6. Large format CNC (computer controlled Machining)¶

At the beginning of this week, we got introduced to the CNC machine. Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the workpiece or tool, the input parameters such as feed, depth of cut, speed, and the functions such as turning spindle on/off and turning coolant on/off.

Group Assignment¶

For the group assignment this week, we were asked to test runout, alignment, speeds, feeds, and toolpaths for the machine

Link to the Group Assignment page

Individual assignment¶

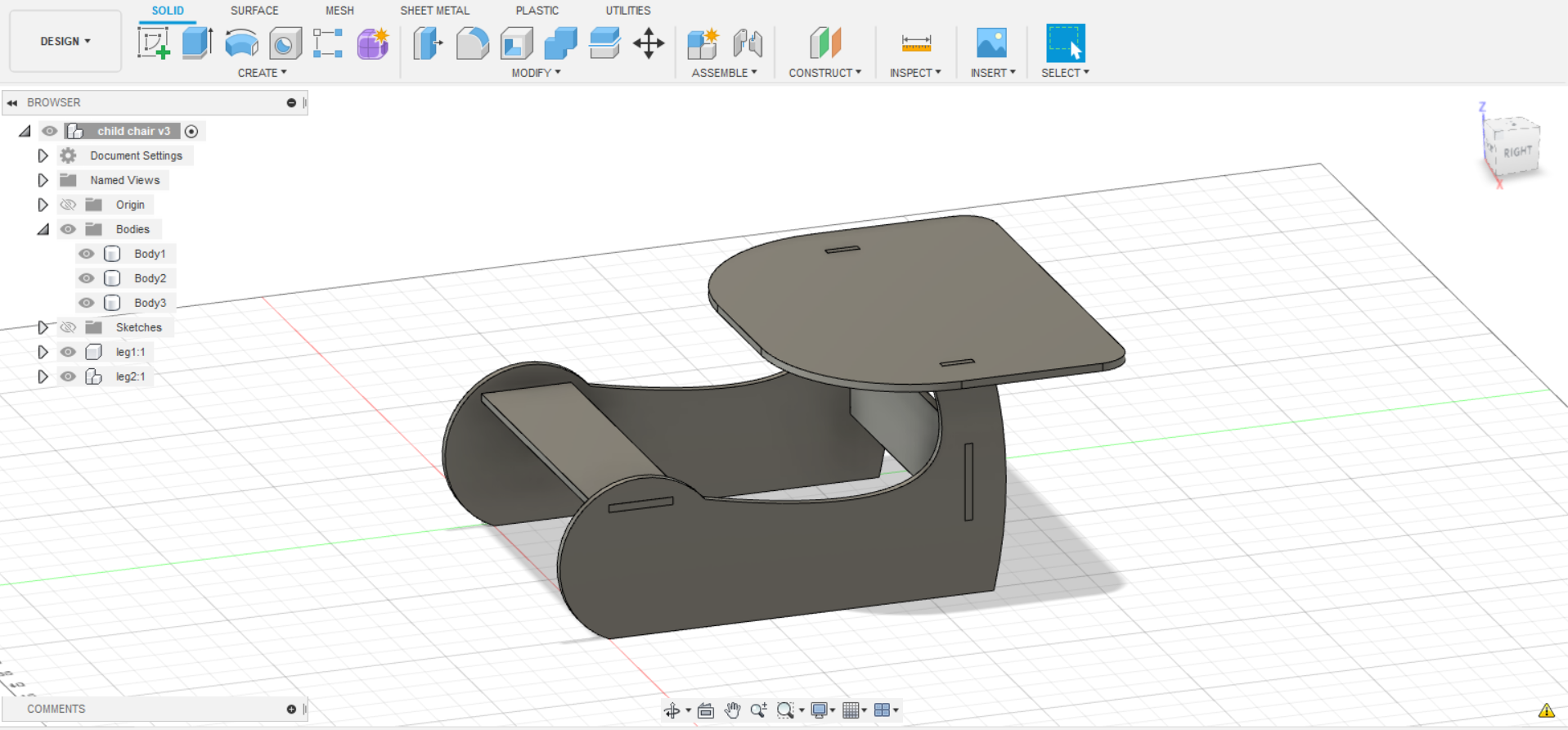

For the Individual assignment, we were asked to design and cut something that could be used by children which will be donated to the Charitable Society for Orphans. I decided to design a chair and a table as one block.

The design¶

I decided to design using fusion 360 for the entire design.

