5. 3D printing and scanning¶

3D Printer is a machine that allows a physical object to be created from a three-dimensional digital model by laying down numerous thin layers of a material in a sequential manner.

3D printing, unlike subtractive manufacturing, allows you to create extremely complicated products. Additive manufacturing is the ideal way for generating prototypes or limited volume / custom products because it can produce them fast and with short lead periods.

Group assignment¶

The group work can be found in my collegue’s website here

Scanning¶

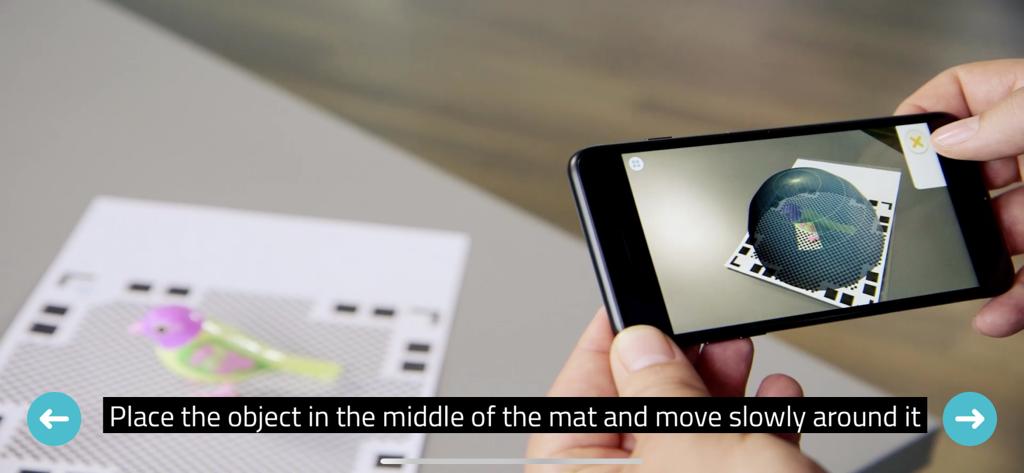

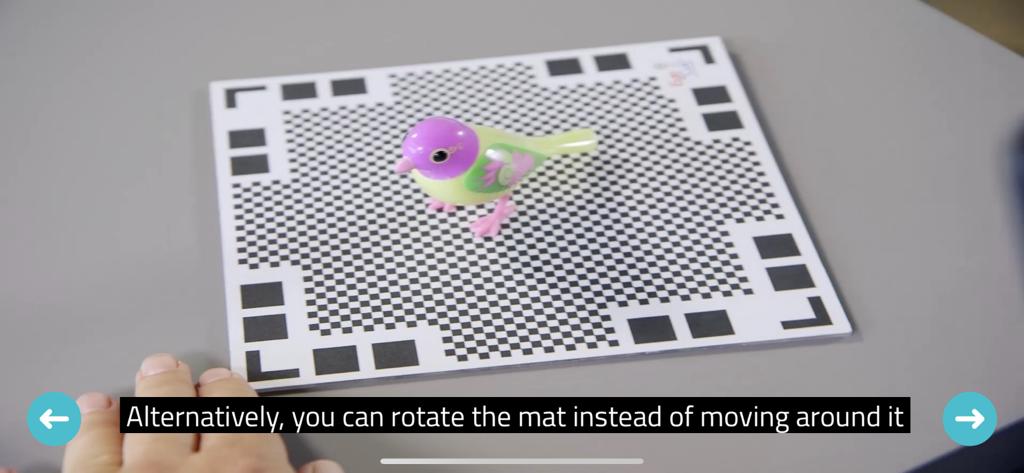

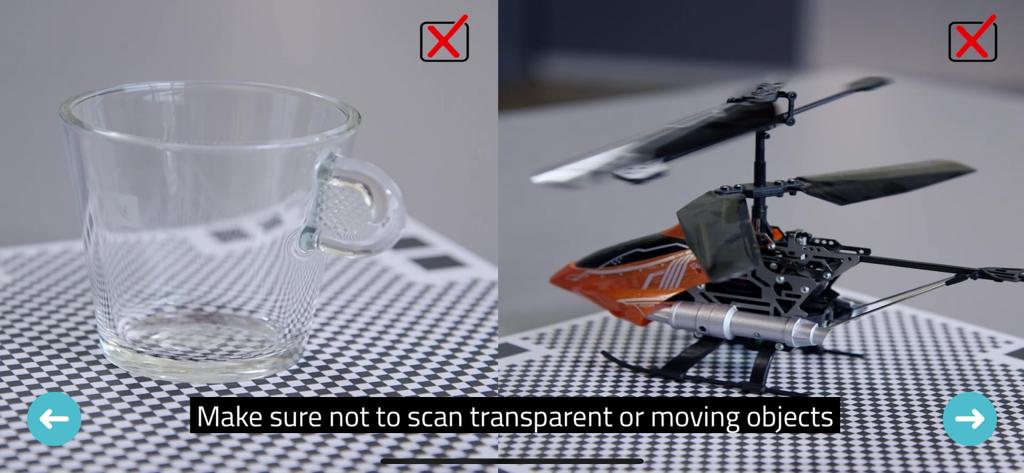

scanning objects can be easily done using Qclone.

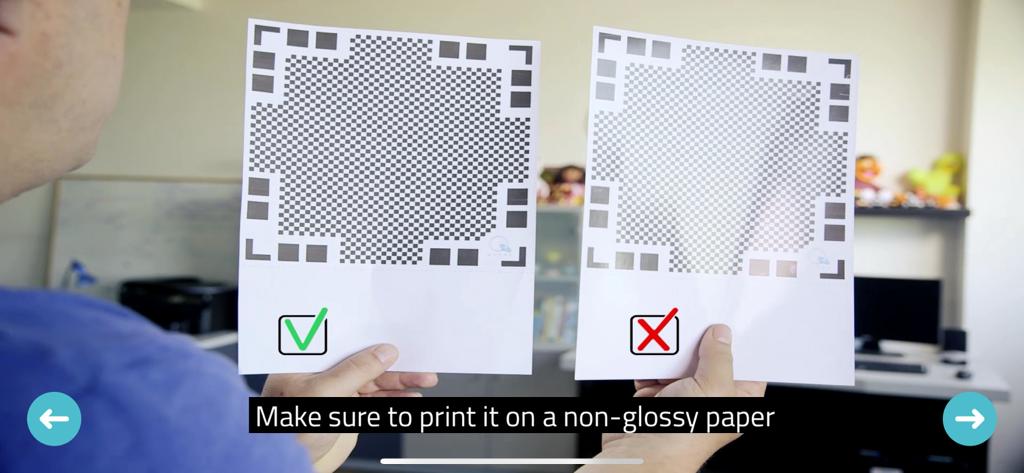

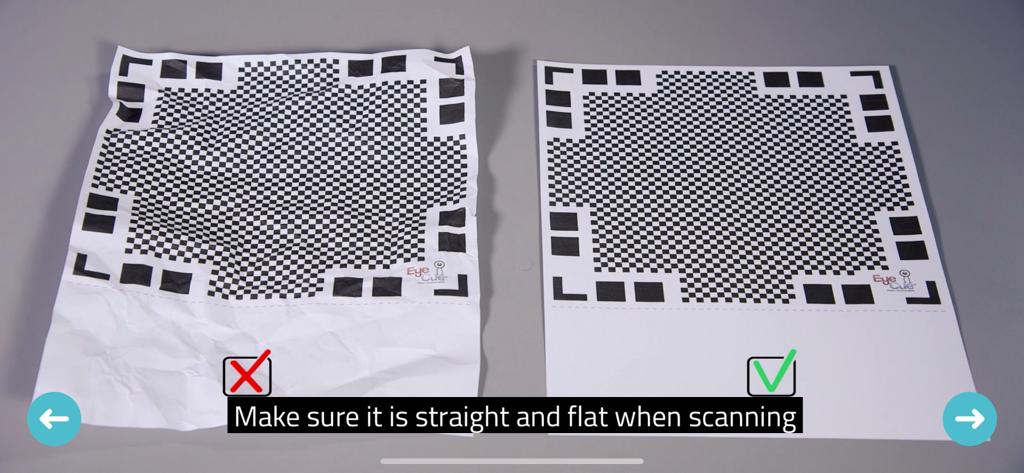

Then follow the below tutorial in order to have a perfect scan.

