6. Large format CNC (computer controlled Machining)¶

-

The word “CNC” stands for Computer Numerical Control.

-

CNC machines are making parts around the world for almost every industry. They create things out of plastics, metals, aluminum, wood and many other hard materials.

So, how do you define a CNC machine?

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape.

Safety rules :¶

It is extremely important that everyone remembers the proper safety rules while operating the machines.

It is extremely important that everyone remembers the proper safety rules while operating the machines.

these are some tips to keep yourself save while using the CNC machine:

- Use the emergency stop button to shut down the machine instantly. This button is located on the handheld unit, the control panel, and other places on the machine.

- Use the emergency stop button to shut down the machine instantly. This button is located on the handheld unit, the control panel, and other places on the machine.

- Ensure that you wear suitable footwear such as safety boots at all times.

-

If you have long hair or you wear hijab, ensure that you keep it tied and fixed when you operate the machine.

-

Wear a proper pair of safety glasses.

-

Take off your jewelry .

-

Keep your hands away from any moving parts during machining processes.

-

Stand clear of the machine whenever it is operational. You should also warn any other people near the risk of being too close to it.

-

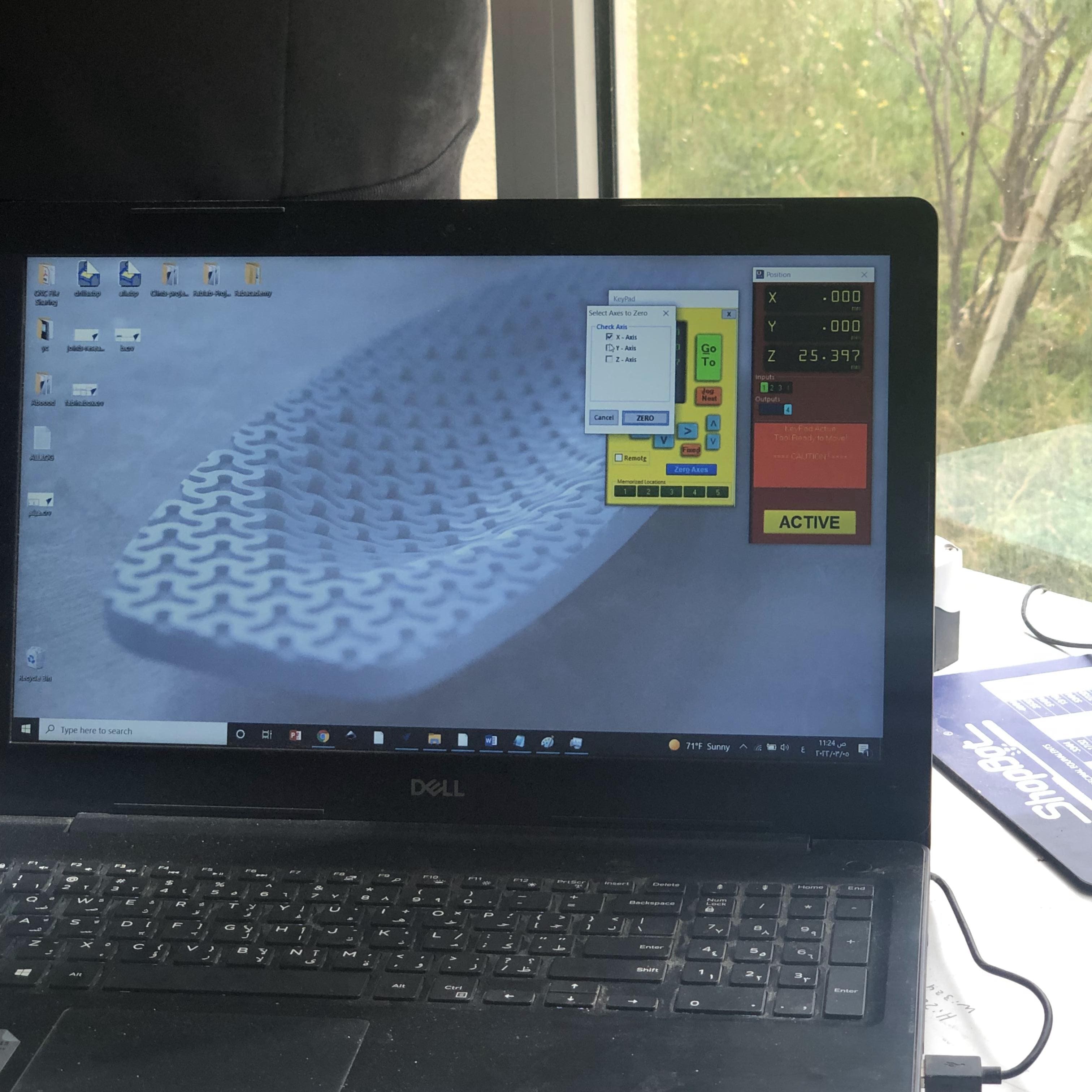

These are the main keys to start operating the machine

Group assignment¶

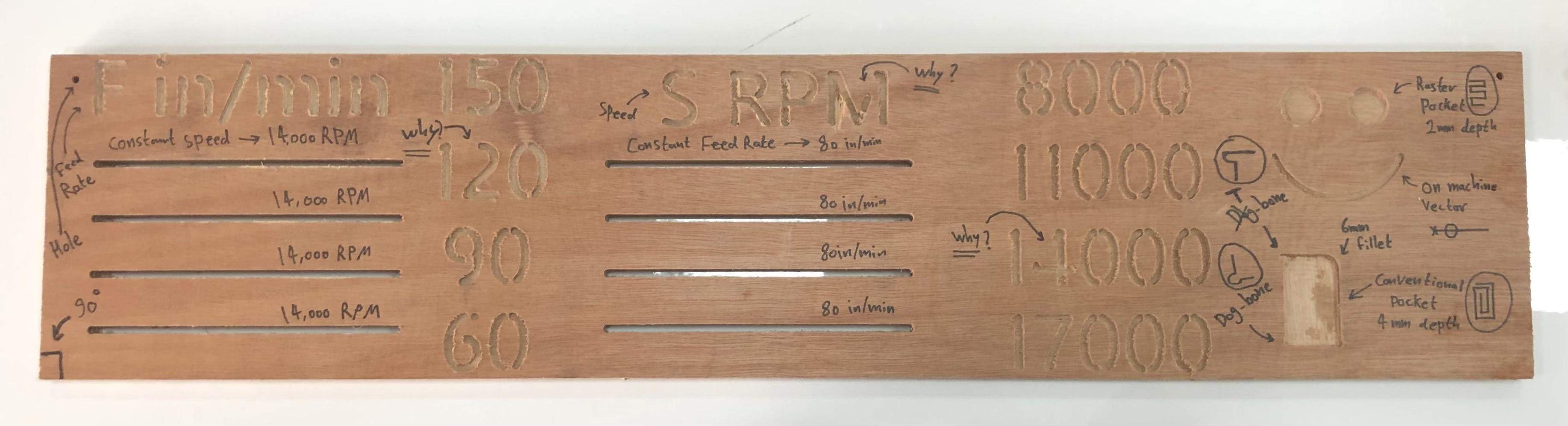

In our group assignment we made a board to test the different settings in the CNC machine.