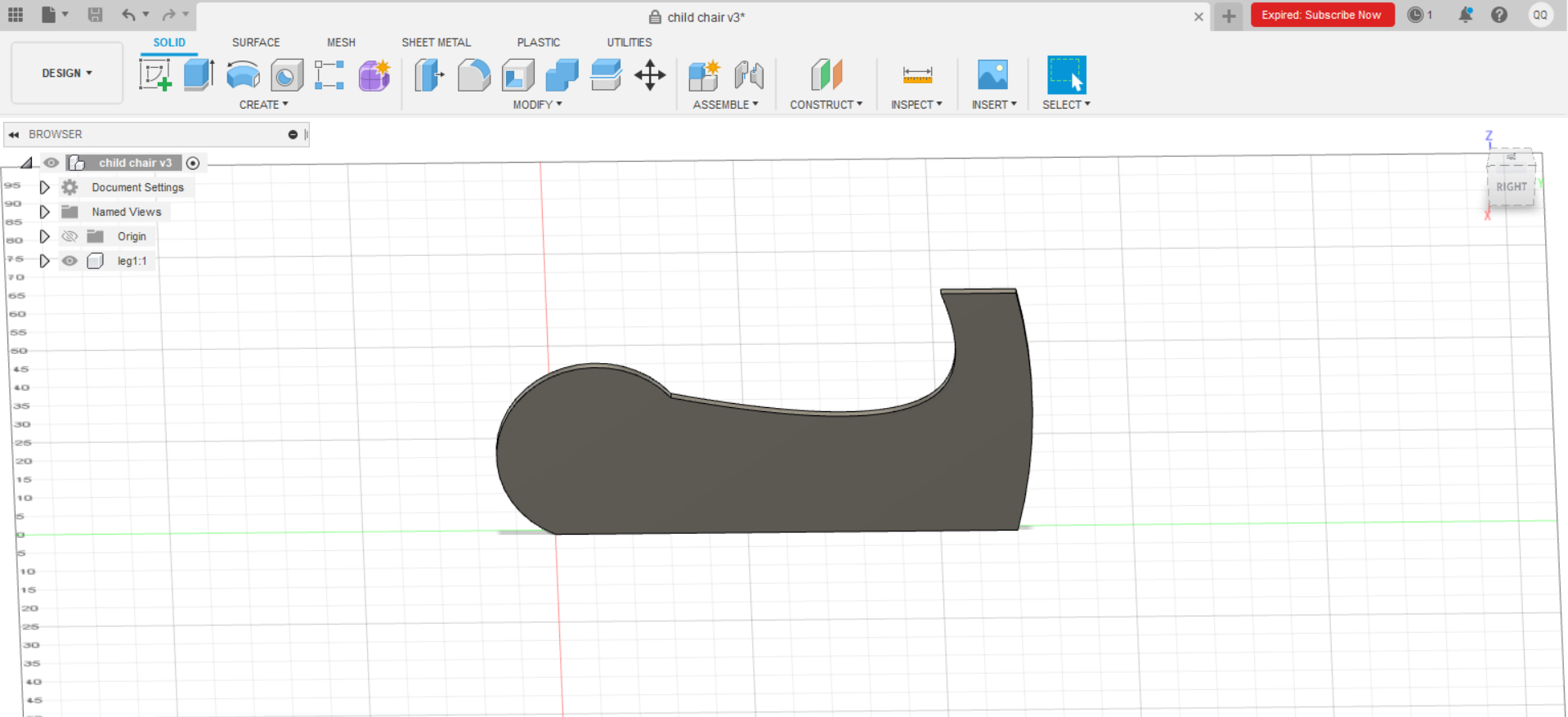

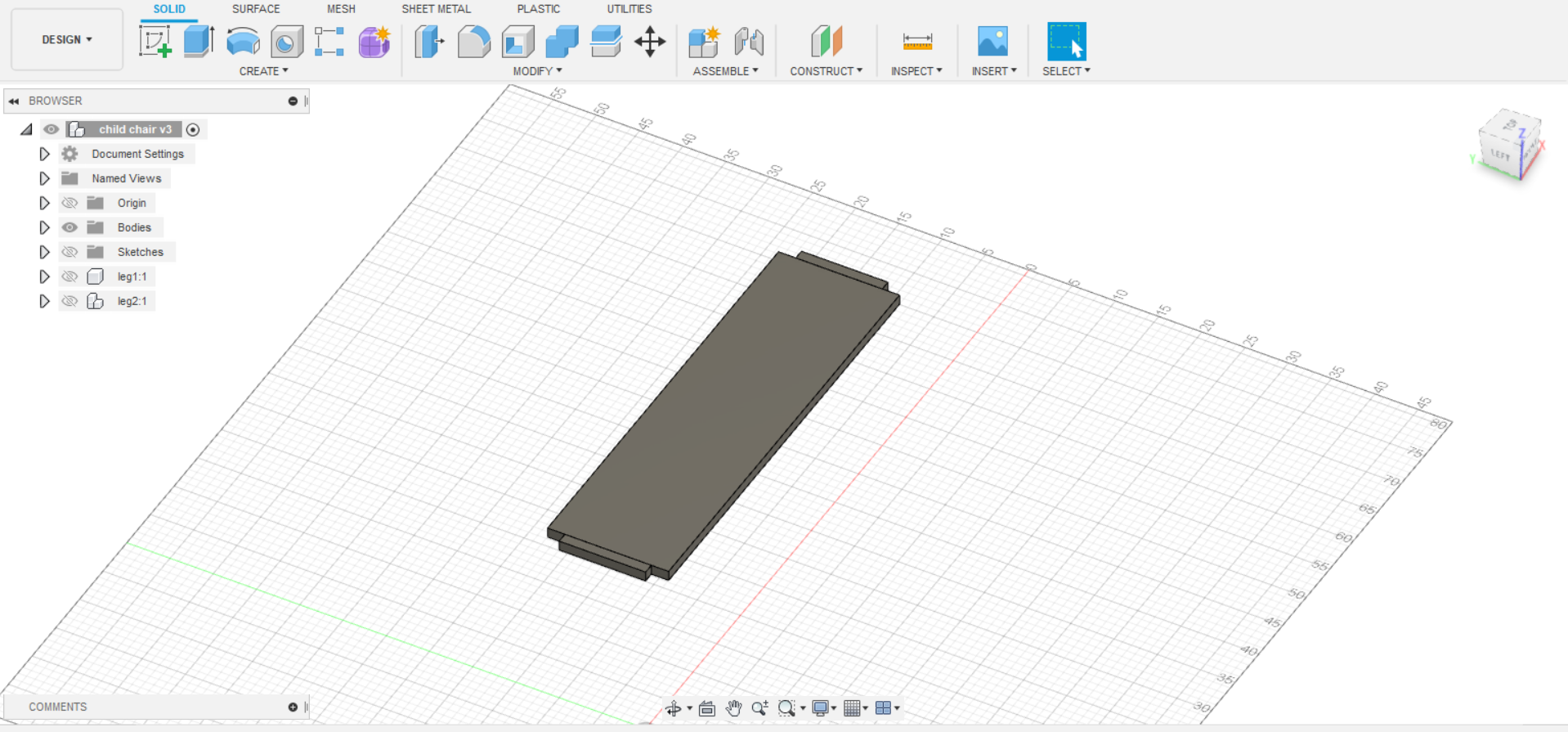

I started by creating a sketch of the first leg

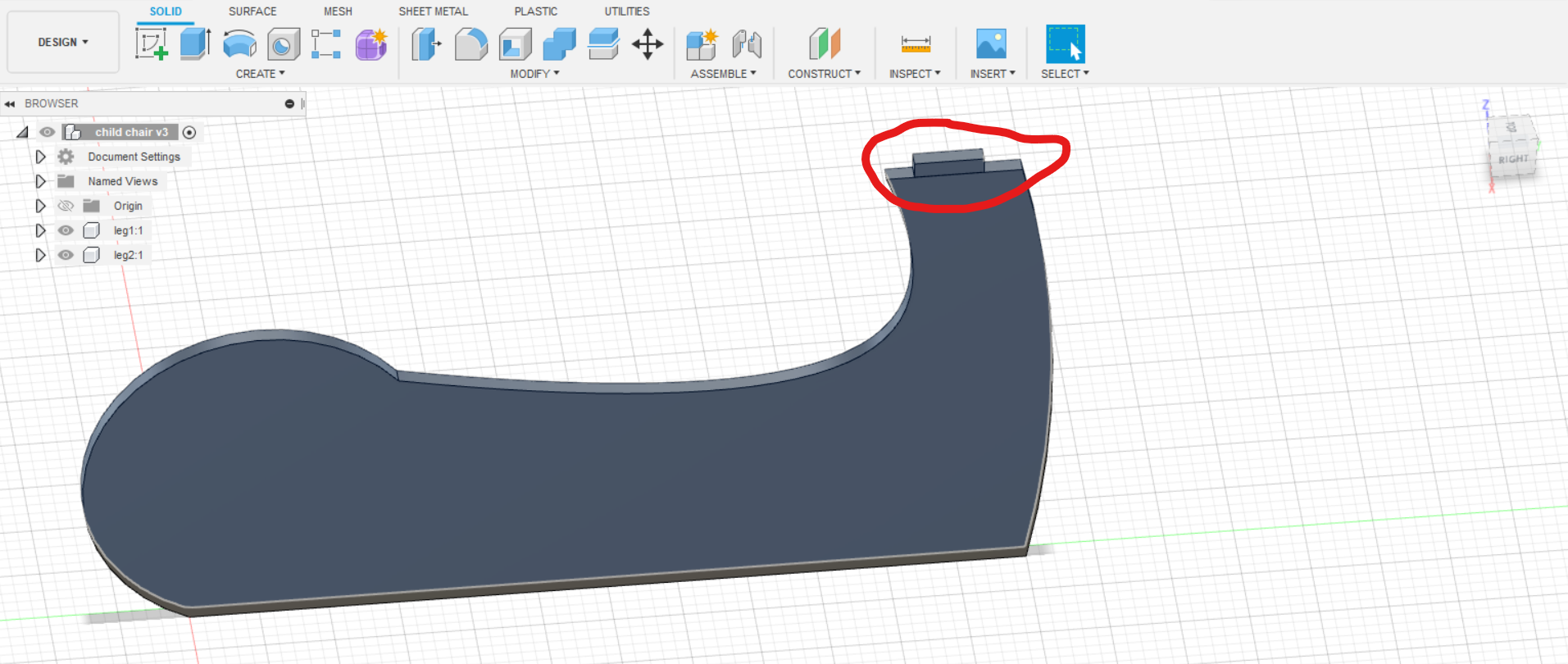