Following the steps above, I scanned a wrench as shown below.

Printing¶

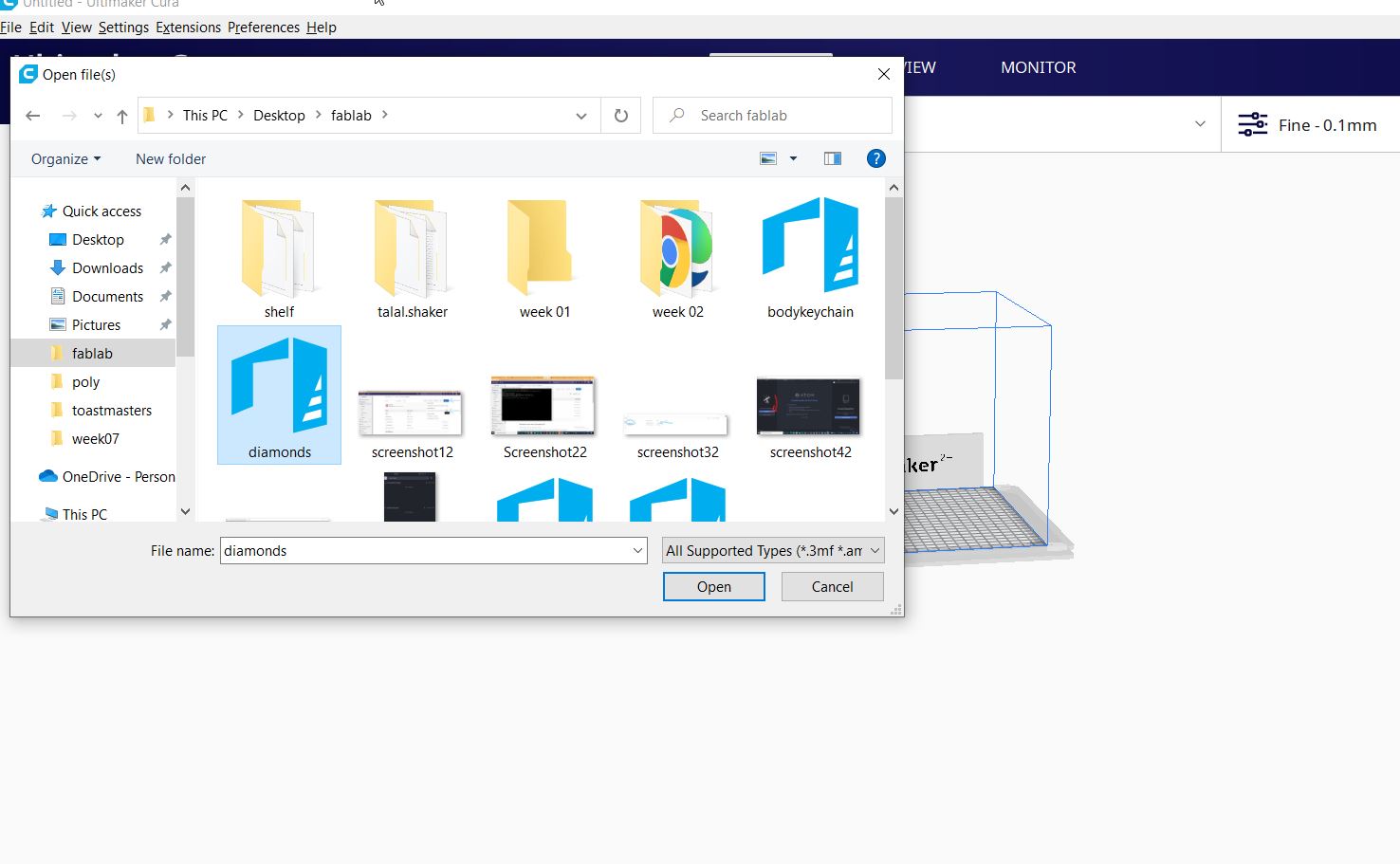

