Bahrain Lab – Week 05: 3D Scanning & Printing

Working with our 3D printers this week was actually pretty fun and surprisingly insightful. Even though I’ve used 3D printers before, taking a closer look at their behavior made me appreciate how detailed and sensitive the printing process can be.

This week wasn’t about creating something fancy—it was about learning how to work with the machine. Just like getting to know a teammate, understanding the quirks of your 3D printer helps you get better results. I now feel a lot more confident setting up clean, successful prints that won’t waste time or filament.

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object. 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine. 3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

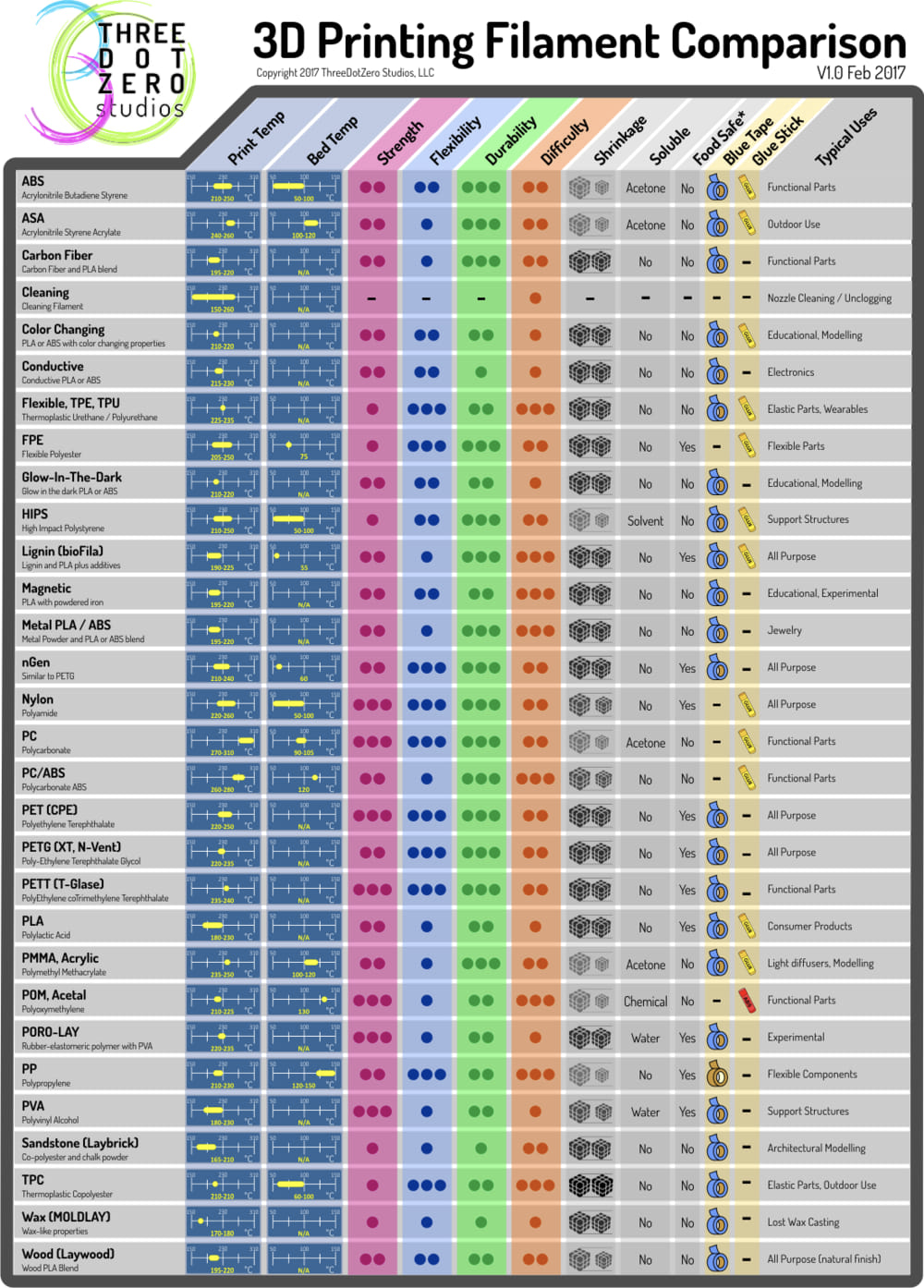

THREE DOT ZERO studios - Copyright 2017 ThreeDotZero Studios. LLC

THREE DOT ZERO studios - Copyright 2017 ThreeDotZero Studios. LLC

In the realm of consumer 3D printing, polylactic acid (PLA) is king. Although it’s often compared to ABS – arguably the next in line to the throne – PLA is easily the most popular 3D printer filament type, and for good reason. PLA is easy to print with. It has a lower printing temperature than ABS, and it doesn’t warp as easily, meaning it doesn’t require a heating bed (although it definitely helps).

