8. Moulding and casting¶

this week I worked I moldded and casted my 3D Design

molding and casting¶

Molding is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. … The liquid hardens or sets inside the mold, adopting its shape. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. A mold is the counterpart to a cast.

Casting is a manufacturing process in which a liquid material is usually poured into amold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

desgining¶

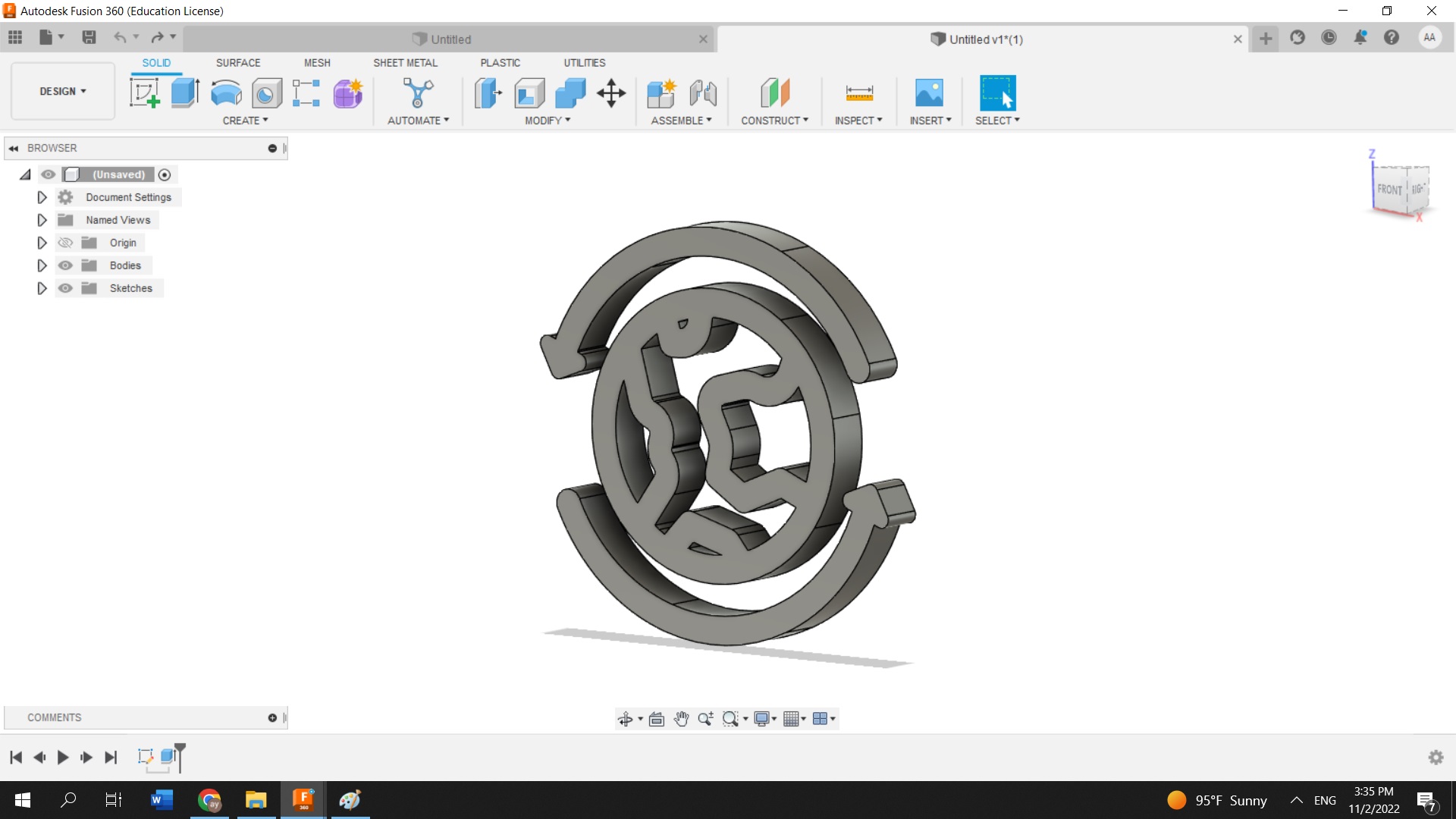

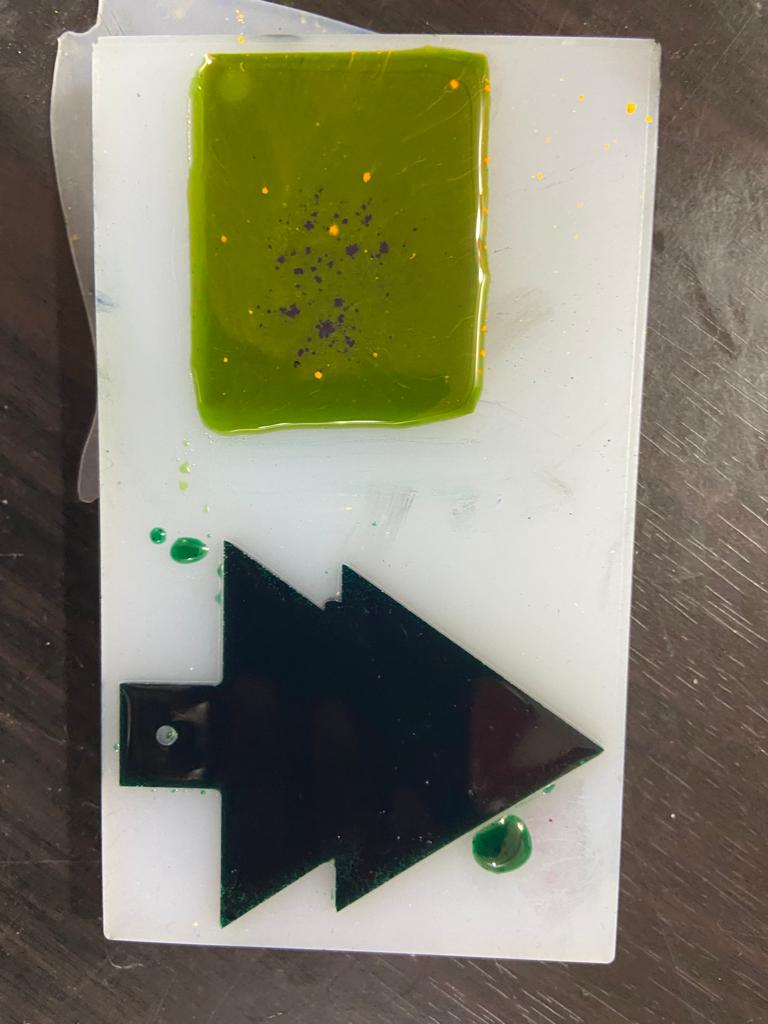

for the design fabrication I took the design from inkscape and then moved it to fusion 360 where I worked in shifitng the design from 2D to 3D by using the extrude tool and it looked like this

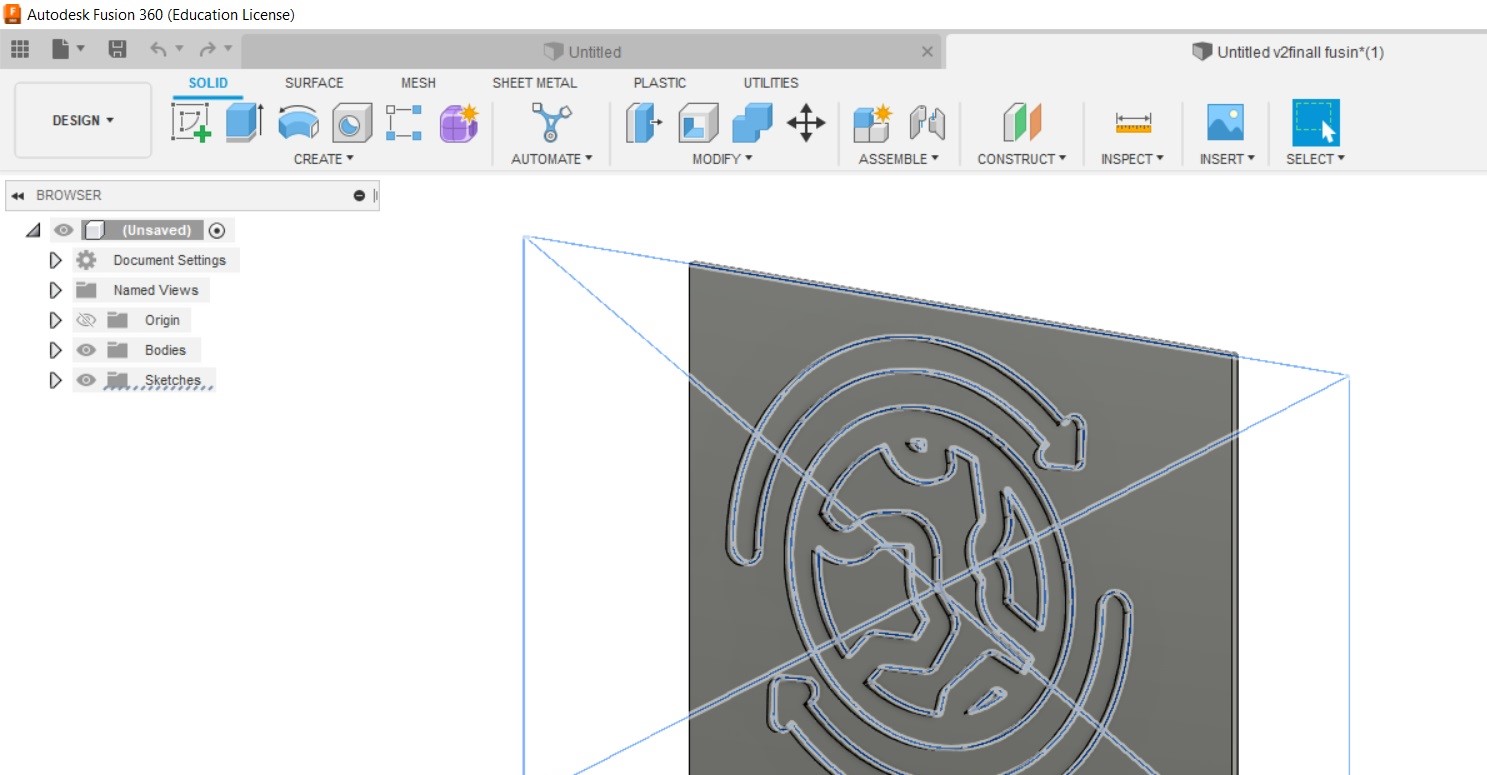

but since I was planningn in a makeing a medal out of it I added another rectangler simple design and I alligened the two piccese togather