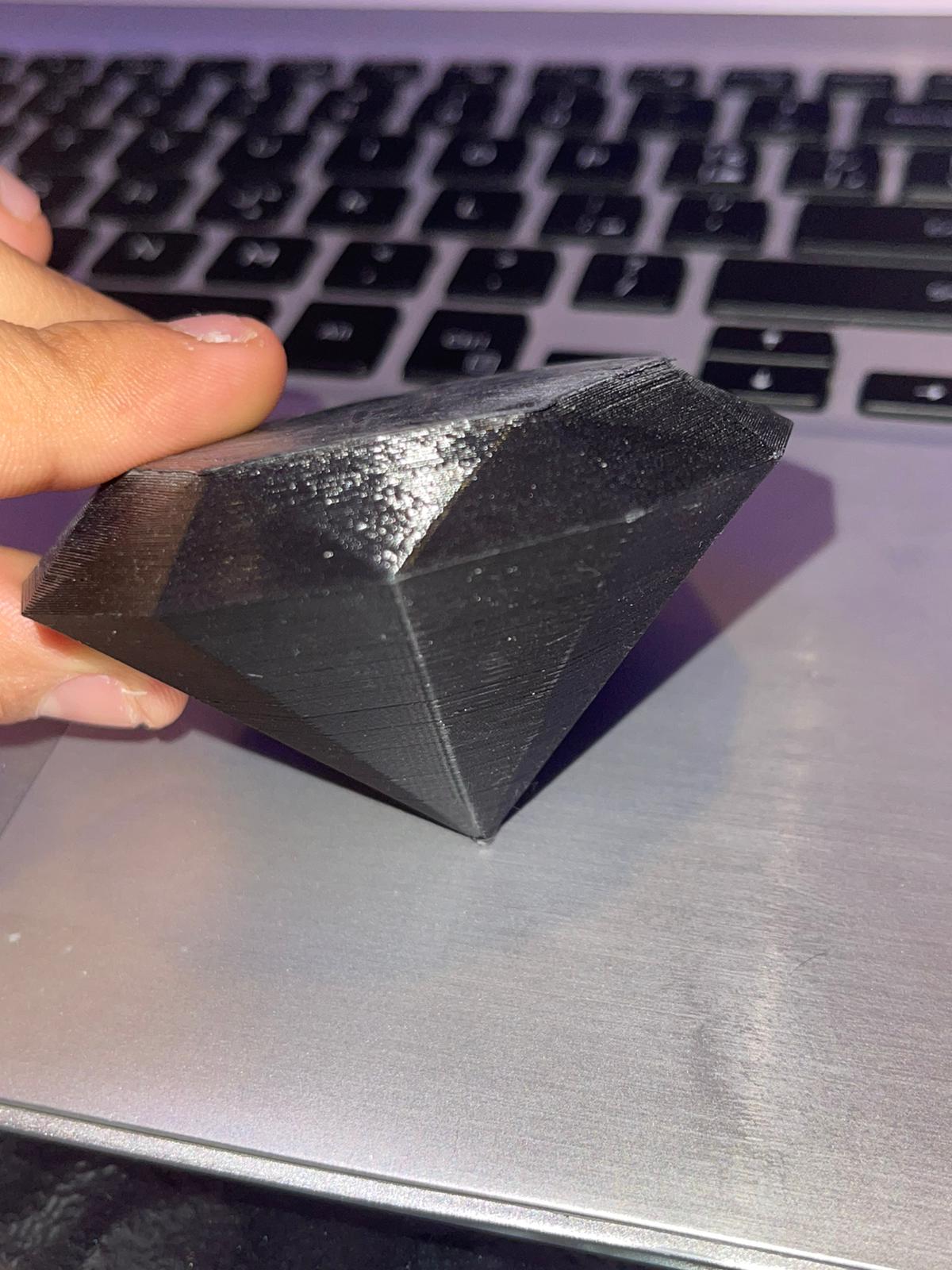

I decdided to print the Diamond design which was made in week02. click here to download the file