3D PRINTER FILAMENT PROPERTIES: PLA

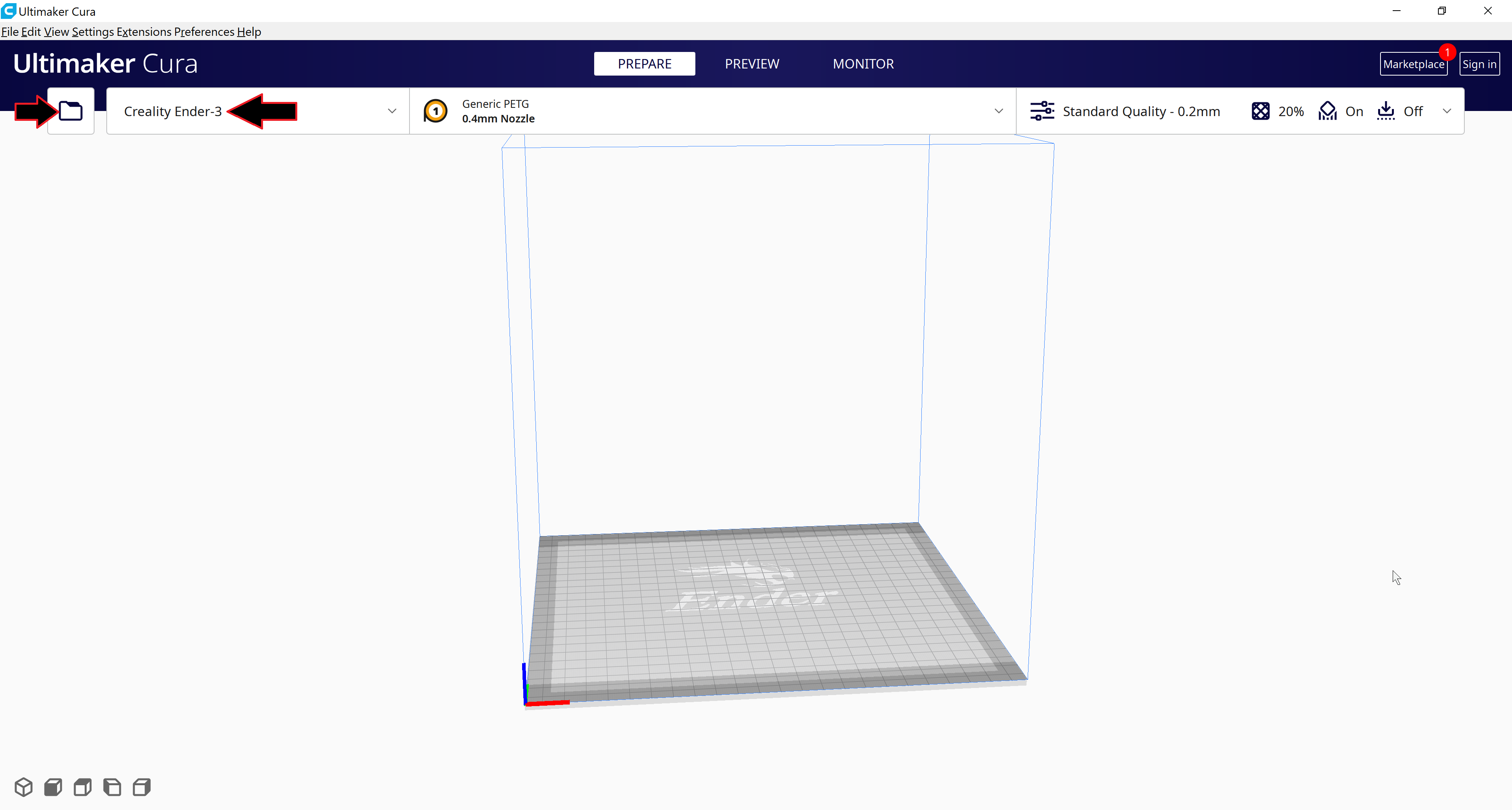

Ultimaker Cura is one of the most popular 3D printing software. it can prepare prints, integrate with CAD software for an easier workflow and it can dive into custom settings for in-depth control.

Ultimaker Cura is one of the most popular 3D printing software. it can prepare prints, integrate with CAD software for an easier workflow and it can dive into custom settings for in-depth control.

