8. Moulding and casting¶

Group Assignment¶

Our group assignment required us to test out the feeds and speeds, alignment, and tool paths (cutting and pocket) of the CNC. We were split into teams of two and given the freedom to research any of the materials. The information needed to complete the assignment was to be entered into a Google document that we would all share and have access to.

Found using the below link: -

Individual Assignment¶

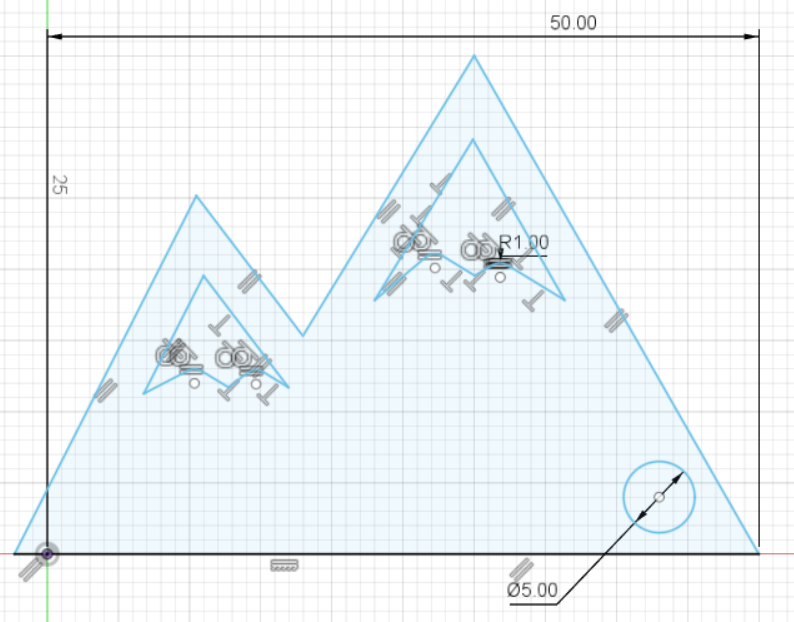

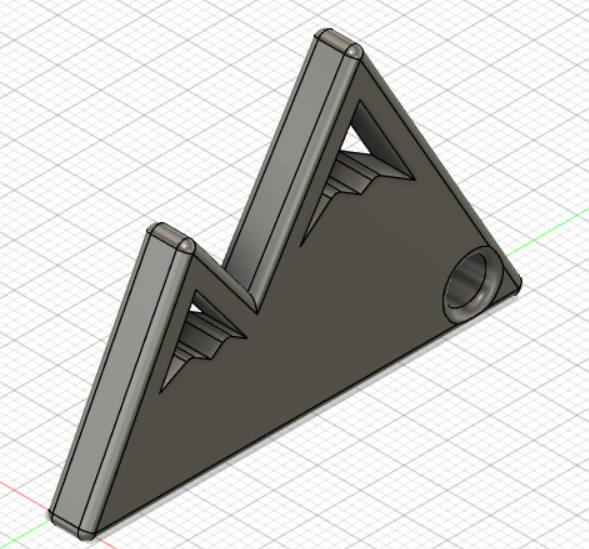

Using resin material to cast a 3d printed object. My idea was to make a keychain that has a unique design. I came up with the idea of drawing two mountains with ice on them, both in different sizes. A whole was also drawn for it to be used as a keychain.

The design had to be a bit complex to do through normal subtraction methods so for that I fillet the edges of the design all around.

