5. 3D printing and scanning¶

This week I started working on 3D printing and scanning.

What is 3D printing and scanning?¶

While 3D scanning is the process of scanning physical objects to create detailed, interactive digital models, 3D printing is the process of making three dimensional solid objects from those digital models.

Group Assignment.¶

In starting we start working in group to understand and work on 3D printing and scanning. from thingiverse we chose our object and we start printing.

What i have learned.¶

before working on 3d printers i had no idea about 3d printers. Using and testing 3D printers helped me to understande the working way of 3D printers, how we can use them how we can over come on any problem we face etc.

Key settings¶

The key settings of the machine are Always stick to the temperature mentioned by the manufacturer to avoid print fails and/or nozzle clogging, in my case, the nozzle temperature should be between 190-210 Celsius and the heated bed temperature should be between 60-70 Celsius.

Quility metrics.¶

I refer that the quility has involved tolerances. These tolerances are determined by two factors: the height of each layer and the diameter of the nozzle being used. The smaller the nozzle and the lower the layer height, the higher the quality.

Performace of differnt 3d printers.¶

To find out the performance of different 3d printers my suggestion is to the most effective thing is speed and time of any 3d printer.

Individual Assignment.¶

After compleating our group assignment i start working on individual Assignment. The task was to creat any 3D object and print it on 3D printing machine.For creating 3D object we can use any online tool or a software and also we can get any ready object from thingiverse for printing on 3D machine.