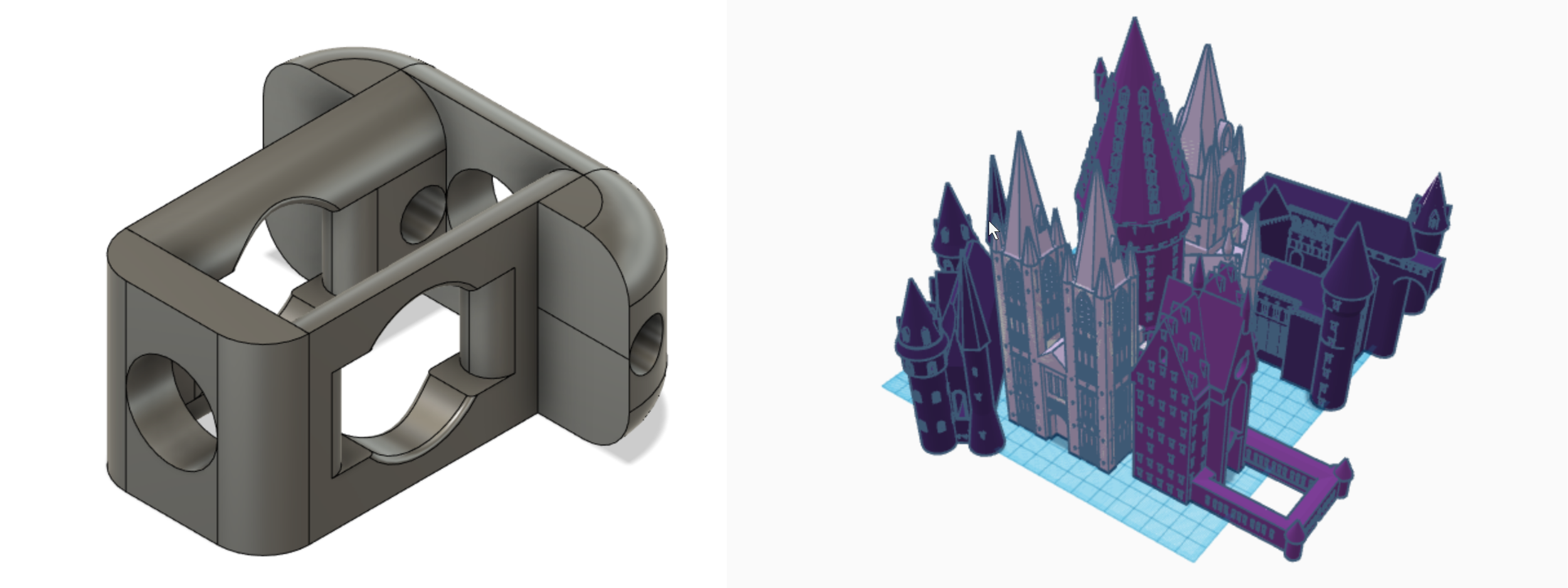

For this project I have designed two projects one in Fusion360 & one in Tinker CAD:

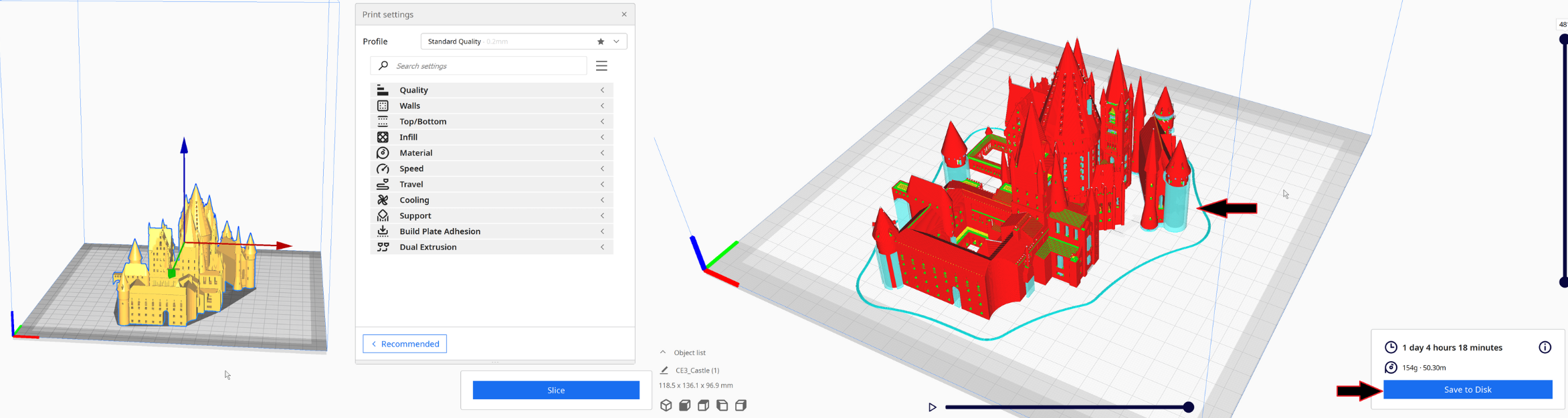

In Ultimaker Cura after finishing my design, I have uploaded my work and chose the type of printer I'm going to print with "Creality Ender-3".