and finally I cut a small circule to make it a proper medal

milling process¶

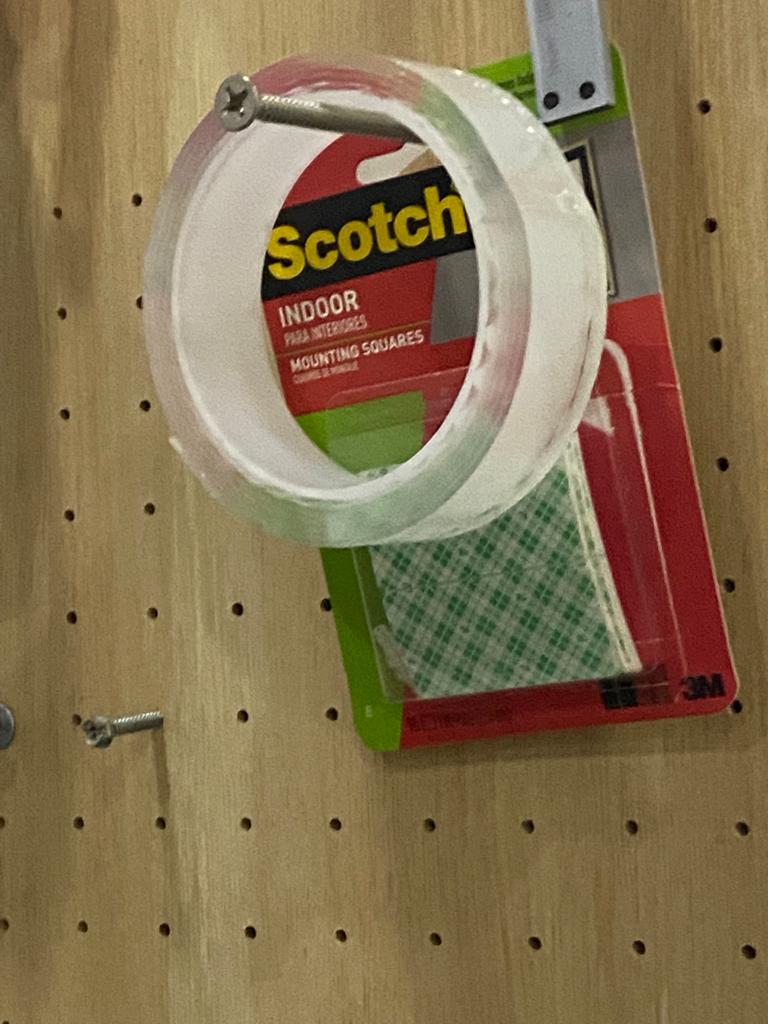

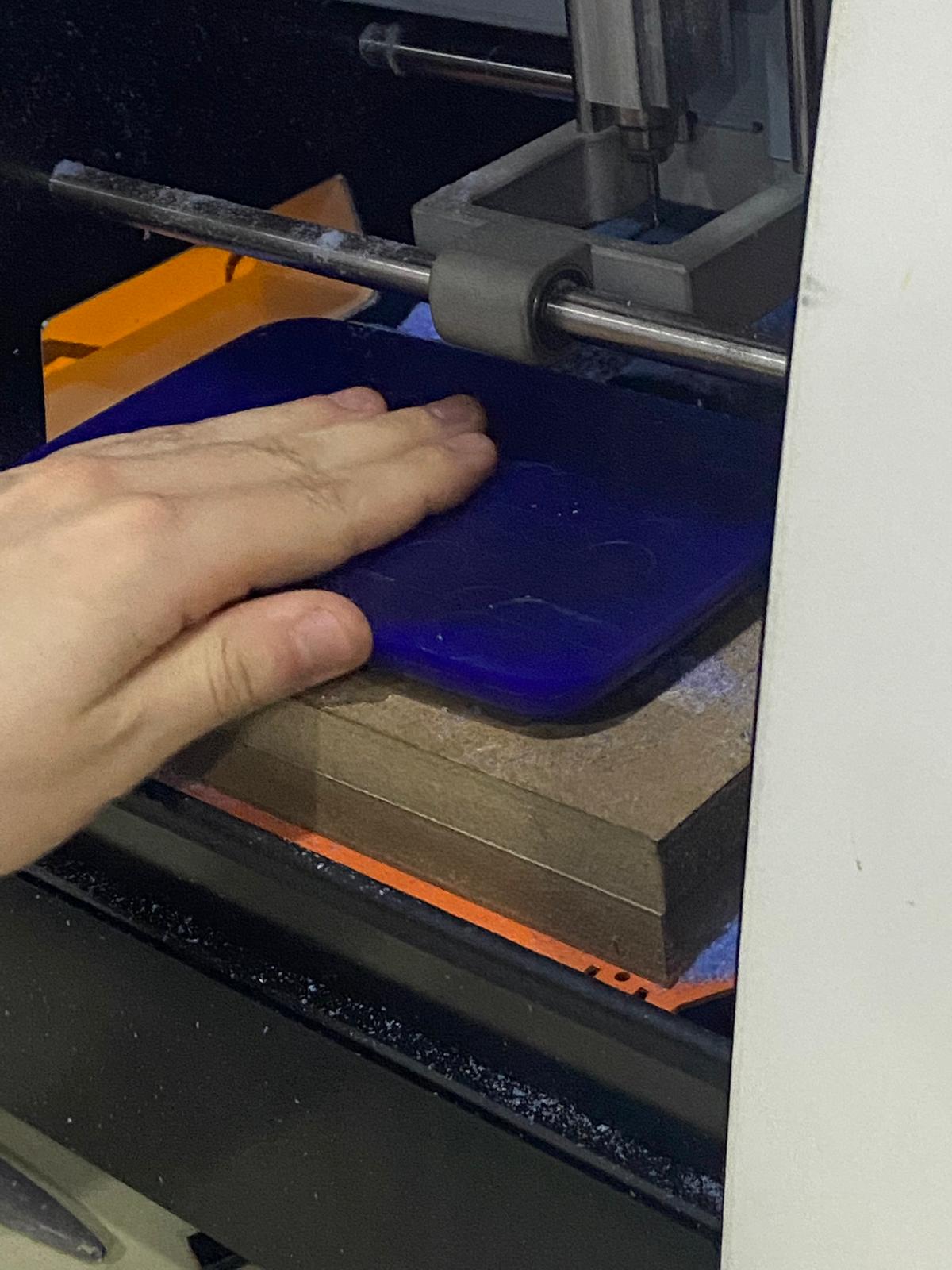

the first thing we did was the prepare the wax for the milling we attched the wax to the bed of the machine

