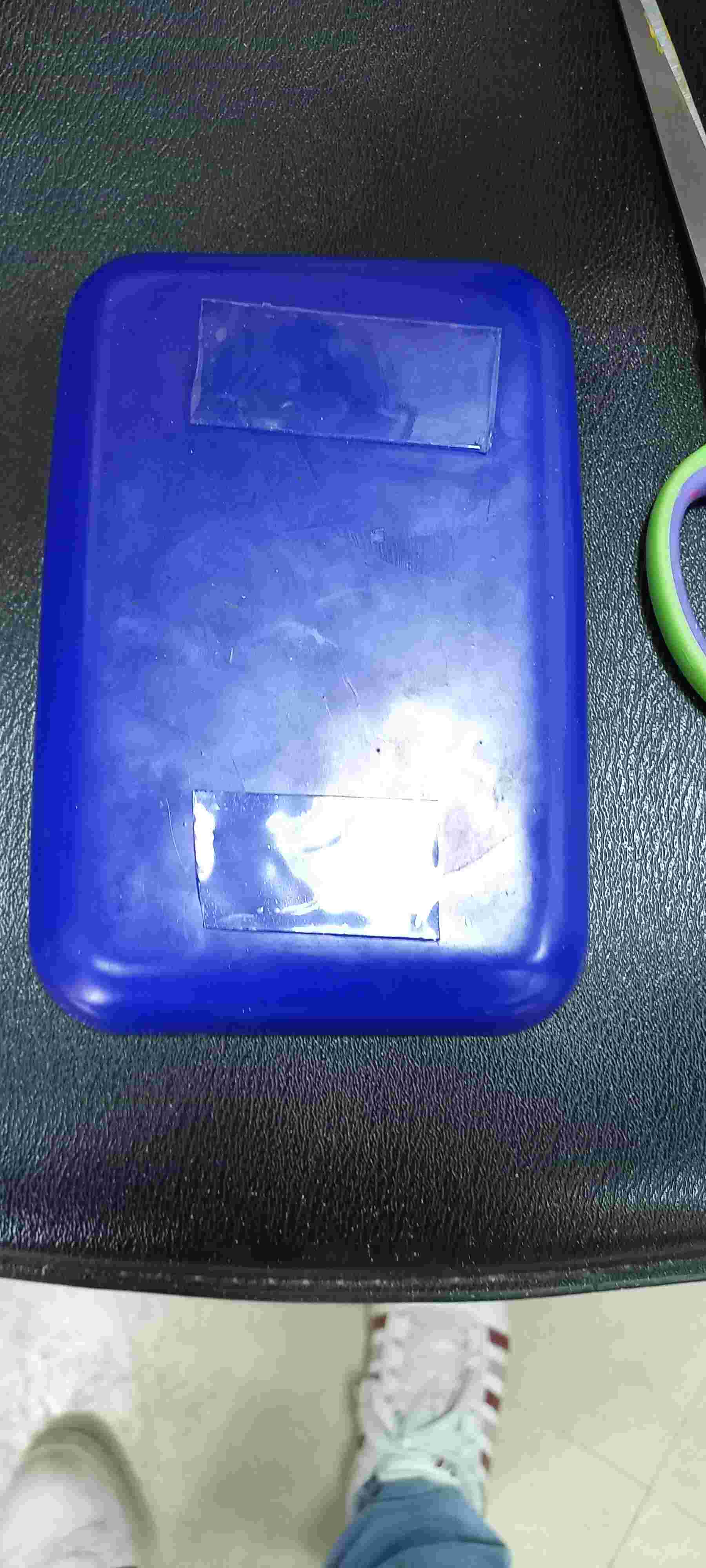

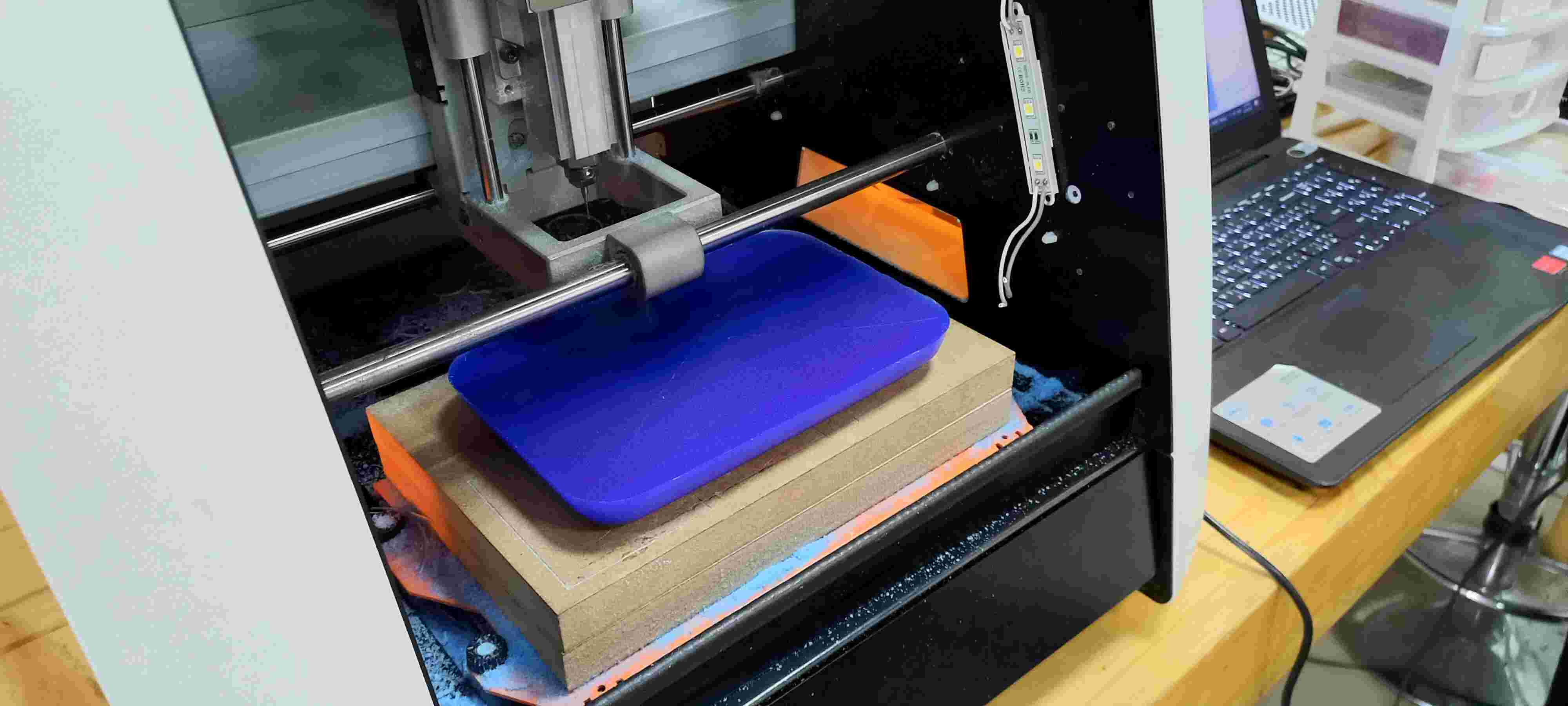

1) Take a piece of machinable wax and tape it from the bottom

This piece of wax will be our workpiece

2) Tape the piece from the bottom with a double sided tape