Original file¶

The process¶

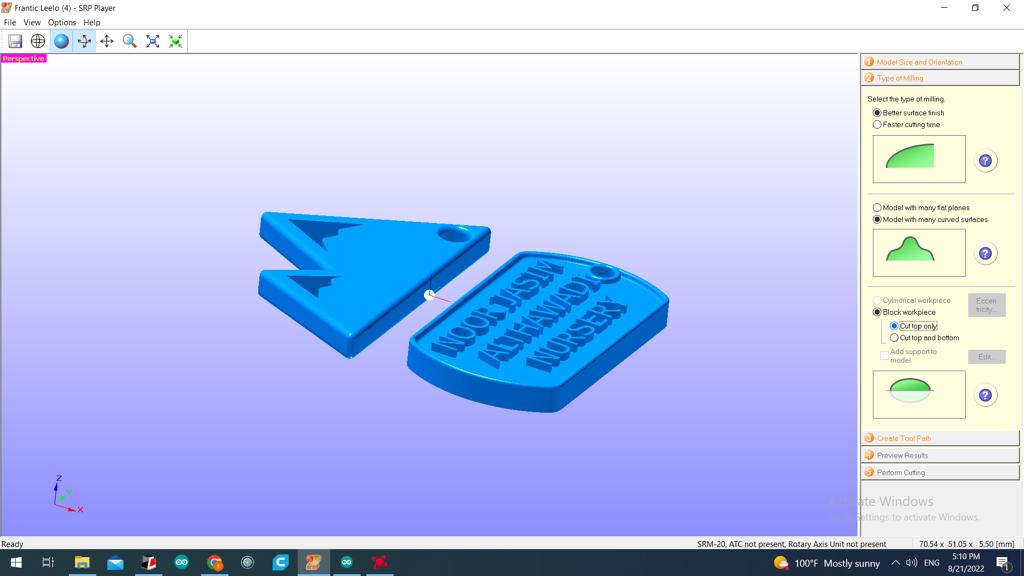

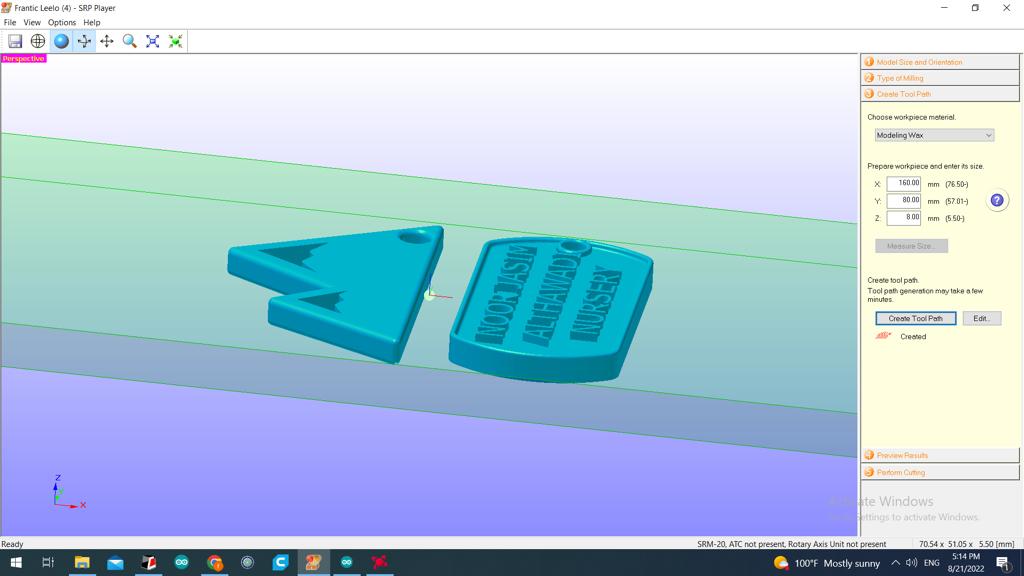

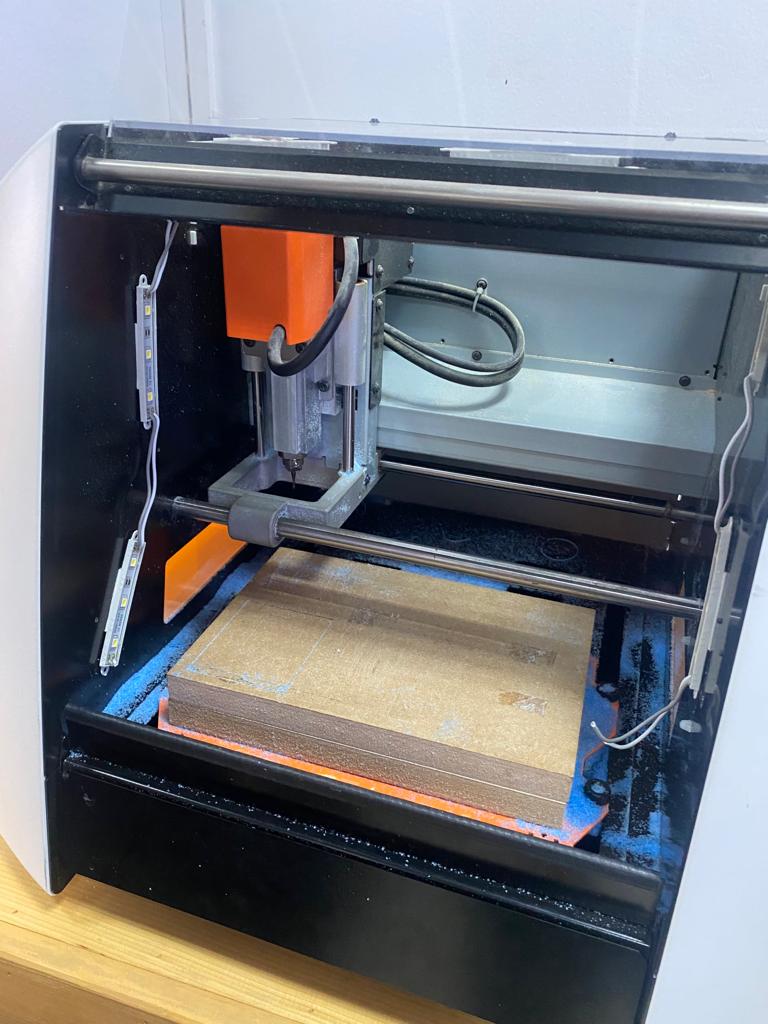

The program used to upload designs to the milling machine