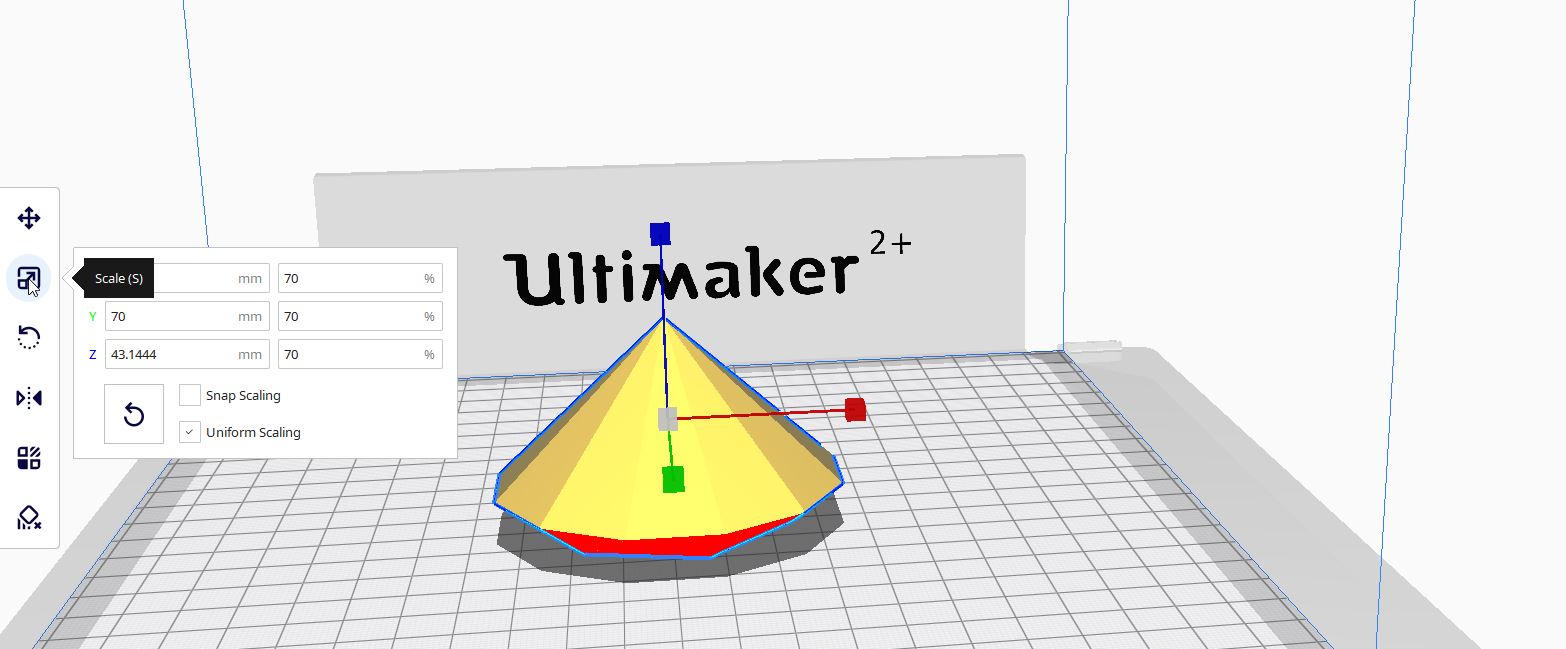

First step was to import the file.

