6. Large format CNC (computer controlled Machining)¶

We used the CNC machine this week to cut larger scale designs that we were working on.

CNC Machine¶

To operate machine tools like lathes and mills, a computer numerical controlled (CNC) machine needs a software. A raw material (metal, plastic, etc.) is used, and it is then cut, polished, drilled, turned, milled, and/or shaped into components that adhere to strict criteria.

Group Assignment¶

Testing the CNC machine and safety requirements click here.

Individual Assignment¶

-The goal is to design and print something for children that can be used and will be donated to the Charitable Society for Orphans.

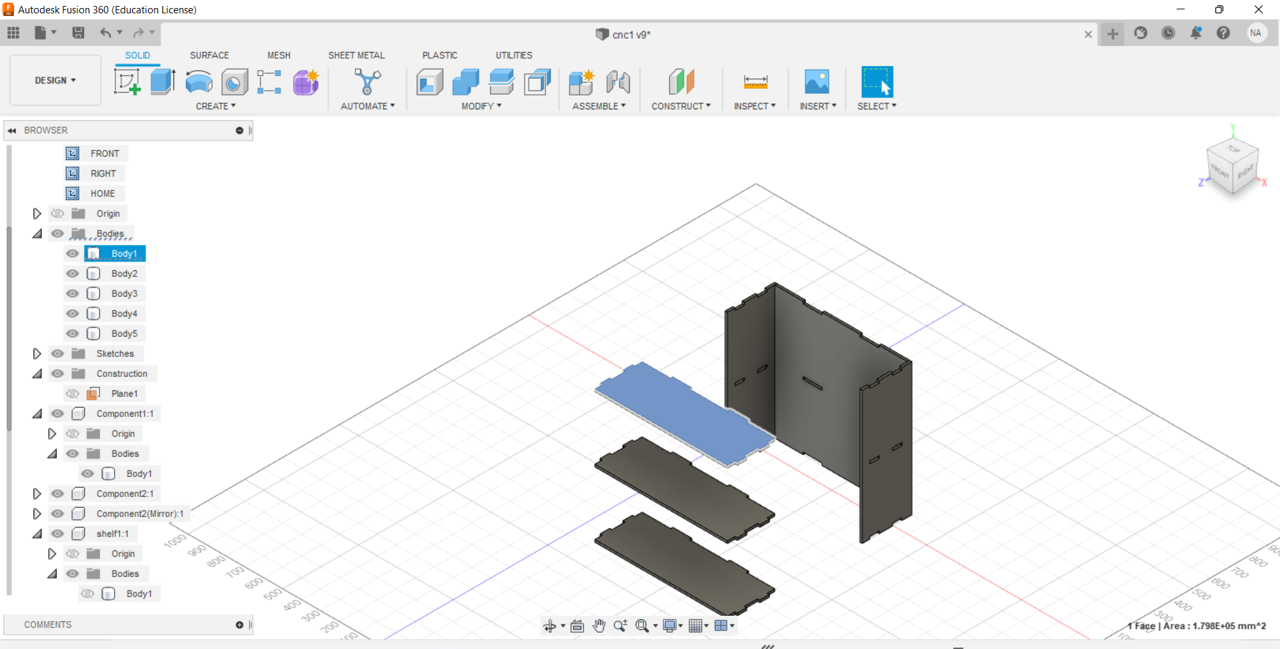

-I used Fusion360 program to design a small shelving uint. The pictures below will show how to design.

The 3D Design¶

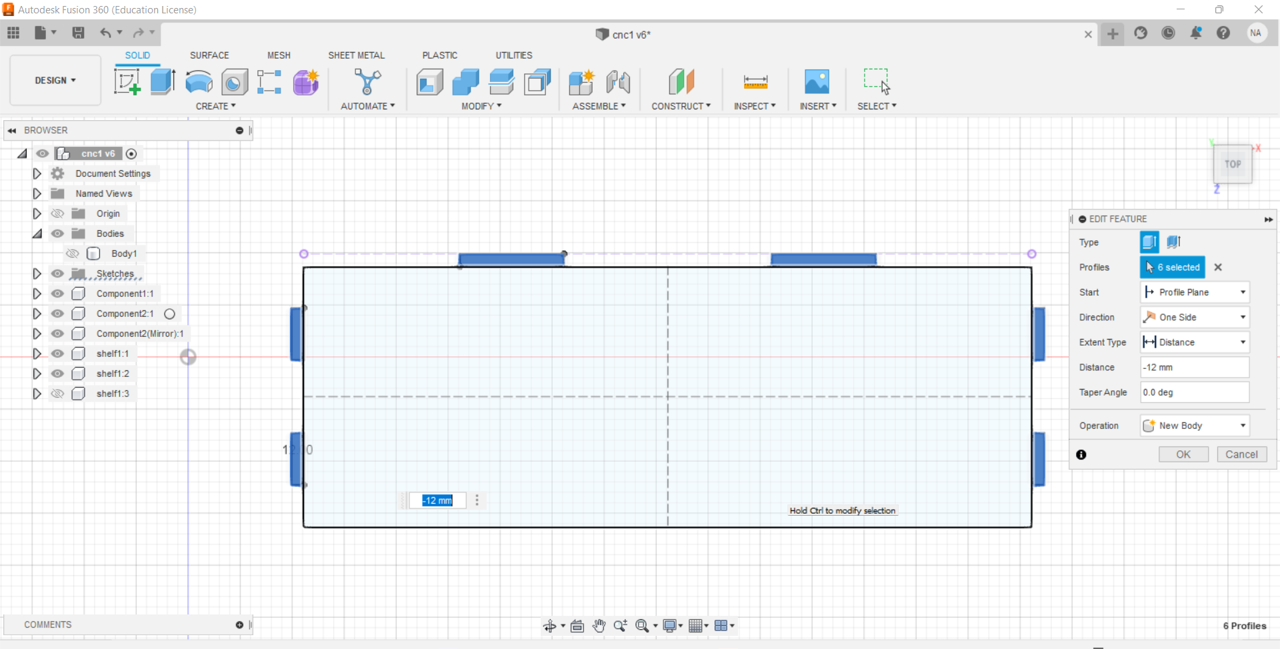

1.First , from modify > change parameters > + > add parameters .

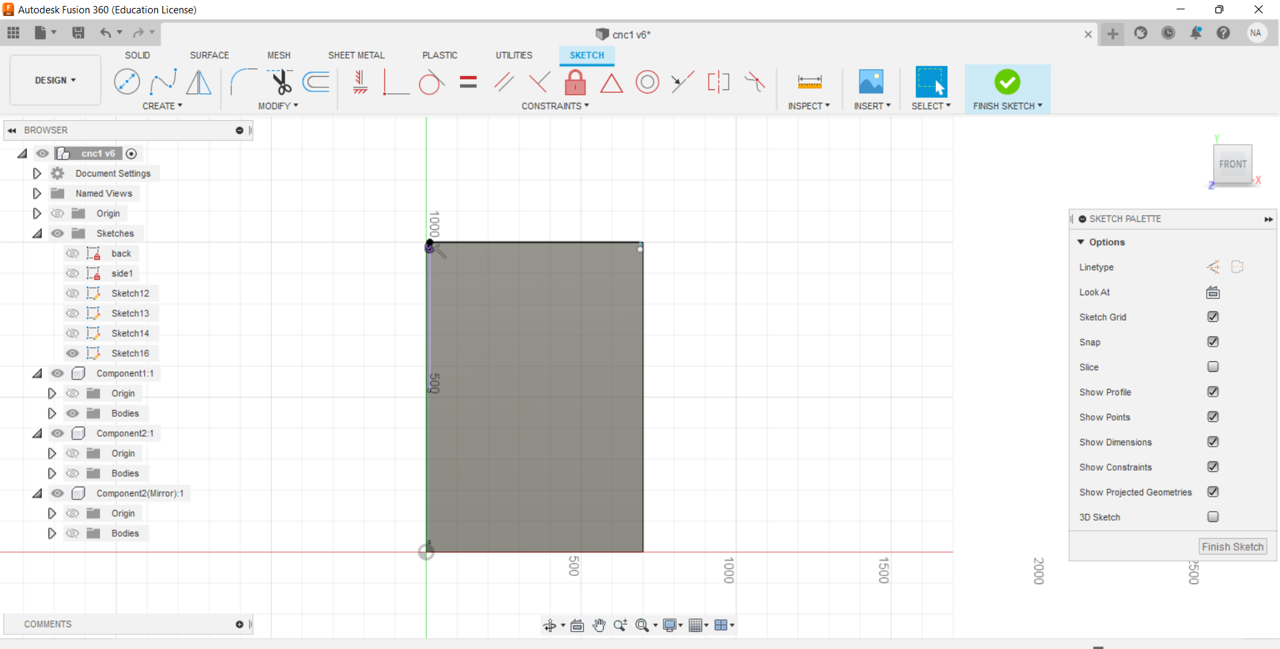

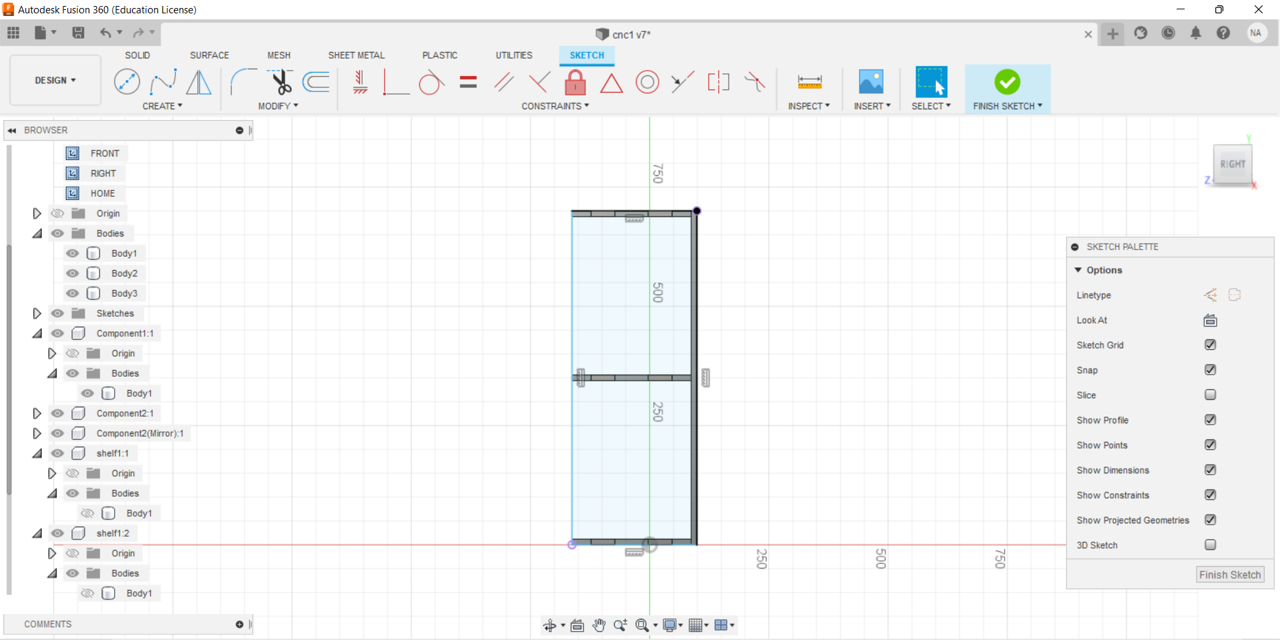

2.Create sketch > rectangle (the length 0.7 m and width 0.7m).