In our group assignment we made a board to test the different settings in the CNC machine.

-

Feed rate feed rate is the speed at which the cutter engages the part and is typically measured in units/minute but in our design it’s measured in in/min. As you can see each number expresses the different feed rate.

-

RPM speed RPM (abbreviated: rev/min, r/min, or r·min−1) is a measure of the frequency of a rotation. As shown each number expresses the different RPM speed.

-

A Pocketing operation it is used when you want remove all material with a closed boundary down to a set depth.

We also tested the T-bone and dog bone

Individual assignment¶

design the object¶

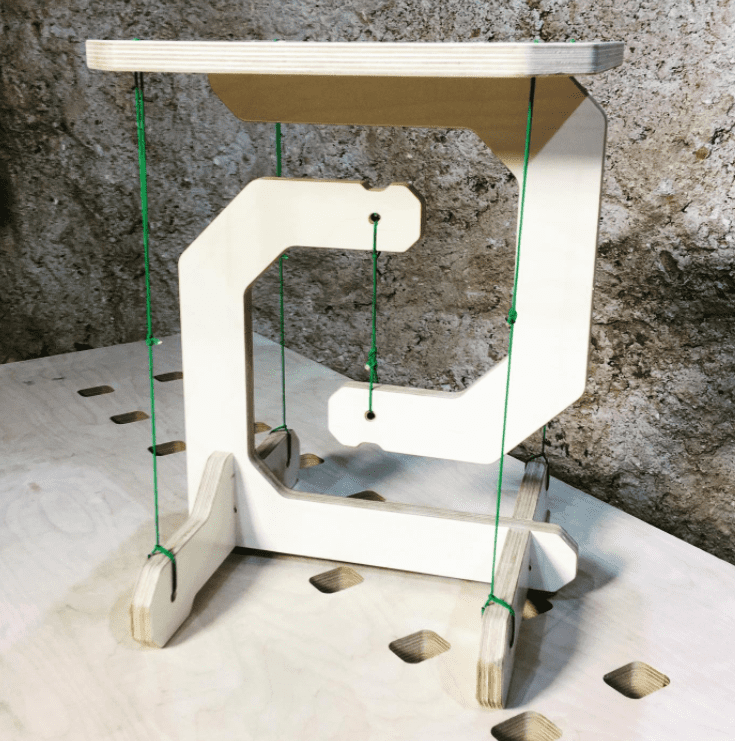