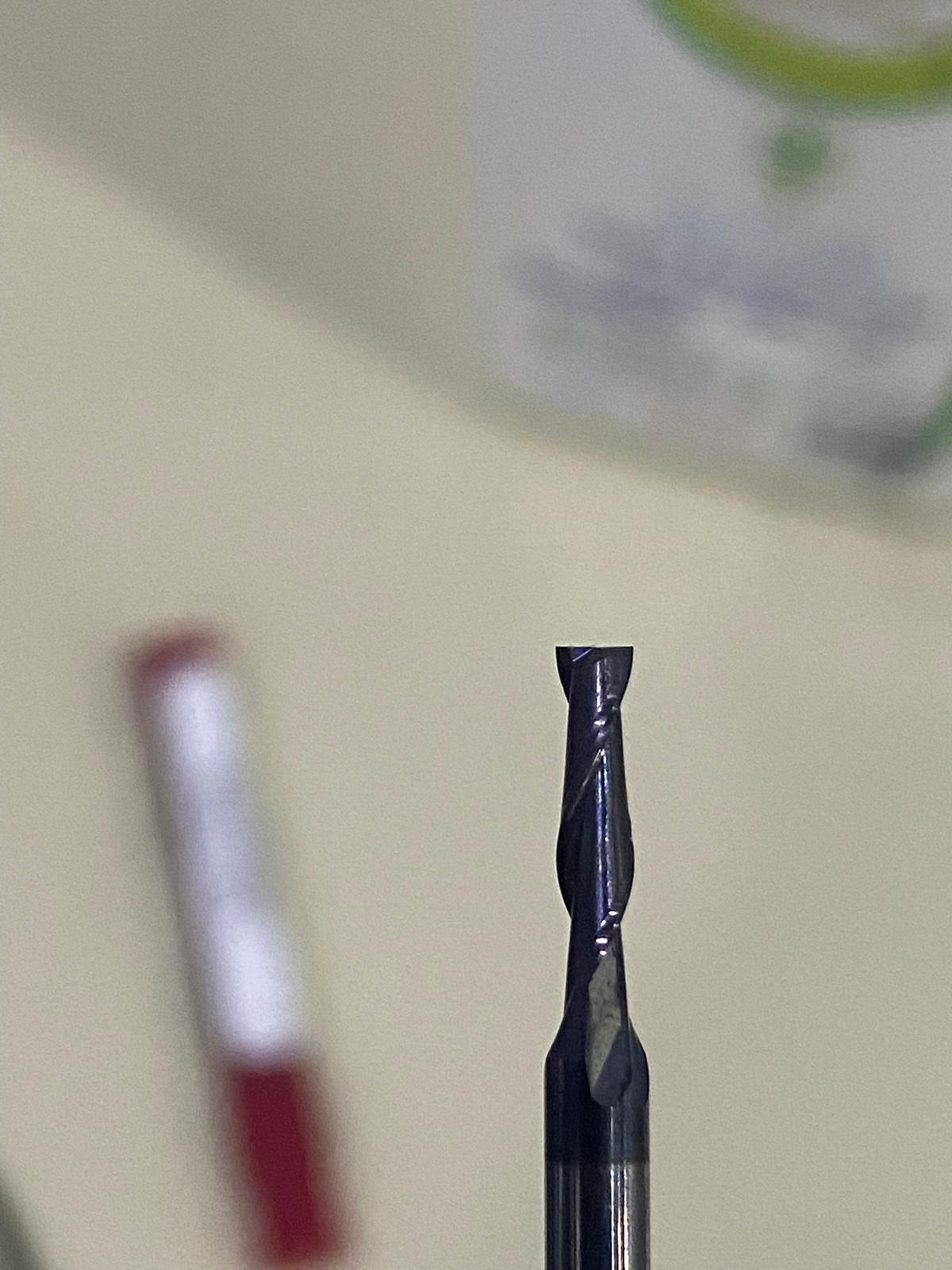

and then we crossed two digonals in the wax to get the needle in the center of the wax as an initial point and not that there are two kinds of needles