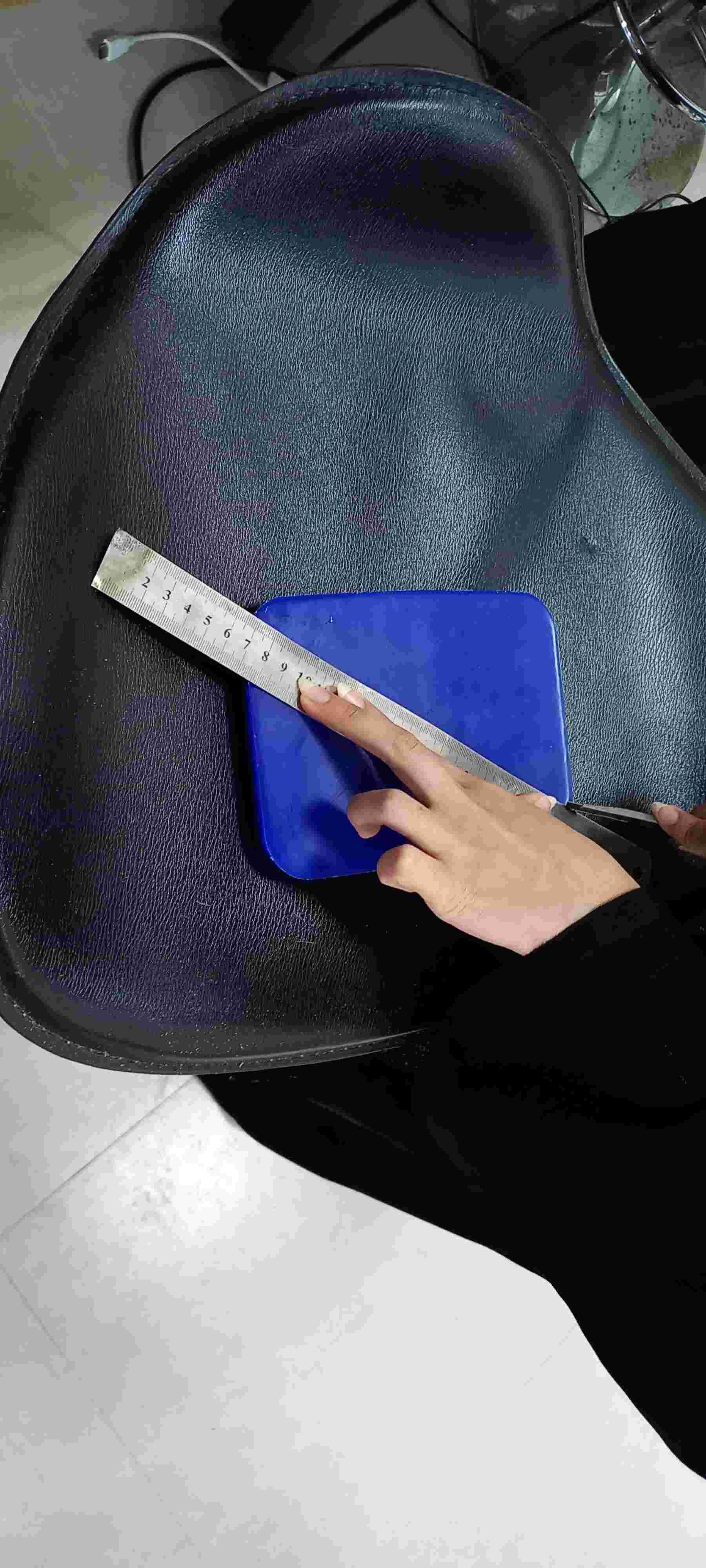

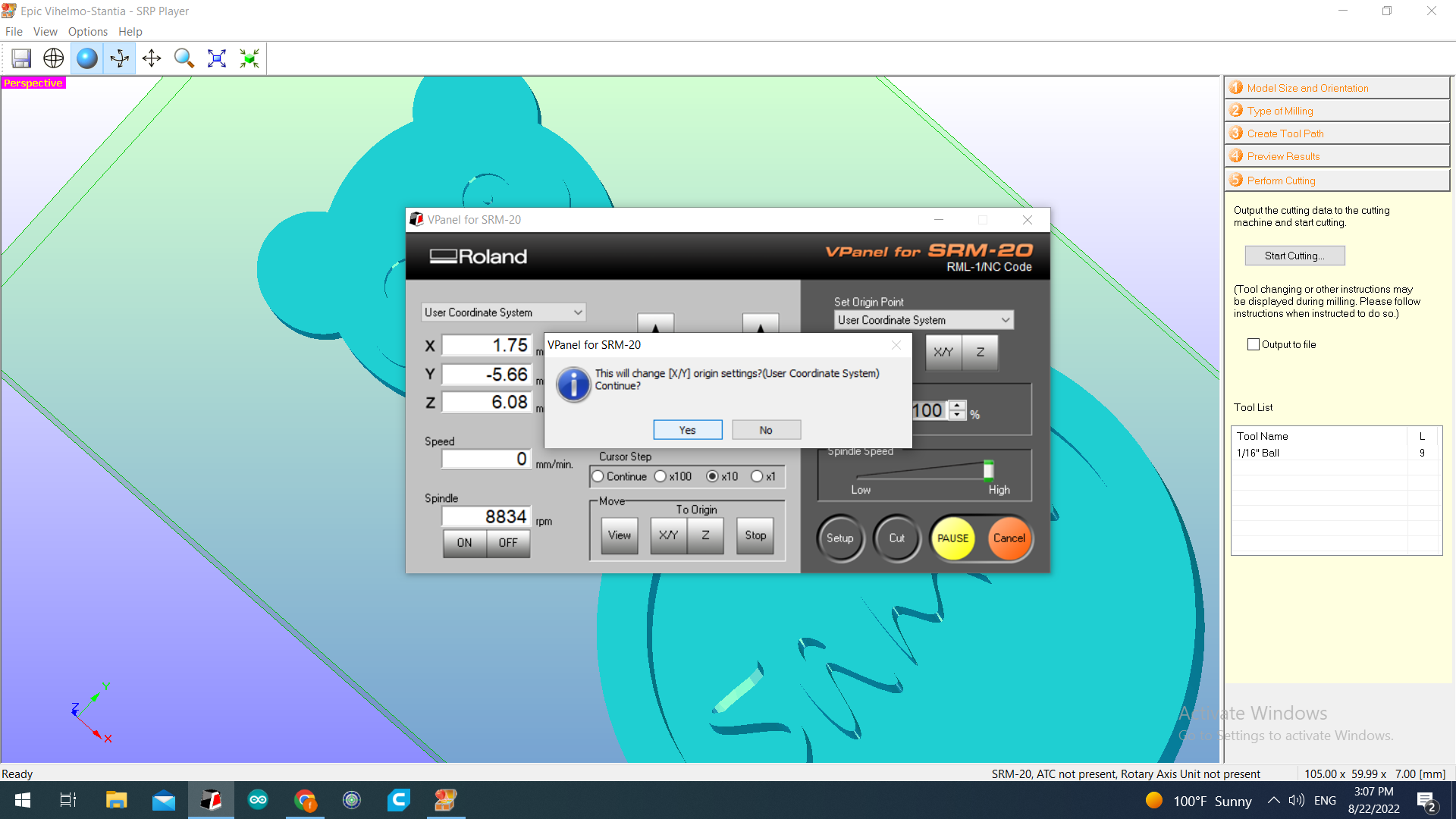

3) Draw two lines that cross the piece in the center

This is the center point of the workpiece

4) The milling machine that we will use is Roland monoFab SRM-20