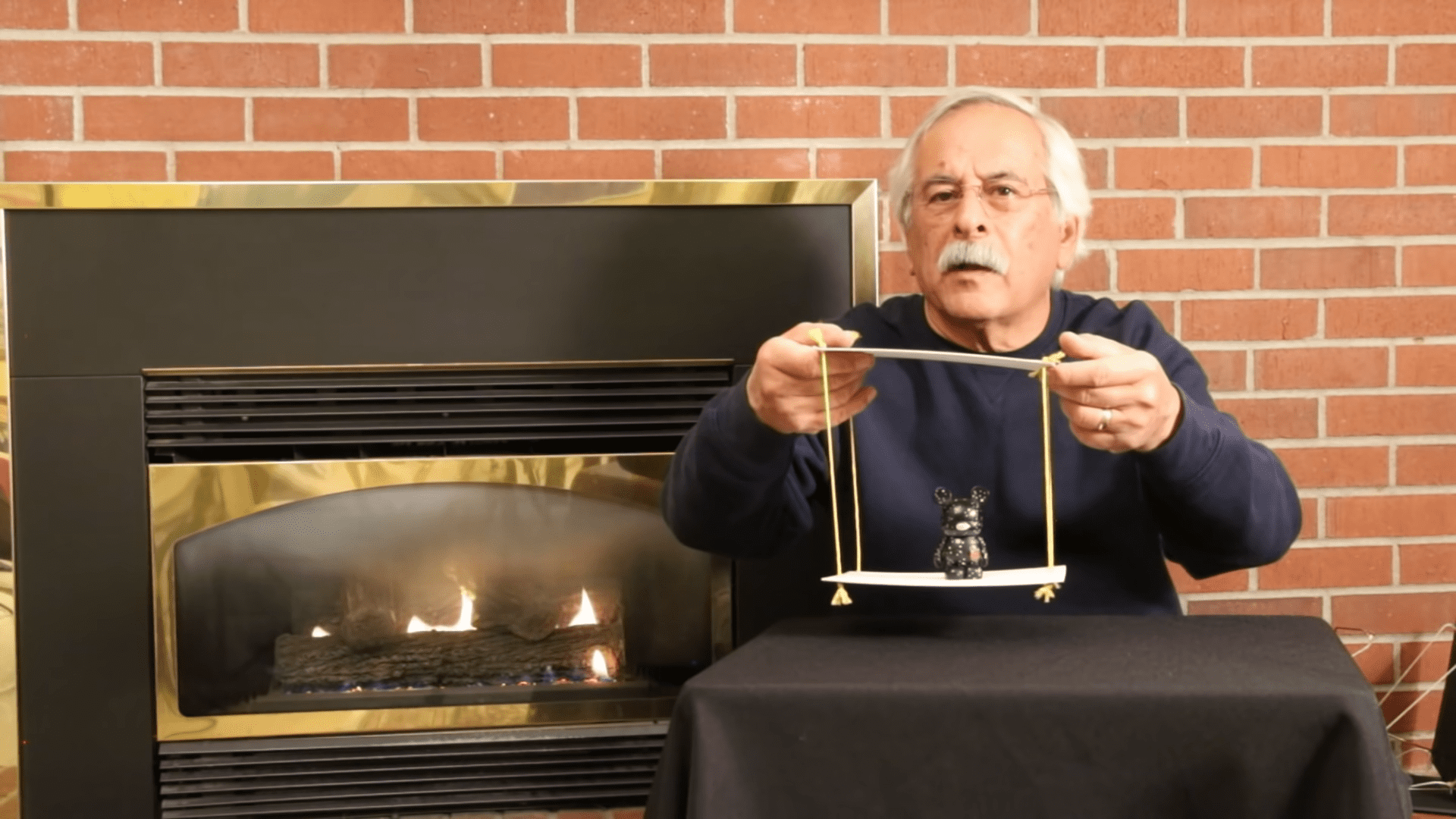

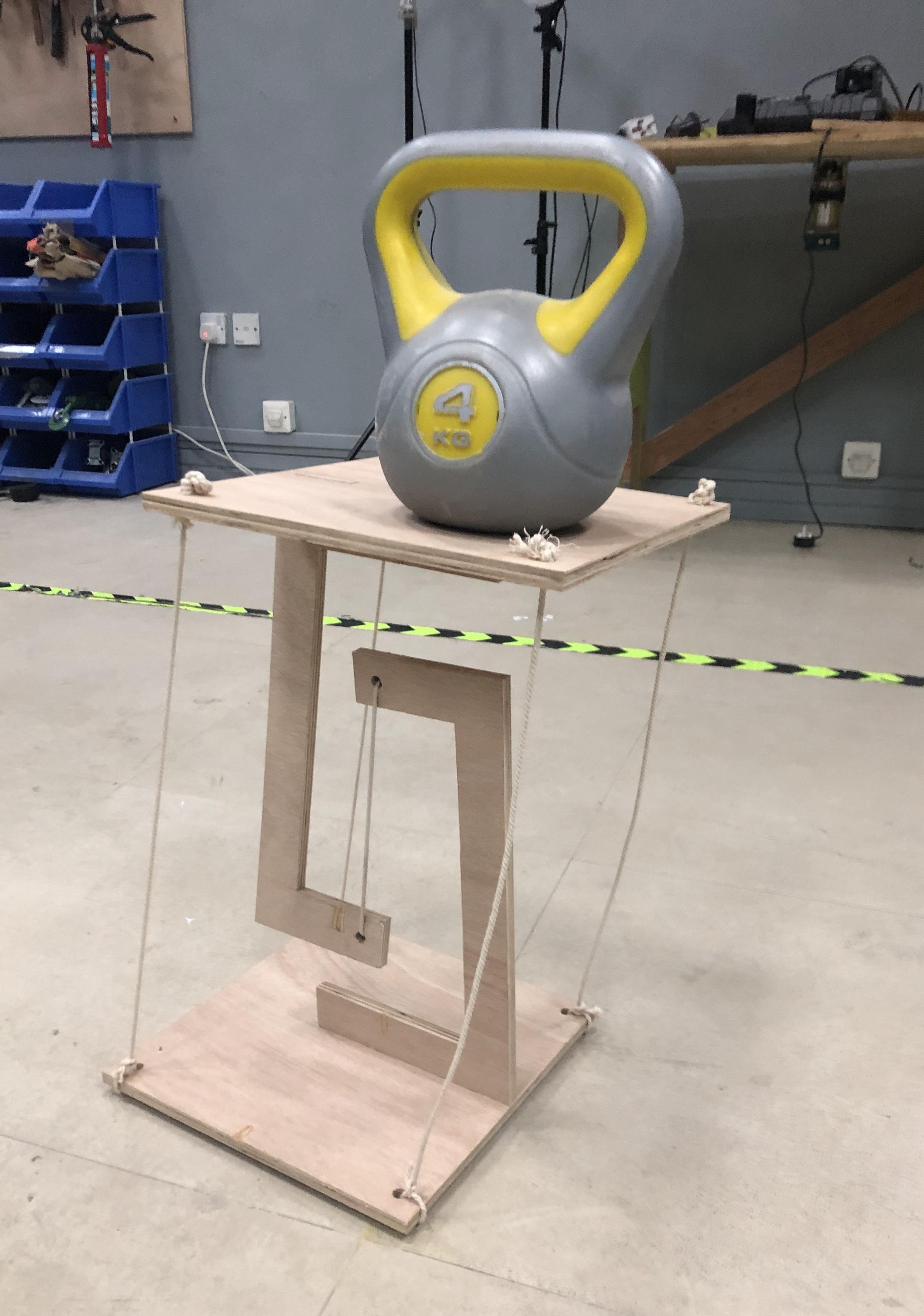

In the phase of searching for inspiration I found this project

I researched the basics and explanation of the tensegrity table to create my own design.

This YouTube video helped me a lot

Tensegrity Table Explained

I researched the basics and explanation of the tensegrity table to create my own design.

This YouTube video helped me a lot

Tensegrity Table Explained

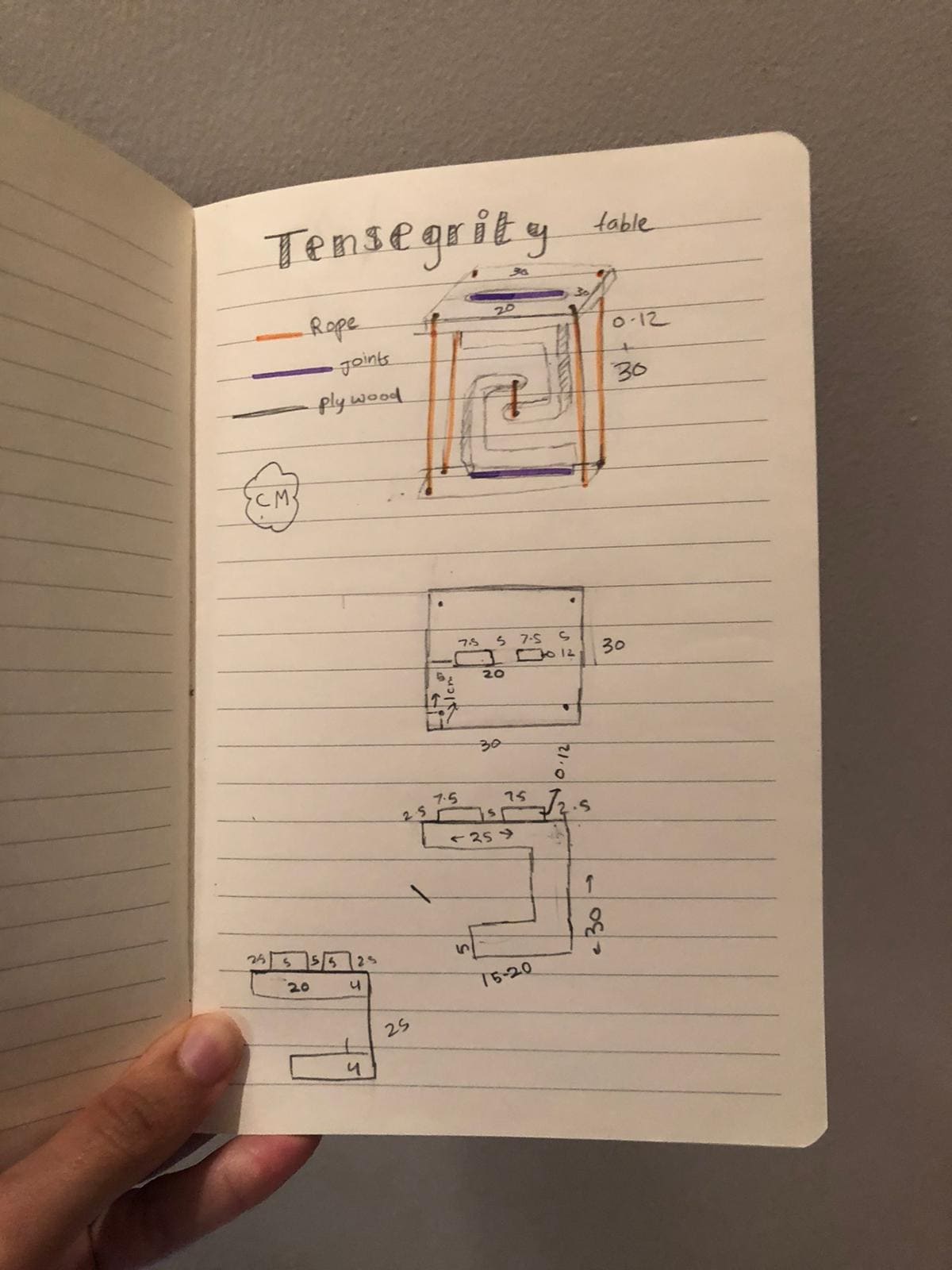

I sketched out my designs to make the digital design process easier

I sketched out my designs to make the digital design process easier

- My design is made using Fusion360 , I transferred my design from my sketch to digital design.