3.Extrude by 12 mm.

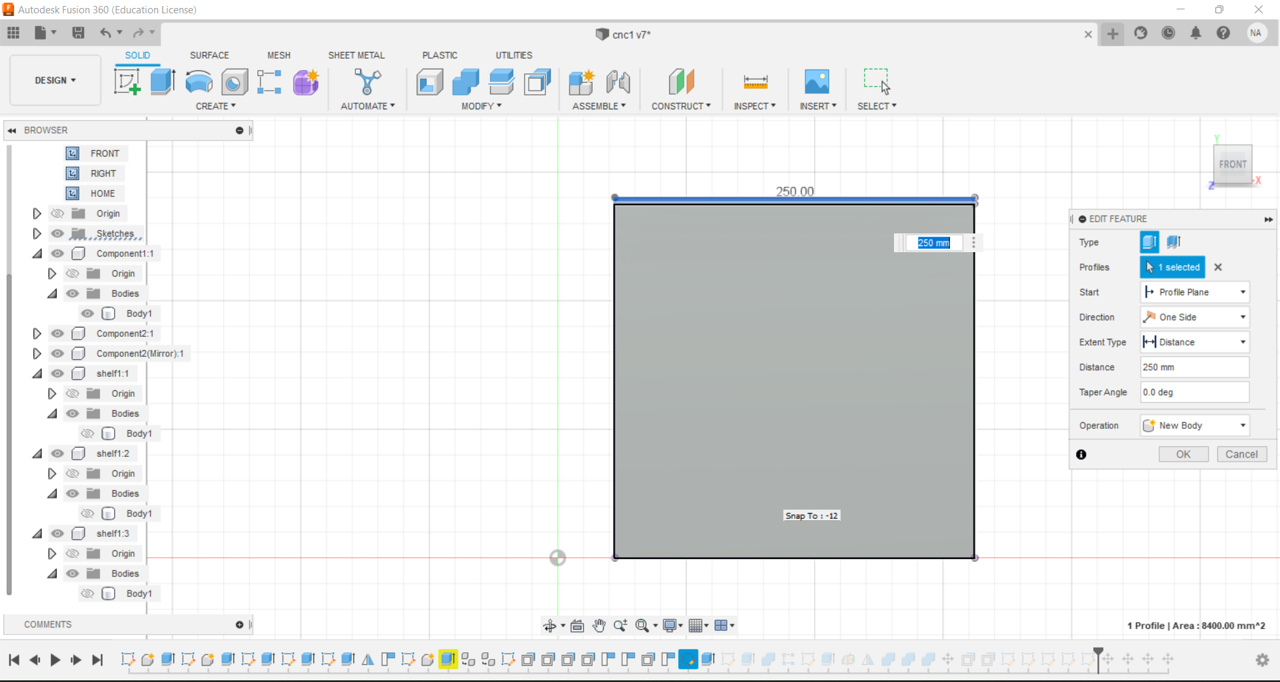

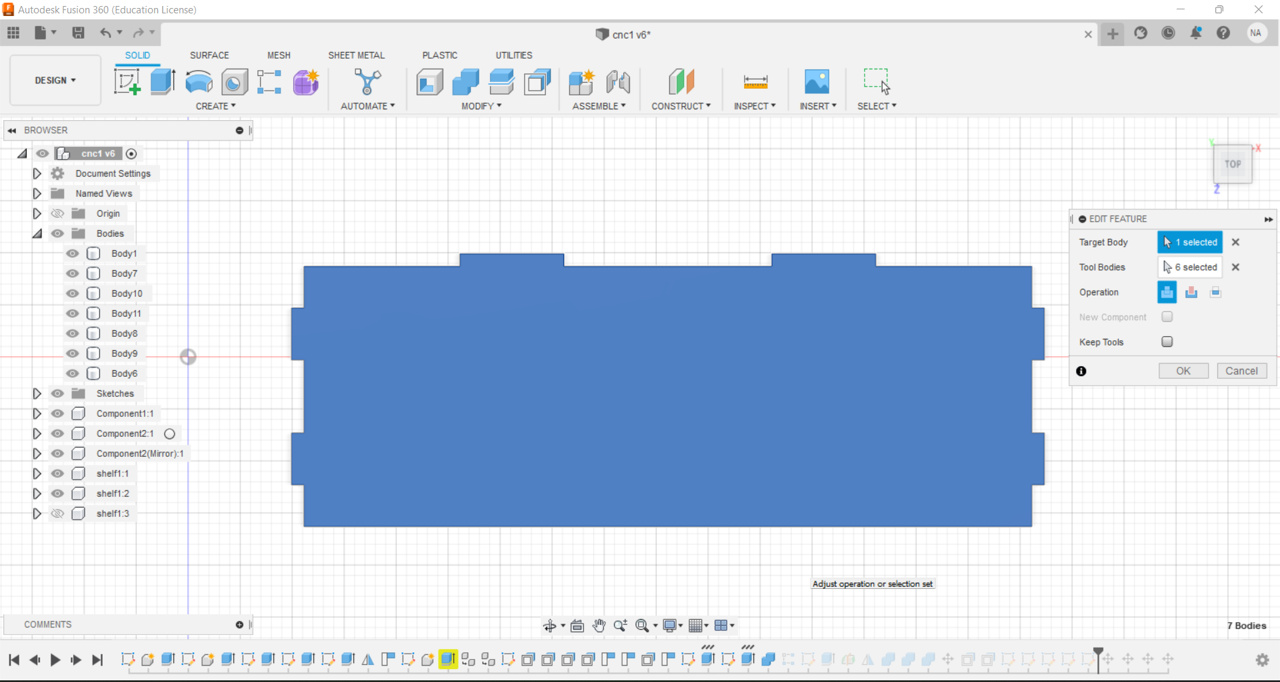

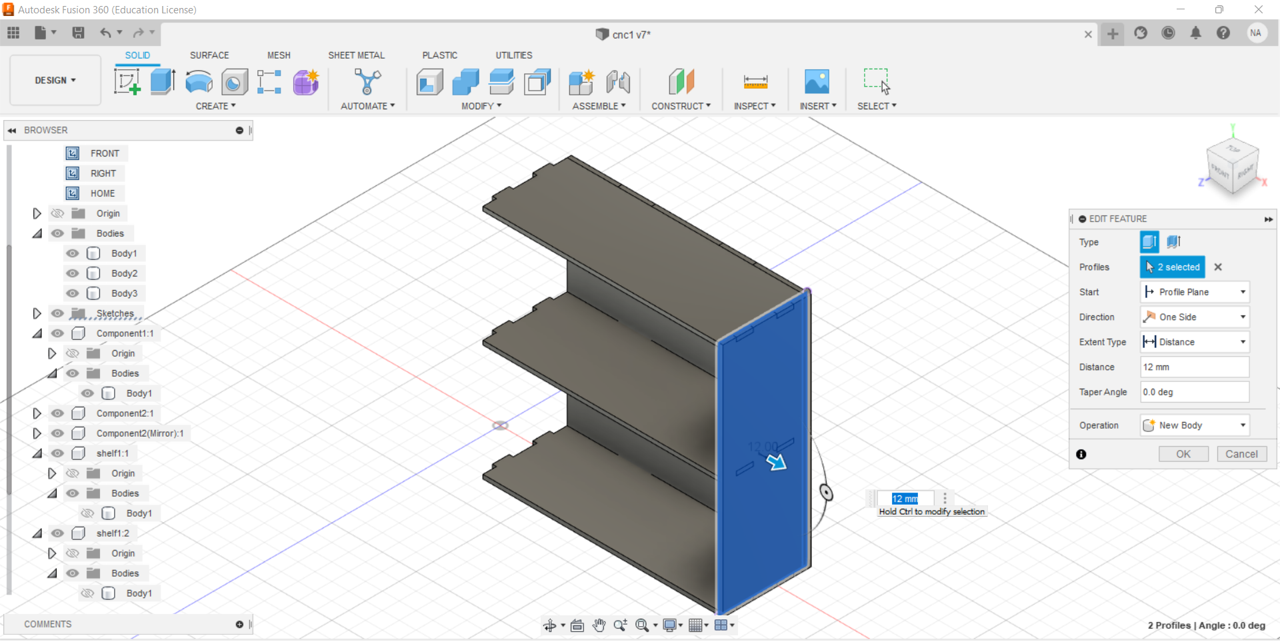

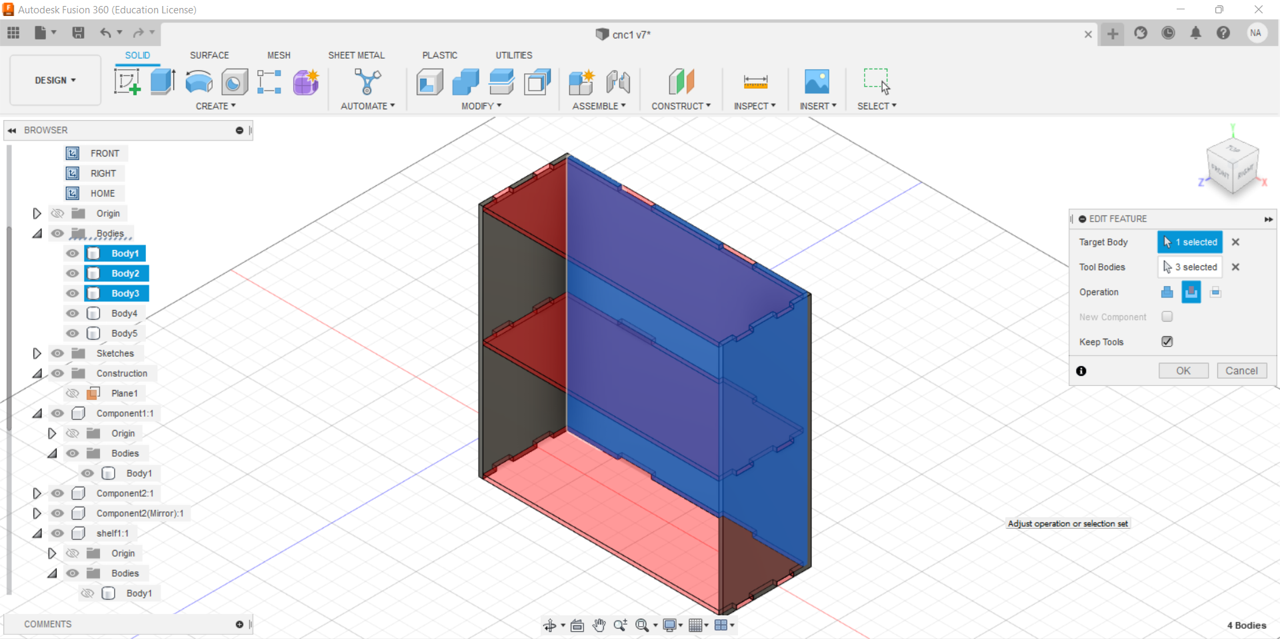

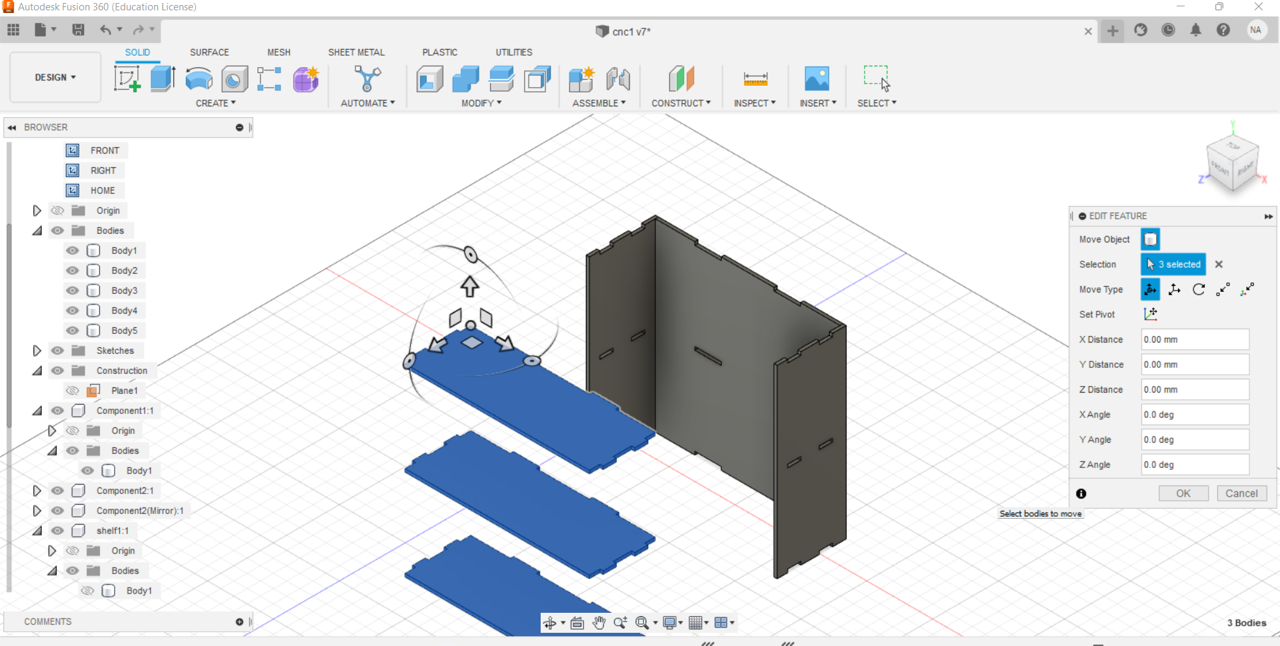

4.Drow rectangle (the shelf) Create sketch > rectangle (the length 0.7 m and width 0.2 m),The operation > nwe body.Then ,Extrude by 12 mm.

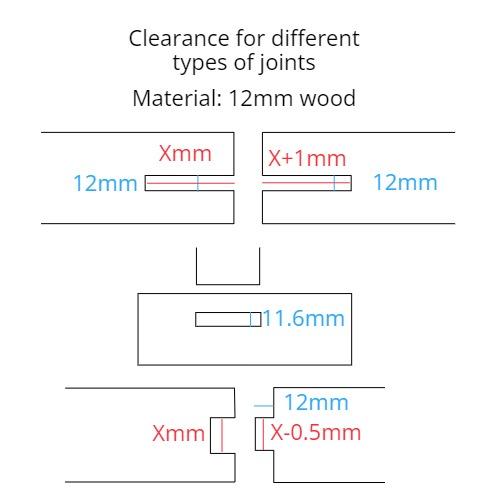

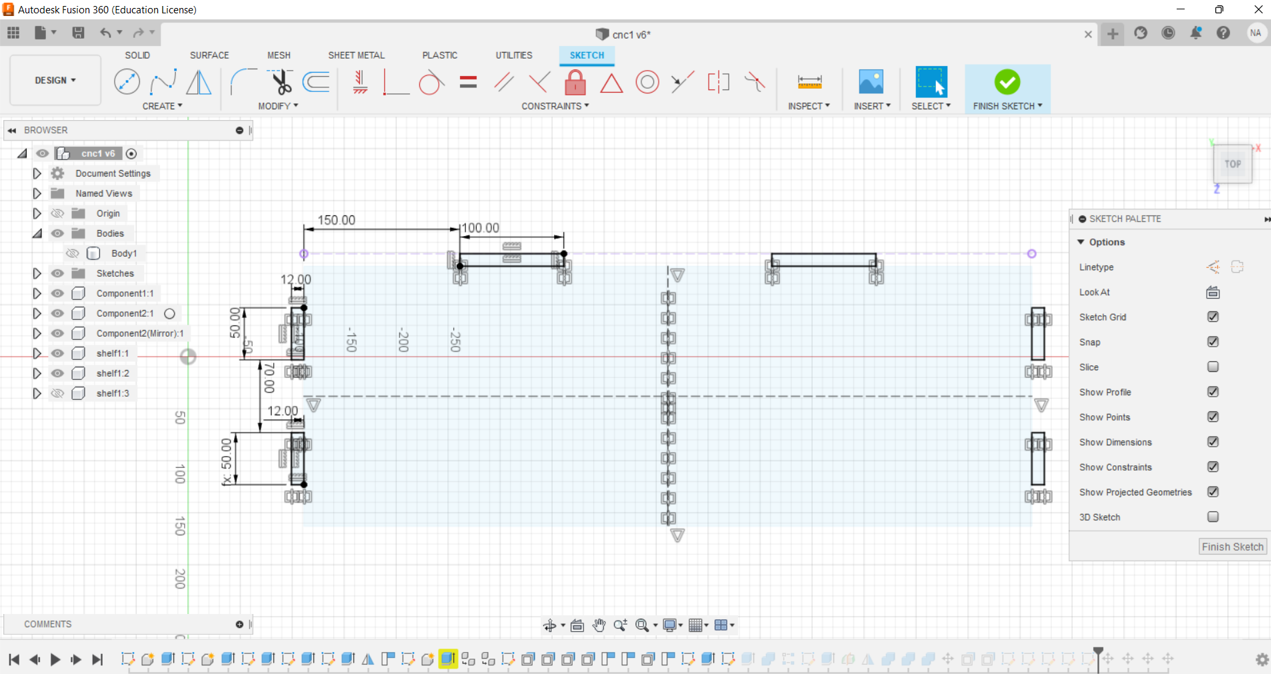

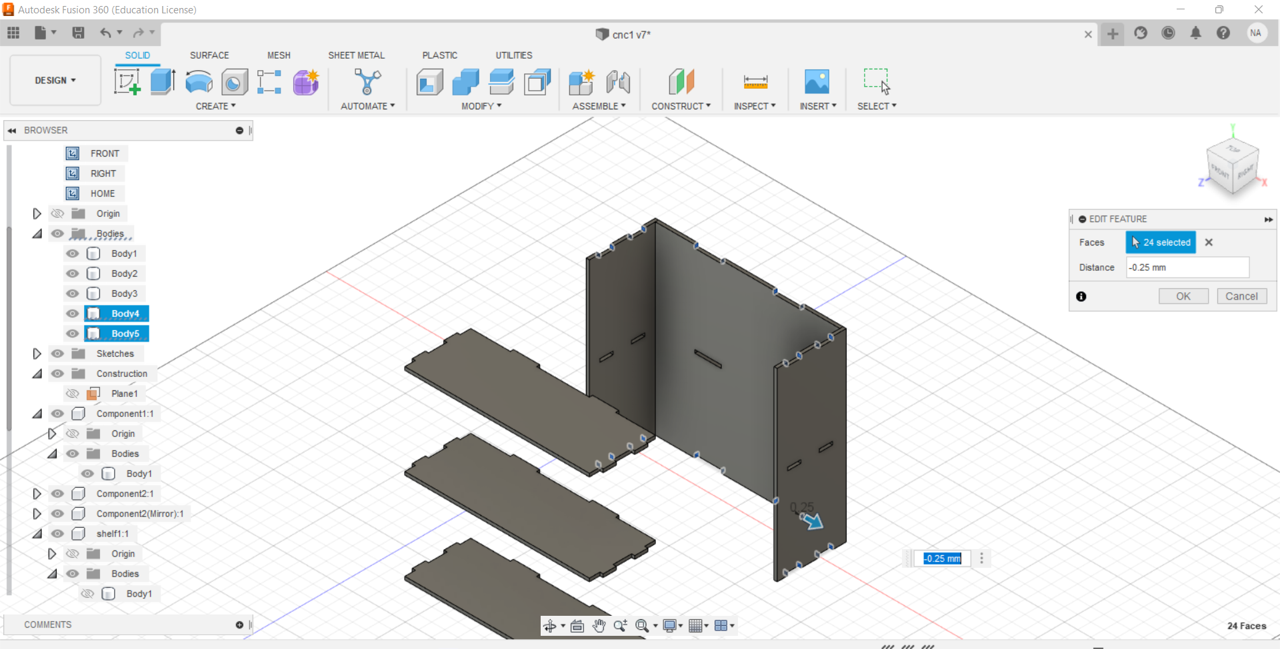

5.Now, For jointe I followed this picture.(The picture from the inspector).