is called RS Player, which is what we utilized next.

Both my design and Jasim Althawadi’s were placed to save time and material.

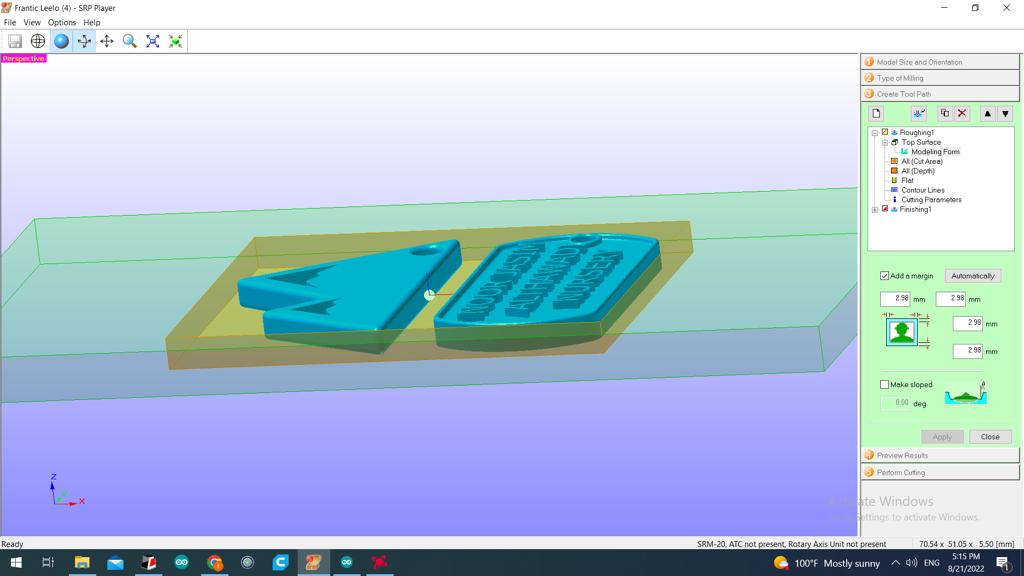

Setting the core and orientation.