Then I created the first joint which will fit on the table

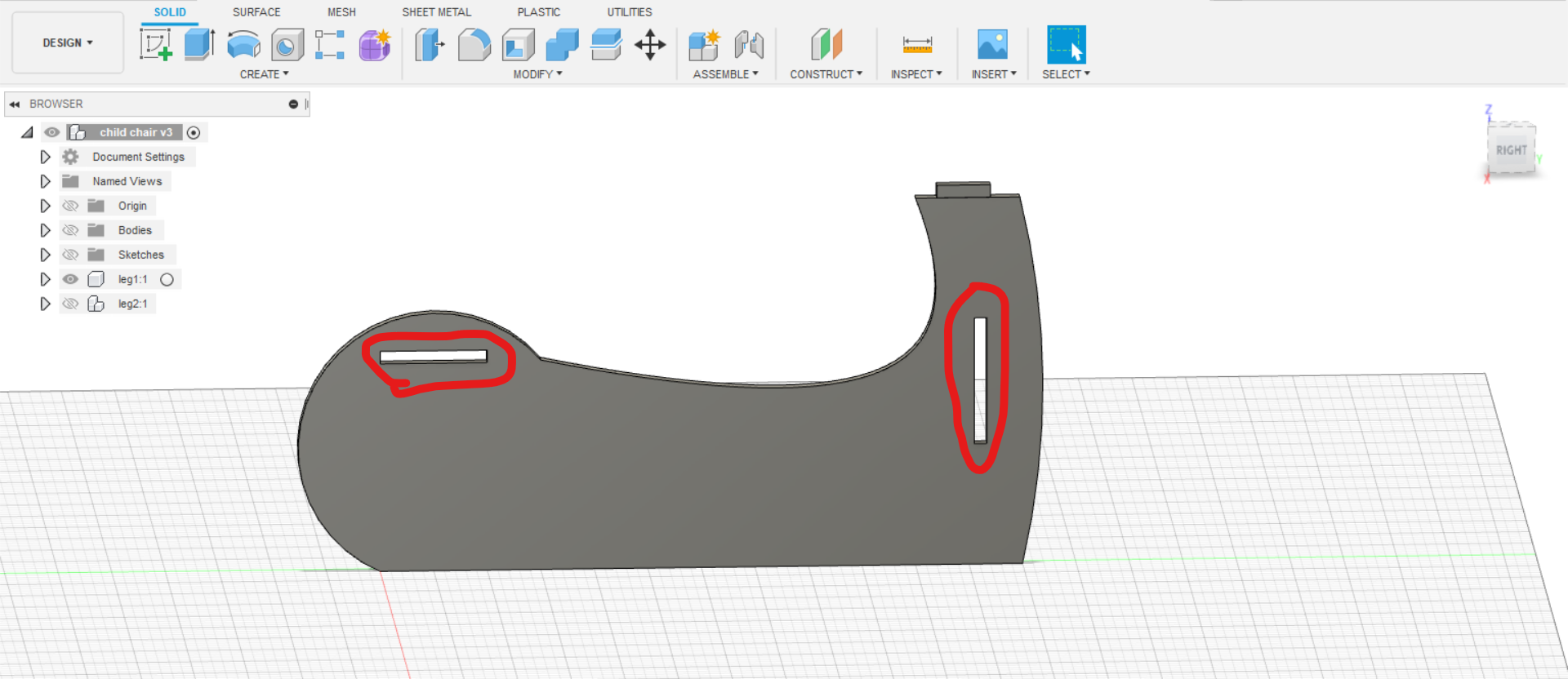

After that, I created two halls on the leg, the first one