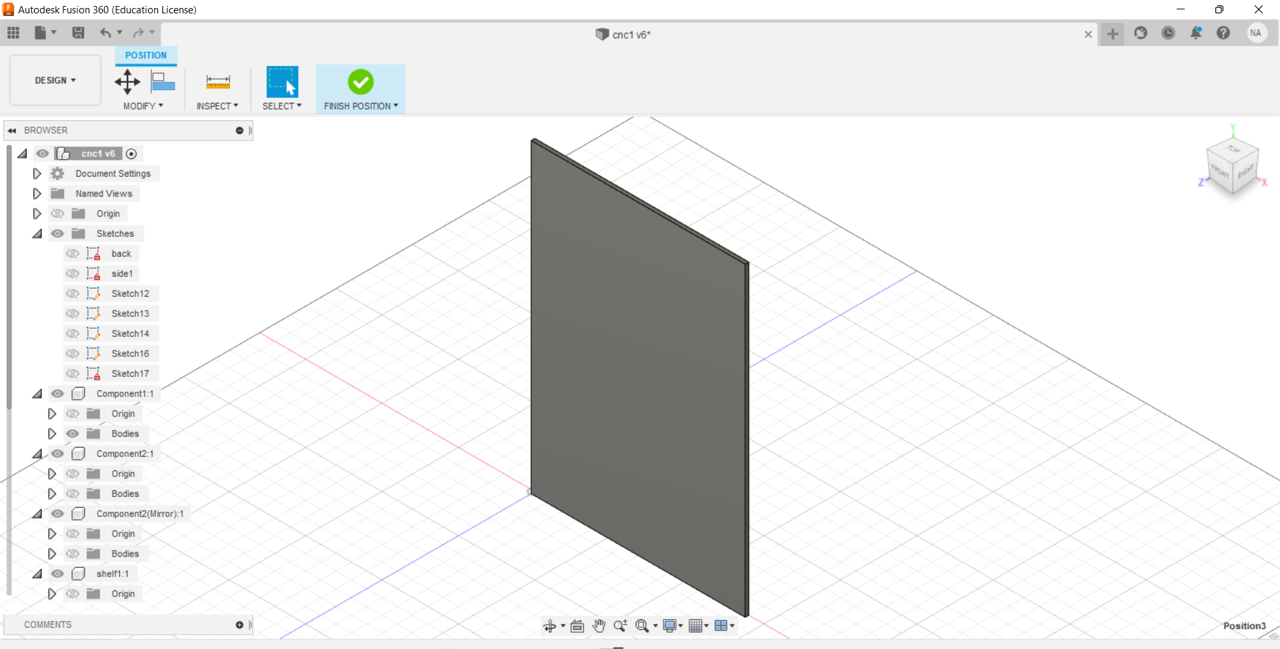

6.For the back base .

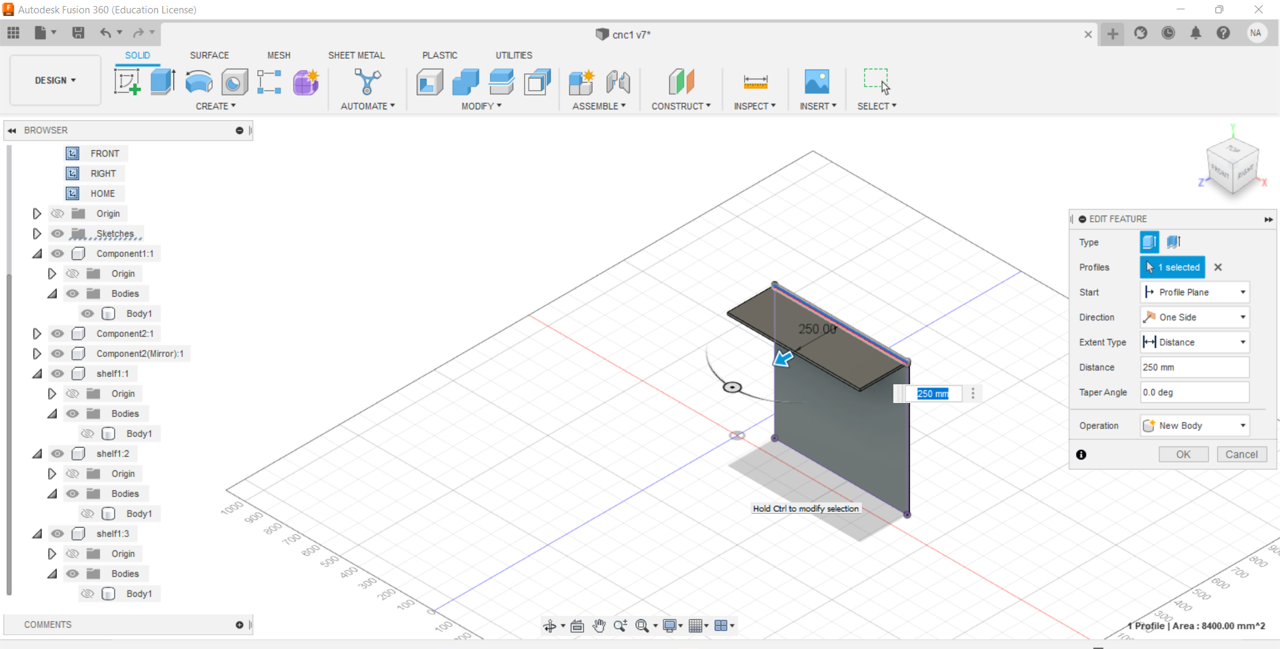

7.For the shelf .

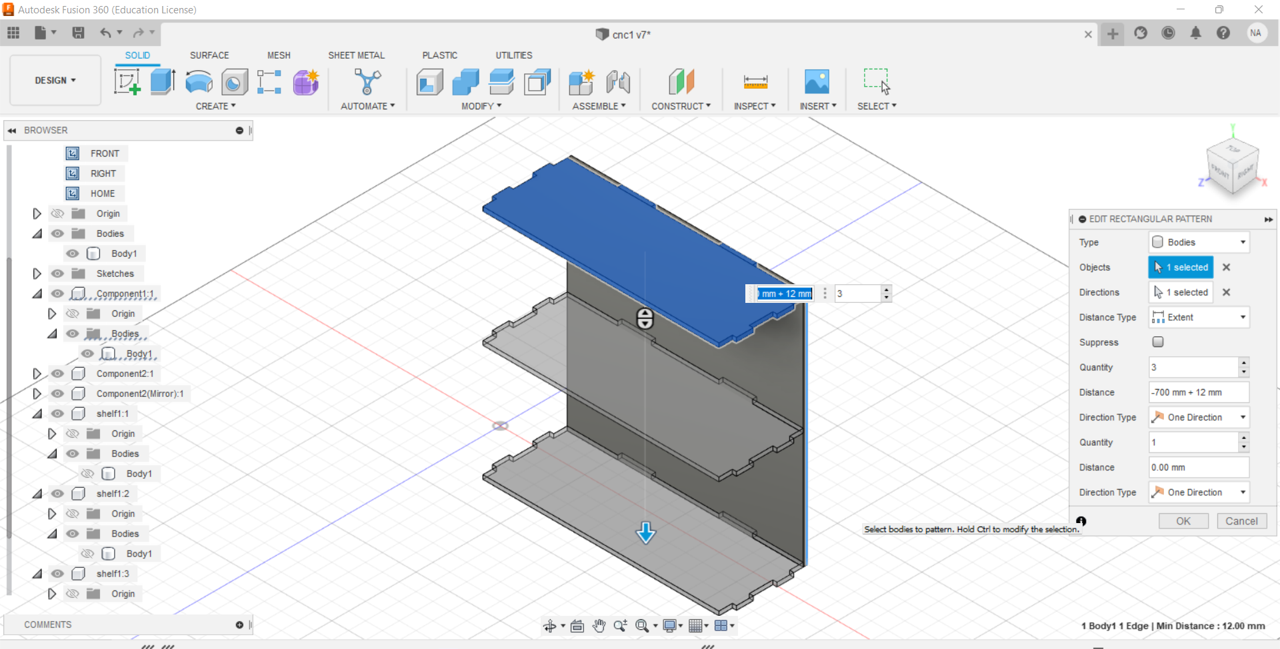

8.By using rectangular pattern tool to repeat the shelf twice.

9.The side of shelving uint.

10.Extrude by 12 mm .