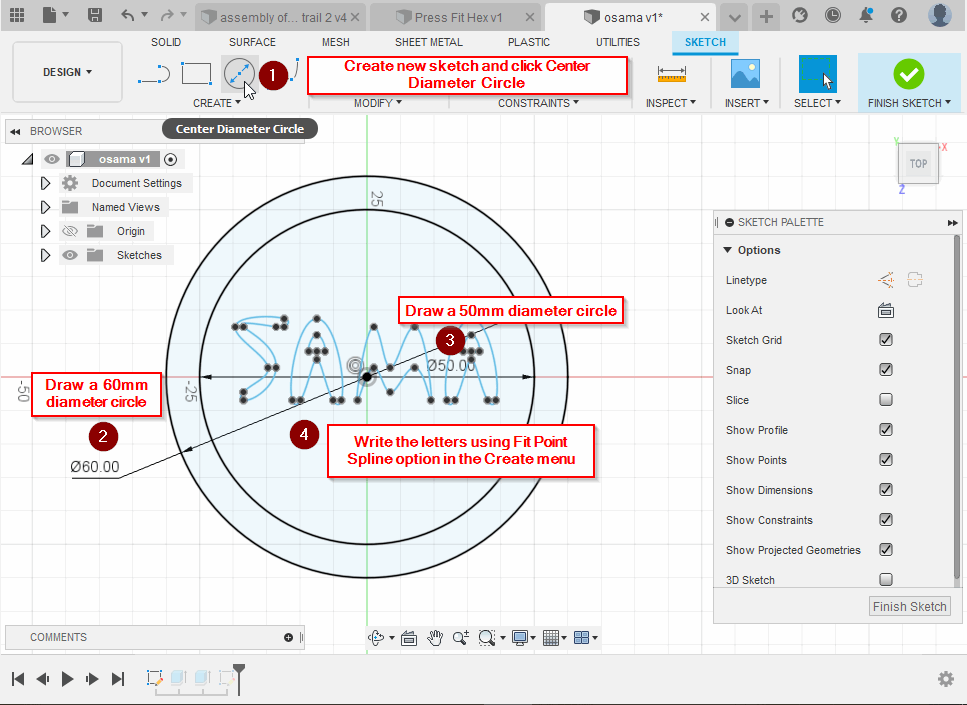

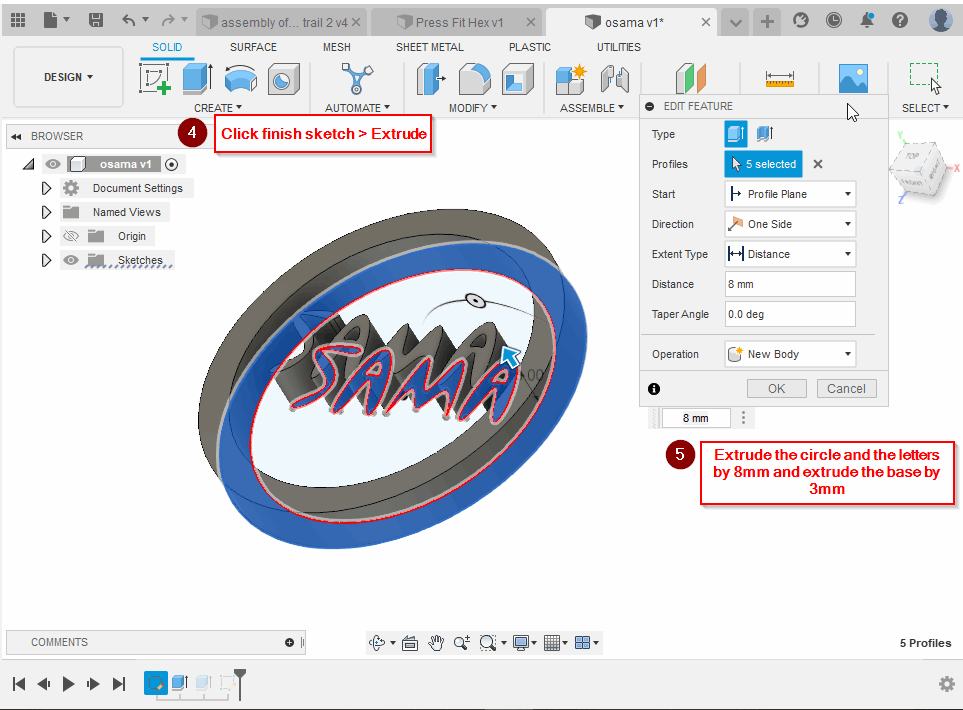

5) Design your desired model

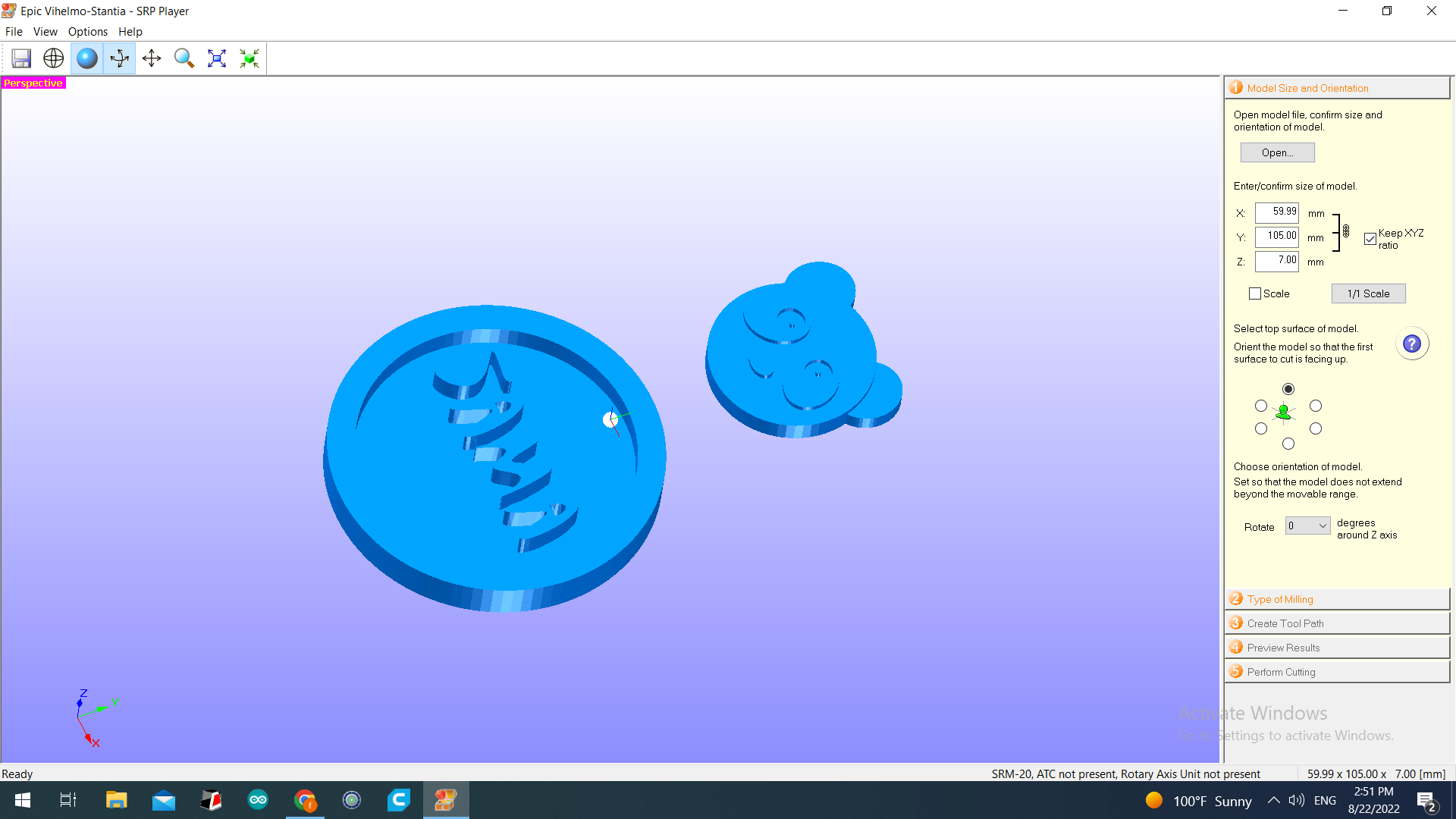

This is the design that I have made, I have made using Fusion 360

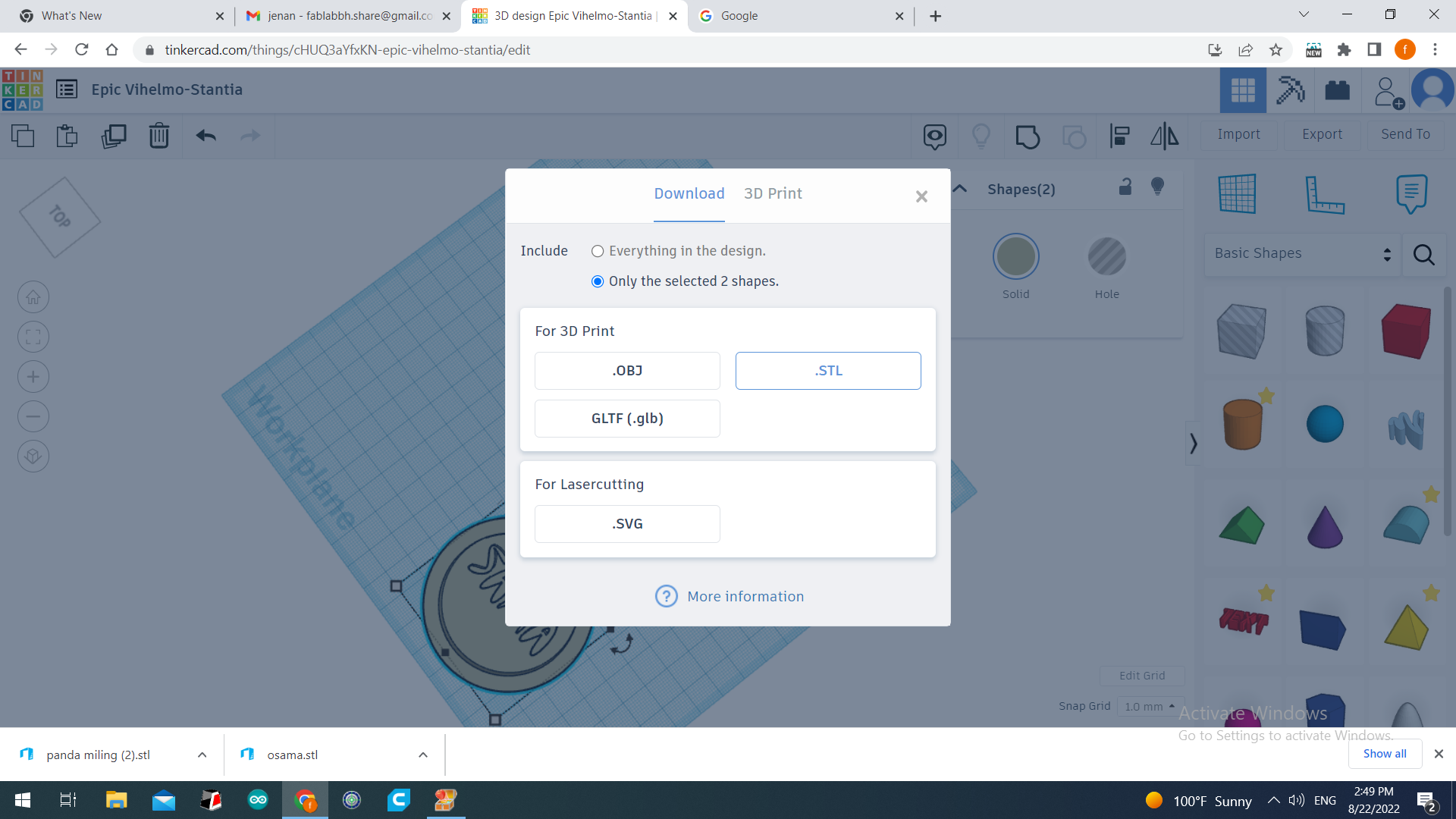

