About Me

Sara AlMutawaa

An engineer graduated from University of Bahrain in Feb, 2020 holding B.sc. in Mechanical Engineering. I did my senior project with a colleague, which was “Simulation and design of a magnetic pump” using Comsol Multiphysics Software, and supervised by Dr. Omar AlAbassi. This project won the 1st place in the “senior project exhibition of collage of engineering”.

Student Agreement

As a Fab Academy student at Fab Lab Bahrain, I am responsible for...

About the Program

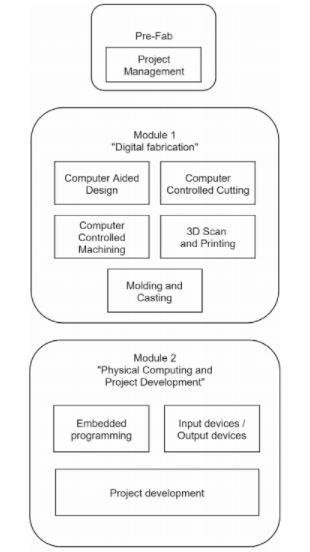

This program consist of three sections to be completed in nine weeks, as explained below:

Pre-Fab

This section is to:

and it consist of two main topics which are:

- Principles and Practices

- Project Management

Module 1

This section focuses on digital fabrication principles an mastering additives/subtructive fabrication design. and it consist of:

- Computer-aided design

- 3D scanning and printing

- Computer controlled machining

- Computer controlled cutting

Module 2

This section focuses on electronic principles and programming. and it consist of:

- Embedded programming

- Input devices/ output devices

- project develpoment

Before we Start

In May,18 2021 I had the first meeting with the Fablab academy instructors Salman AlAraibie and Duaa AlAali. The meeting was an introduction to the program, instructors and get to know other cadidates.- Preliminary course calendar:

| Week | Week start date | Topic |

|---|---|---|

| 1 | May, 24 2021 | Project Management |

| 2 | May, 29 2021 | Computer-Aided Design |

| 3 | June, 5 2021 | Computer Controlled Cutting |

| 4 | June, 12 2021 | 3D Printing and Scanning |

| 5 | June, 19 2021 | Computer Controlled Machining |

| 6 | June, 26 2021 | Embedded Programming |

| 7 | July, 3 2021 | Input & Output Devices |

| 8 | July, 10 2021 | Moulding and Casting |

| 9 | July, 24 2021 | Project Development |

- Lectures and Reviews

The program lectures were given by Neil Gershenfeld, Amarican professor at MIT.

Week 1: Principles and Practices

This lecture talks about the history that makes what we are living now considering fabrication possiple. I wrote a simple note of what I learned in the lecture as the following.

Week 1: Project Management

Week 2: Computer-Aided Design

Student are free to choose any drawing software that will lead to the final project, and the software they are more comfortable with. I have experince in AutoCad and Inventor drawing softwares, as I studied and use them during studing in university. I used these softwares mostly for drawing mechanical parts and assamble them.

Our instrutors shared there experince and introduce us to different drawing softwares.

Week 3: Embedded Programming

Embedded Programming is a totally new topic for me, so I faced some difficulties to understand, where I had to read, watch and listen to many information to get to know what is embedded programming.

Week 4: Input & Output Devices

I used the same program Arduino IDE to program the Arduino Nano and make these devices do a certain function such as rotating the motor.

Week 5: Computer-Controlled Cutting

- Demonstrate and describe parametric 2D modelling process.

- Identify and explain processes involved in using the laser cutter.

- Develop, evaluate and construct the parametric construction kit

- Identify and explain processes involved in using the vinyl cutter.

Week 6: Computer Controlled Machining

The Learning outcomes for this week are:

Week 7: Moulding and Casting

The learning outcomes from this week are:

Week 8: 3D Scanning and Printing

- Identify the advantages and limitations of 3D printing.

- Apply design methods and production processes to show your understanding of 3D printing.

Week 9: Project Development

- Create your own integrated design.

- Demonstrate 2D & 3D modelling capabilities applied to your own designs.

- Select and apply appropriate additive and subtractive techniques.

- Demonstrate competence in design and programming including an input & output device.