will fit with a chair, and the other will fit with the support.

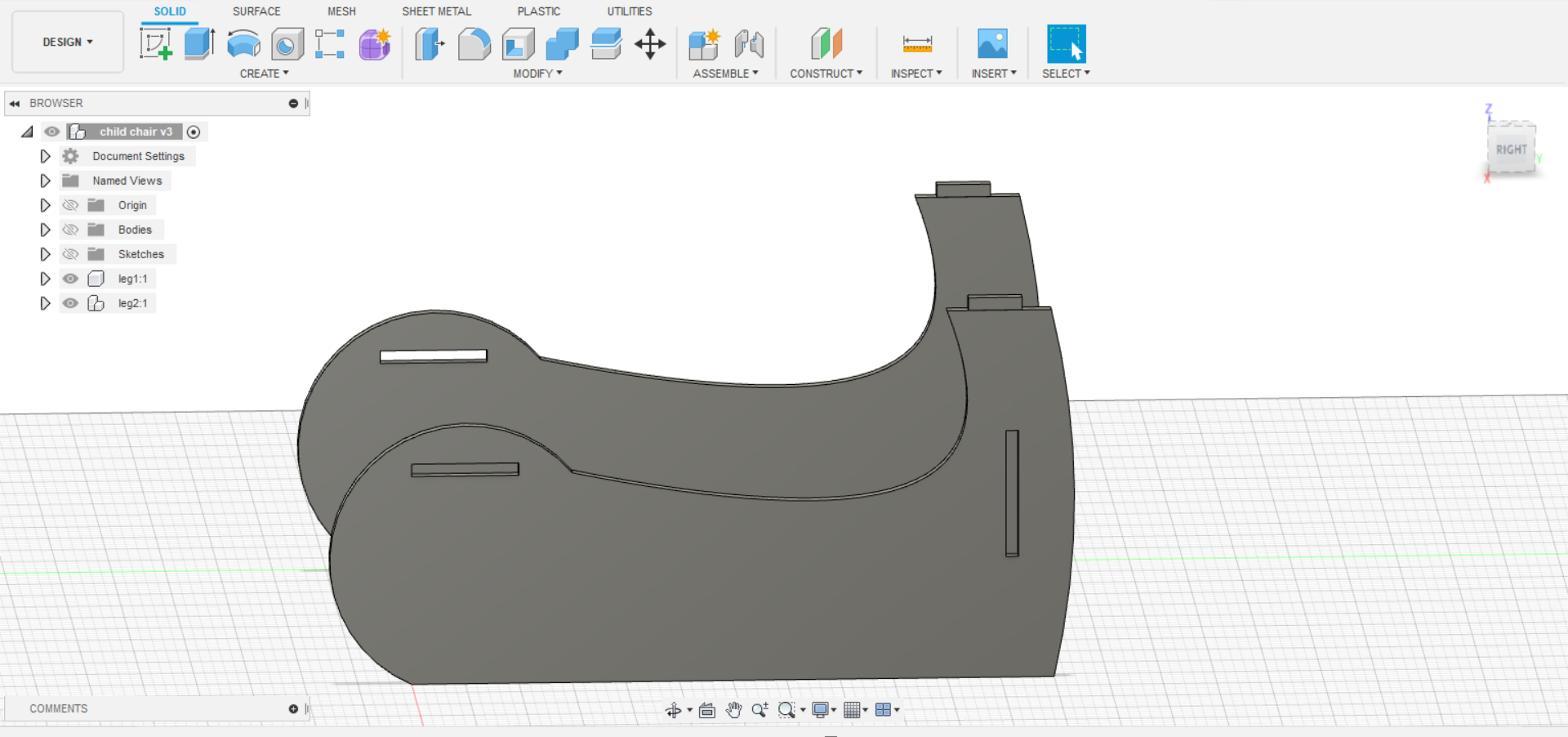

Then, I made a copy from the leg such that I have two legs.