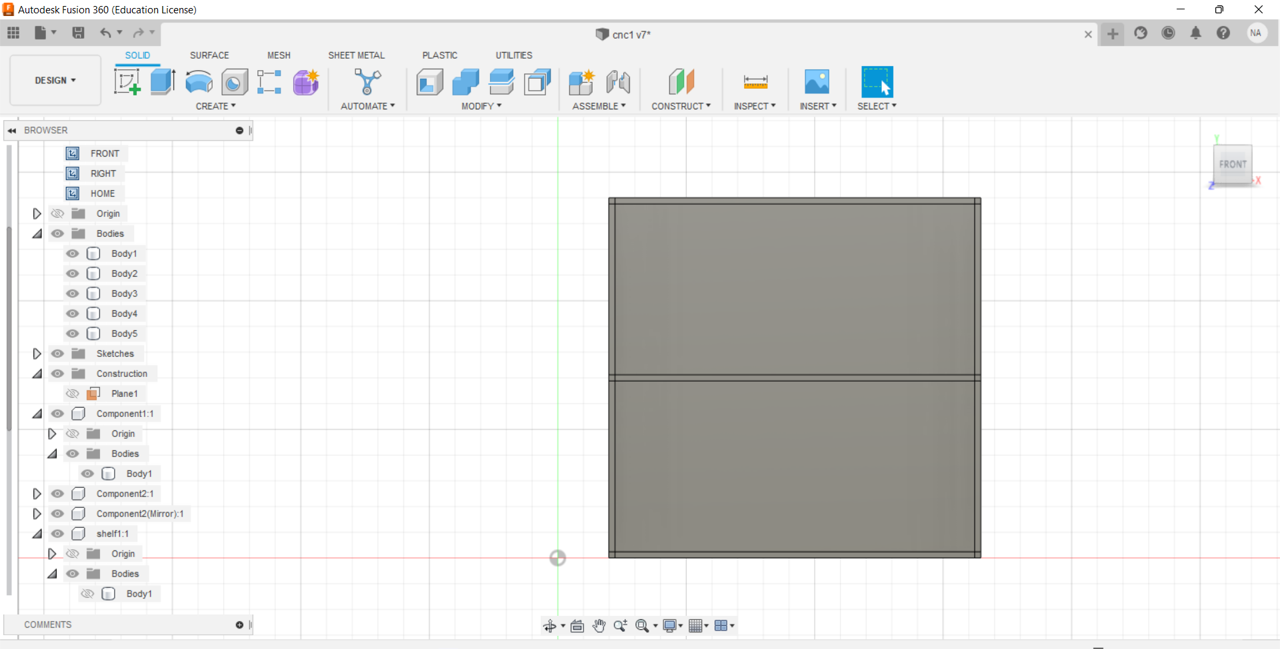

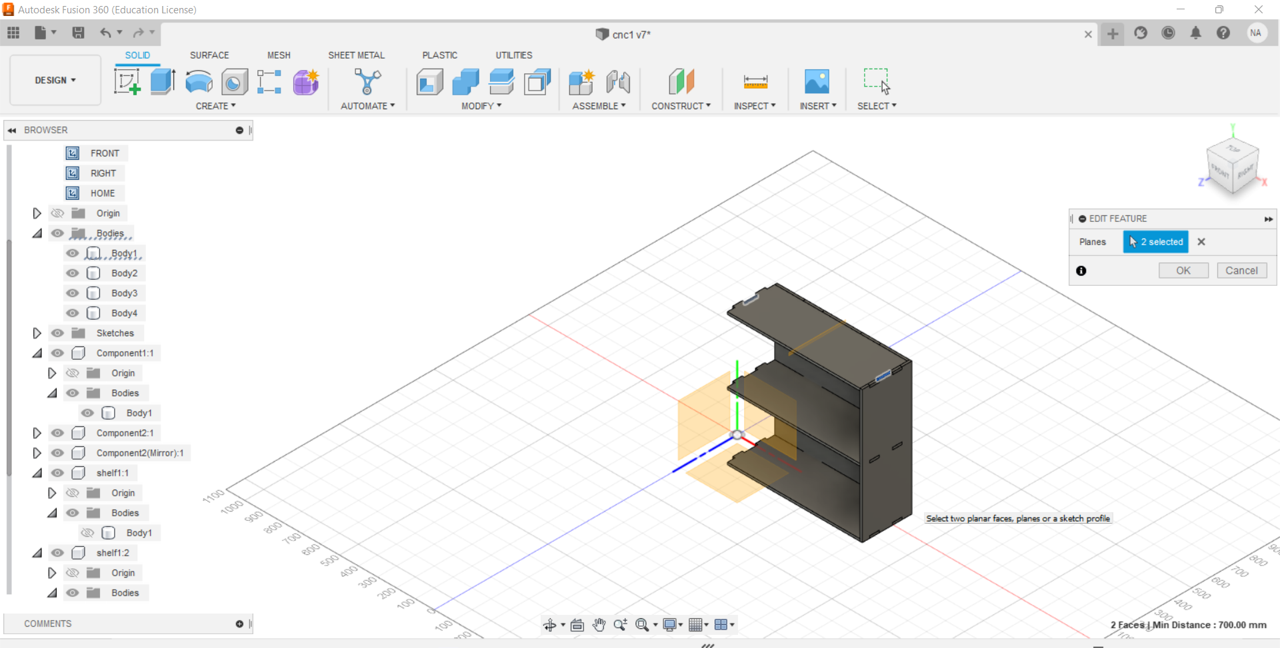

11.From construct > midplane > select > ok .

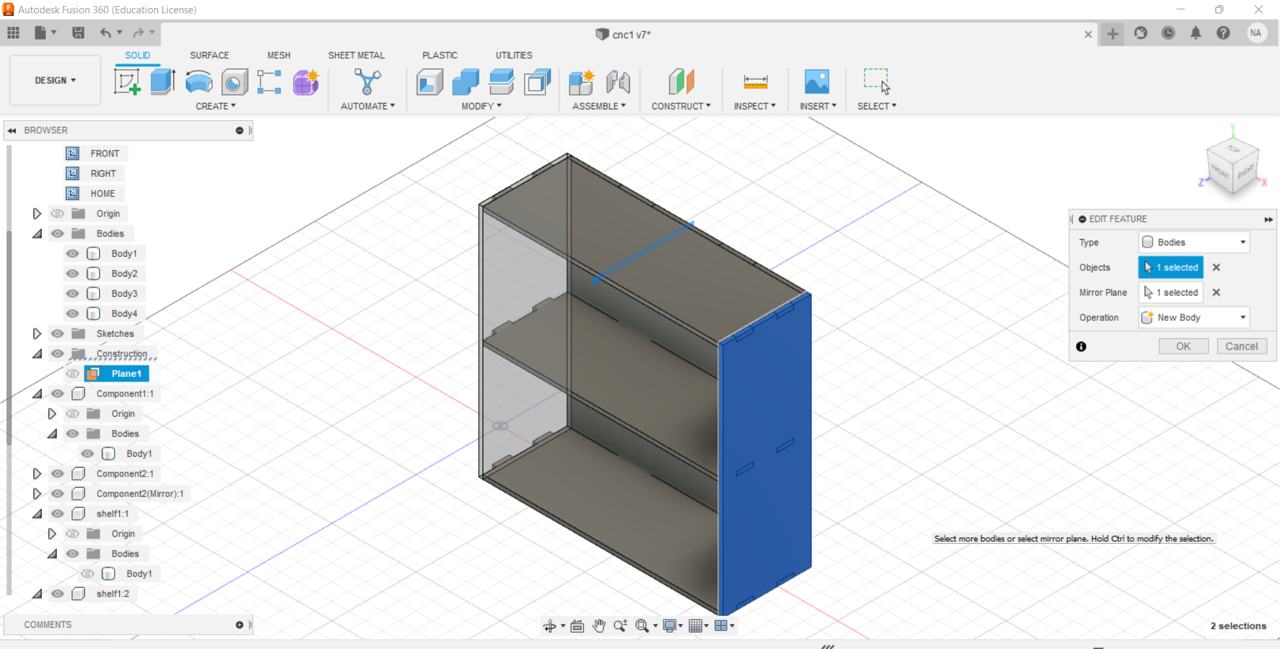

12.From Create > mirror > select > ok .

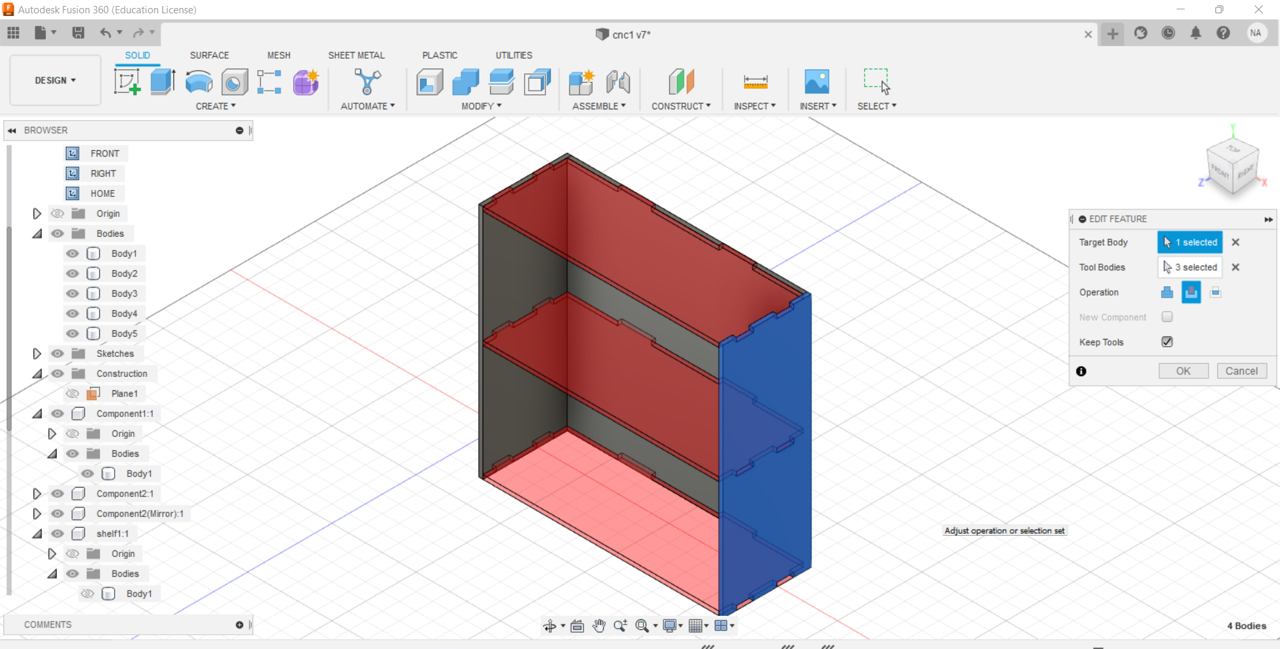

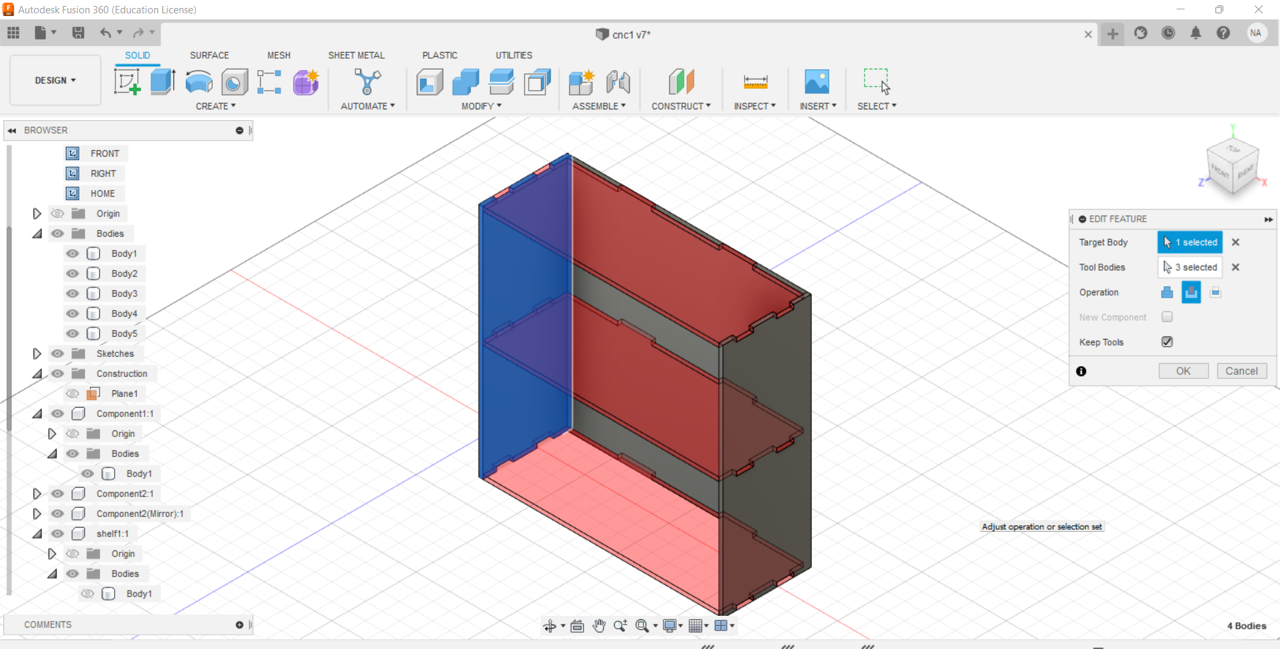

13.After that , to fix the shelfs jointes with the sides and back base. From modify > combine.

14.For the jointes to be correct and stable, the openings must be slightly reduced from on side .