SBR PLAYER SOFTWARE¶

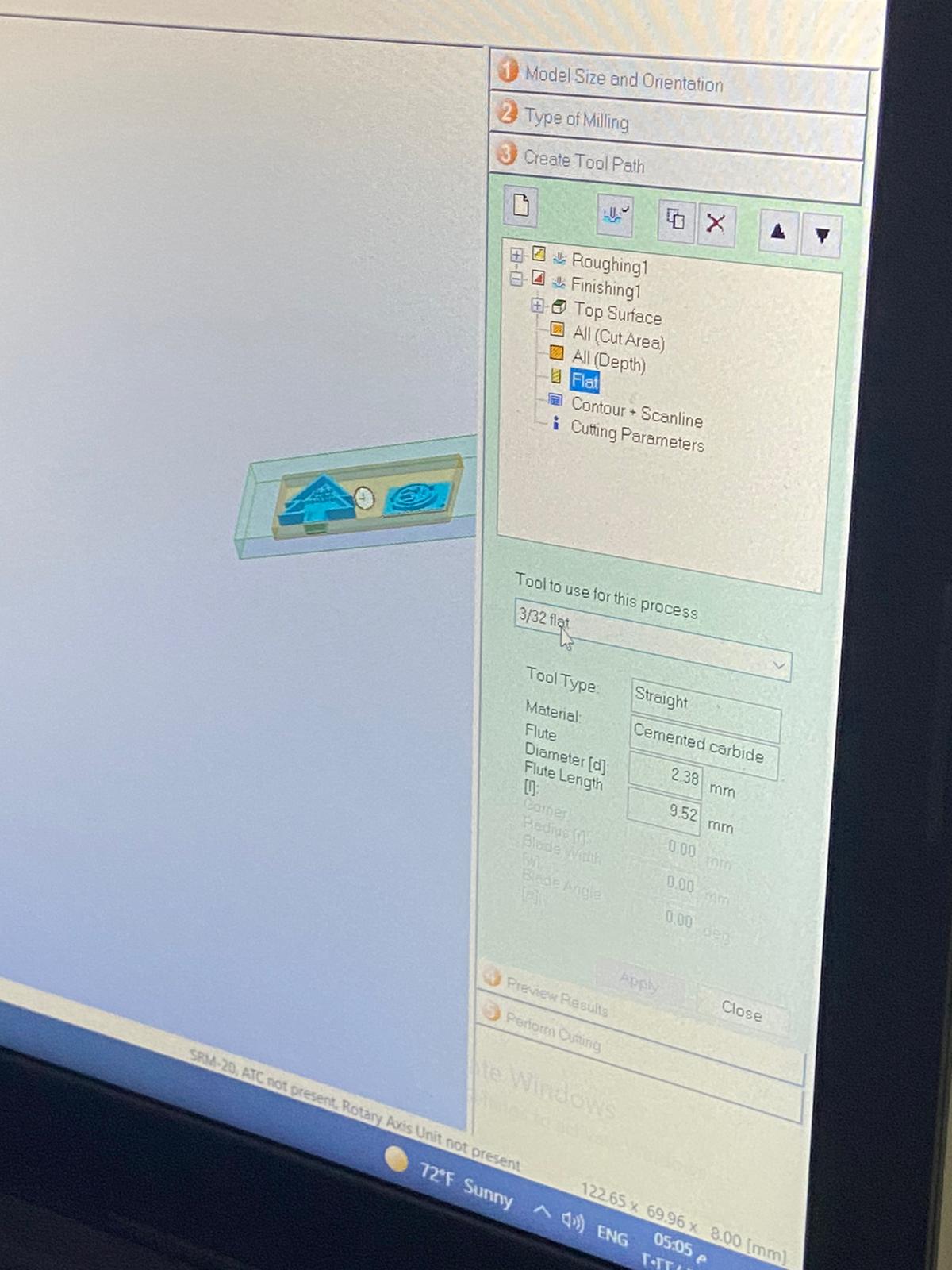

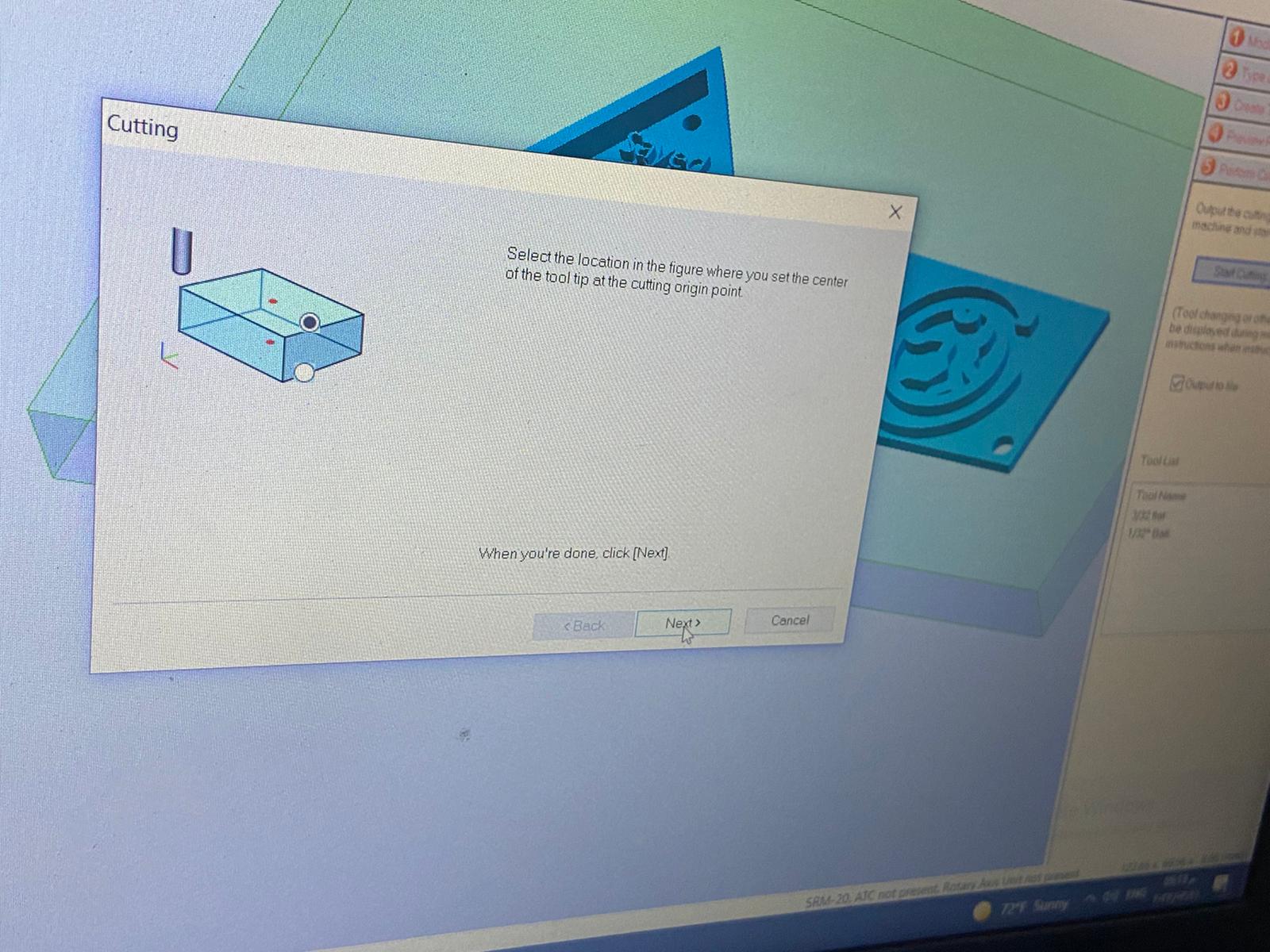

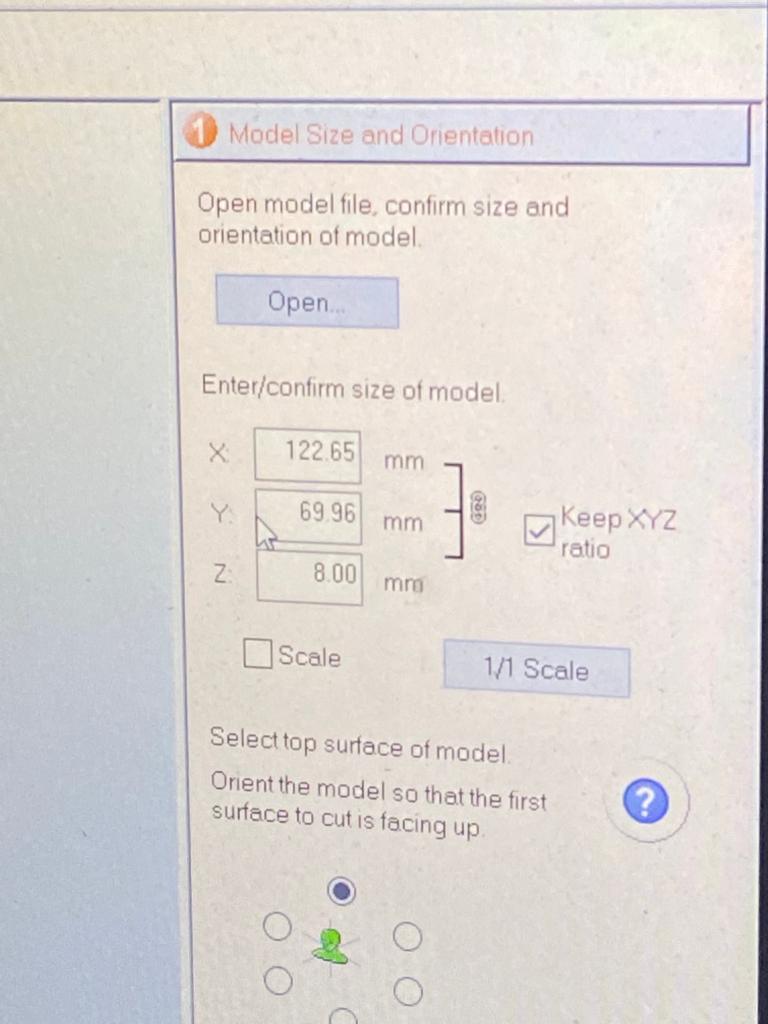

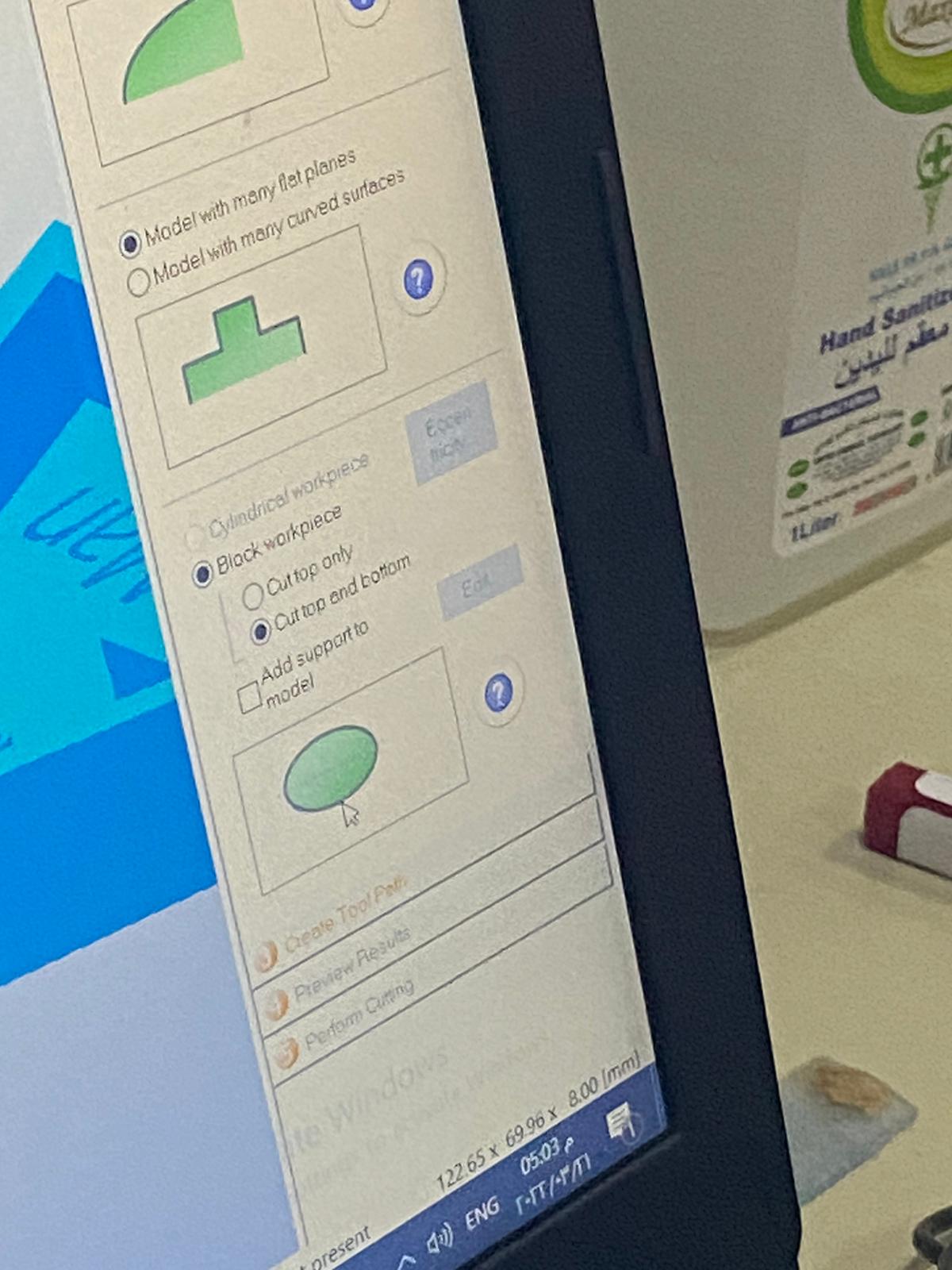