My 3D object.¶

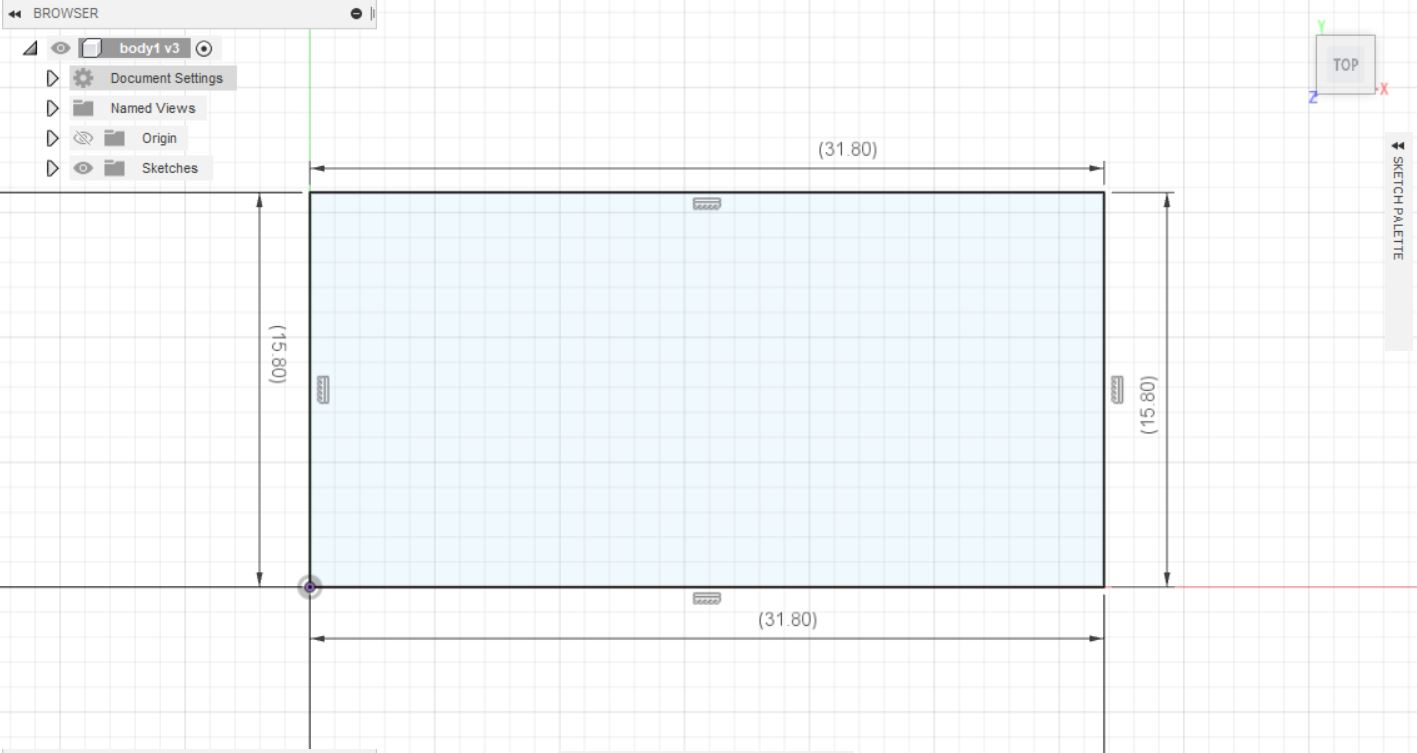

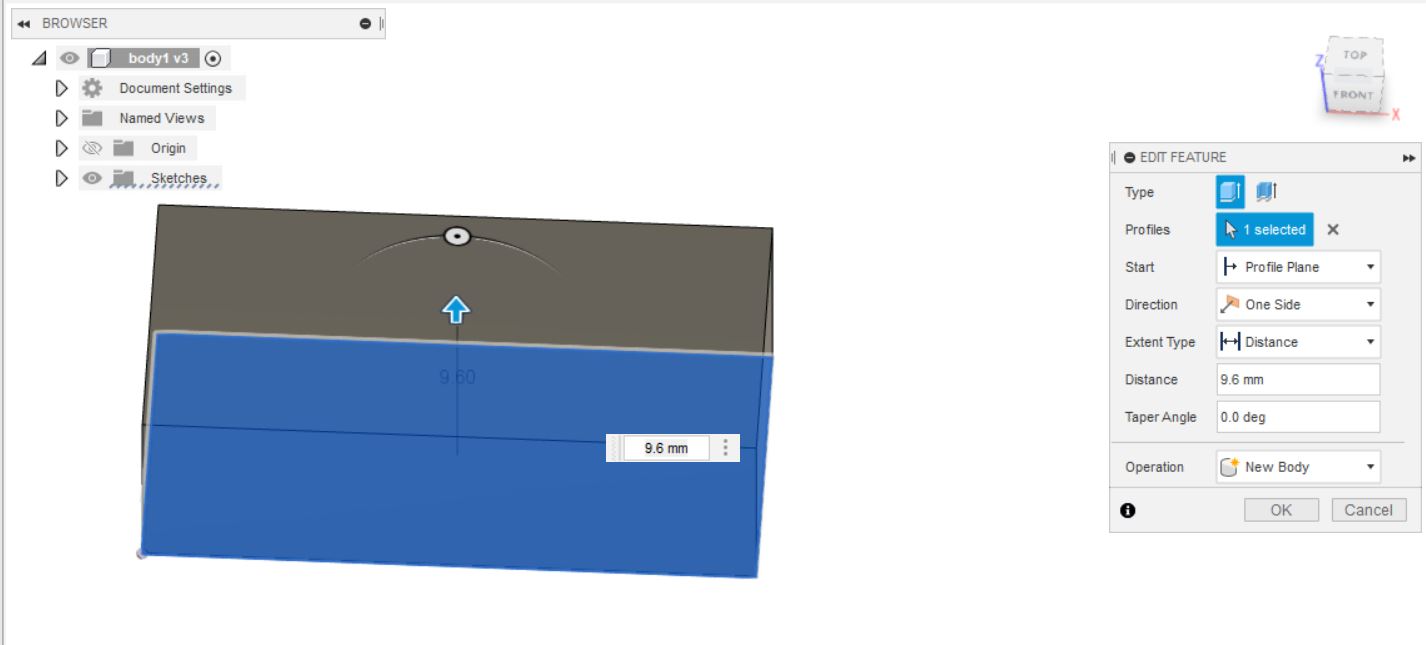

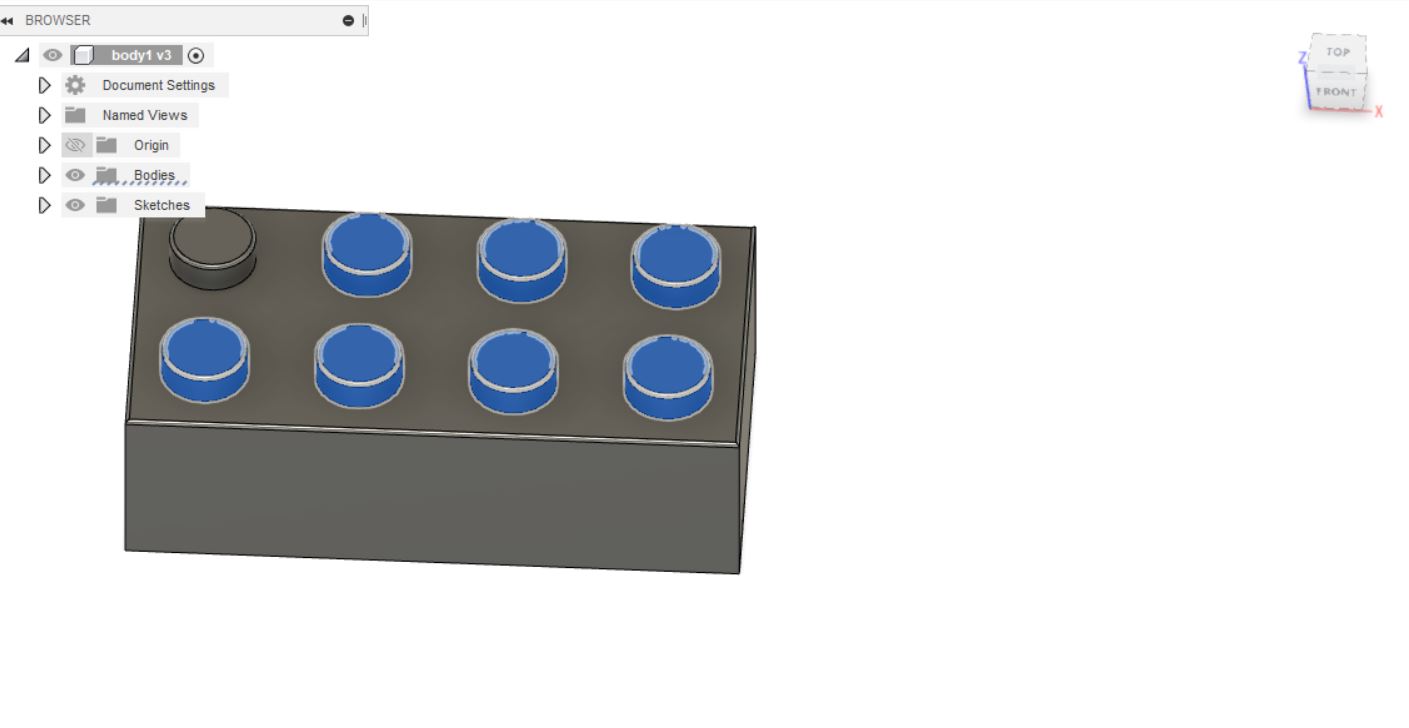