Deciding the type of milling which is top only.

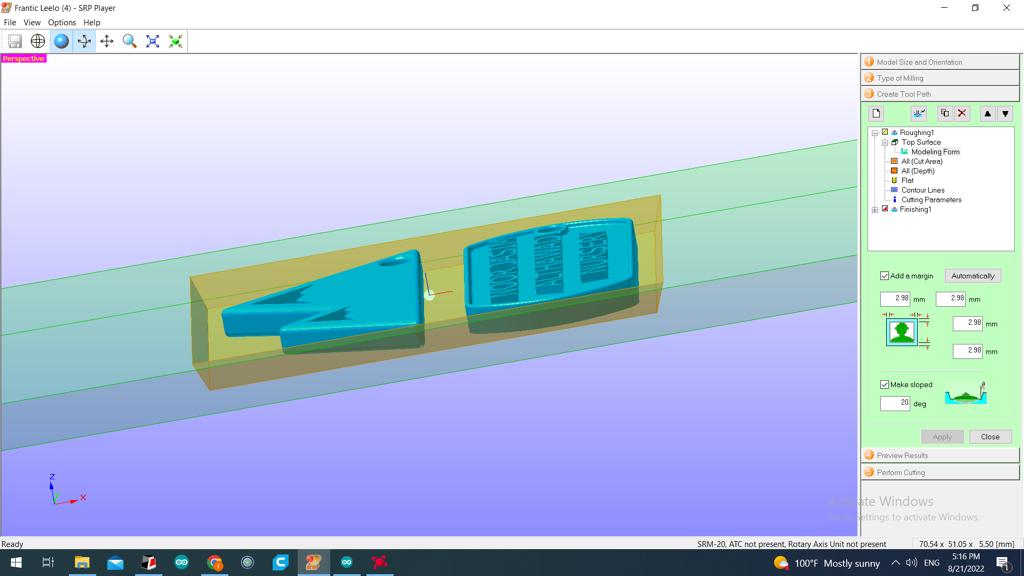

Creating the tool path

Making a slope to easily remove it once its dry.

Reviewing the result to make sure everything is well.