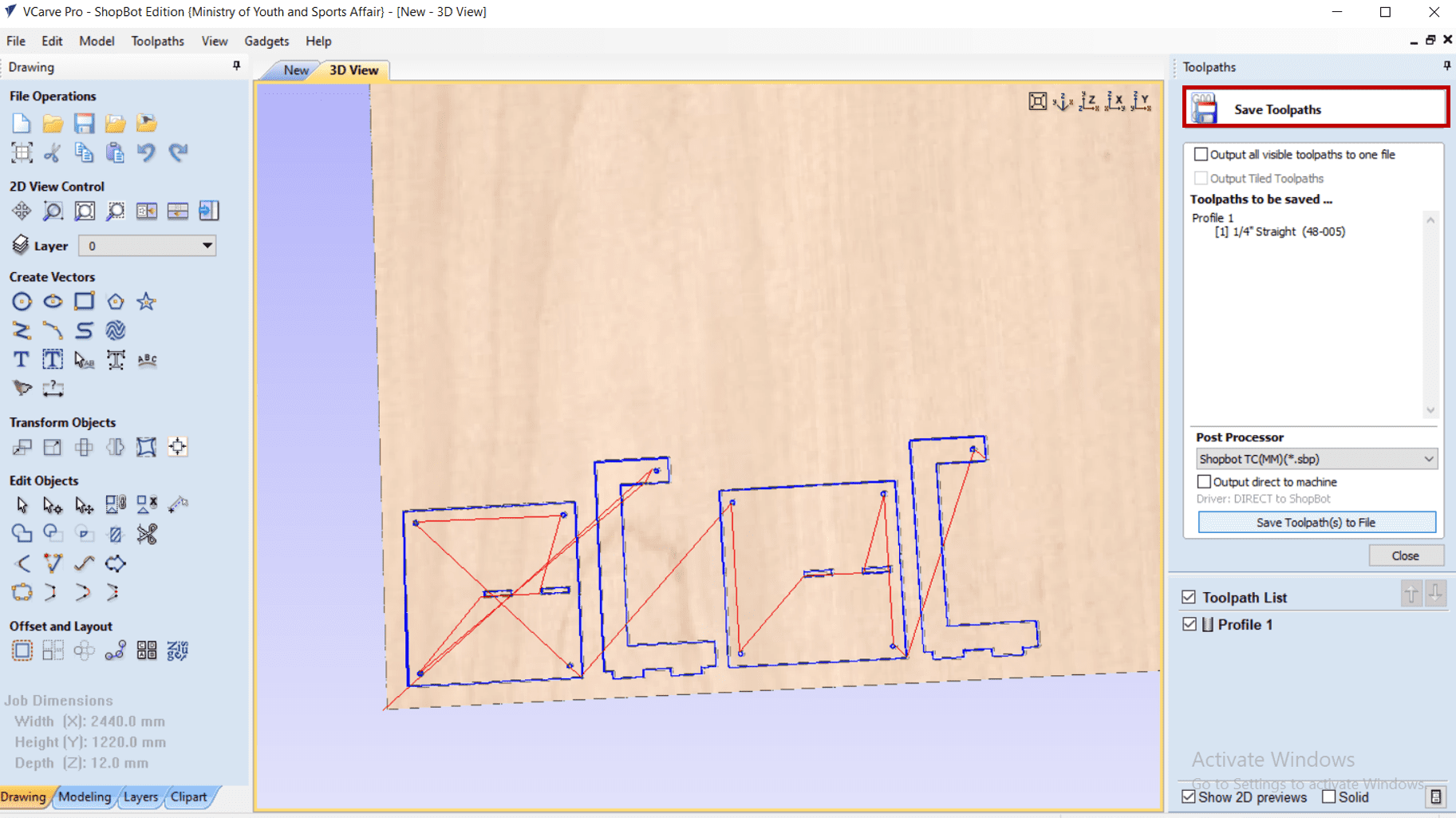

VCarve(toolpath)¶

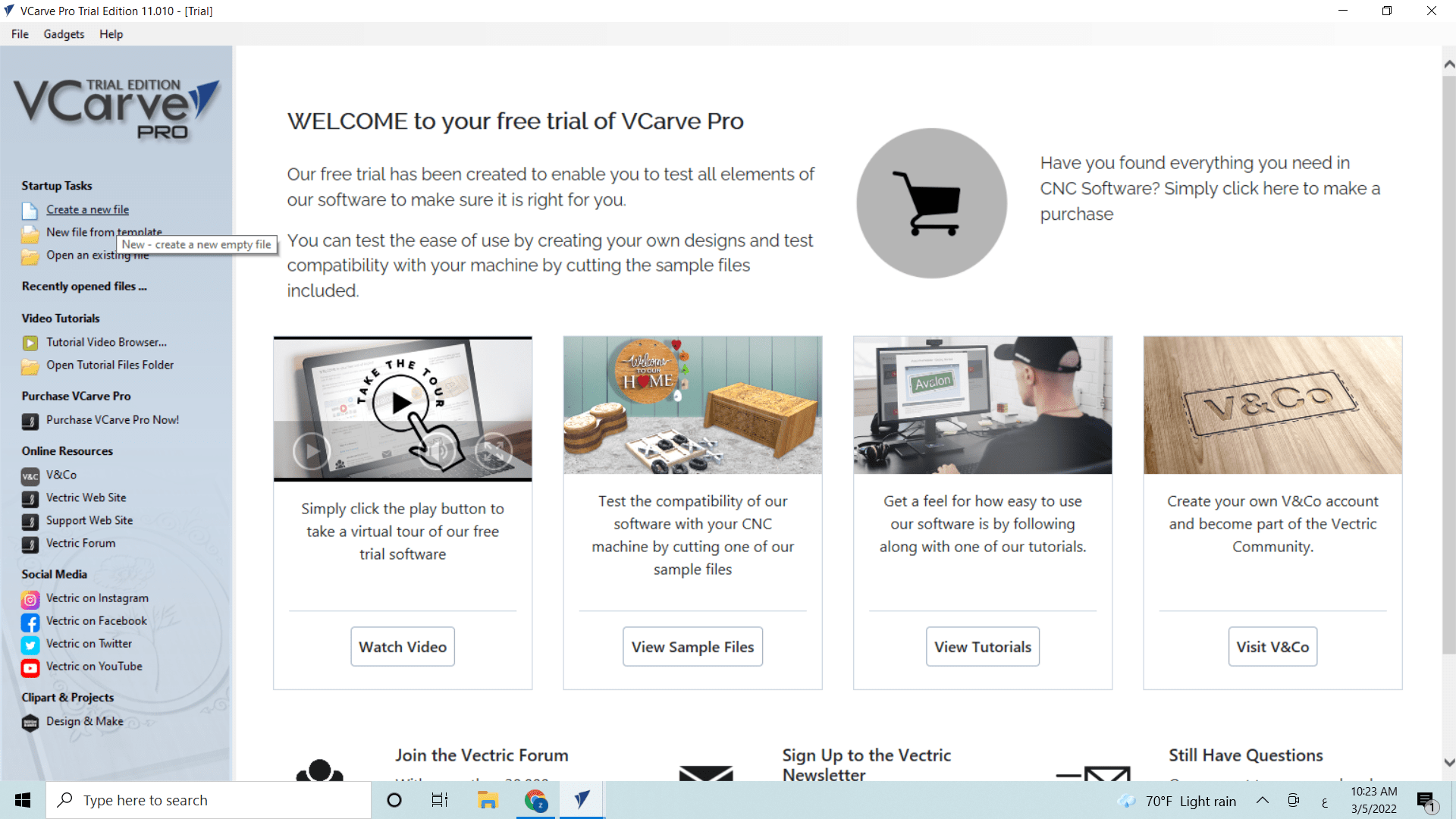

This is the link to download the free trial of Vcrave

- click here to download v carve

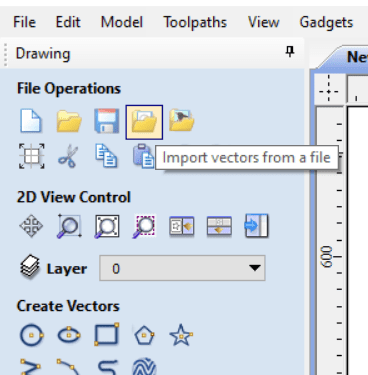

- Click the (Import vectors from file ) to show you design in the software and make sure it is a dxf file