to use the machine we needed to uplaod the design through SBR play software , first we upload the design and specify the size of the design and finally chose the type of the miling

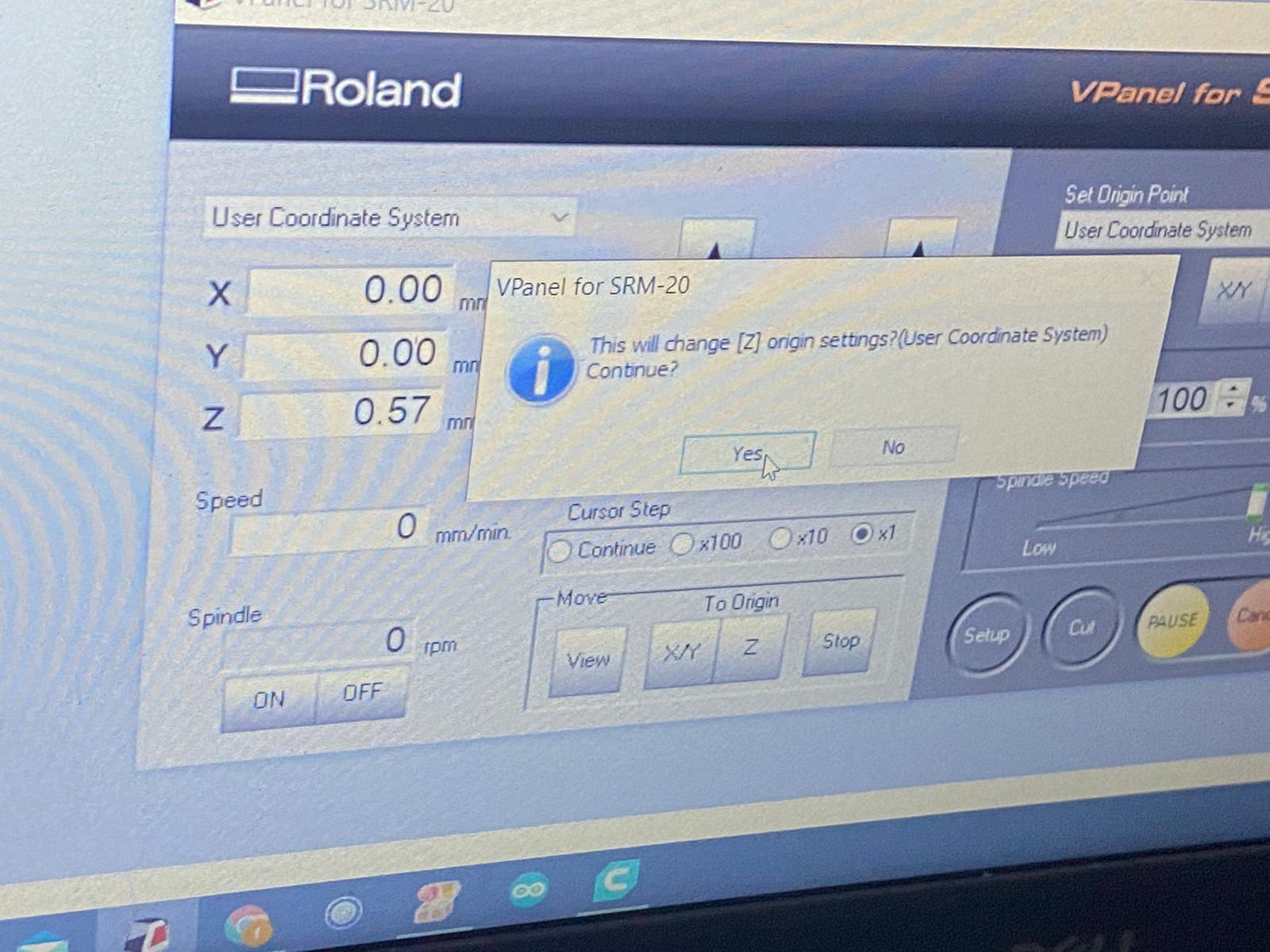

the second step was to specify the speed and the suitable molding geometry and finaly set the needle in the origin and start the milling process