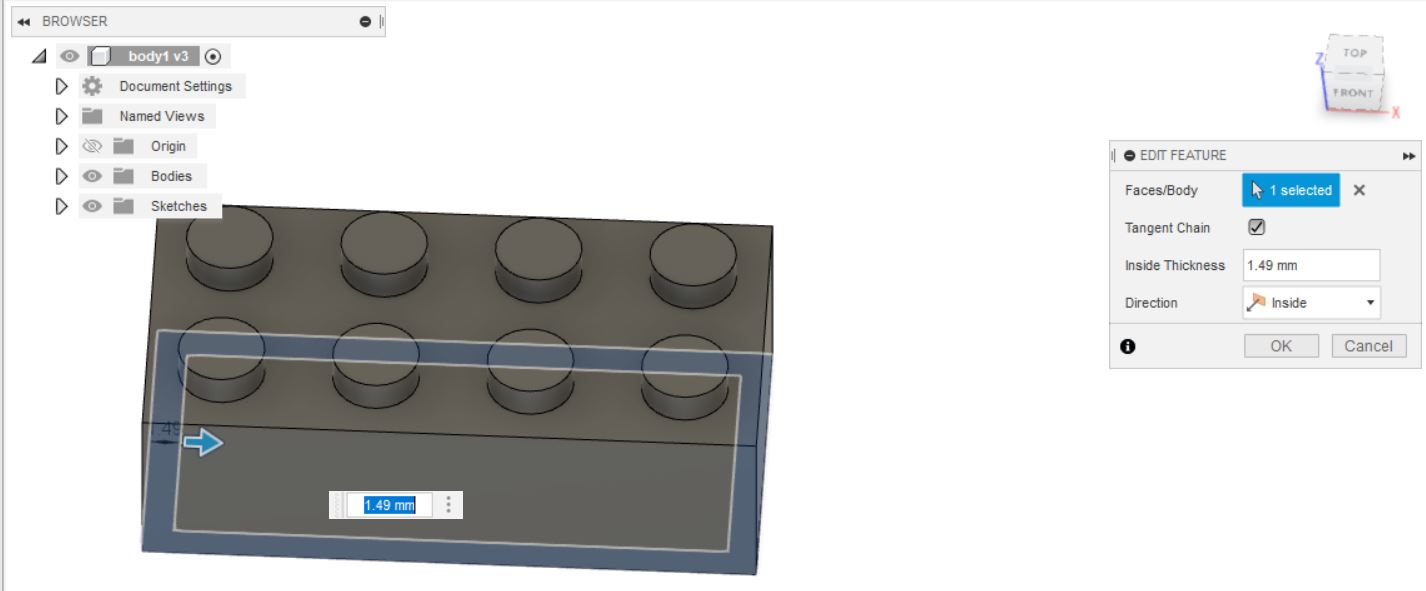

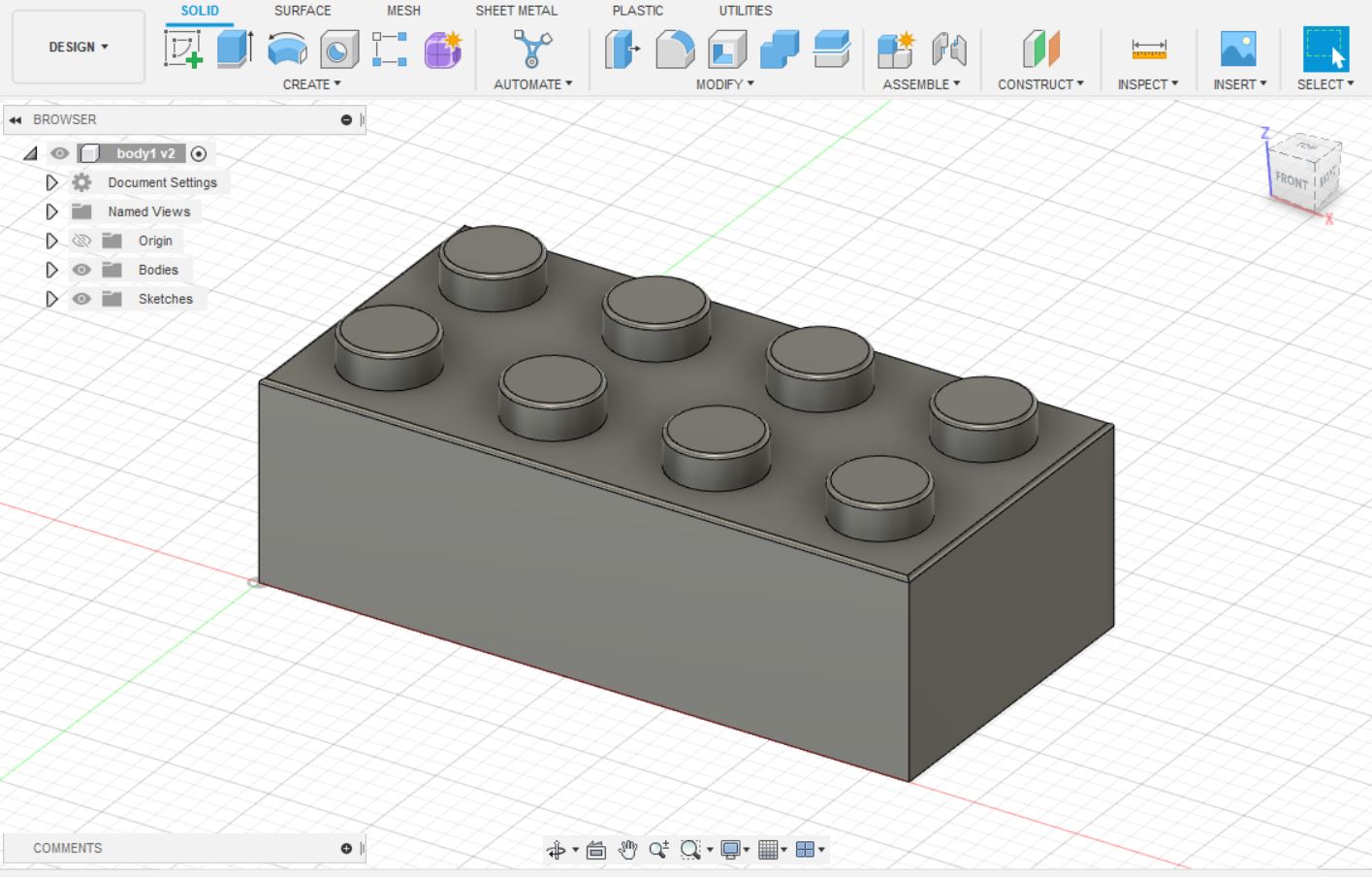

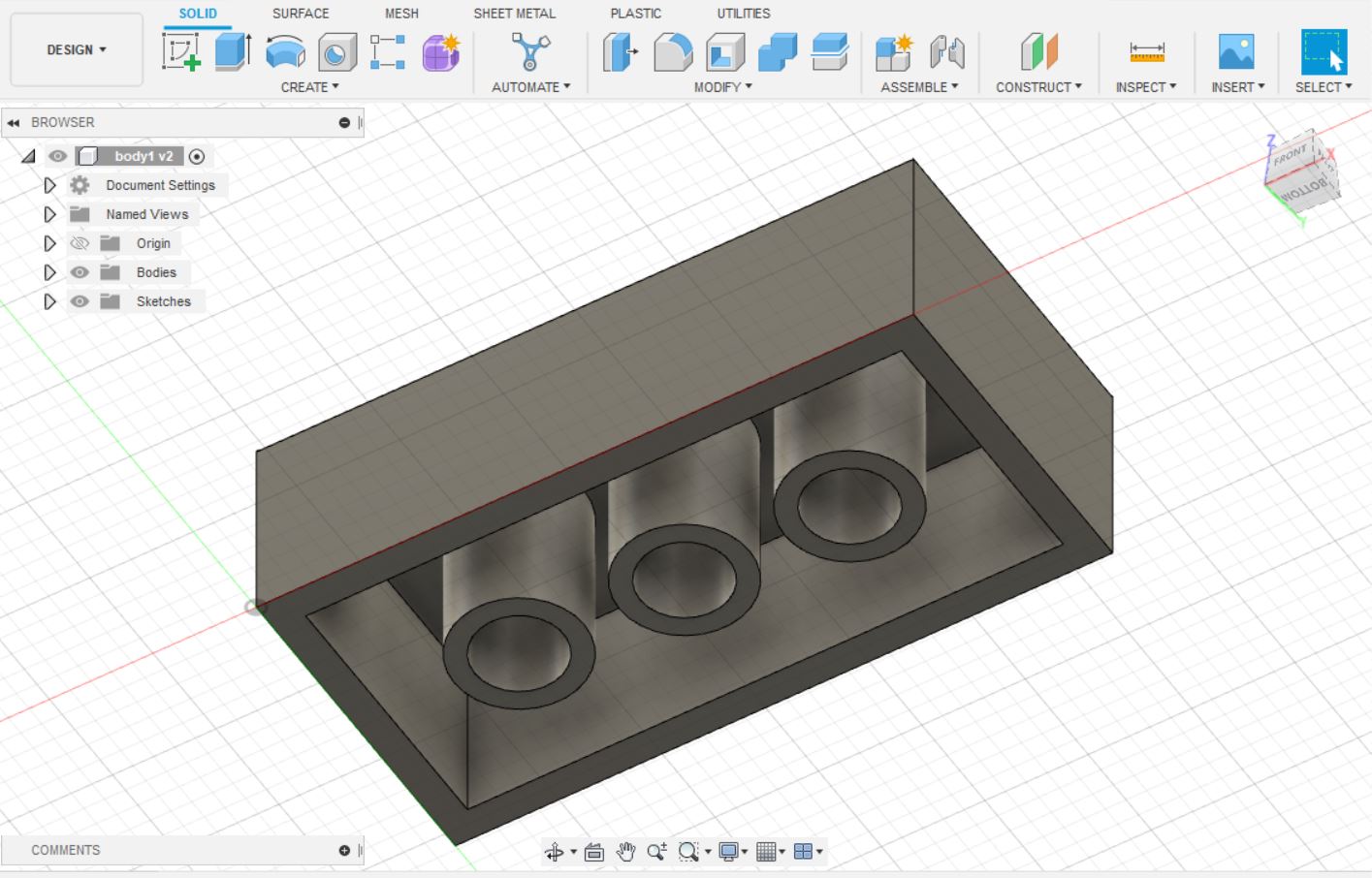

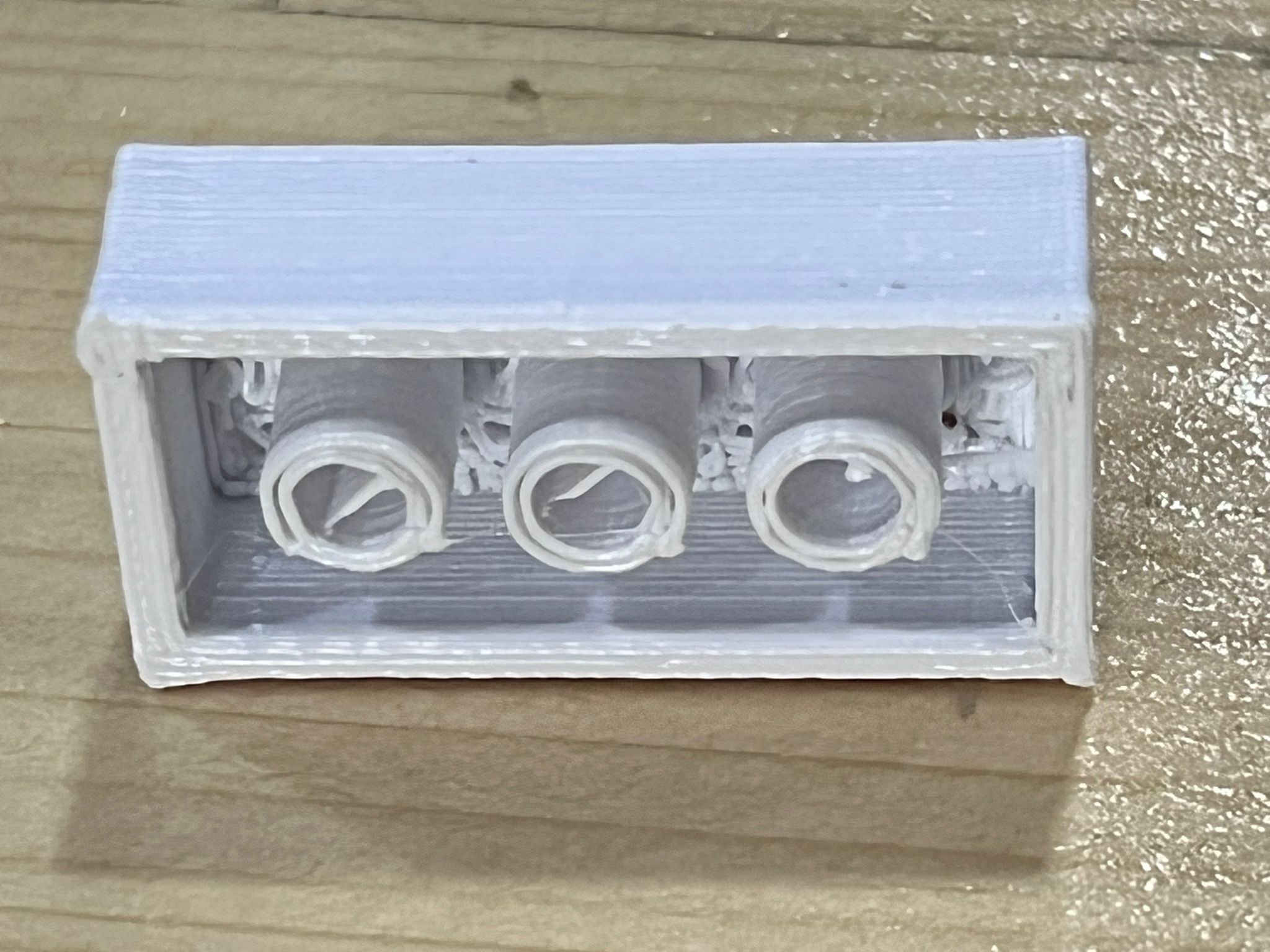

I start working on fusion 360 to create a 3D oject for printing on 3D machine. I created a toy block using fusion 360 by following a youtube toturial. As we can see the process in the pictures shown below.

- I started to create sketch of the object with random parameters and then extruded the object and then i created the joints on top and bottom. It could not be easily made subtractively because it has overhangs, nested parts, meshes as we can see in pictures shown below.