-

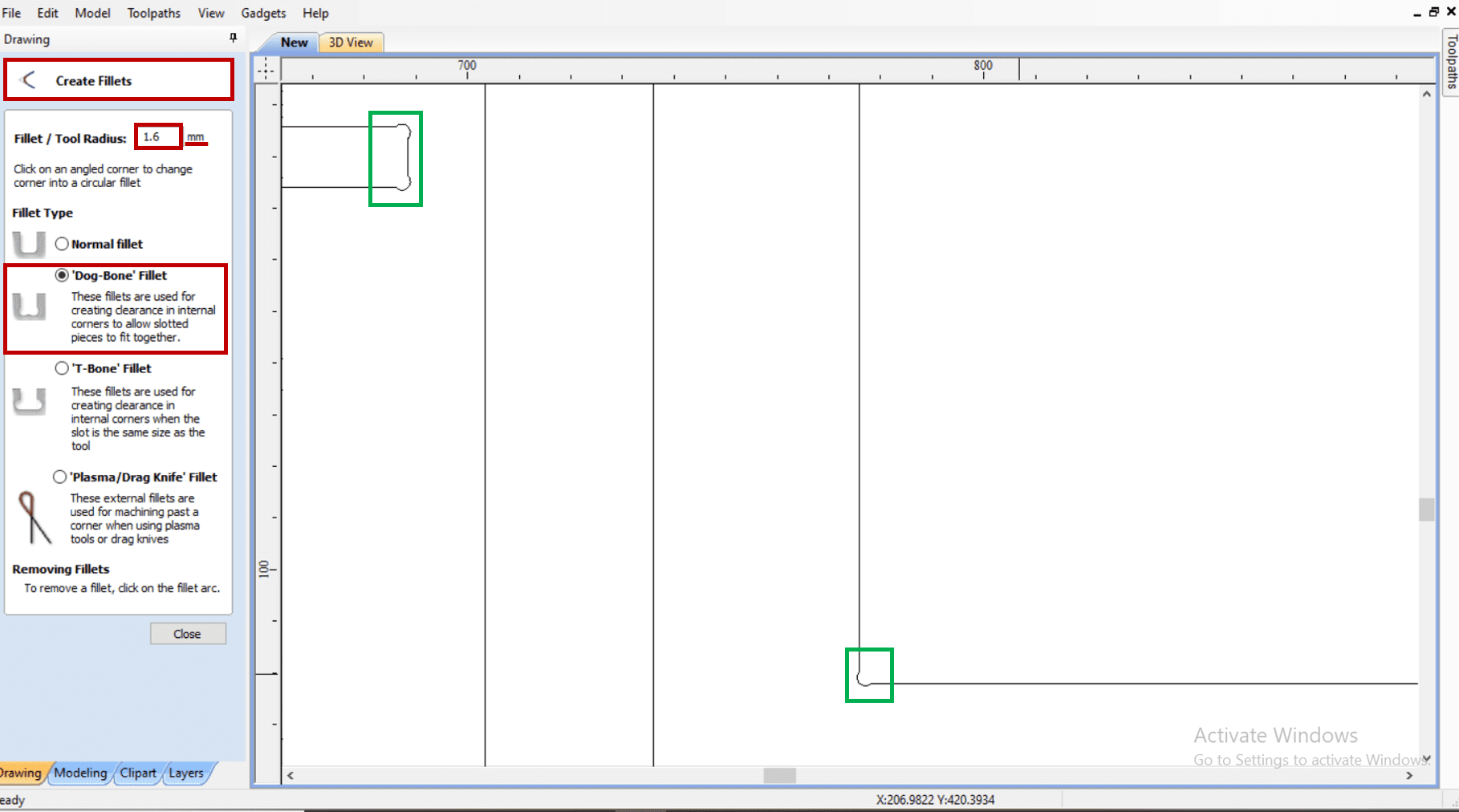

We manufacture dog bone fillet to allow the machine to cut the inner corner since the machine’s bead is normally circular and the angles in the corners are 90 degrees, which means that when the machine cuts, the corners may be skipped and the joint size may be incorrect.