There are multiple options to adjust in the printing settings such as:

After adjusting everything you need, click on "Slice" to check the time it will take to finish the printing and how the support will look like.

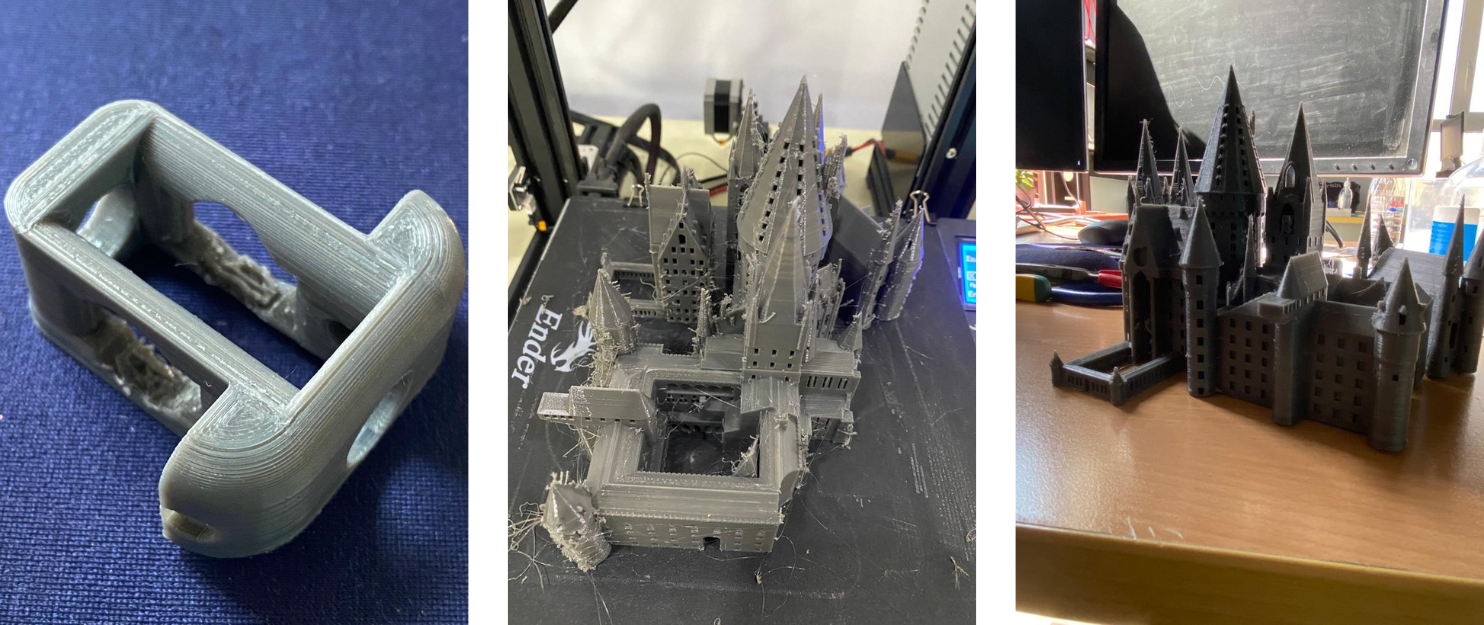

After finish from printing this is how my prints looks like, plus after cleaning the support this is how the Castle & the T-tool shape looks like.

Download My Design: Castle

Edit on My Design: Castle

3D scanning is a way to capture a physical object's size and shape into the computer world as a digital 3-dimensional representation. 3D scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds.

Qlone is an all-in-one 3D tool, it can scan real objects by using your phone's camera, modify them in app and seamlessly export the result to many platforms, 3D file formats and 3D printers.