6) Save the model in .STL format

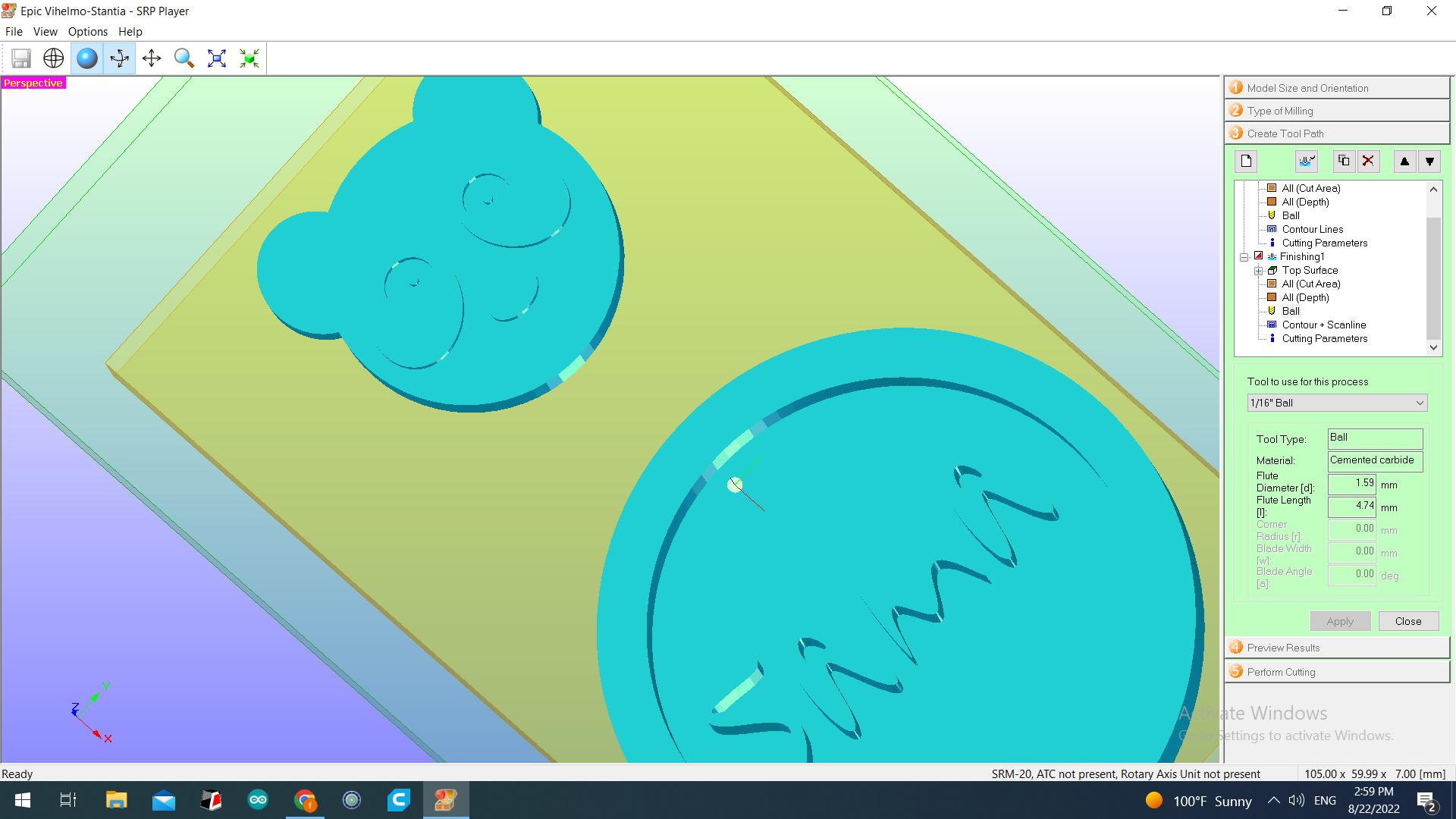

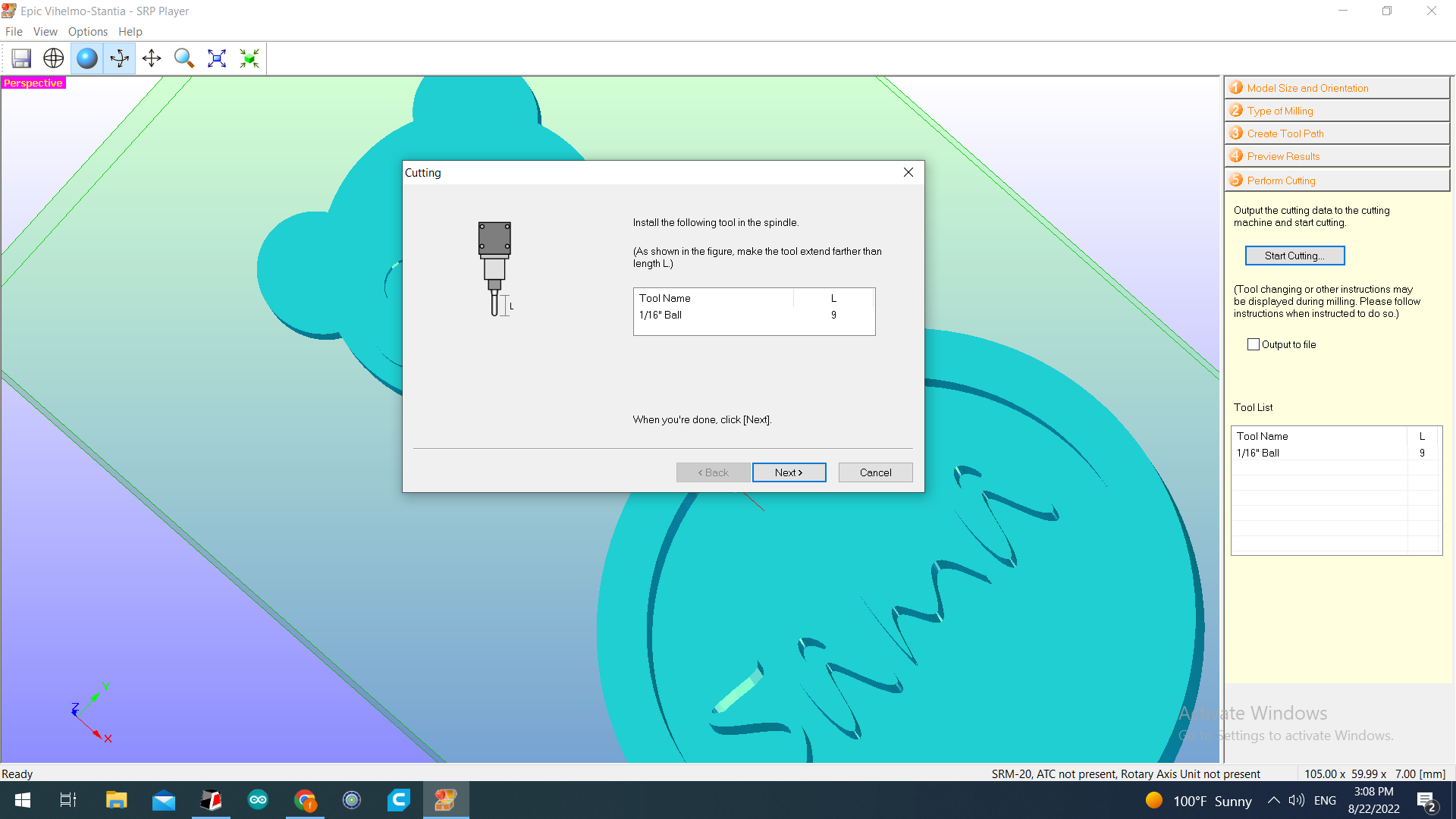

7) Open it in SPR Player

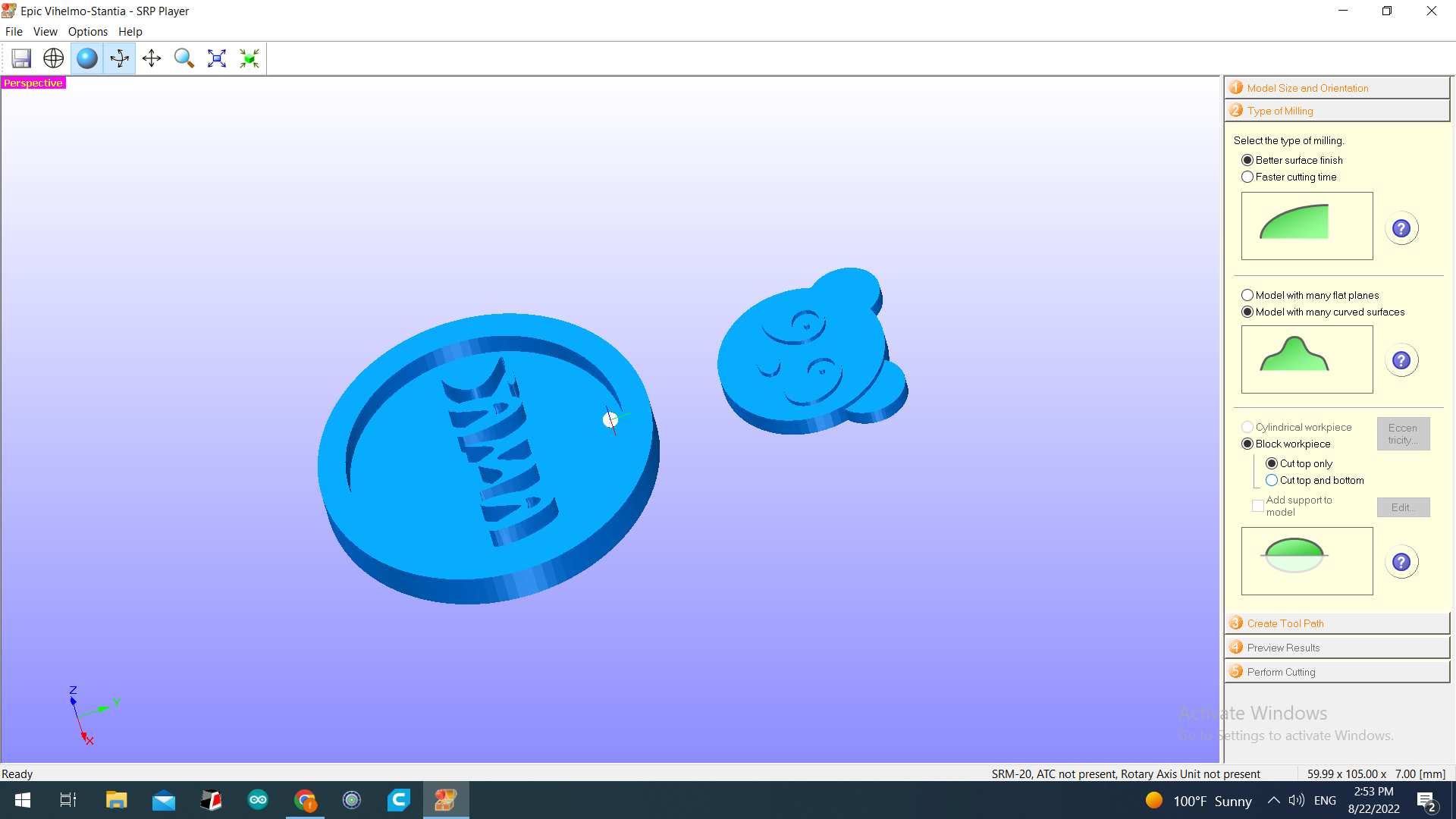

8) Choose your milling preferences

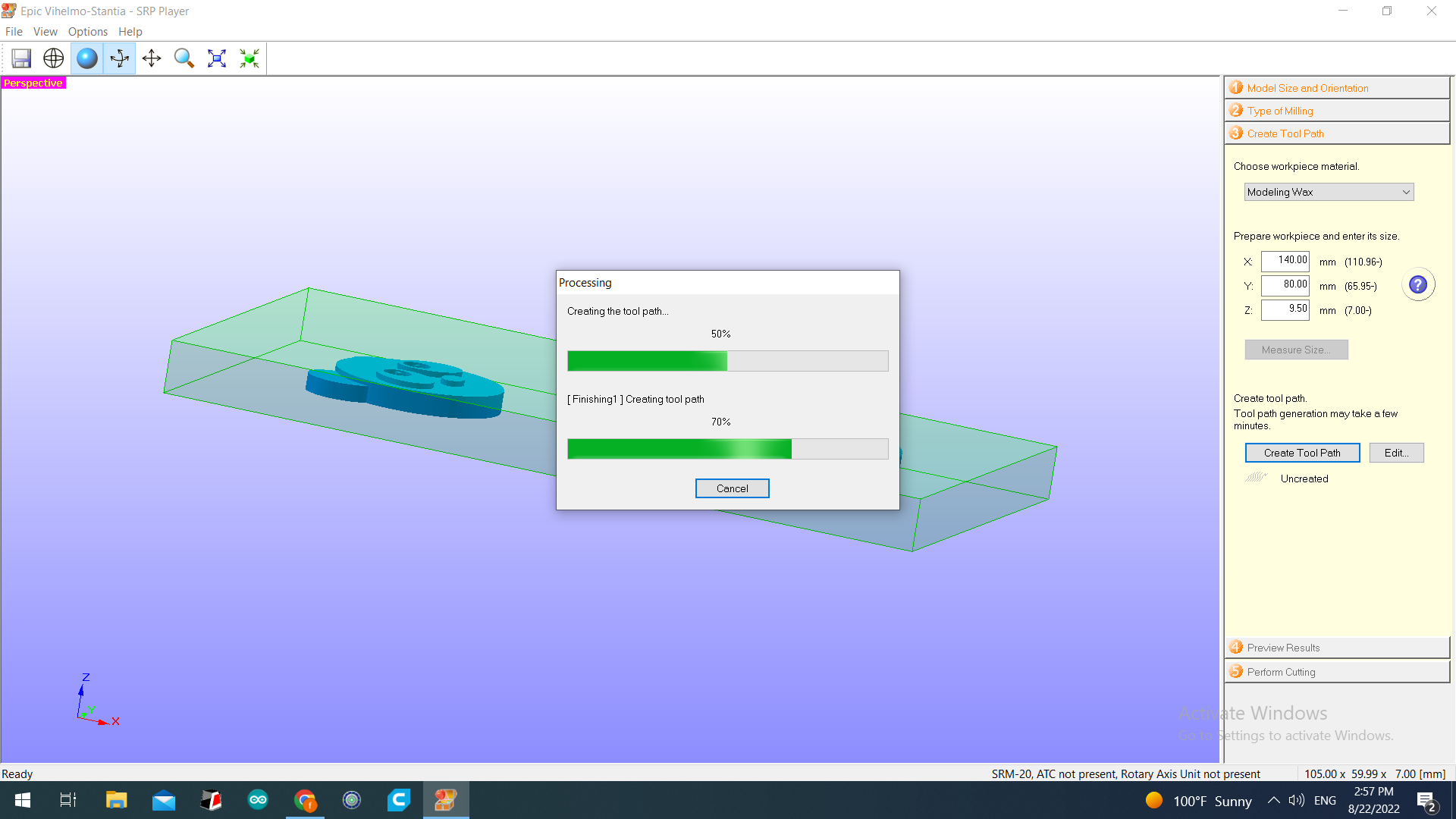