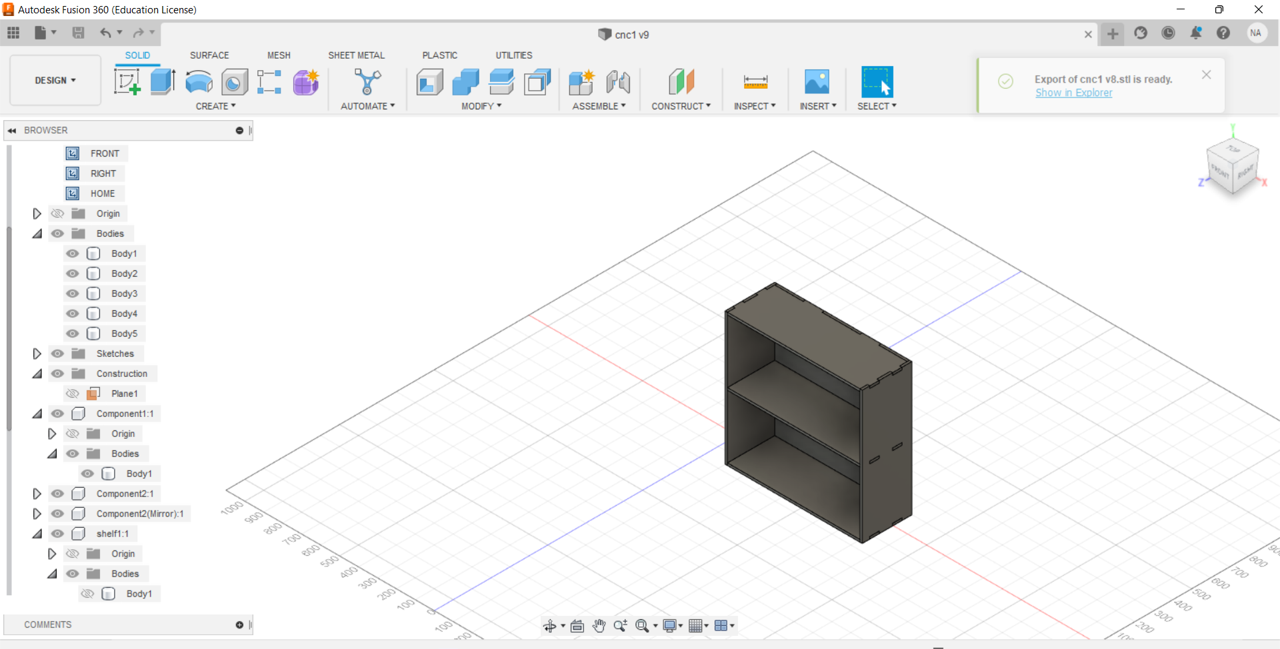

15.Final look .

16.In 3D model.

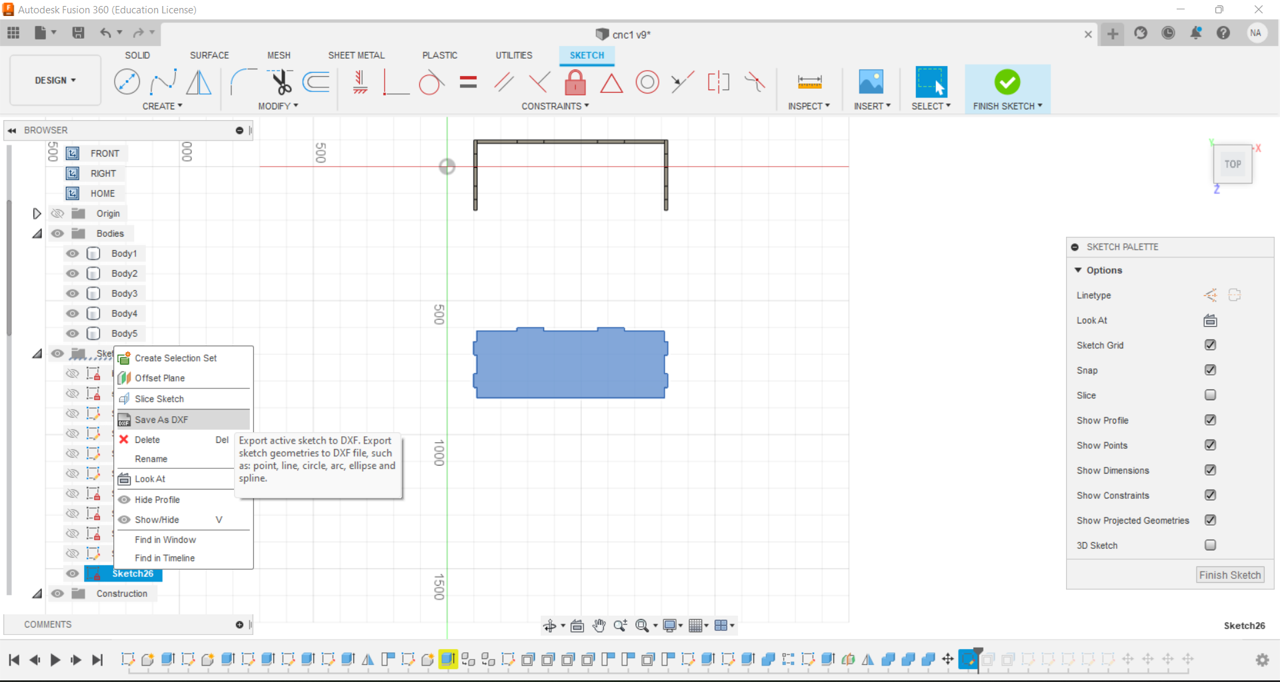

16.The design was converted into a dxf file so that the CNC machine’s motor could accept it.select the body > Create sketch > save it as dxf.(Each piece is kept separately ).send it by email.

CNC Printing Machine¶

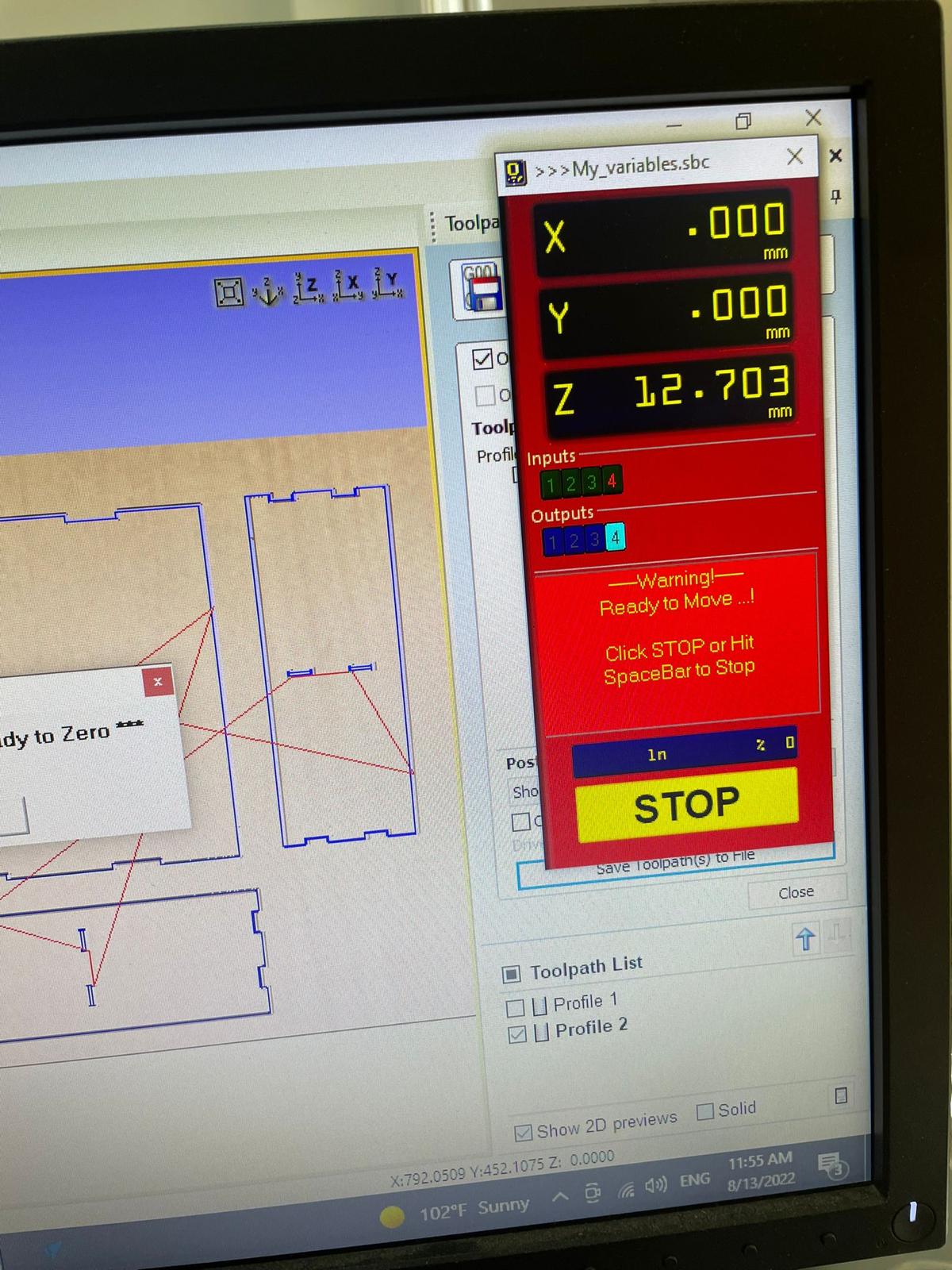

The design is printed through the Vcare program. Vcarve software is already installed on the computer linked to the device.