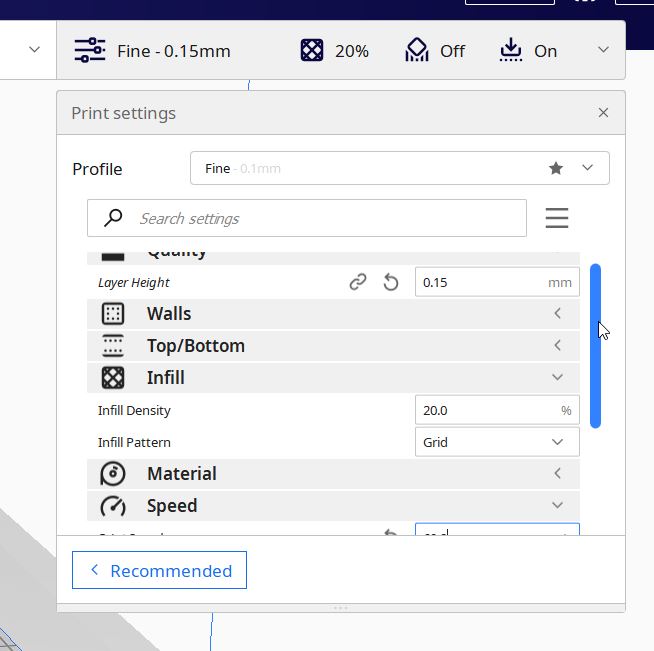

Then I asjusted the scales of the design on the bed, as well as the infill of the filament as shown below.

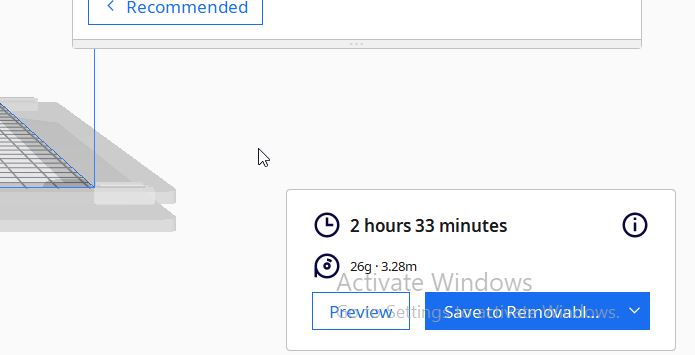

Finally I had to preview the print which shows the duration of the printing.

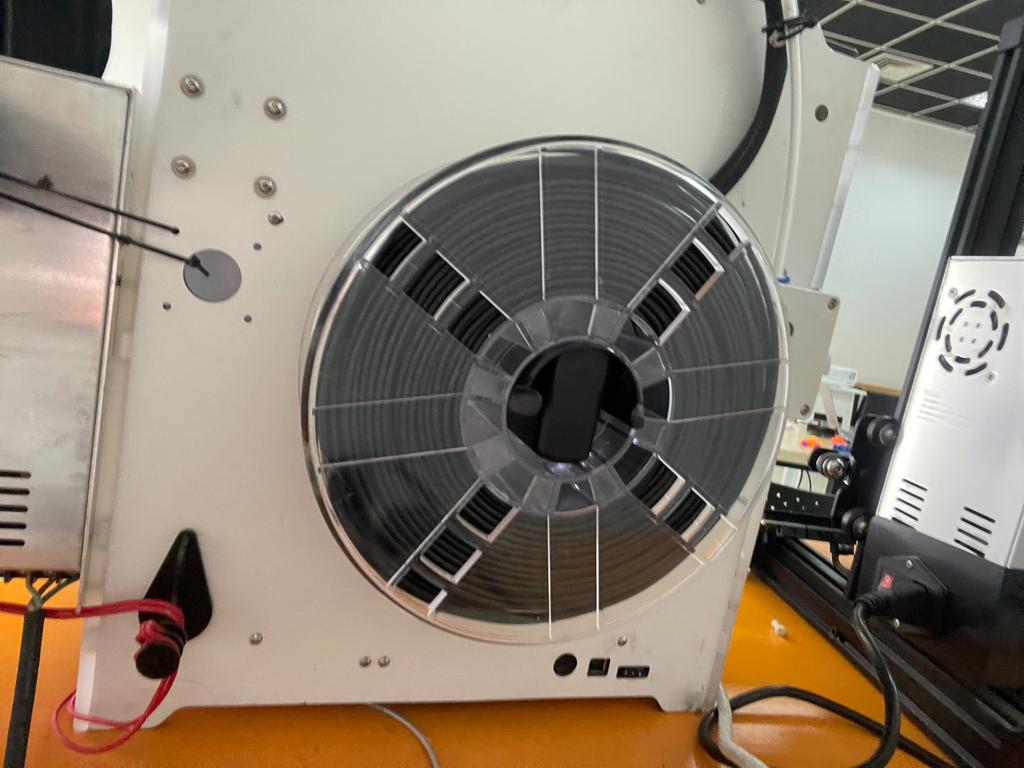

Now the fun part begins. You need to check whether there is enough filament or not.