9) Write your workpiece dimensions

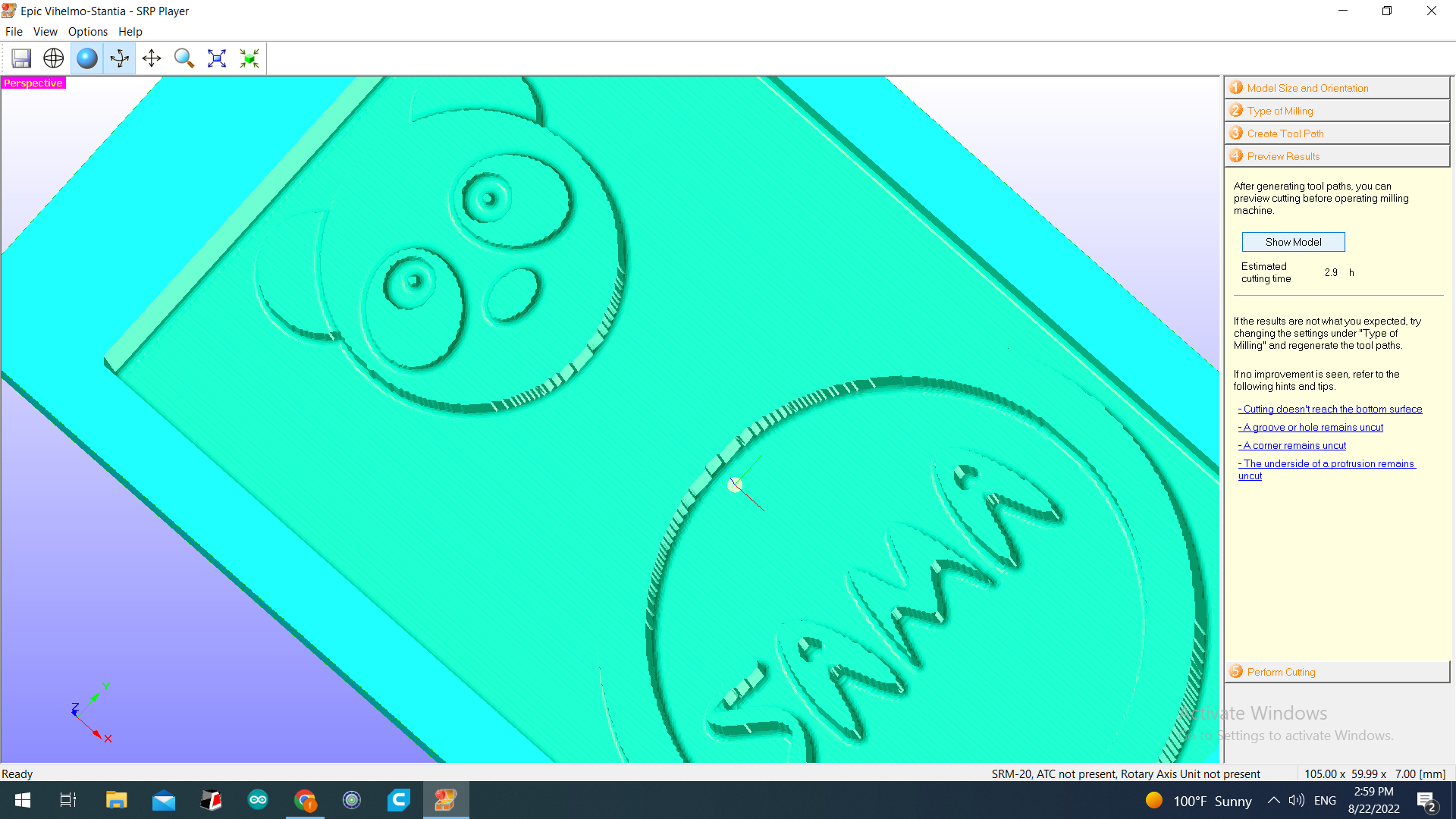

10) Preview the end result

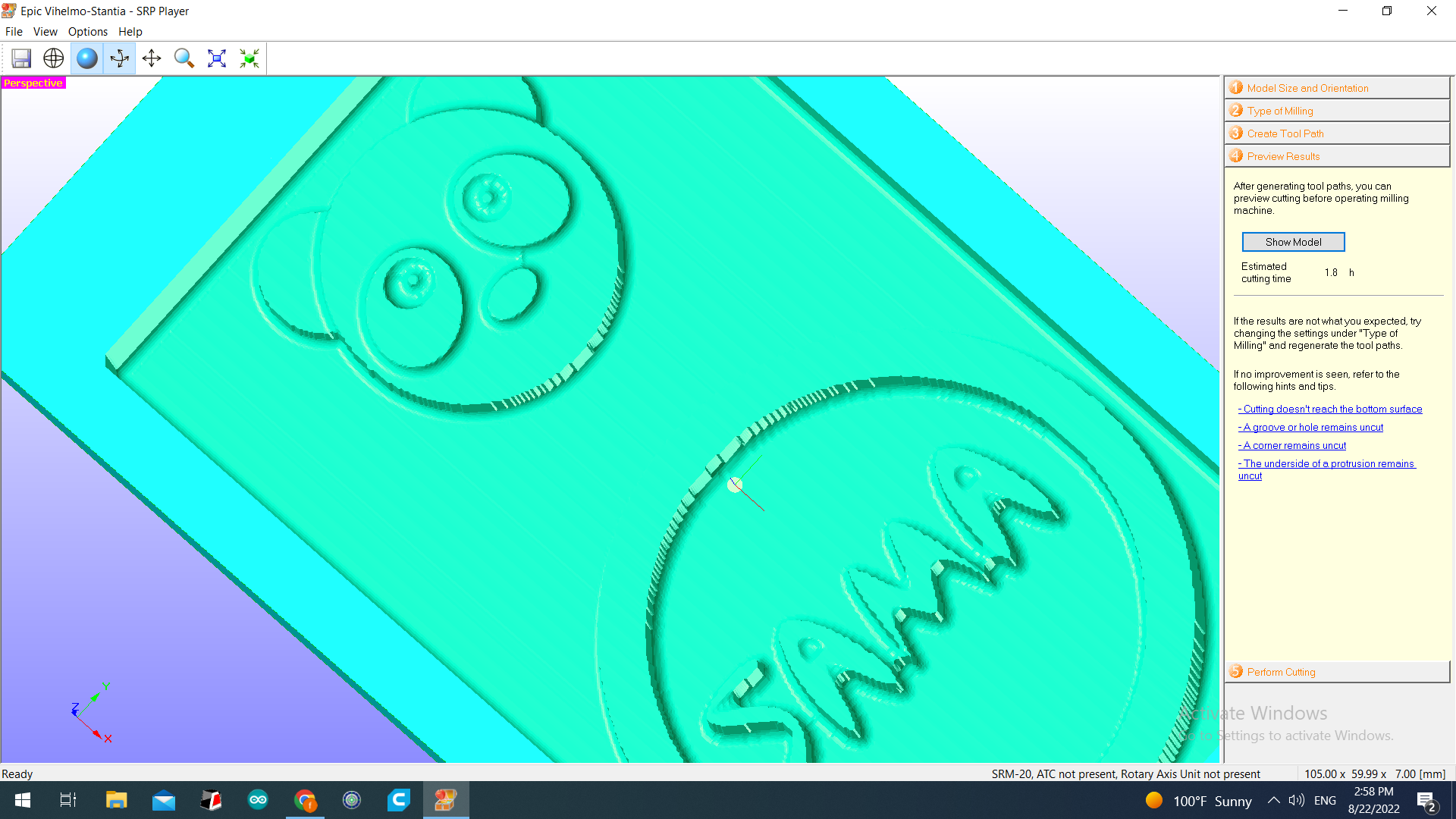

The tool path is too big for the design (tool bit is large)

11) Choose smaller tool bit size (1/16 inch)