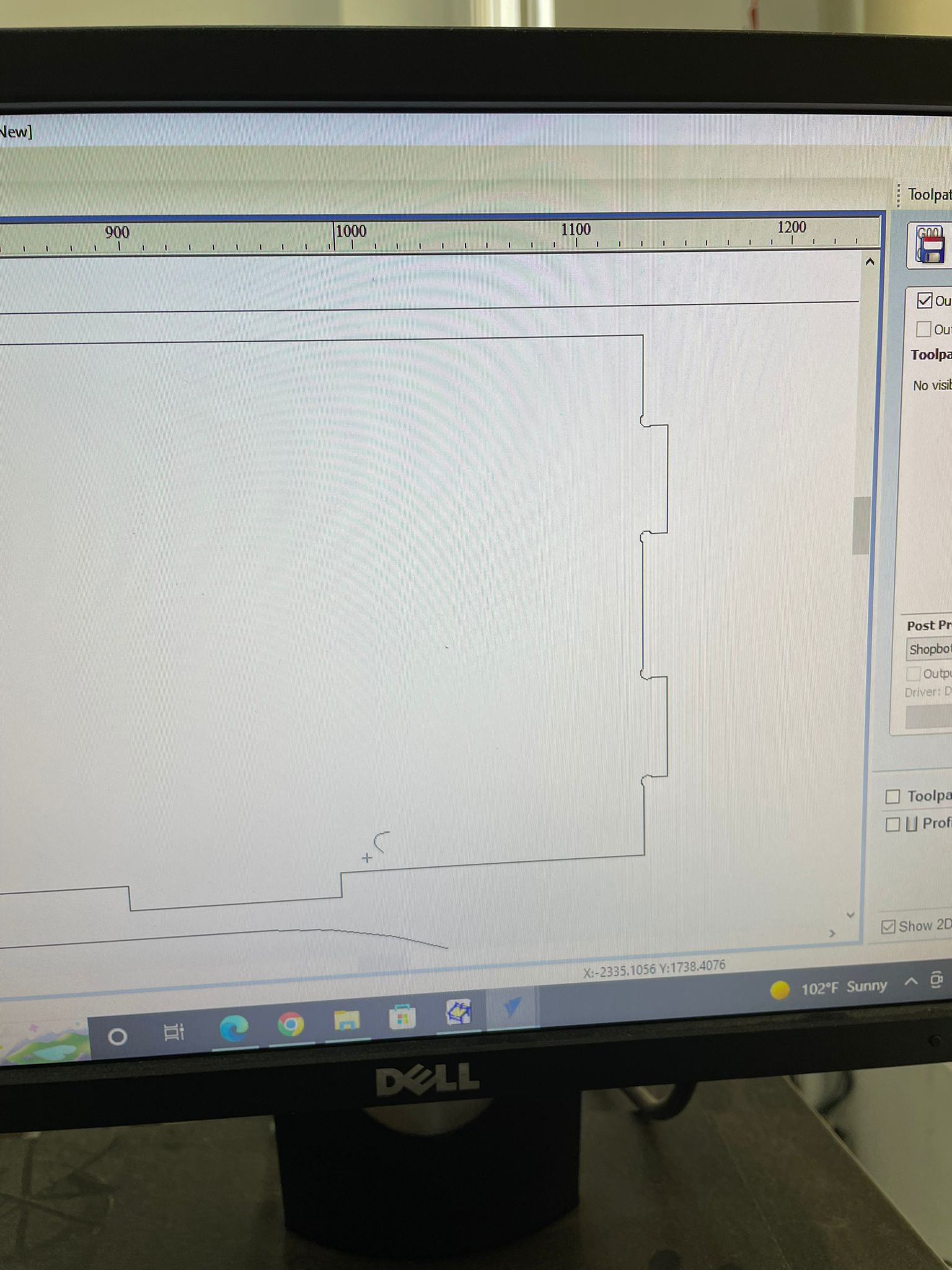

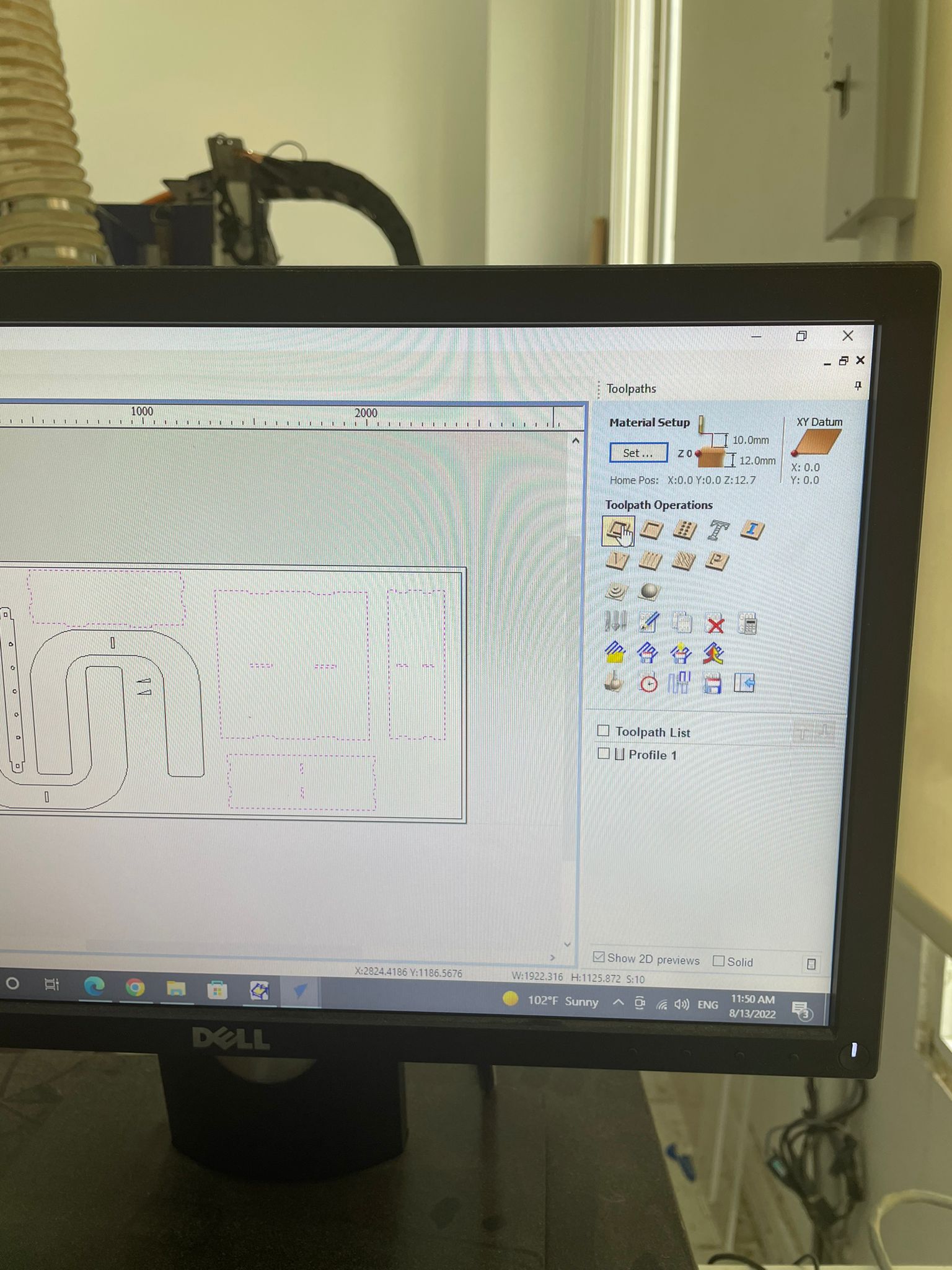

1.Determine the dimensions of the piece of wooden sheet (240x120m).

2.On the left side file > import the file as dxf .

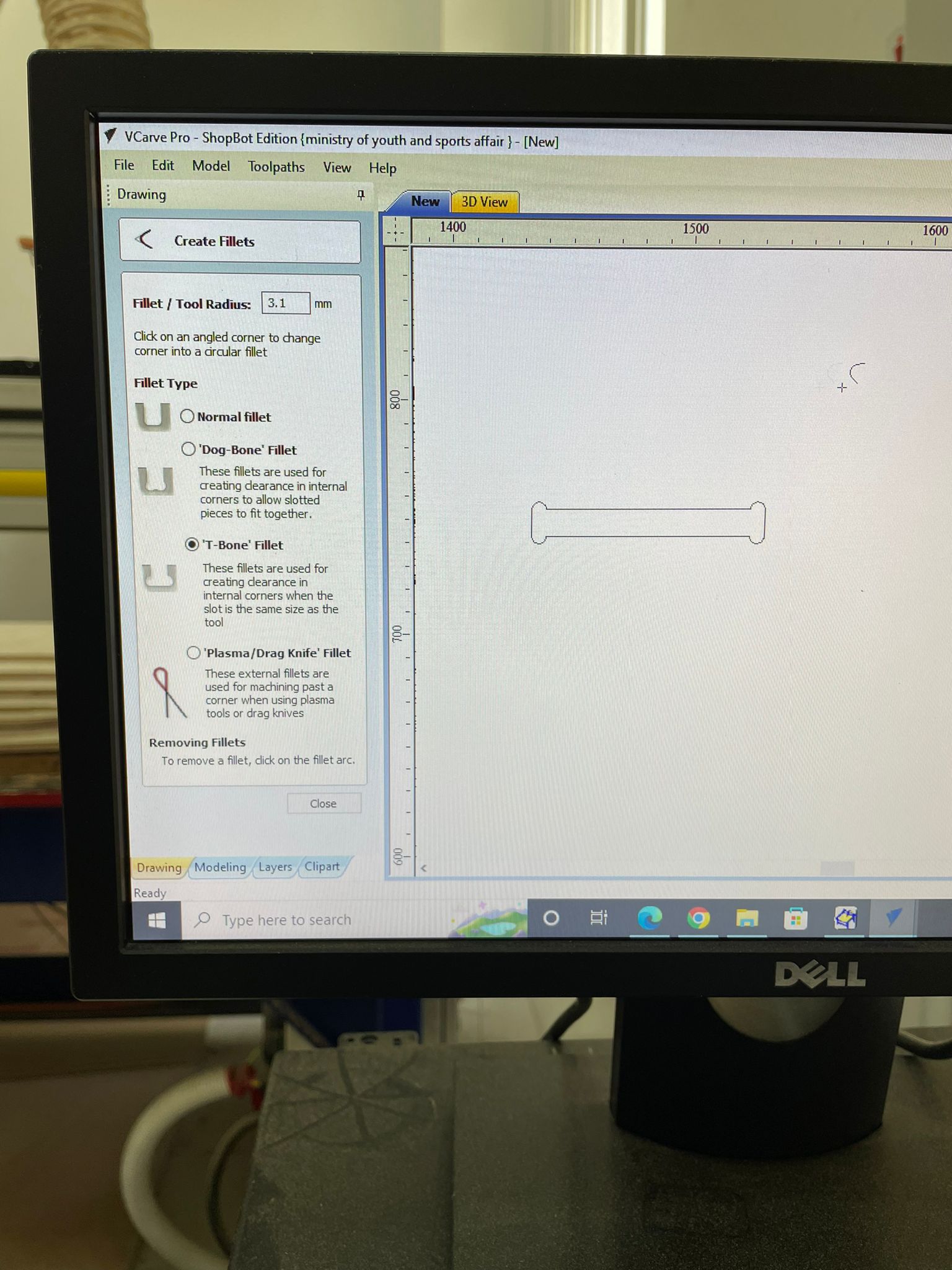

3.The CNC machine cannot go to 90 degree for inner coner,So we will Change the jioint type to T-Bone fillet.And outer coner Dog-Bone fillet.