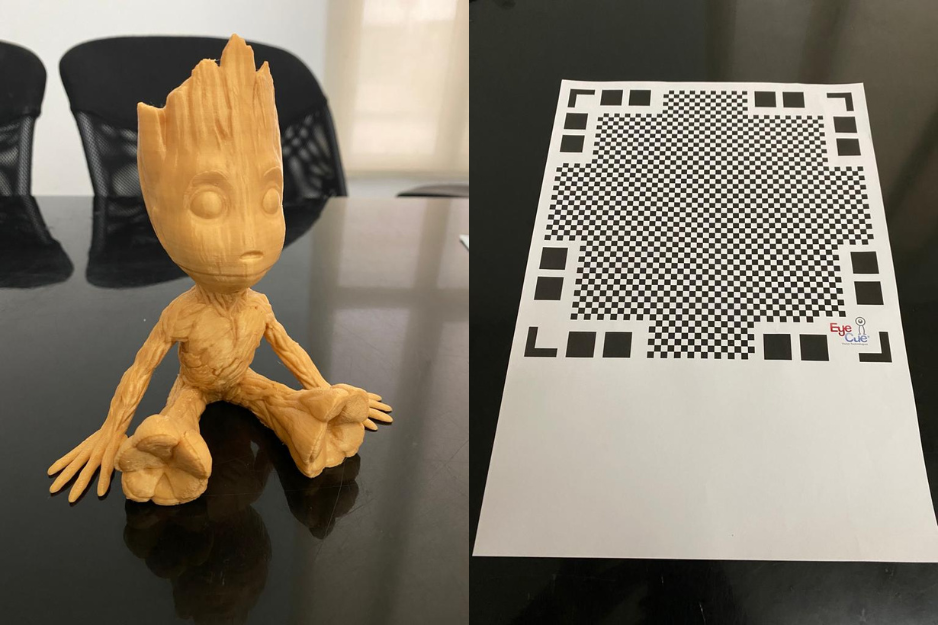

For this assessment I will need the following:

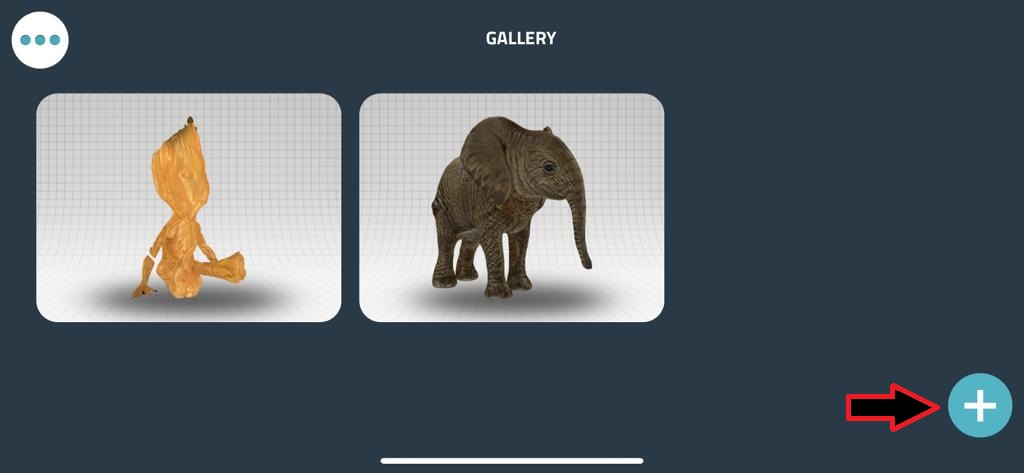

First step is to click on the "+" sign to scan a new design.

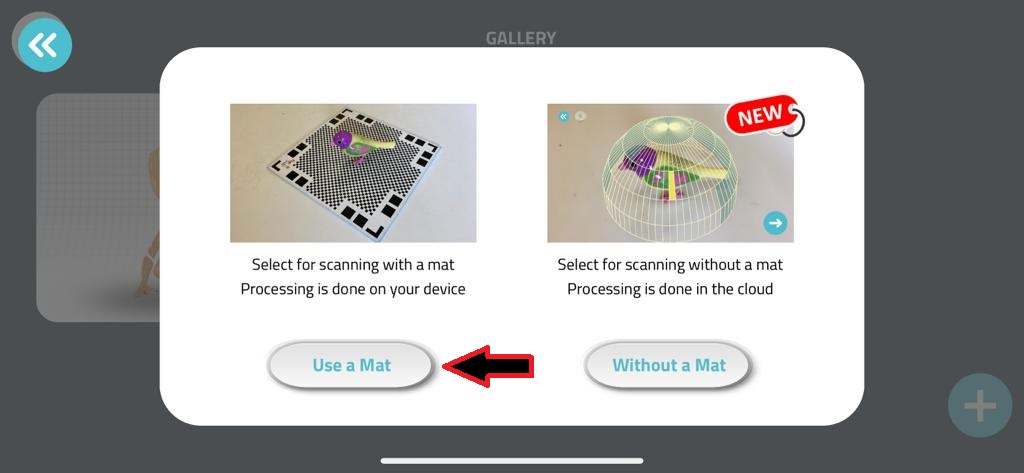

Next choosing the method of scanning either with mat or without, & I have choose with Mat.