-

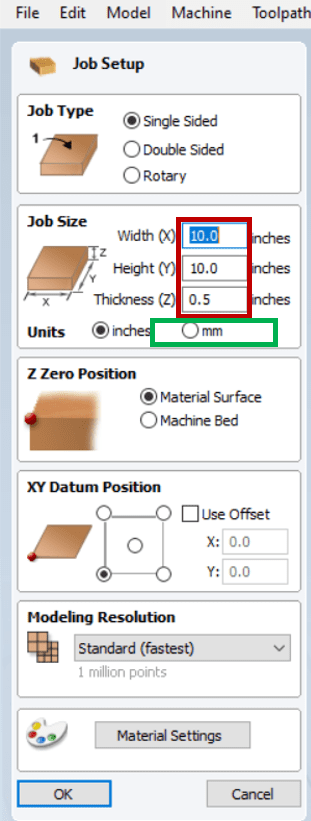

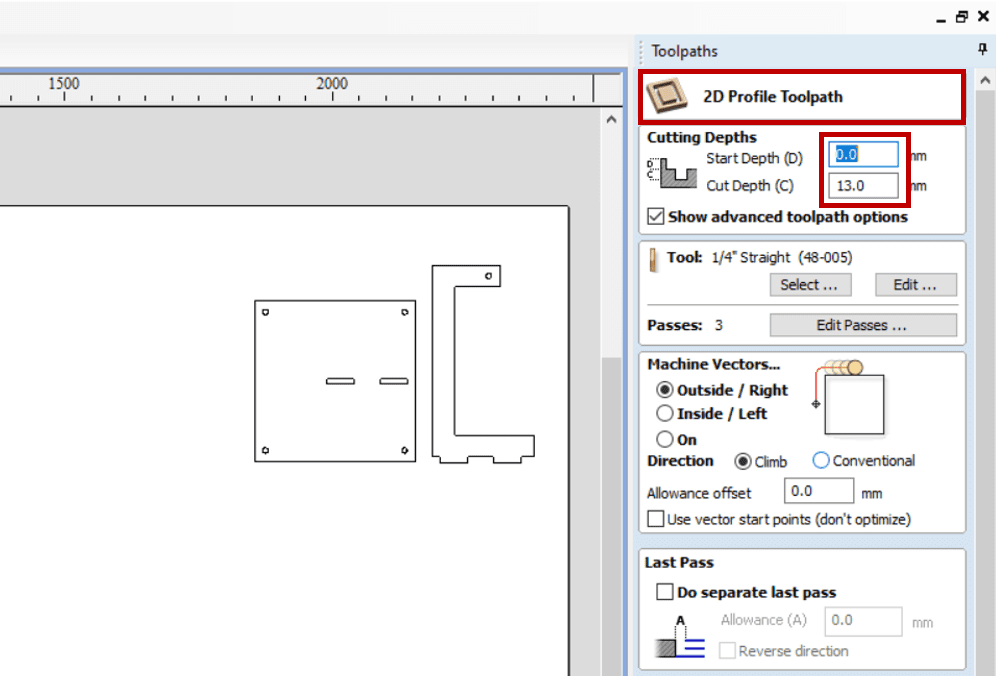

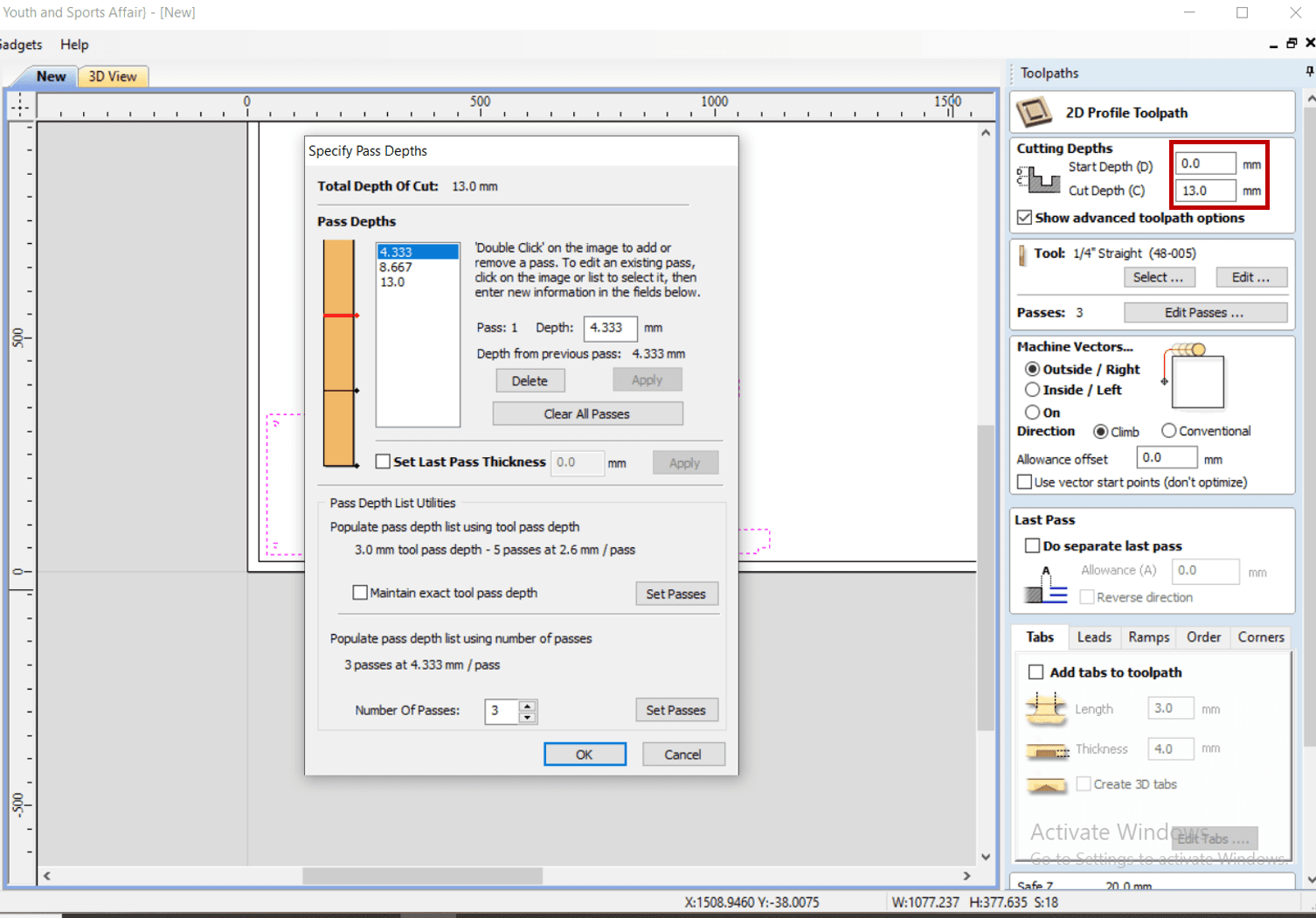

There are other sorts of tool paths, but the 2D profile toolpath is the most commonly used. Type the start depth and cut depth to adjust your settings. As you can see, the cutting depth is slightly greater than the thickness of the wood, which is done to ensure that all parts are properly cut.

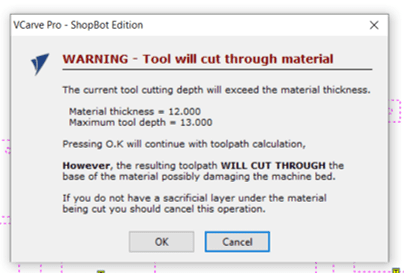

- A warning will appear because the wood thickness is less than the cutting depth, but this is exactly what we need because the machine bed is protected by extra pieces and the extra depth is only 1mm.