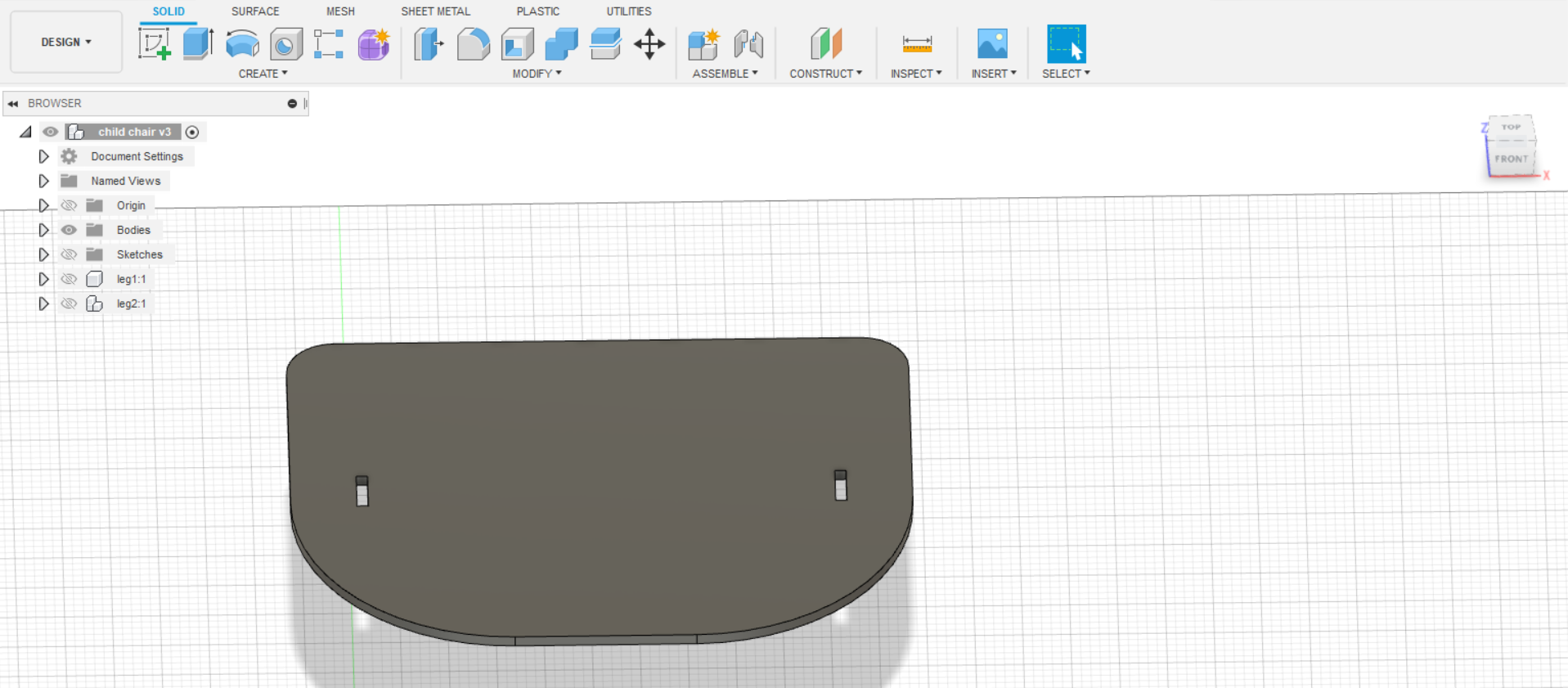

After that, I created this piece which is meant to be the chair and will fit with two legs

Then, I created a square that was meant to be the table and filled the edges, and made two holes in it to fit with two legs