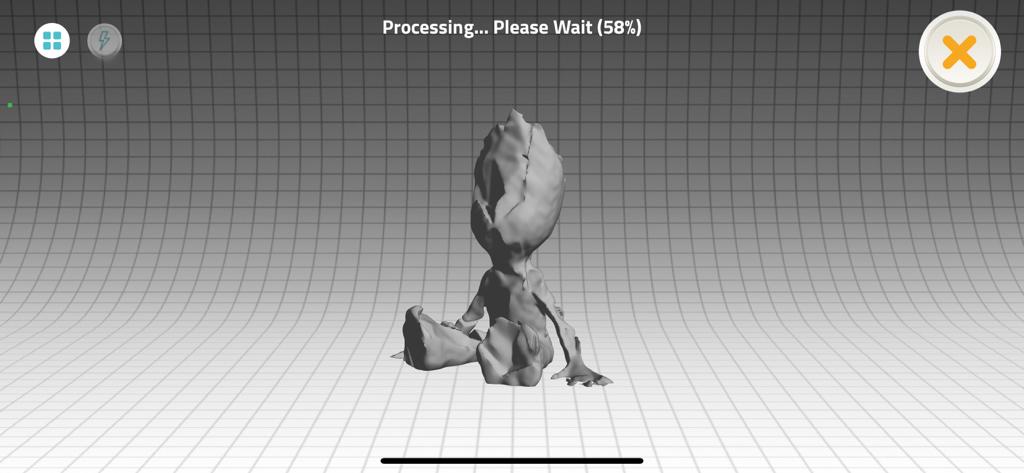

After completing the full scanning, the application will take time to complete the processing.

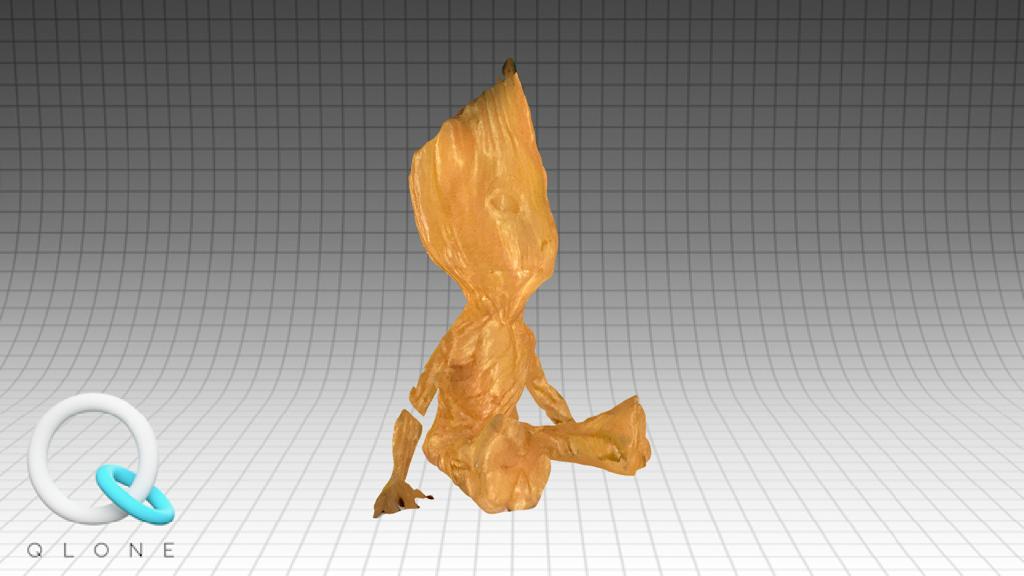

Finally this is how it looks like after completing the processes.

Kinect is a line of motion sensing input devices. The devices generally contain RGB cameras, and infrared projectors and detectors that map depth through either structured light or time of flight calculations, which can in turn be used to perform real-time gesture recognition and body skeletal detection, among other capabilities. They also contain microphones that can be used for speech recognition and voice control.