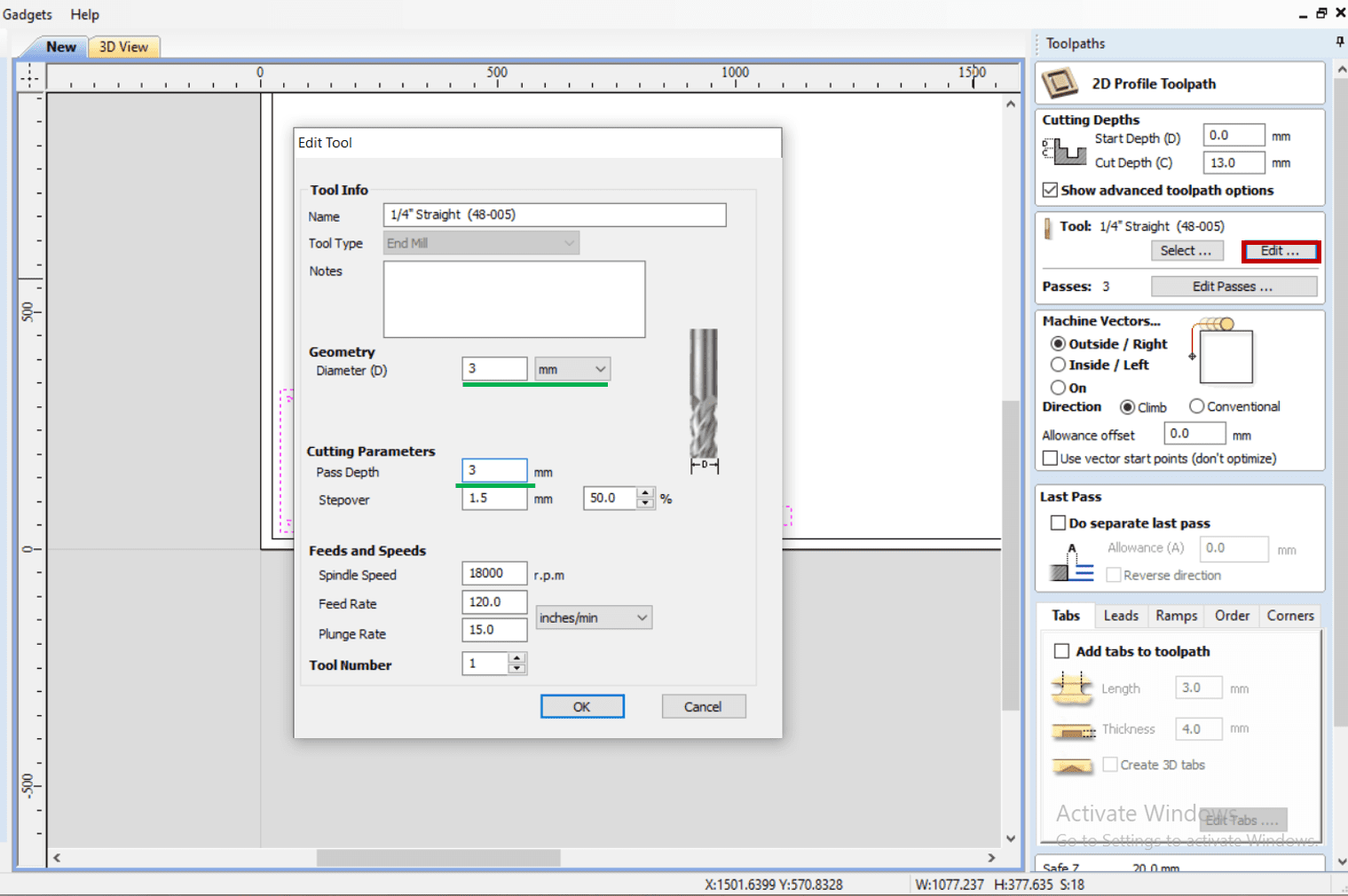

- Choose the right size for the tool

-

and Adjust the start depth and the cutt depth.