milling process and final result looked like this

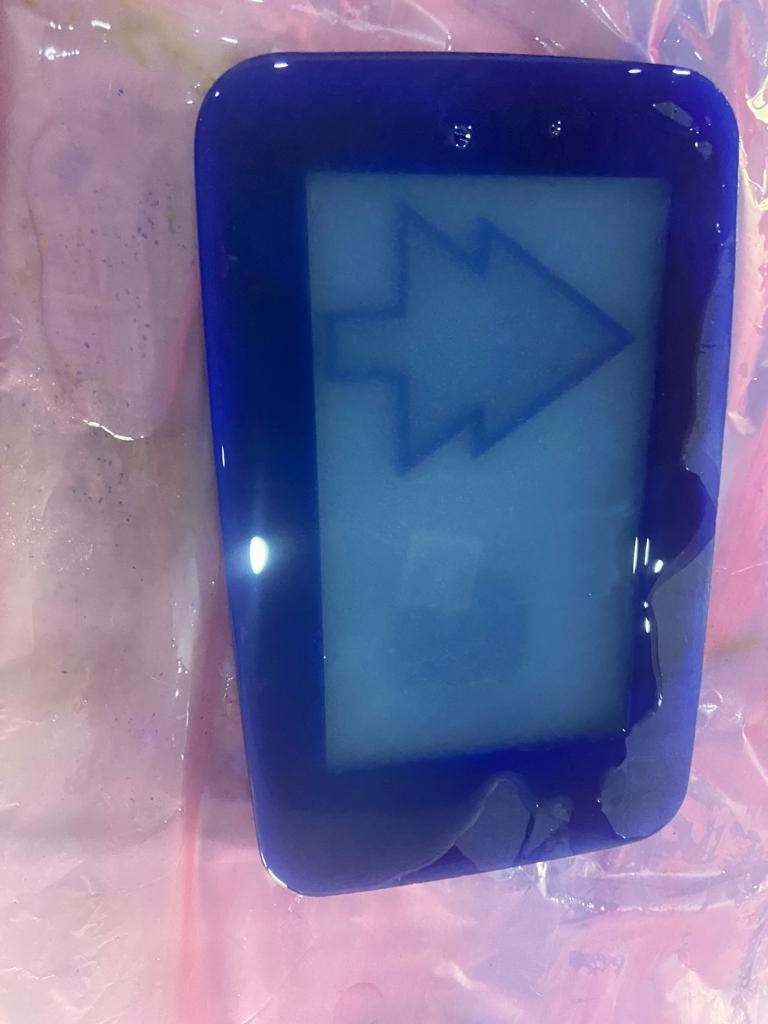

I took around 100 g of silicon A and then added 100 g of silicon B because the ratio between them is 1:1 and then I added the mixture to my mold

molding¶

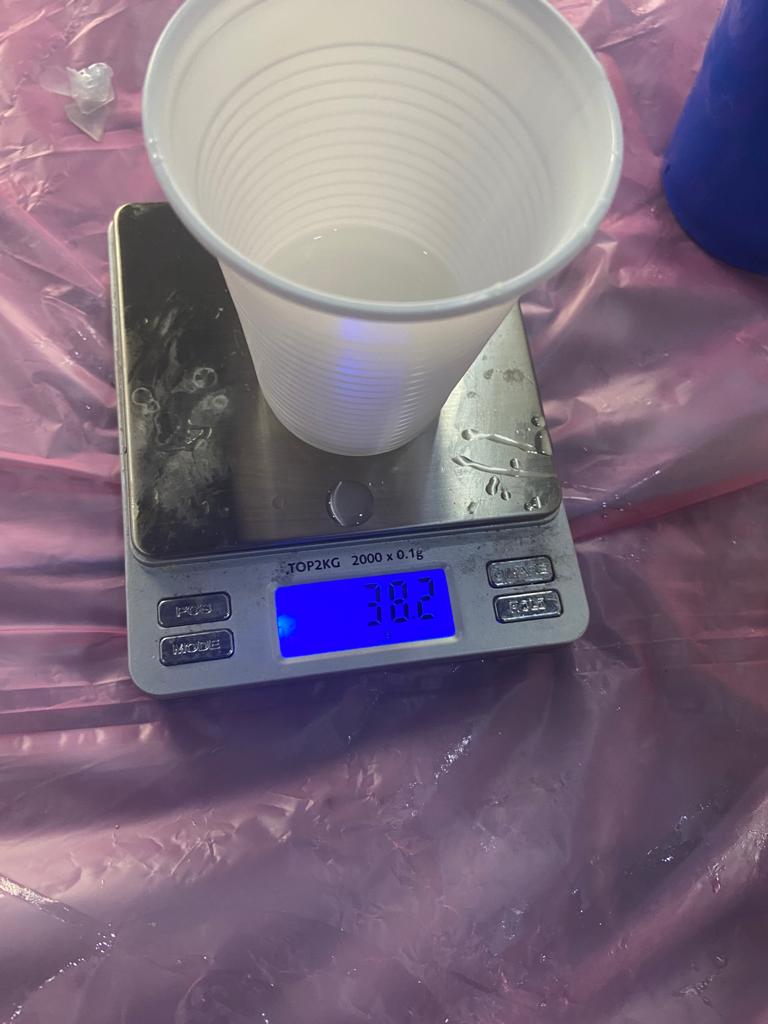

for the molding I started with adding water into the mold to detrmine how much of the silicon A & B must be added , and the the result was around 70 gram , but it reality we needed more

casting¶

in this final step I followed the safety measures to use the epoxy resin, FOR EXAMPLE Putting safety glasses, gloves, a respirator, and proper protective clothes for the job, and after that I mixed 50 gram of resin and 30 gram of hardener ratio is 1:6 and stirred the mixture for 3 minutes before pouring it over the mold to cure

story behind the piece¶

when I thought about something to mold and cast tI thought about something that may represent sustainability hence you can see the earth circled by arrows and the green and the yellow colors represent the earth. if you are interested to know how your daily activities/ decisions impacting our plant please visit ecological footprint calculator

group assignment¶

you can find the details of the group assignment in