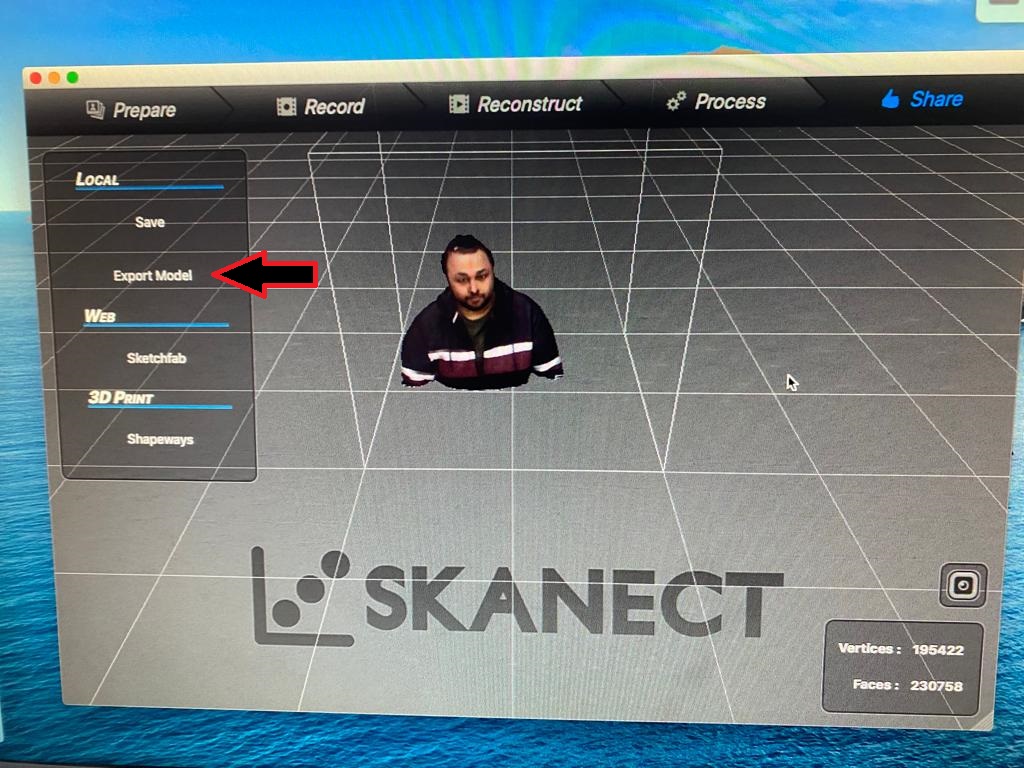

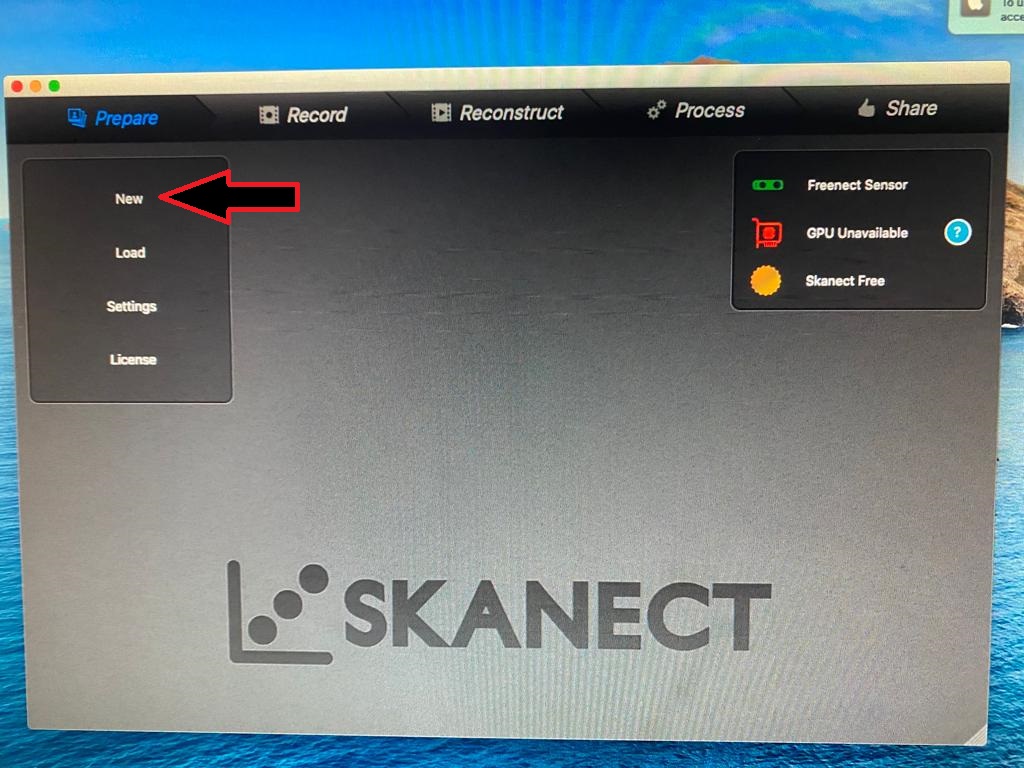

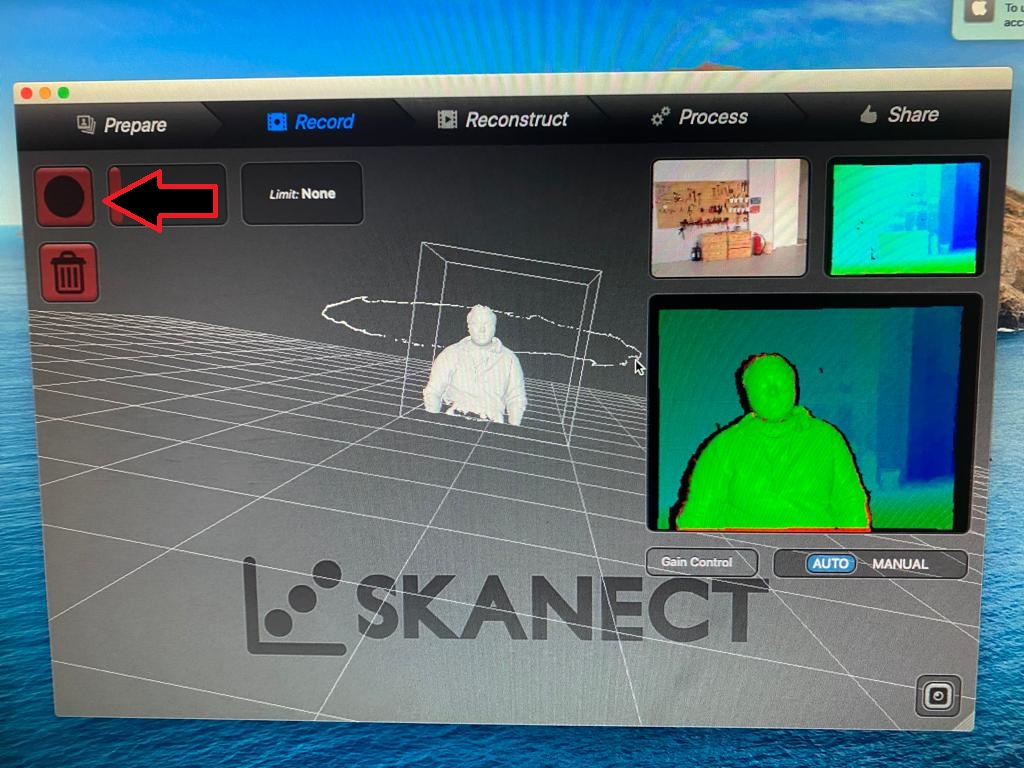

For this assignment I have used an application called "SKANECT", which is built for the Kinect. First part to click on "New".

Next adjusting the position of the chair with the camera, plus it can be adjust using the Reconstruct. After adjusting all and making sure the body looks green, I can