12) Preview the end result

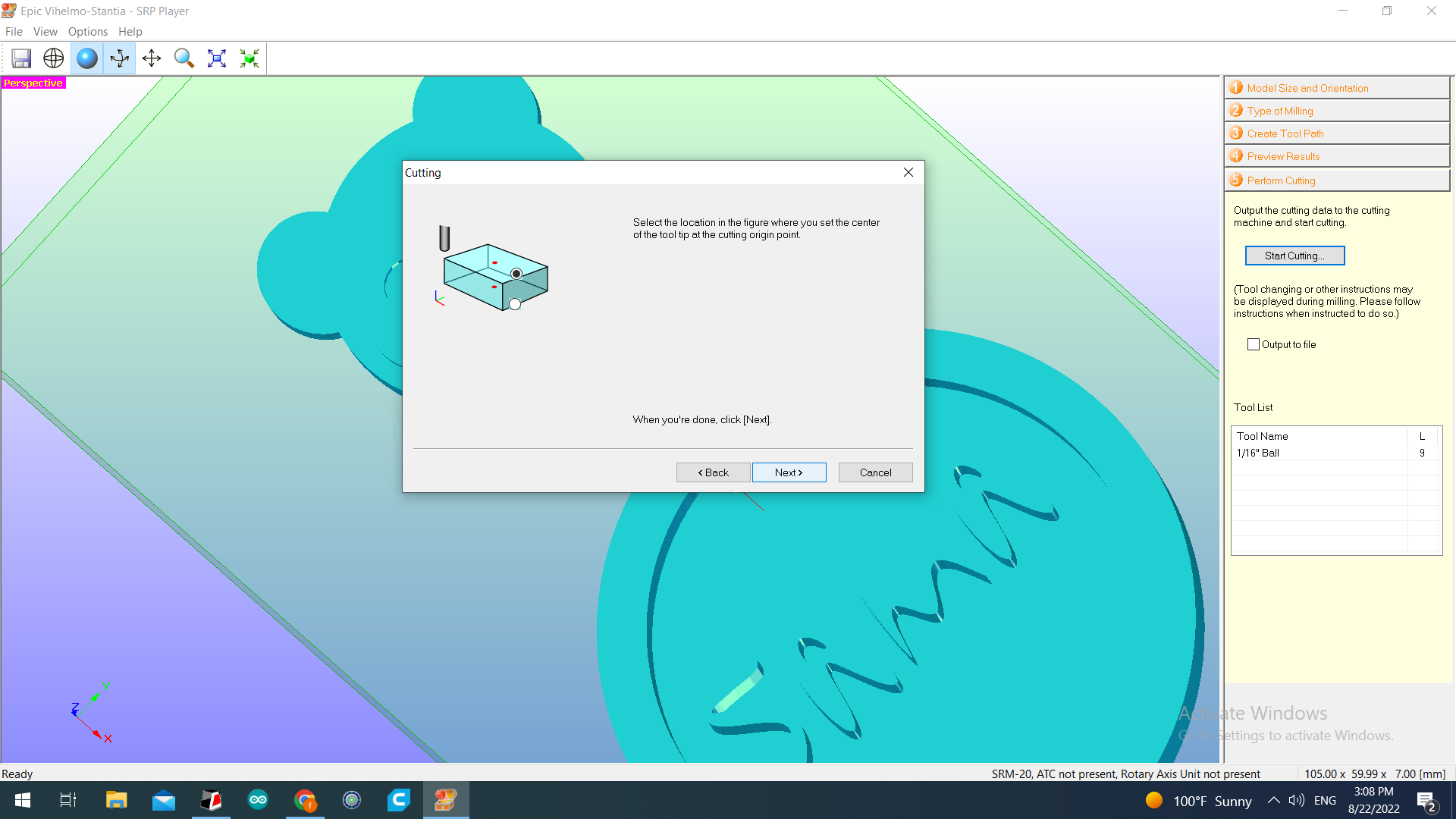

13) Set the z-axis origin on the center point of the workpiece

14) Start the Cut

15) After cutting rinse any wax excess with water

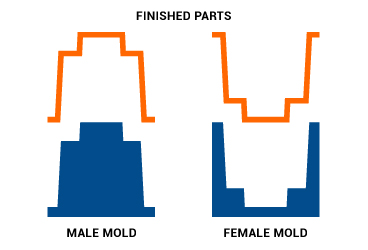

Note: notice that the type of cut is male (the shape is upward), the reason is that when you pour the mold, the mold takes the shape of the cut material and it becomes female mold

