Final Project¶

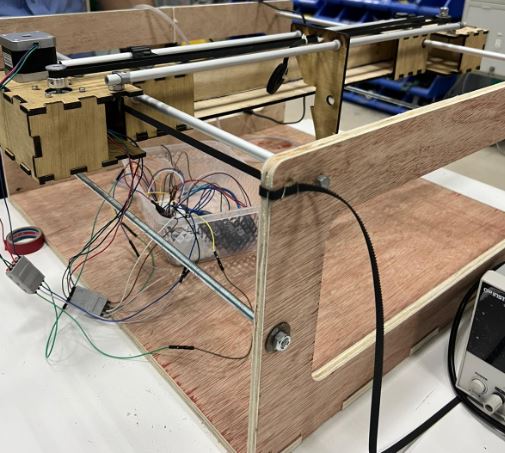

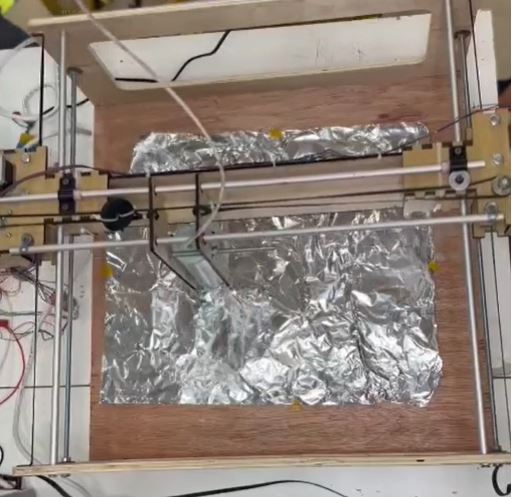

Our project was to produce a pizza maker which distributes the dough on any shape desired by the user. The pizza maker has got 2 axis. The Y axis and X axis. The mechanism of the movement of the machine is produced by stepper motors, belts and bearings.

A video of the Project¶

Heroshots¶

Contribution¶

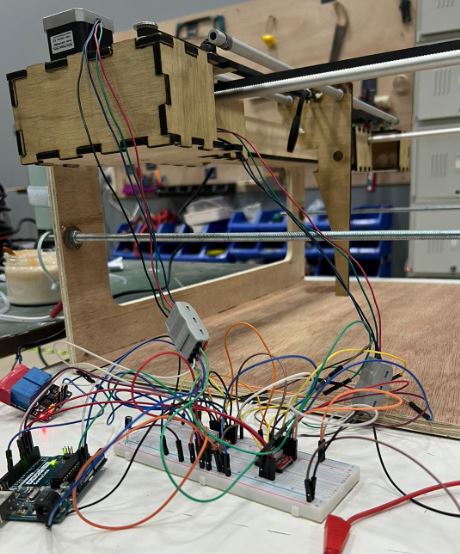

Qasim and I collaborated on the task, as part of a larger project that involved other members, namely Sayed, Husain, and Weaam. Our specific focus was on developing the machine’s methods of movement. We extensively researched various potential mechanisms, evaluating their advantages and disadvantages. After extensive research and experimentation, we found that the most effective mechanism for our machine involved the use of belts driven by gears, controlled by stepper motors.

Utilizing the resources available in the Lab, we designed the most optimal mechanism using components at our disposal. We then proceeded to design the inner structure of the machine, which consists of two mirrored parts. The inner structure serves the purpose of housing the CNC mechanism and the container for pizza dough. It ensures the container remains centered and facilitates movement in the X and Y axes through electric motors located within this structure. The inner structure is supported by shafts that connect it to the two sides of the outer structure.

To achieve precise and controlled movement, we incorporated stepper motors to control the gears that drive the belts. This design allowed for smooth and reliable motion of the pizza dough container. The belts, connected to the gears and attached to the container, provided the necessary functionality for our machine. Through an iterative process involving trial-and-error, we optimized the design, determining that the combination of belts driven by gears, controlled by stepper motors, provided the best combination of reliability, efficiency, and ease of use for our specific application.

We also used a laser cutter machine to cut the inner structure with precision. The two mirrored parts of the structure are connected by two shafts, securely holding the container in place. This design ensures the container’s stability while allowing movement along the desired axes. The final design of the machine incorporated the optimal mechanism, the inner structure, and the stepper motor-controlled movement system, resulting in a successful implementation for our project.

The main documentation can be found in Sayed’s website which includes alot more detailed information regarding the pizza maker.