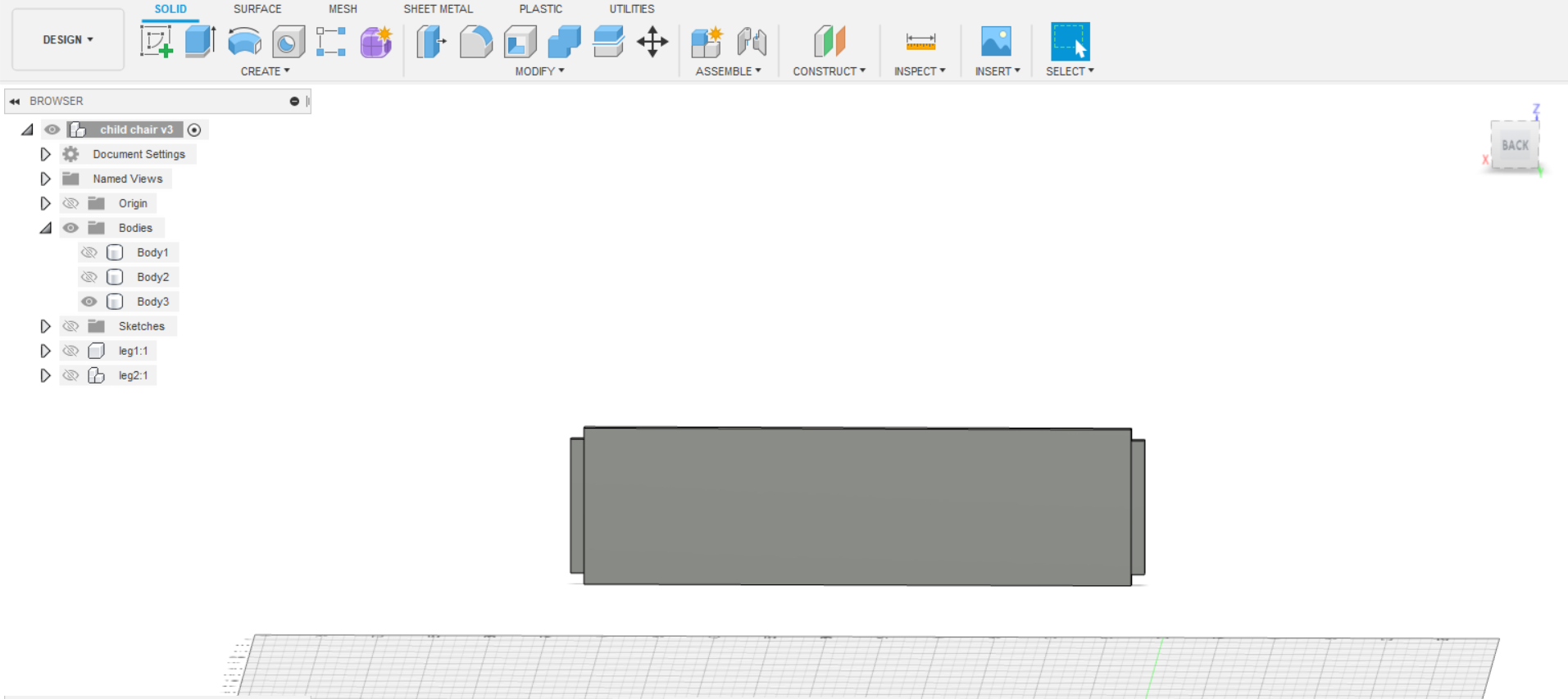

The final piece is the support that will hold and connect the two legs

Here how the final design looks like after combining the pieces together

Design files -Click here to download the legs design -Click here to download the support design -Click here to download the chair design -Click here to download the chair design -Click here to download the fusion360 file

CNC machine¶

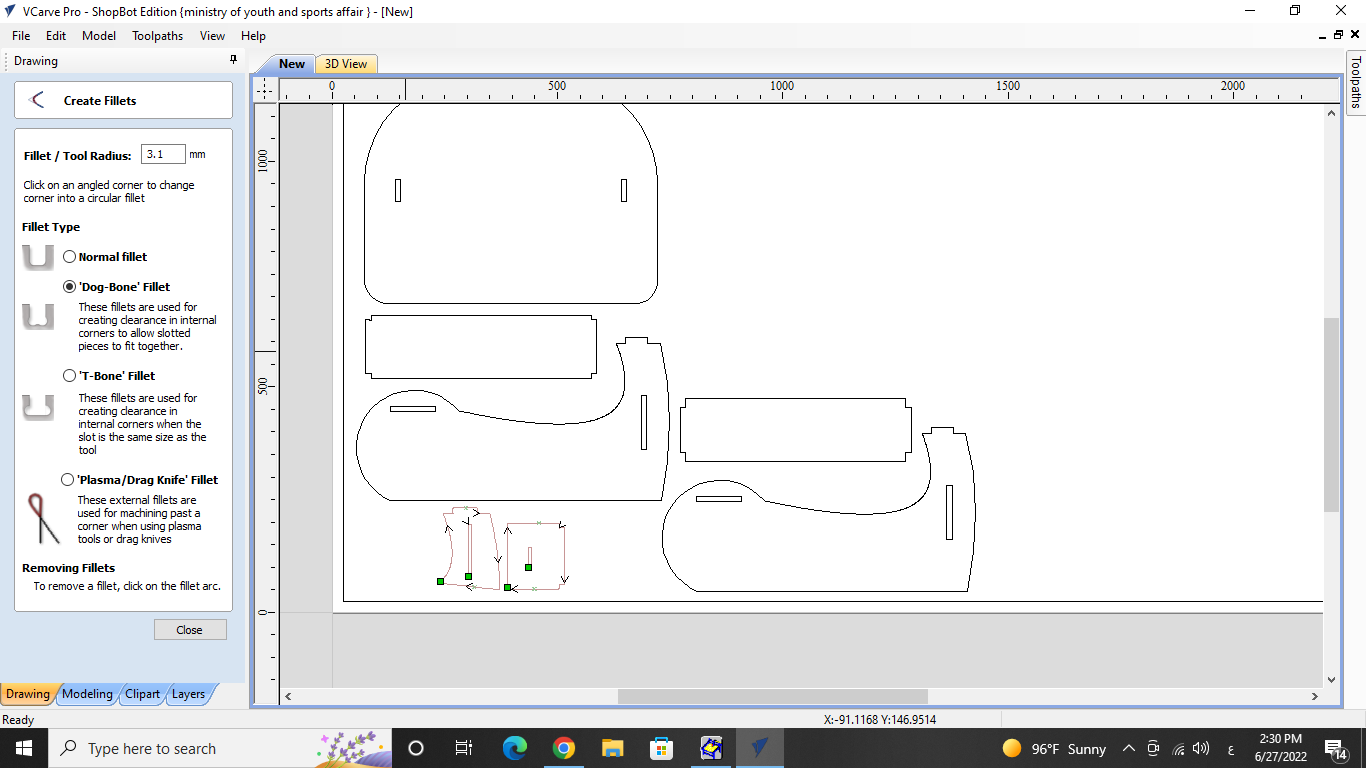

In order to speak with the machine, we should use a specific application called V curve which is already installed on the PC connected to the machine.