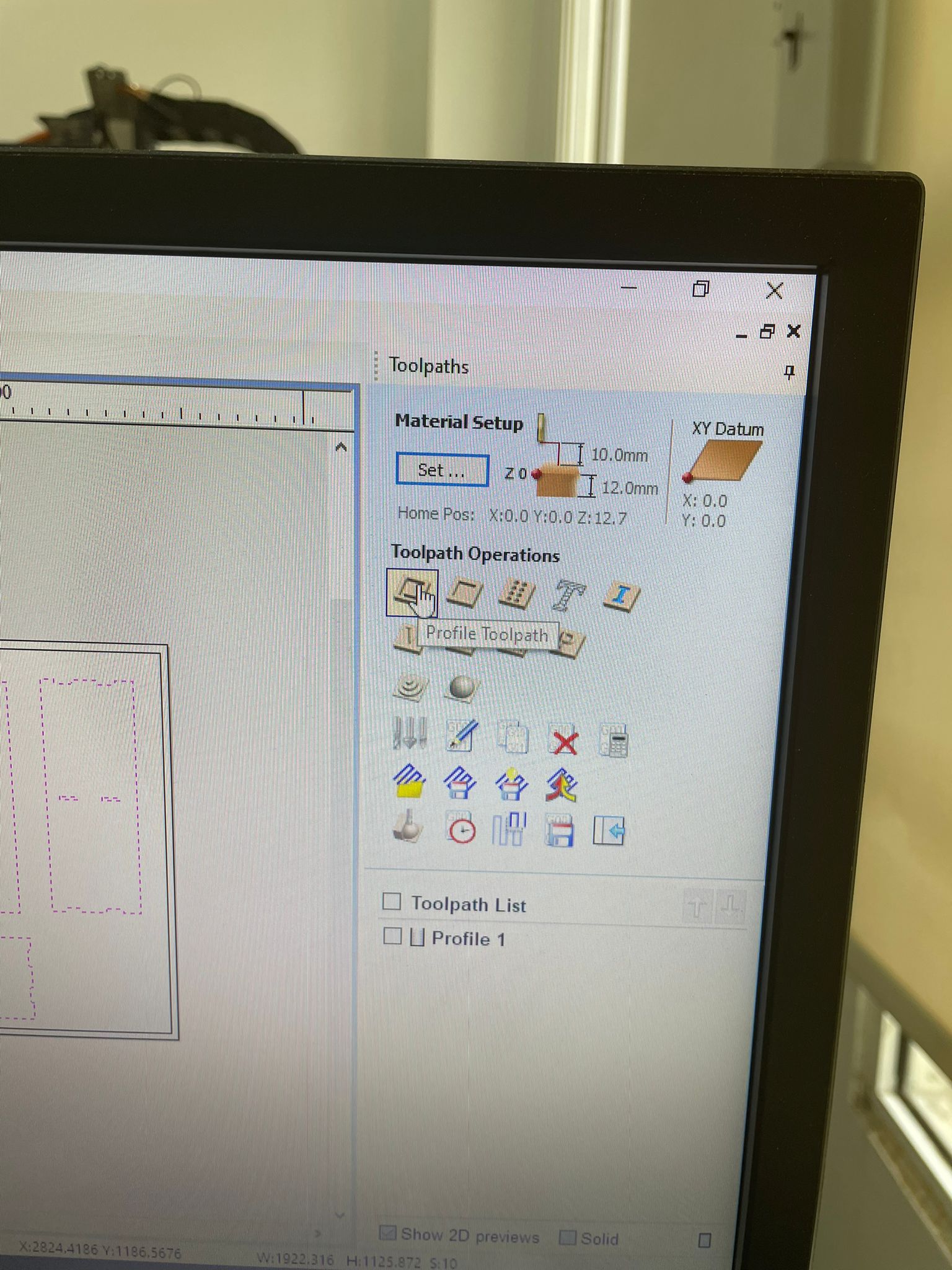

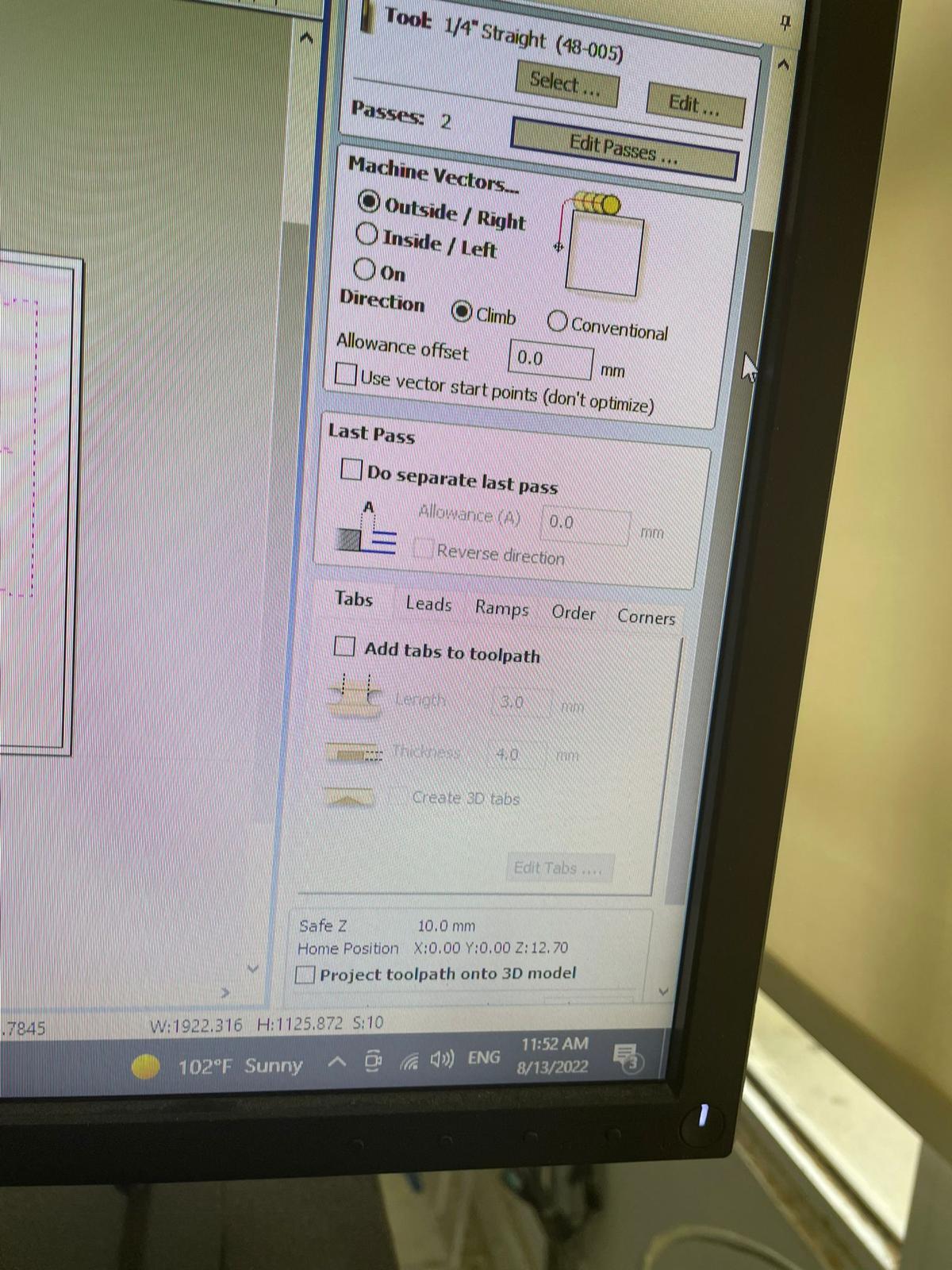

4.On the left side click switch to Toolpathstab> Toolpaths (on the rightside) >profile Toolpath.To feed rate of rotational speed.

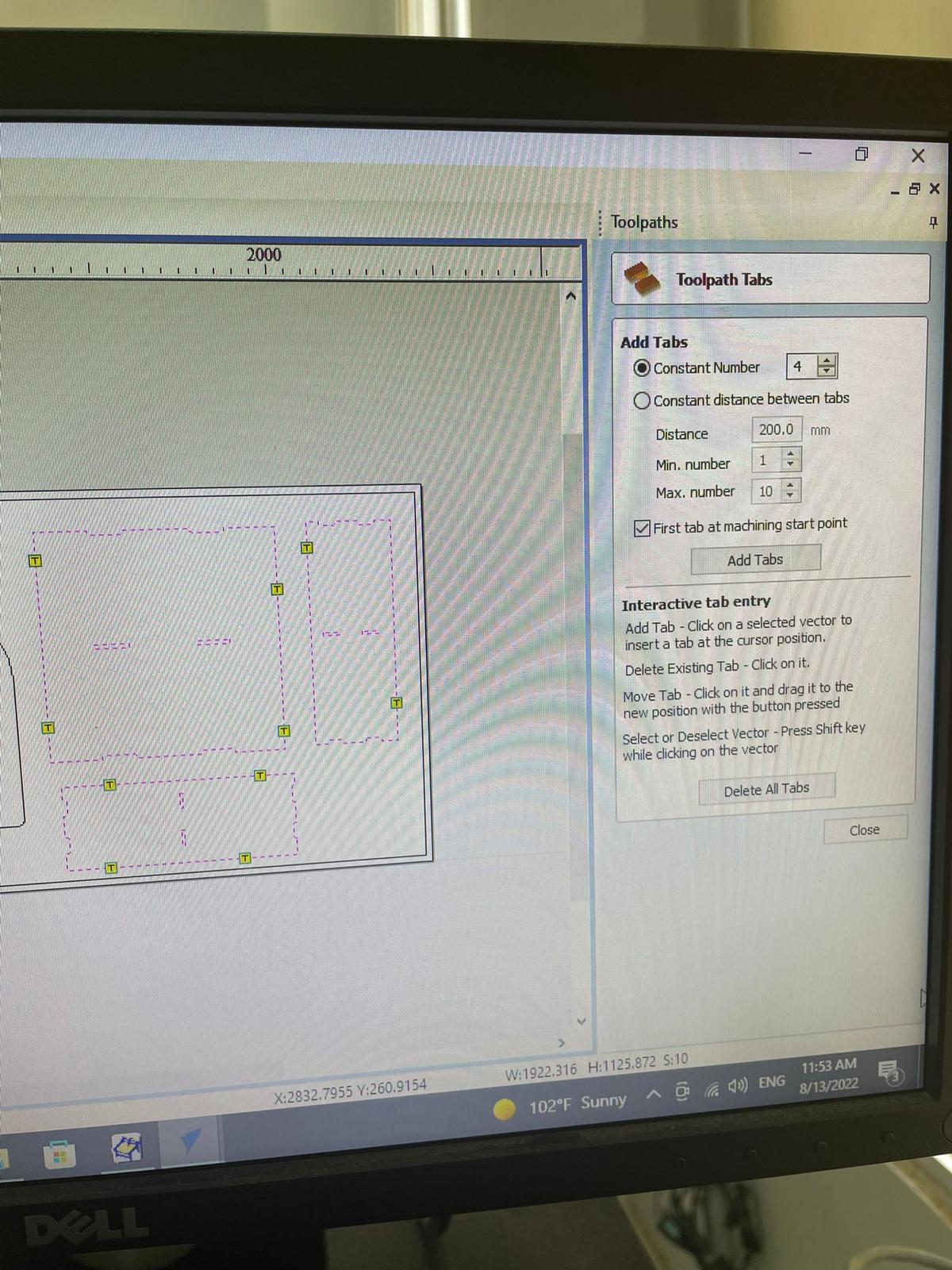

5.To ensure the part’s stability during cutting and to achieve the highest level of precision, these tabs are utilized as placements that are not cut along the toolpath. You may also change the parameters dimensions of the tabs .

6.Before start printing must make sure and know the safety conditions and how to turn off the machine when the problem occurs.Also , wear a safety glass.

7.Start

Final Look¶

By useing these tools to sanding .

By useing Rubber hammer for mounting parts.

My Opinion¶

This is the hardest week in Fab Lab Academy.The design took a lot of time and I faced a lot of difficulties to make the joints. In addition, sanding requires a lot of strength and effort. I would like to thank inspector Abdullah for providing a lot of help