-

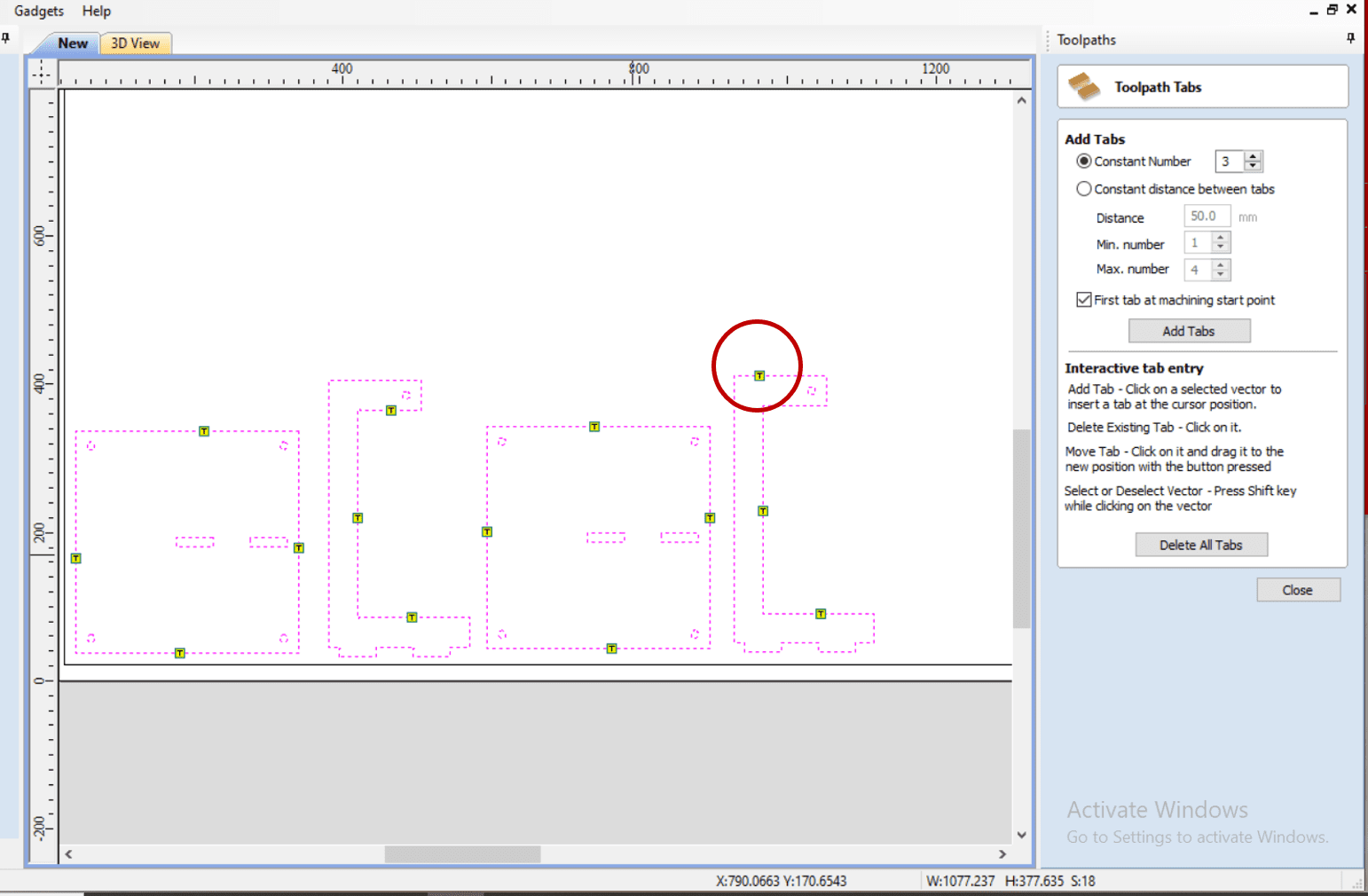

We add a tabs tool path to keep the pieces in place

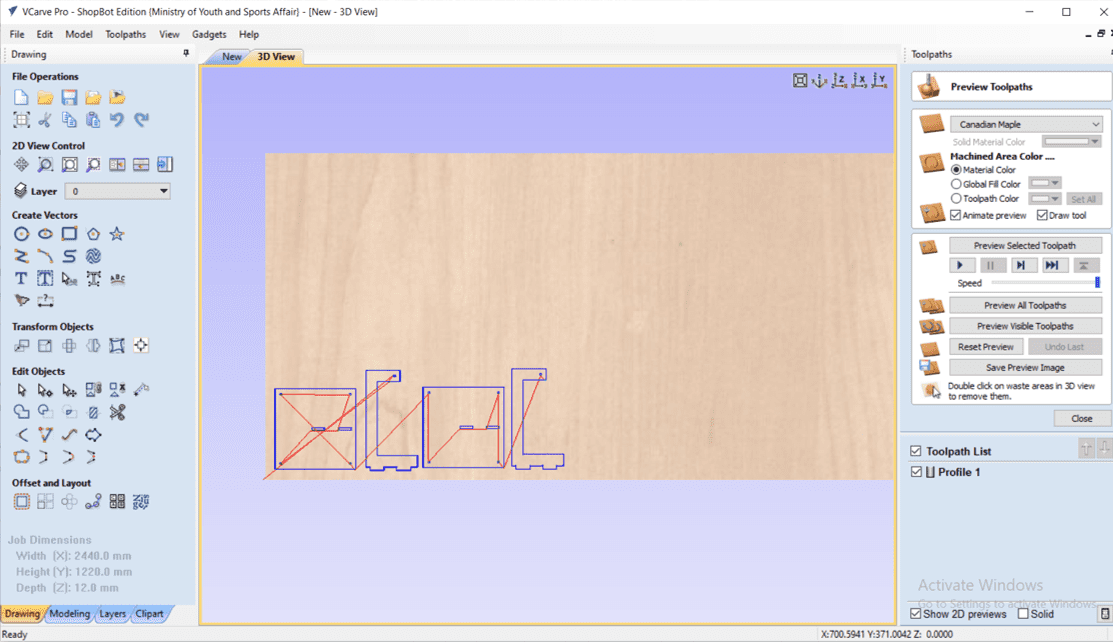

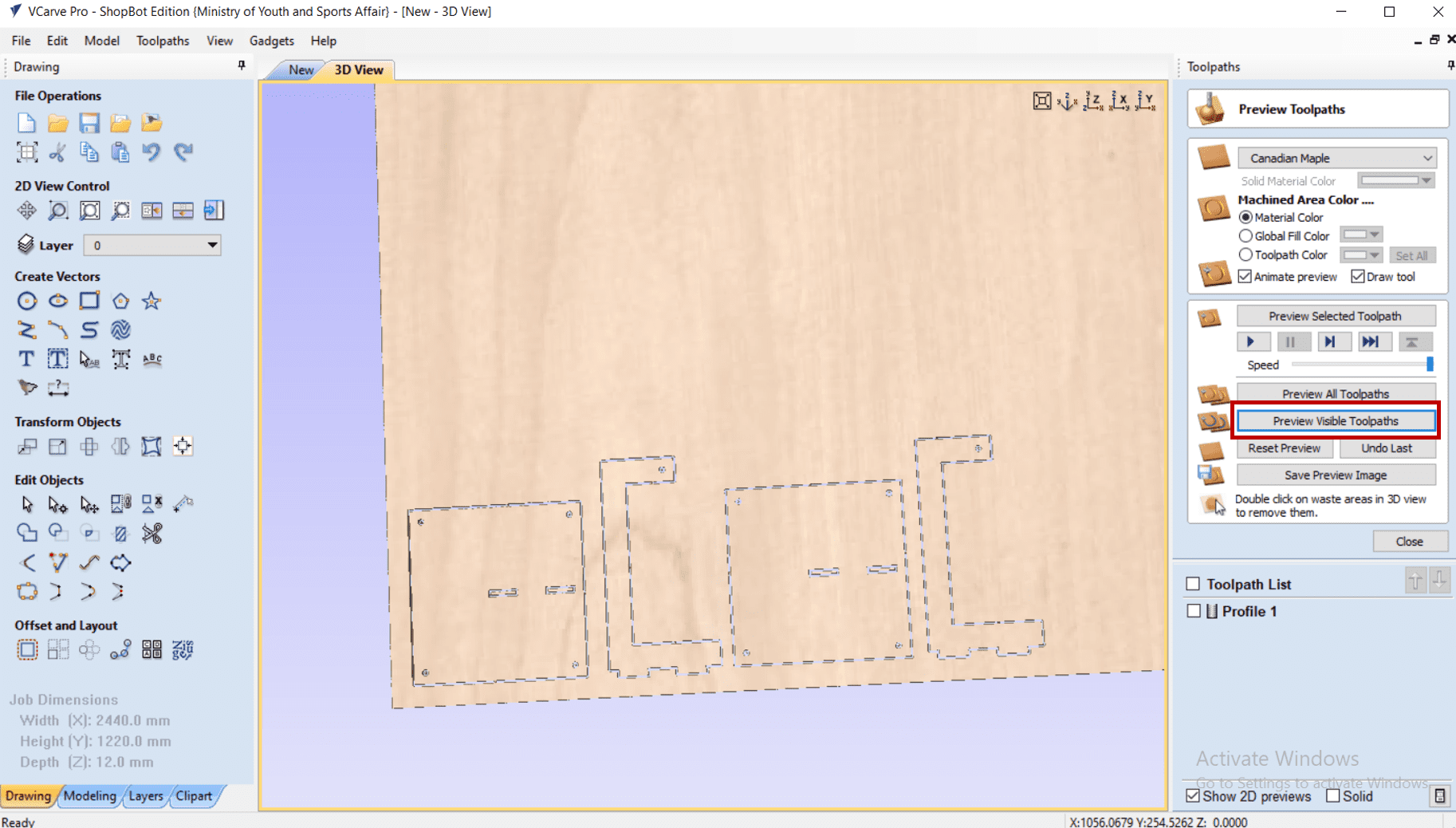

- prereview the toolpath to make sure everything is perfect.

- save the toolpath

Assembly¶

Hero shot¶