start by clicking on the record button. I had to move in slow movement clockwise position in order for the camera to be able to fully scan me.

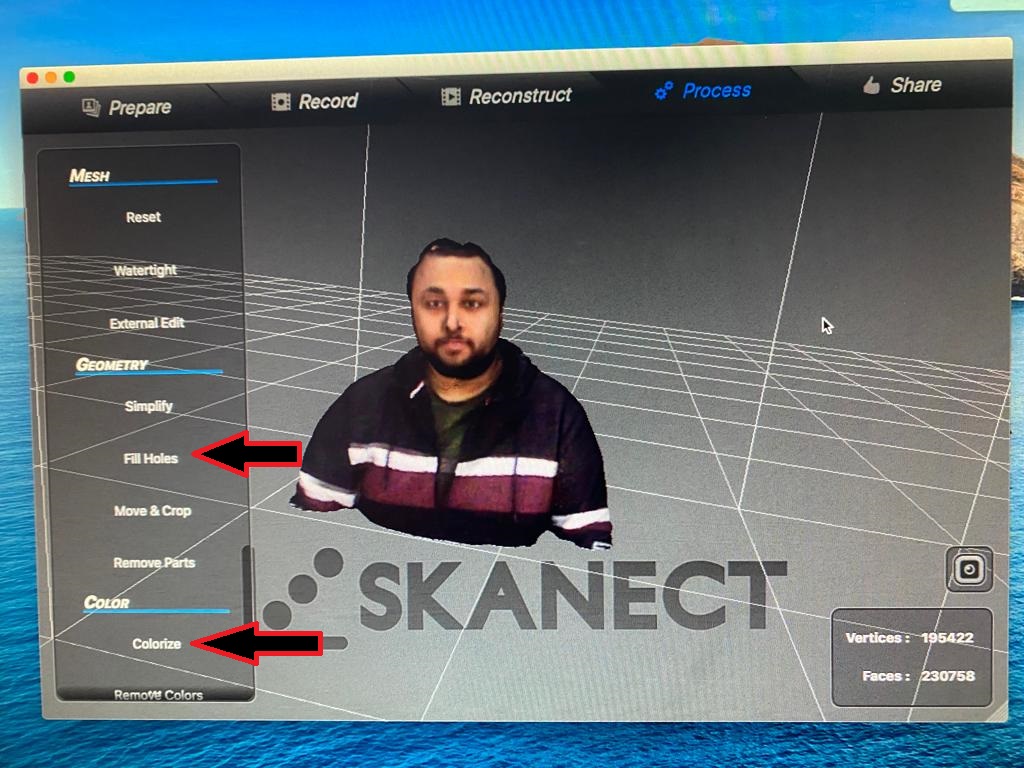

After it finish I was able to fill the holes I had one the top with "Fill Holes" & color my body with "Colorize".

Finally the application can export the file Model to different type, I order to be utilize in different applications.