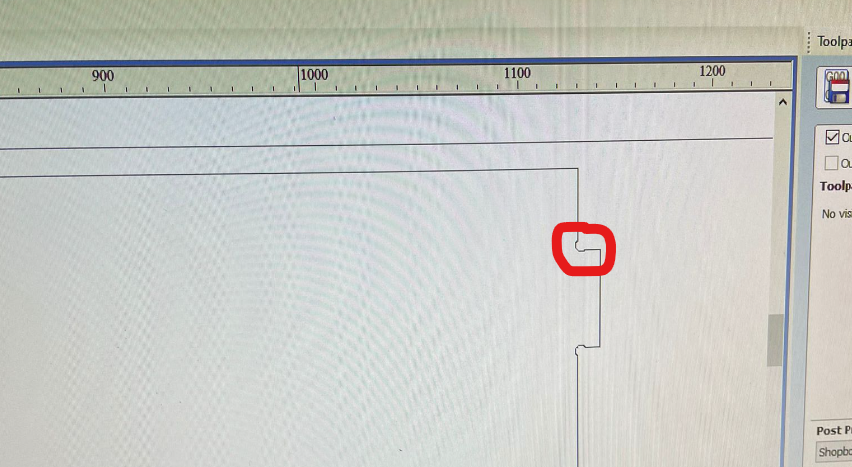

Firstly, we determine the dimensions of the piece of the wooden sheet (240x120m). Then, we import the files of the designs we created. Since the CNC machine cannot go to 90 degrees for the inner corner, So we will Change the joint type to a T-Bone fillet, and the outer corner Dog-Bone fillet as shown below.

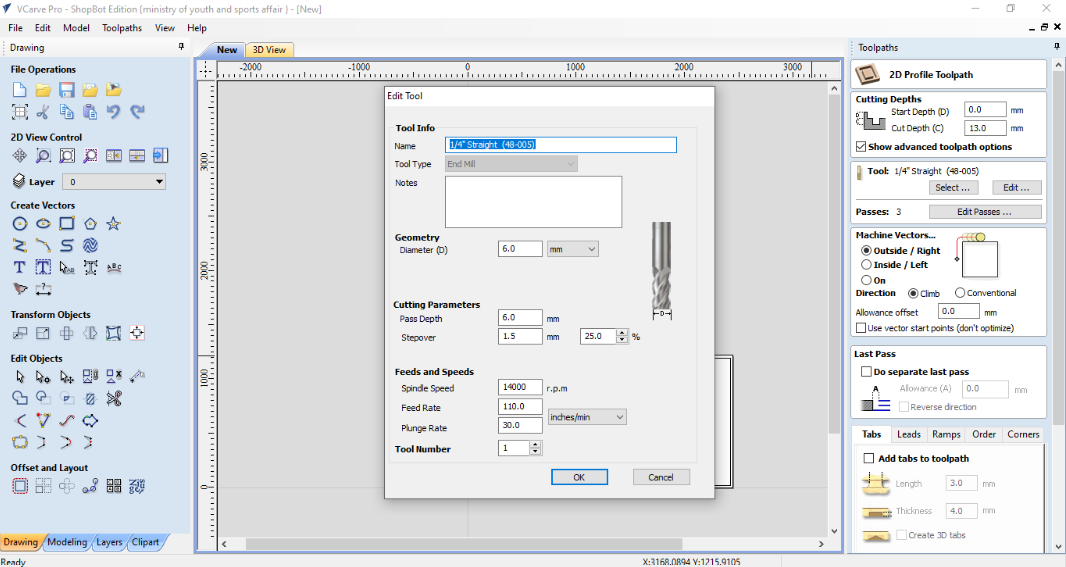

The settings of machine and the toolpath

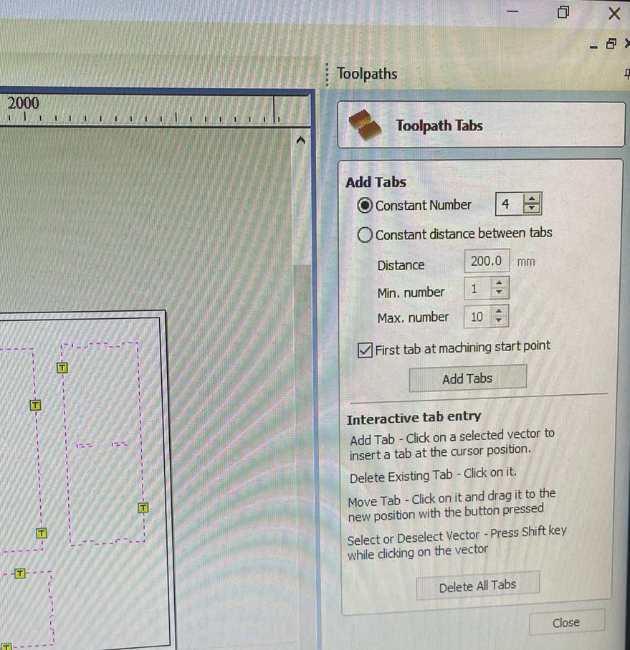

To ensure the part’s stability during cutting and to achieve the highest level of precision, these tabs are utilized as placements that are not cut along the toolpath. You may also change the parameter dimensions of the tabs.