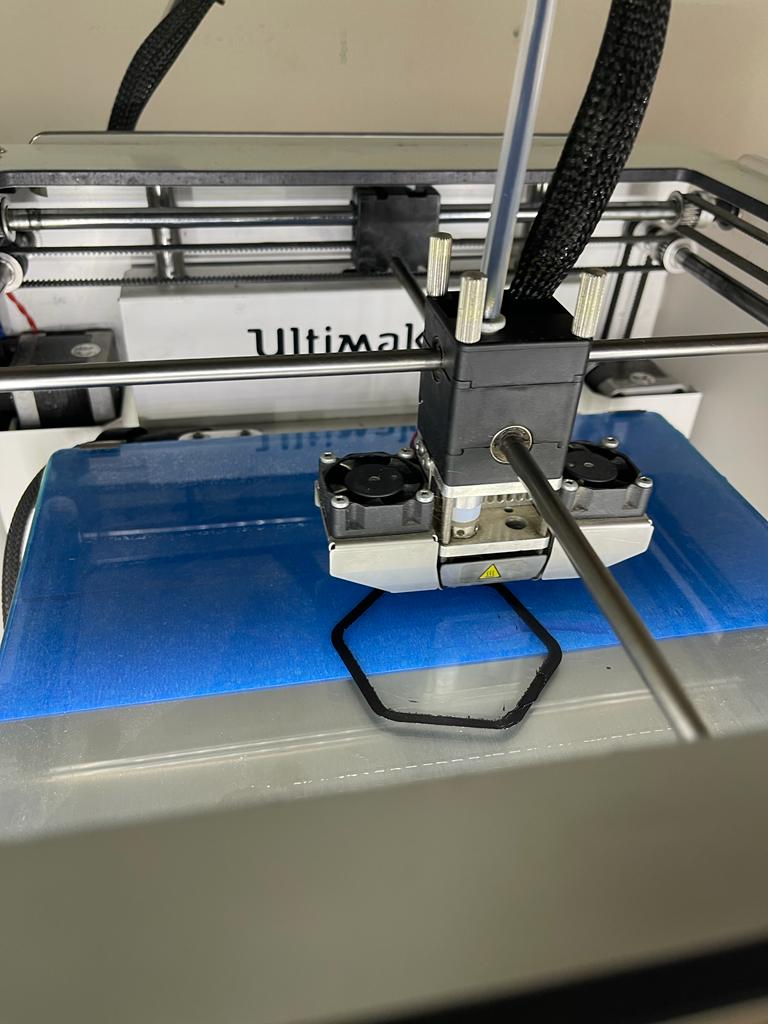

Then, the design was uploaded into an SD card which was then inserted in the 3D printer. And the desired file is chosen using the printer.

Finally, some filament will come out from the nozzle as a test before the printer starts printing the actual design.

.

.

