Group project - Production of Plastics using Bio Materials¶

Activity 1¶

Two different recipes of making plastics were taken from Bioplastics Cookbook using Corn Starch and Agar.

Corn Starch¶

First of all, glycerine (10g), water (80ml), corn starch (1.6g) and vinegar (15ml) were mixed in a pot. This milky coloured mixture was stirred and heated (medium) for 10 minutes. Also, made sure that we had a viscous solution and the water had been evaporated by the end of the specified time period. While heating, blue colour was added to the mixture. This blue viscous solution was transferred to a rectangular mould fixed on an acrylic sheet. It was left there to dry for 24 hrs.

Agar¶

This experiment required glycerine (2.7g), water (40ml) and agar (1.6g). The same procedure was followed as with corn starch, mixing the ingredients followed by heating and stirring for 10 minutes. The prepared viscous solution was taken out on an acrylic sheet with a circular mould. The solution was left there to dry for 24 hrs.

Activity 2¶

Re-usable composite mold was made using the instructions from a YouTube Video, but with different amount of ingredients which are shown in the table below.

| Ingredients | Quantity |

|---|---|

| Glycerine | 15 ml |

| Water | 15 ml |

| Gelatine | 3 g |

Activity 3¶

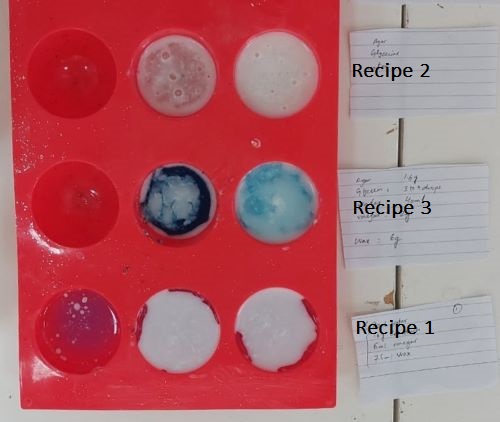

Machinable wax was produced with 3 different recipes.

Recipe 1¶

| Ingredients | Quantity |

|---|---|

| Corn Starch | 1.6 g |

| Water | 80 ml |

| Vinegar | 15 ml |

| Wax | 5.5 g |

Recipe 2¶

| Ingredients | Quantity |

|---|---|

| Agar | 1.6 g |

| Water | 40 ml |

| Vinegar | 15 ml |

| Wax | 8 g |

Recipe 3¶

| Ingredients | Quantity |

|---|---|

| Agar | 1.6 g |

| Water | 40 ml |

| Vinegar | 2 g |

| Wax | 6 g |

These experiments were supposed to produce Machinable Wax, but it didn’t meet the expectations. Recipe 2 and Recipe 3 were somewhat in a good shape but not brittle enough that would make them machinable. Also the undissolved wax layer can be seen on the surface which is not suitable. This might be due to some processing elements such as heating the wax or the amount of ingredients used. The result from Recipe 1 was mostly liquid, it didn’t solidify. This might be due to the excess of water or may be should have been kept for heating a little longer so that wax dissolves in the solution. These errors are yet to be investigated.

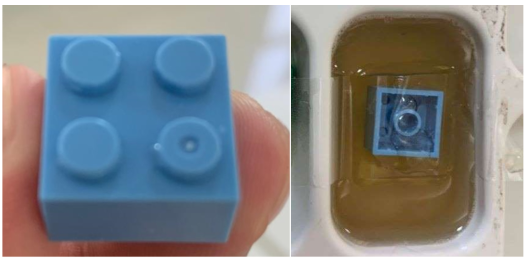

Composite Mold Recipe¶

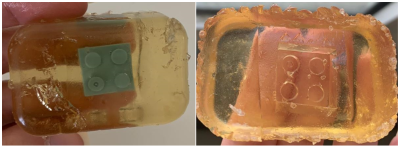

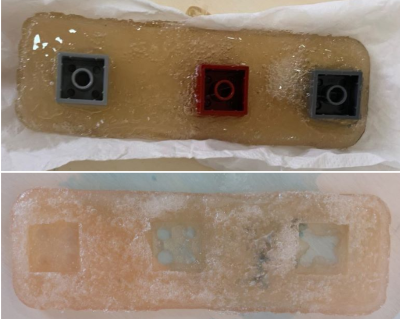

Re-usable composite mold was prepared once again following the same procedure as mentioned above but with different amount of ingredients. Prepared solution was poured on a tray, molding it in shape of Legos.

Lego’s shape was moulded on the composite-mold, to the fine details. But the composite mould was a little fragile. While removing one of the Lego, the mould broke down a little.

| Ingredients | Quantity |

|---|---|

| Glycerine | 24 ml |

| Water | 20 ml |

| Gelatine | 4 g |

Same experiment was repeated but replaced glycerine with cooking oil. Obviously it didn’t end well. The composite mold was all covered in oil. Some images are shared below.

Agar and Foam Bioplastic¶

A different recipe of making Bioplastics was used from Agar and Foam. A dishwasher soap was used for foam.

| Ingredients | Quantity |

|---|---|

| Agar | 1.6 g |

| Water | 40 ml |

| Soap | 6 ml |

Corn starch¶

Casting¶

Re-melting molds¶

Composimold perfect one and another one¶

Agar composite¶

Research¶

Bioplastics¶

Bioplastics are polymers produced from renewable resources (corn starch, agar etc) thus conserving limited natural resources and reducing greenhouse gas emission. They are sustainable and most of them are biodegradable. Bioplastics are in huge demand in many industries (such as food packaging, agriculture, composting bags etc). With further material improvement they can be used in biomedical, electrical and other products.

Most commonly known bioplastics are polylactic acid (PLA), polyhdroxybutyrate (PHB), soy based plastics, cellulose polyesters, starch based bioplastics, vegetable oil derived bioplastics etc. Bioplastics are still not very successful in many fields due to their limitation of properties. To improve properties of bioplastics, polymer blends and composites are studied. For polymer composites or bio composites, various types of fillers have been studied, including inorganic fillers (e.g., calcium carbonate, nanoclay), natural fibers (both wood and plant fibers), and other types of fillers such as carbon nanotubes. In general, adding fillers to polymers will improve properties such as stiffness, strength, gas barrier properties, melt strength, thermal stability, etc.

Biocomposites¶

Biocomposites are of great importance to the material world because they provide unique properties that do not exist naturally.

Wax¶

Machinable wax (wax added plastic) 1-Beeswax 2-Soywax 3-Paraffin Wax