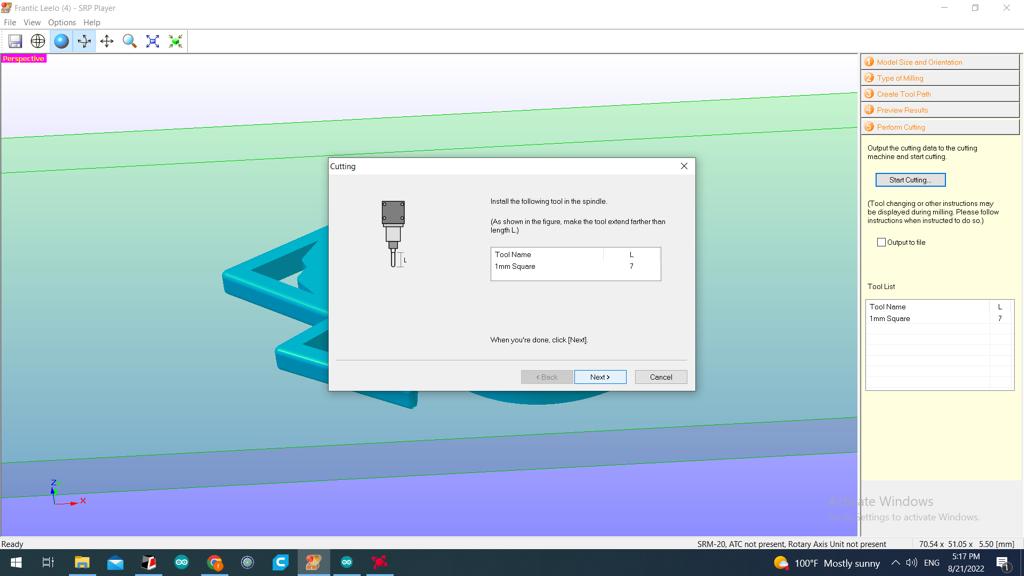

Type of tool used and its thickness

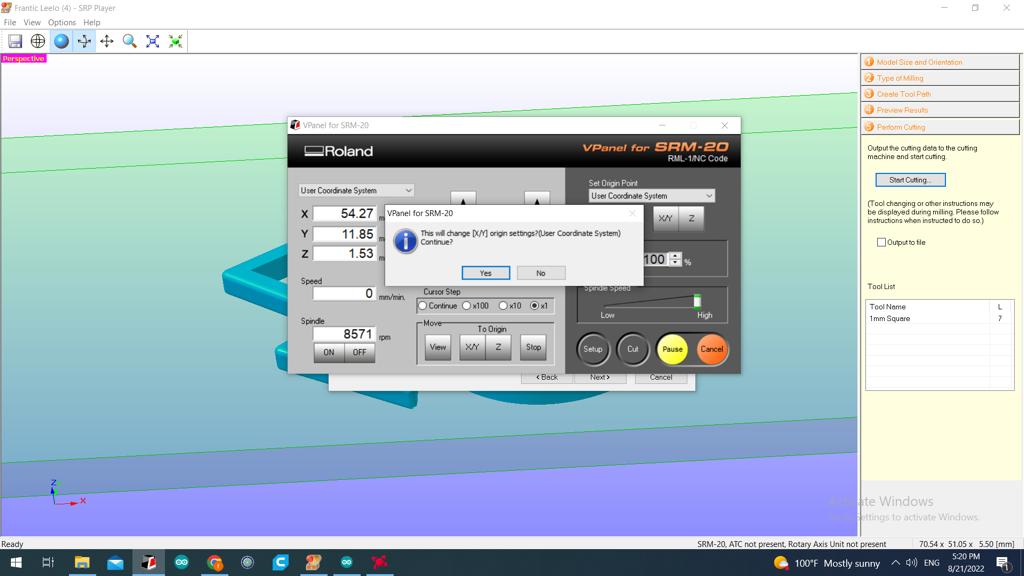

Now setting the origin by putting the material on the machine and drawing an X on the center of it.

Last review

Changing the bit to the selected size and placing a double tape to make sure it does not move while cutting.

Final Result after cutting.