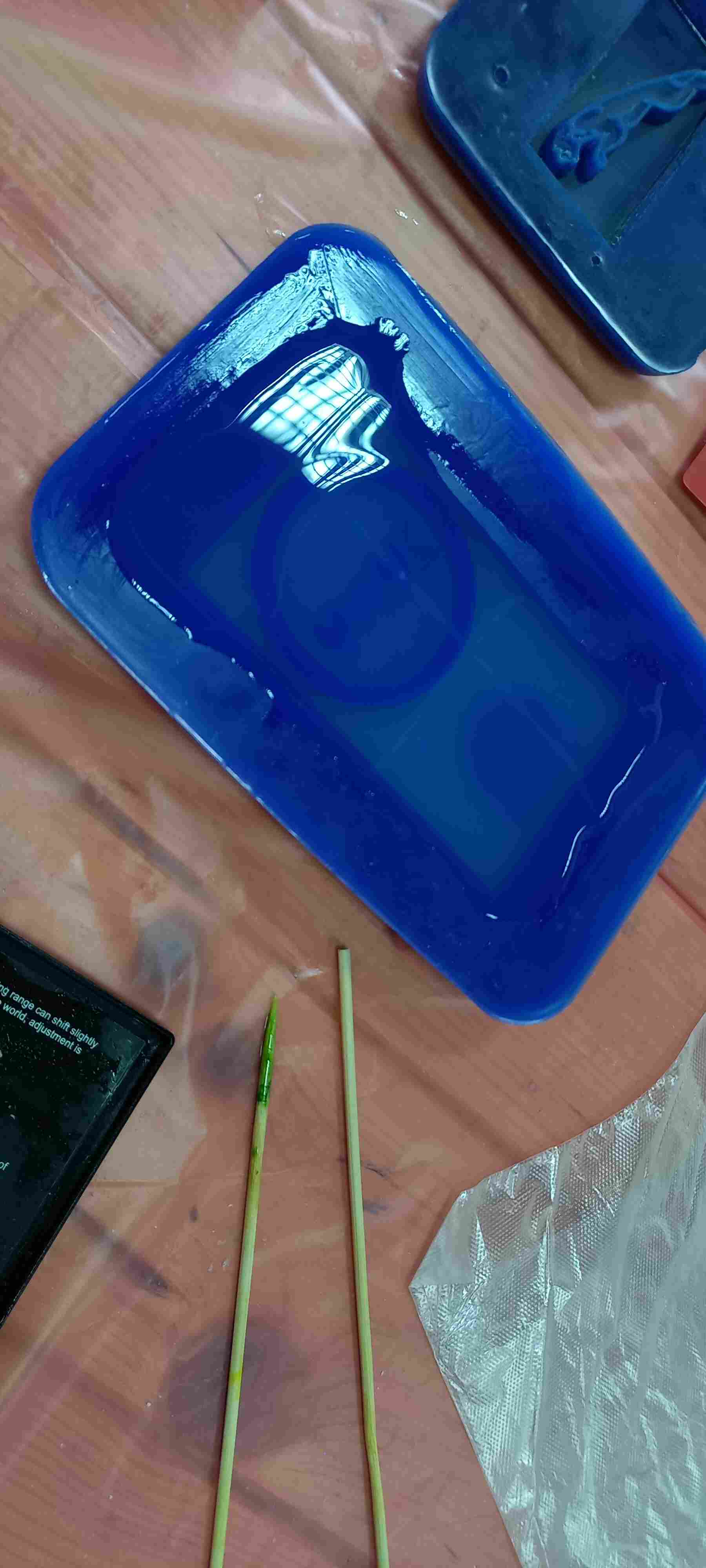

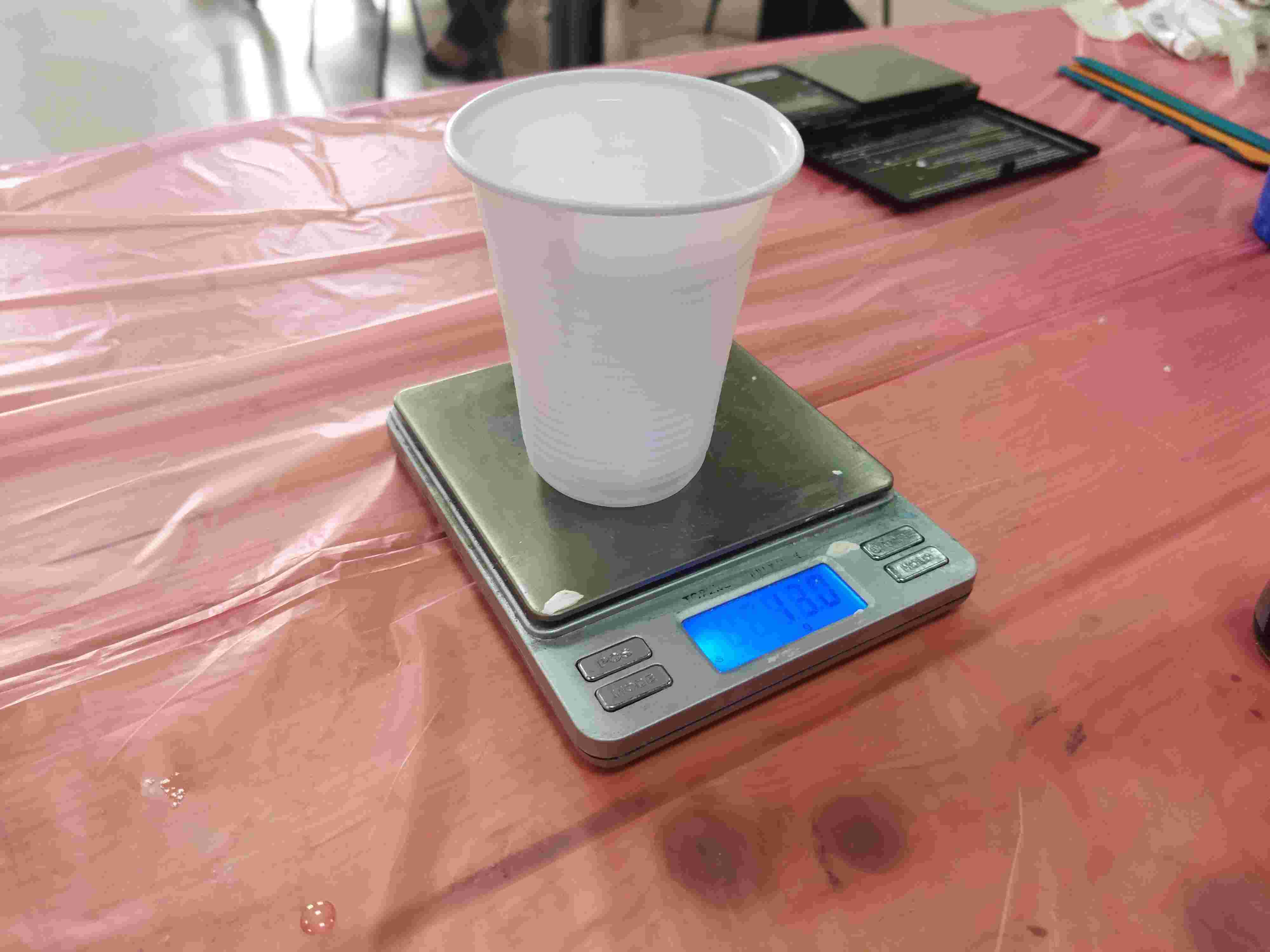

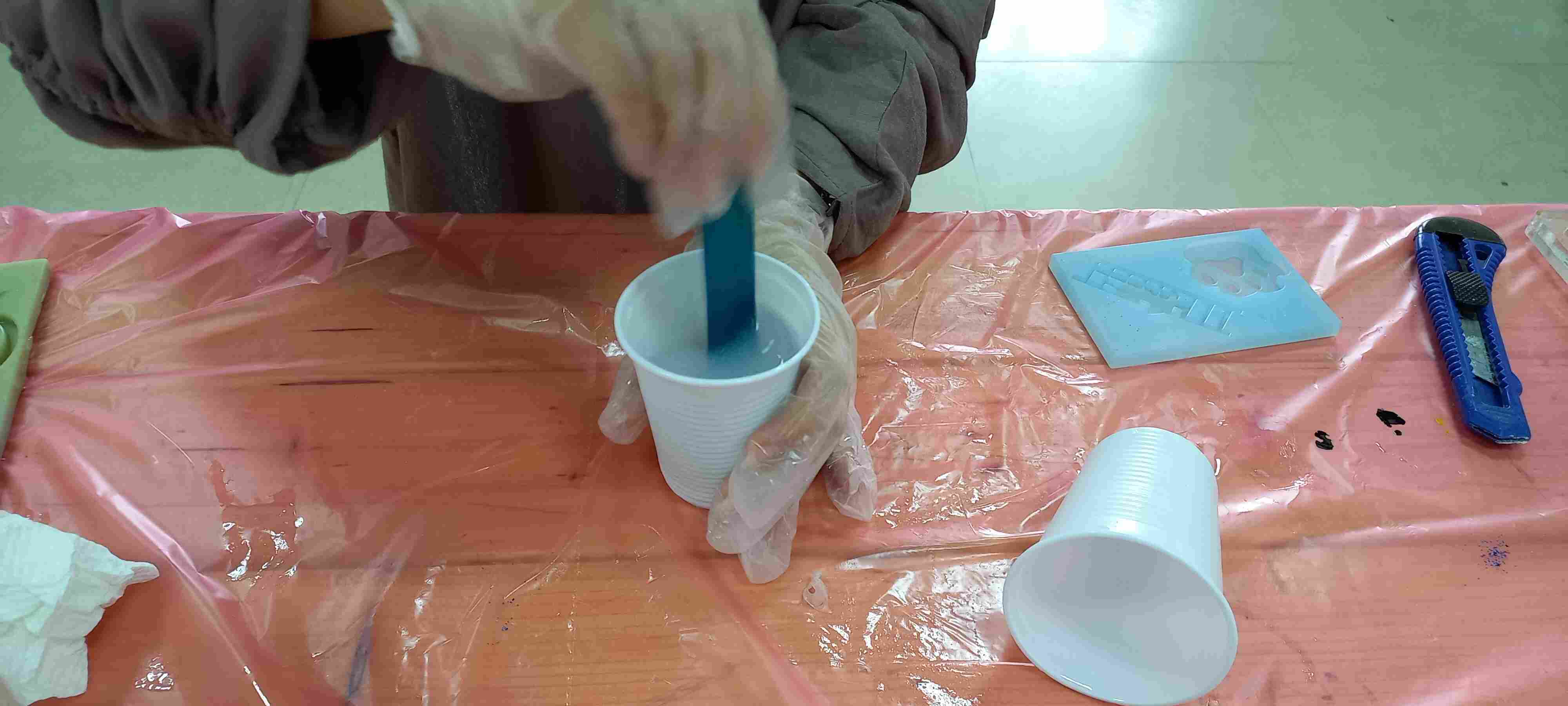

16) Mix Silicon and Silicon Hardener in a cup

The ratio is 1:1

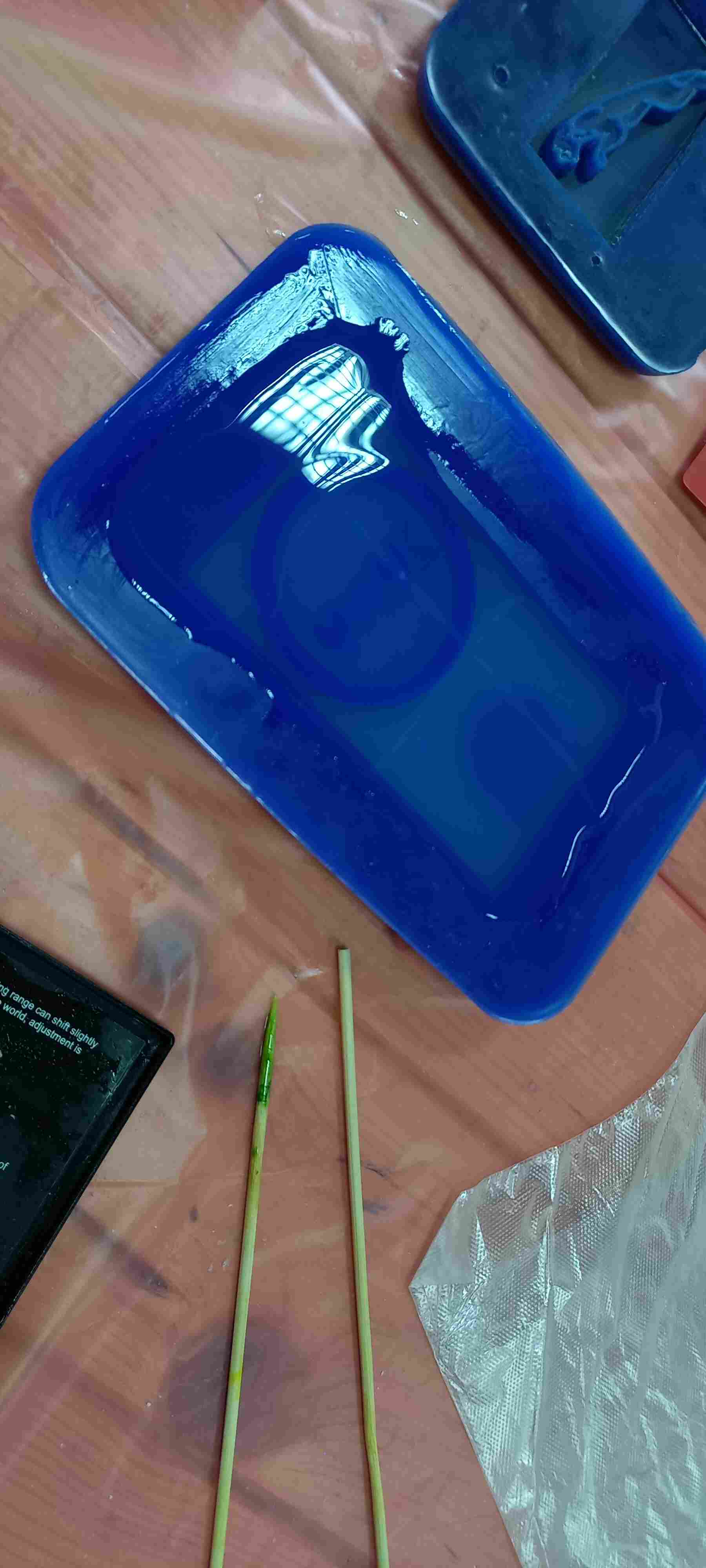

17) Pour the mixture into the wax and wait for 24 hours

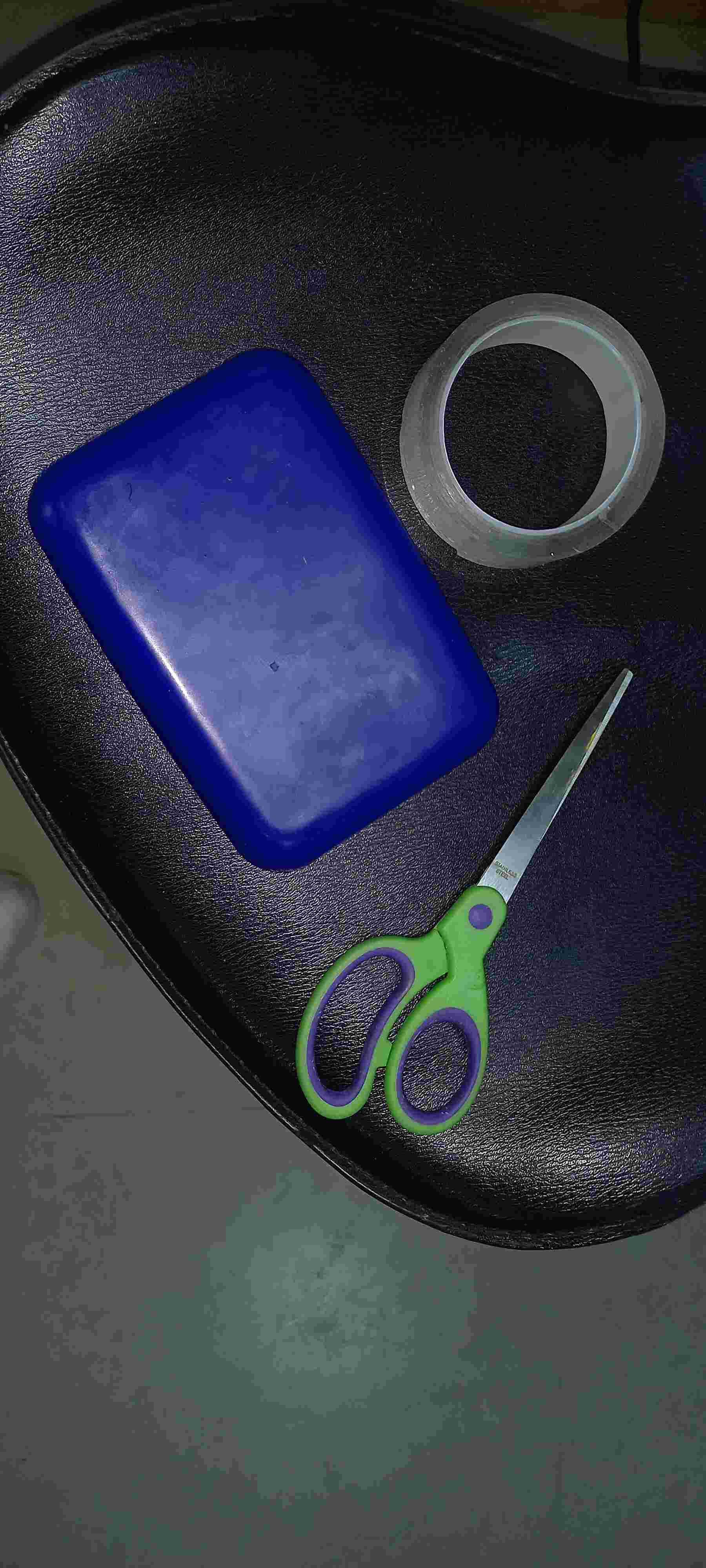

The result

Note: The mold is a female mold

Casting¶

What is casting?¶

Casting is when you pour a material into a mold to create a cast, which in return gives you the final shape of the design

What type of material to use?¶

In this assignment, we have materials like resin, PIFITO Oatmeal Melt and Pour soap base and dry putty to choose from, but materials to be casted can vary from molten metal to plastics.

Sefety for resin¶

- Keep away from children.

- Should be stored in a dry place and preferably in the original container (temperature between 20C-25C)

- Do not swallow, call a doctor immediately if you swallowed the product.

- Wear gloves when you use the product and wear masks for pregnants (it may cause an allergic skin reaction).