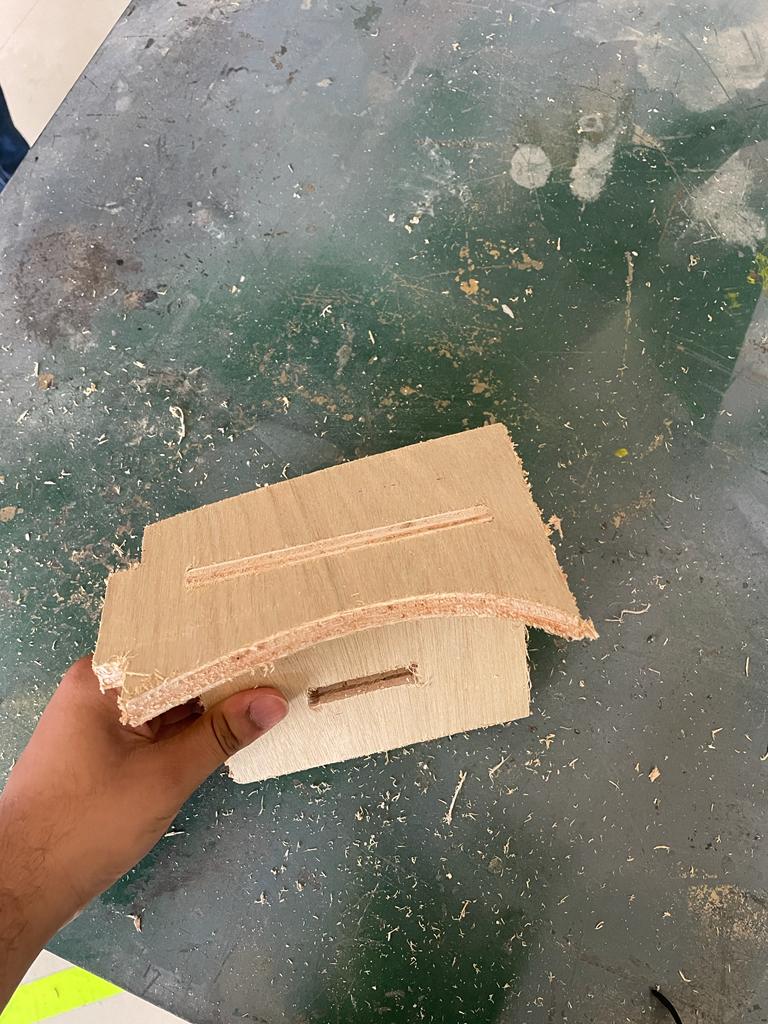

After That, we cut a small piece such that we can test the joints before cutting the hole design and waste the material if something goes wrong

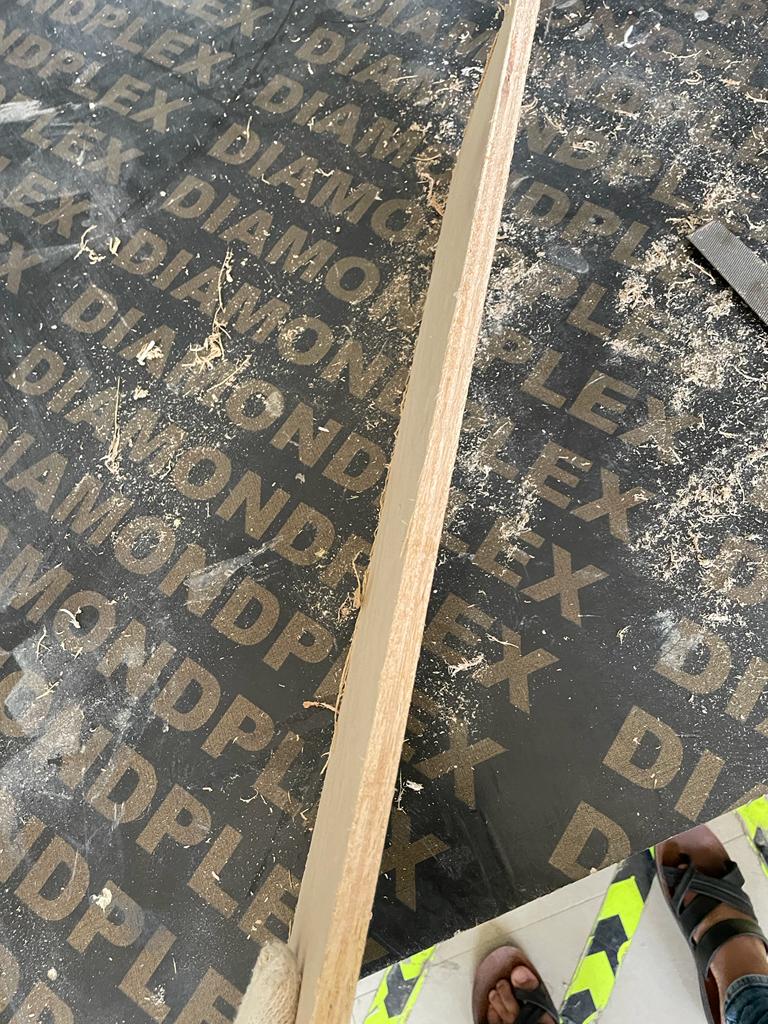

Then, we start cut the hall design.

Then, I started sanding the pieces using the below tools.

here is how it looks after sanding

Finally, it is time for combining these pieces together.

Heroshots¶