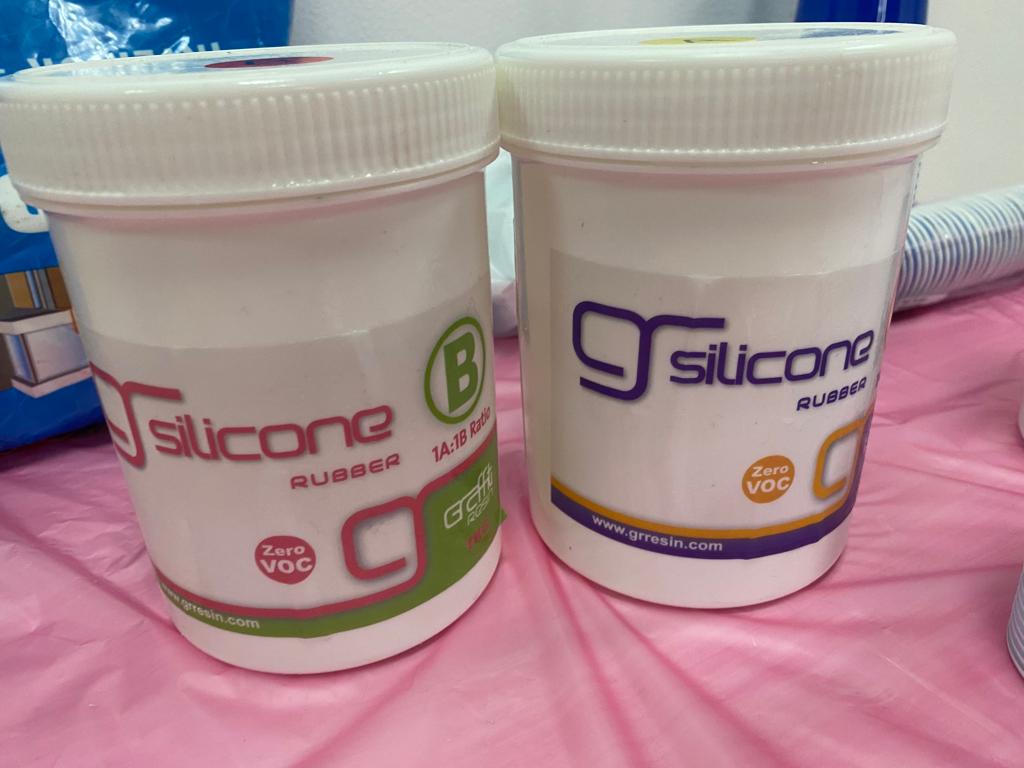

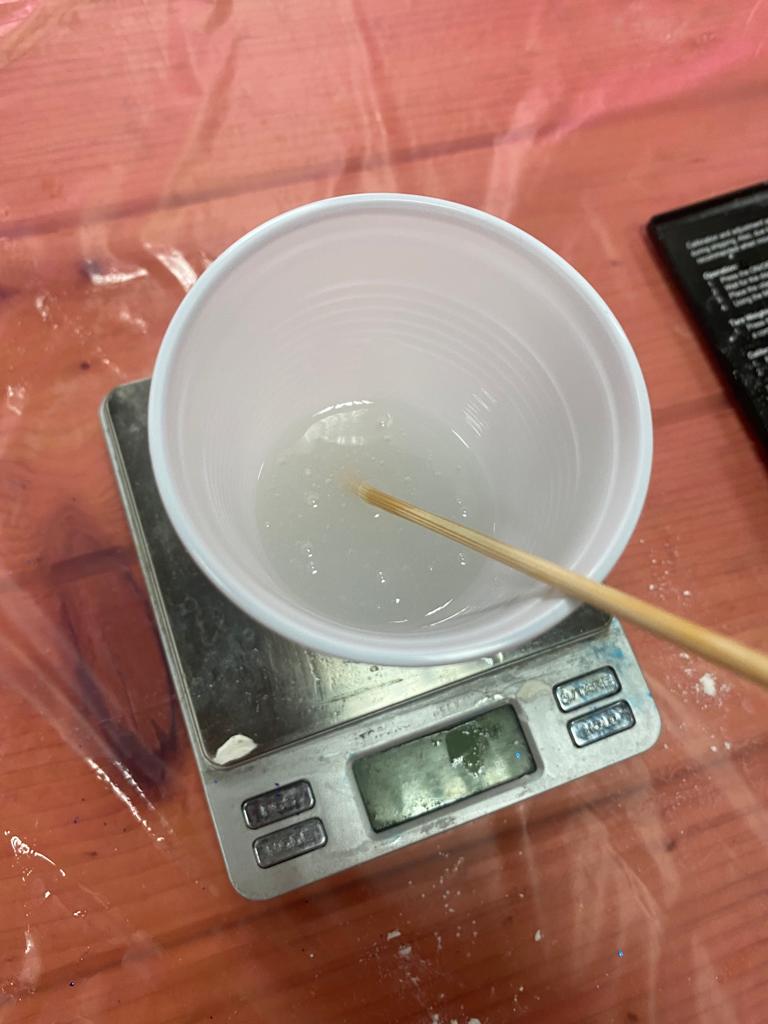

These two materials are mixed to create the mold at a ratio.

Left out to dry for 12 hours at least. Then two other materials were mixed 50% each to create the cast. Different colors were available I selected green on top because I could not find white, while putting brown on the bottom to make it look like sand.

Hero Shot¶

Hero Shot¶

Problems faced¶

-

Trying to mix the materials for the cast exactly within the recommended ratios.

-

Seeing bubbles when pouring the material into the mold which was solved by going really slow.