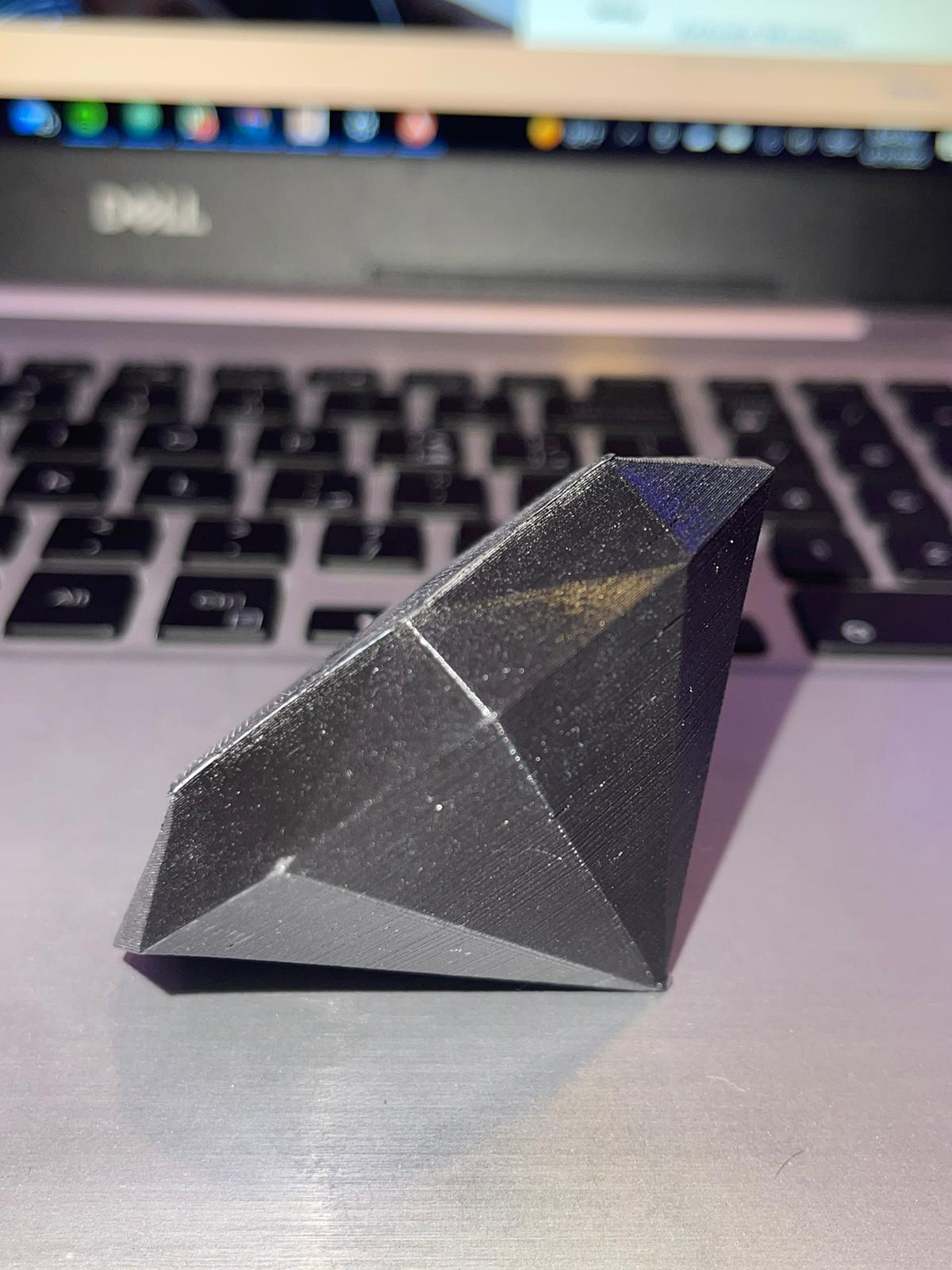

Hero Shots¶

.

.

.

.

Why 3D printer?¶

In simple words, The method of adding numerous layers to build an object is known as additive manufacturing. Subtractive manufacturing, on the other hand, creates parts by removing or cutting away material. The diamond is a design with many slopes and curves, hence this is way easier and only possible to be done using additive manufacturing which in this case was the 3D printer.

What have i learnt from 3D printers?¶

I have learnt that 3D printers can print very complex designs with bends and curves of all kind, they can also print flexible objects. 3D printers also dont take much desk space which is another advantage.The filaments used in the printers come in many different types of materials which is very useful so you print an object of your choice with the physical properties that you desire.It is also possible to control the infill of the materials which is very useful as it determines the hardness/softness of the material. On the other hand, due to the 3D printer being very precise while printing the object it sometimes take upto 24 hours or days to complete a design as it prints the object layer by layer with all details. Also, the bed of the printers are often small which makes it not possible to print large objects.