- In case the product comes in contact with eyes, rinse cautiously with water for several minutes.

For more information visit our group assignment link

Steps to create the cast¶

1) Choose your material

I have chosen Resin

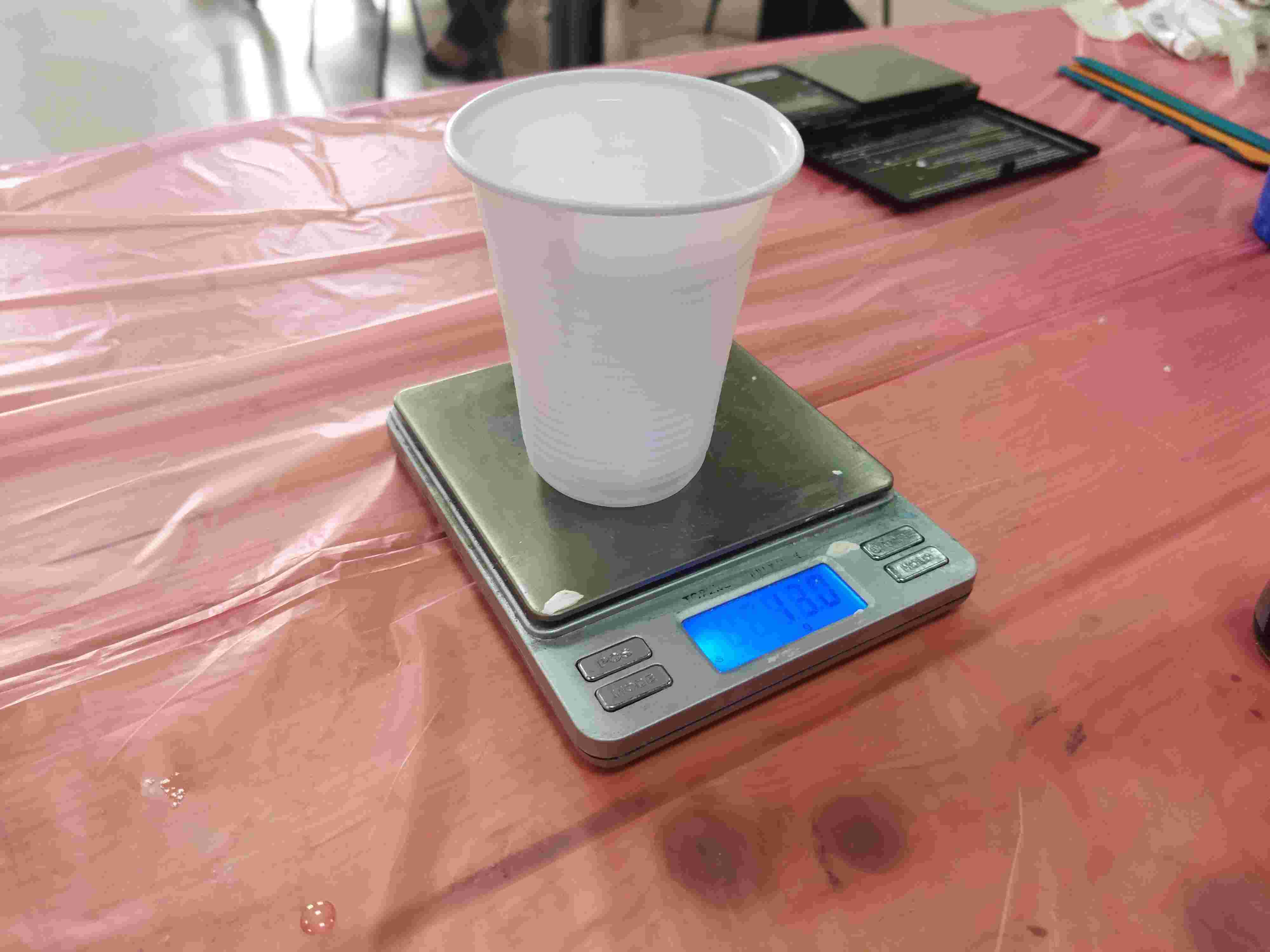

2) Mix the Resin and the Hardener for 3 minutes

ratio of 10 Resin : 6 Hardener

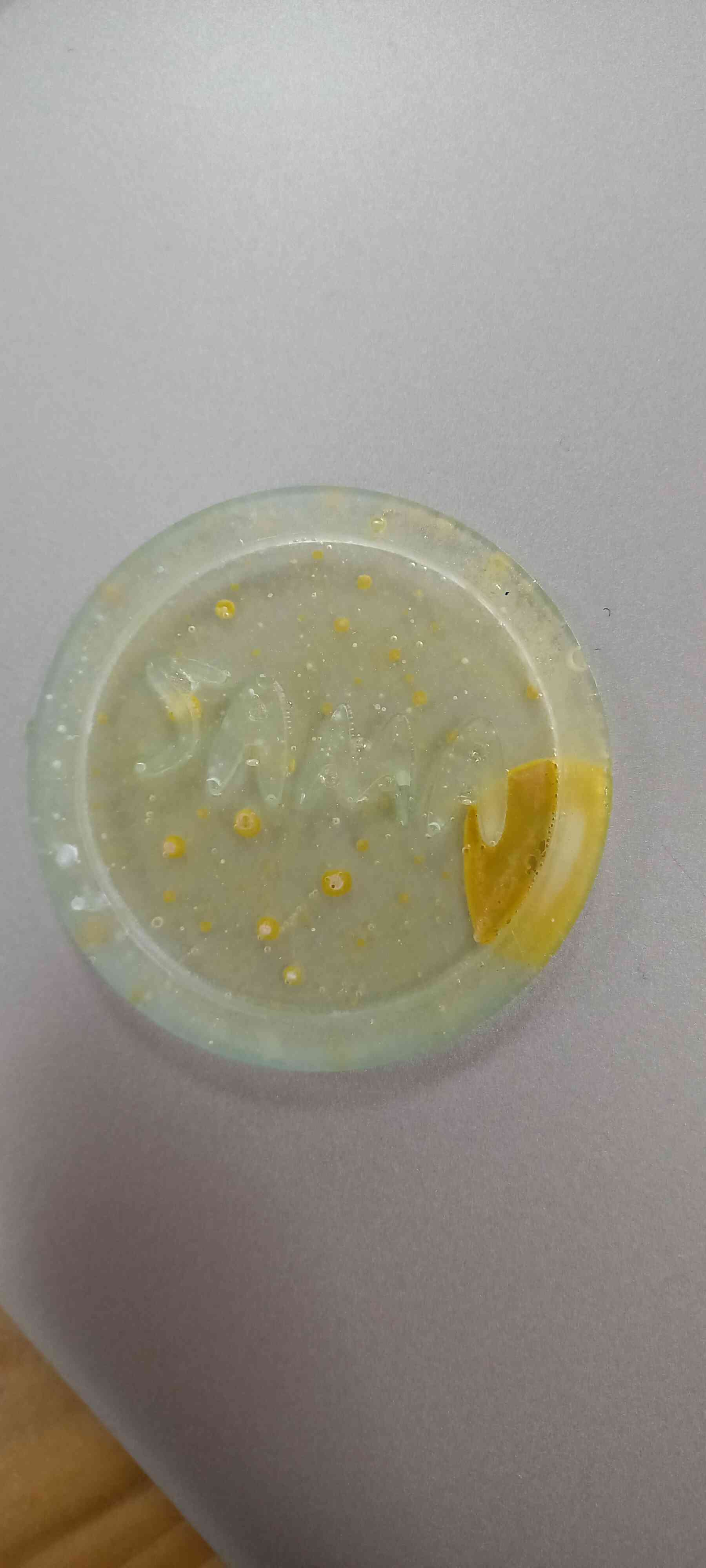

3) Pour it in the mold and let it solidify for 24 hours

The result

Group Assignment¶

Check out this link for our group assignment

Final Thoughts¶

Casting and molding with silicon and resin can achieve great surface finish and accurate dimensions if done correctly, moreover, it has a great aesthetic look to it especially if colors are added to the mixture.

In manufacturing, casting can be great in copying designs with difficult dimensions, and it has some excellent mechanical properties, for example; Cast iron has great hardness and toughness properties.

Introduction to Cast Iron: History, Types, Properties, and Uses