Why this was not easy to made?¶

As it has holes and adges and buttons this was bit hard for me to create so this took lot of my time after watching soo many toturials i was able to do it.

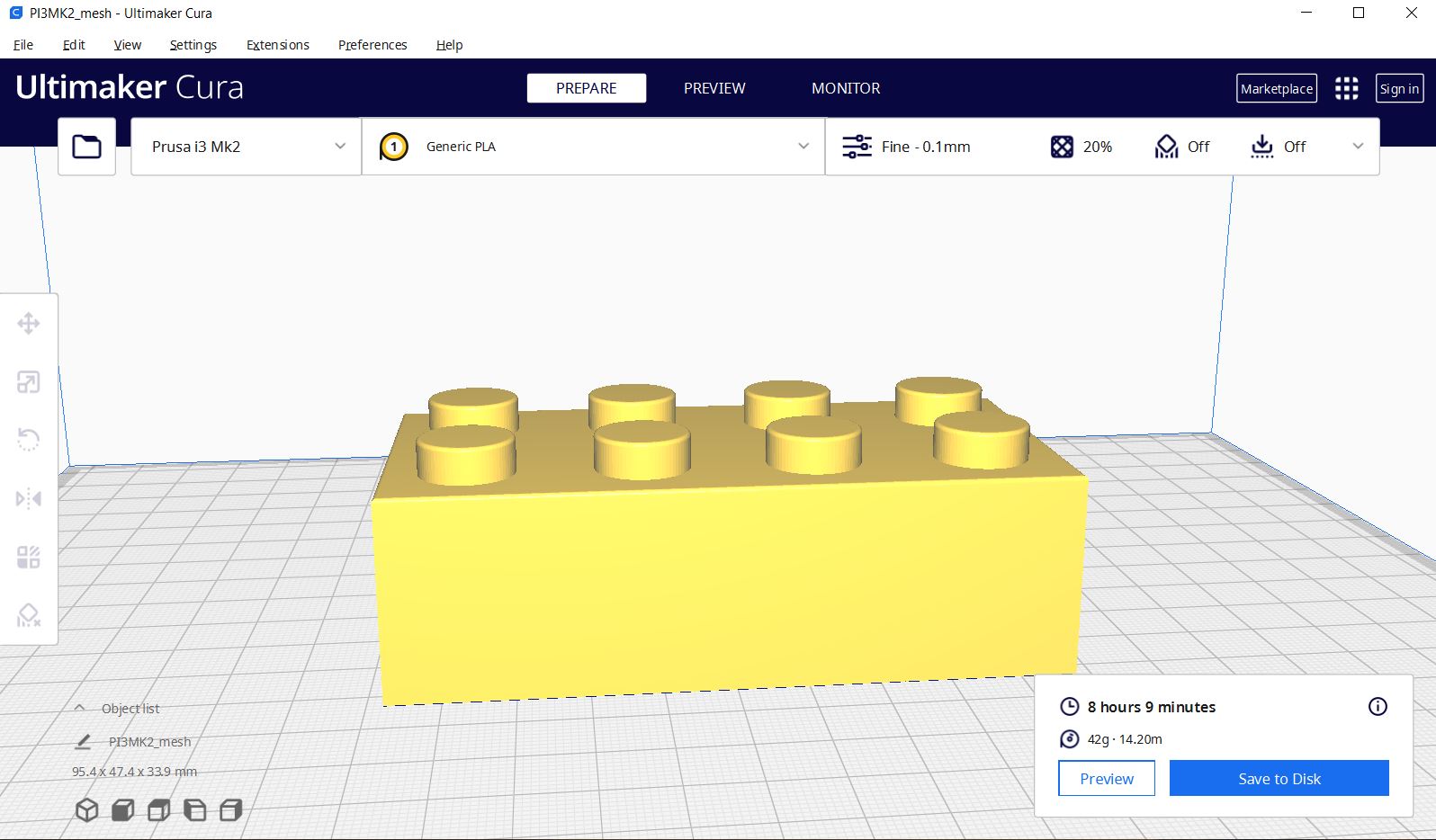

Ultimaker Cura.¶

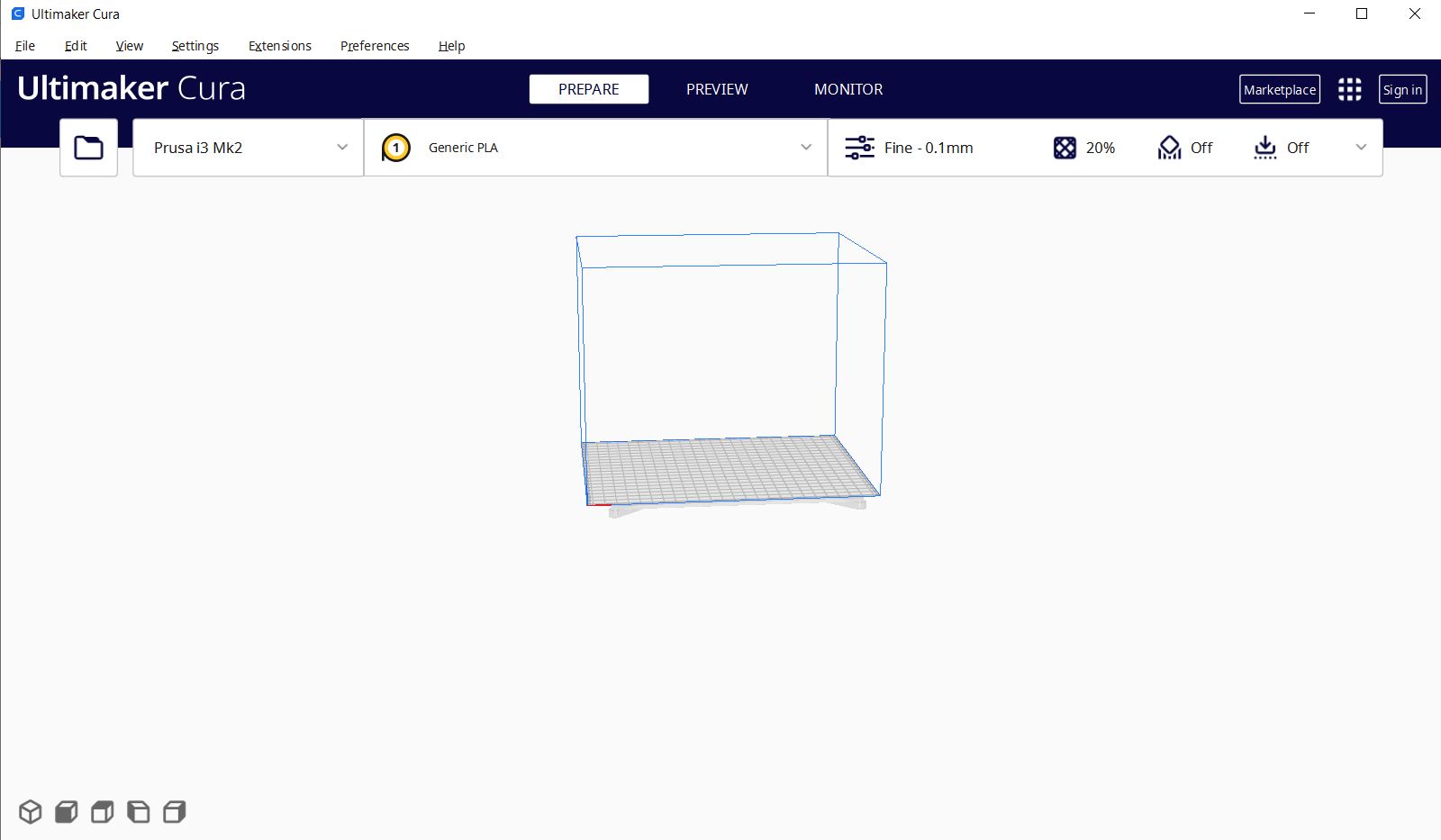

Ultimaker Cura is the world’s most popular 3D printing software. Prepare prints with a few clicks, integrate with CAD software for an easier workflow, or dive into custom settings for in-depth control. It was created by David Braam who was later employed by Ultimaker, a 3D printer manufacturing company, to maintain the software.

Downloading Ultimaker Cura.¶

After finishing my 3D ojbect shape in fusion 360 i start to [download] (https://ultimaker.com/software/ultimaker-cura) Ultimaker Cura which is open source slicing application for 3D printers in which i will modify my object for 3D printing and i will send the object to 3D printing machine.

Generating Files.¶

After compleating the 3d object i started to generate file for printing in 3D.It was easy to generate my files as one of our instructor thout me the process and easy ways.

Using Ultimaker Cura.¶

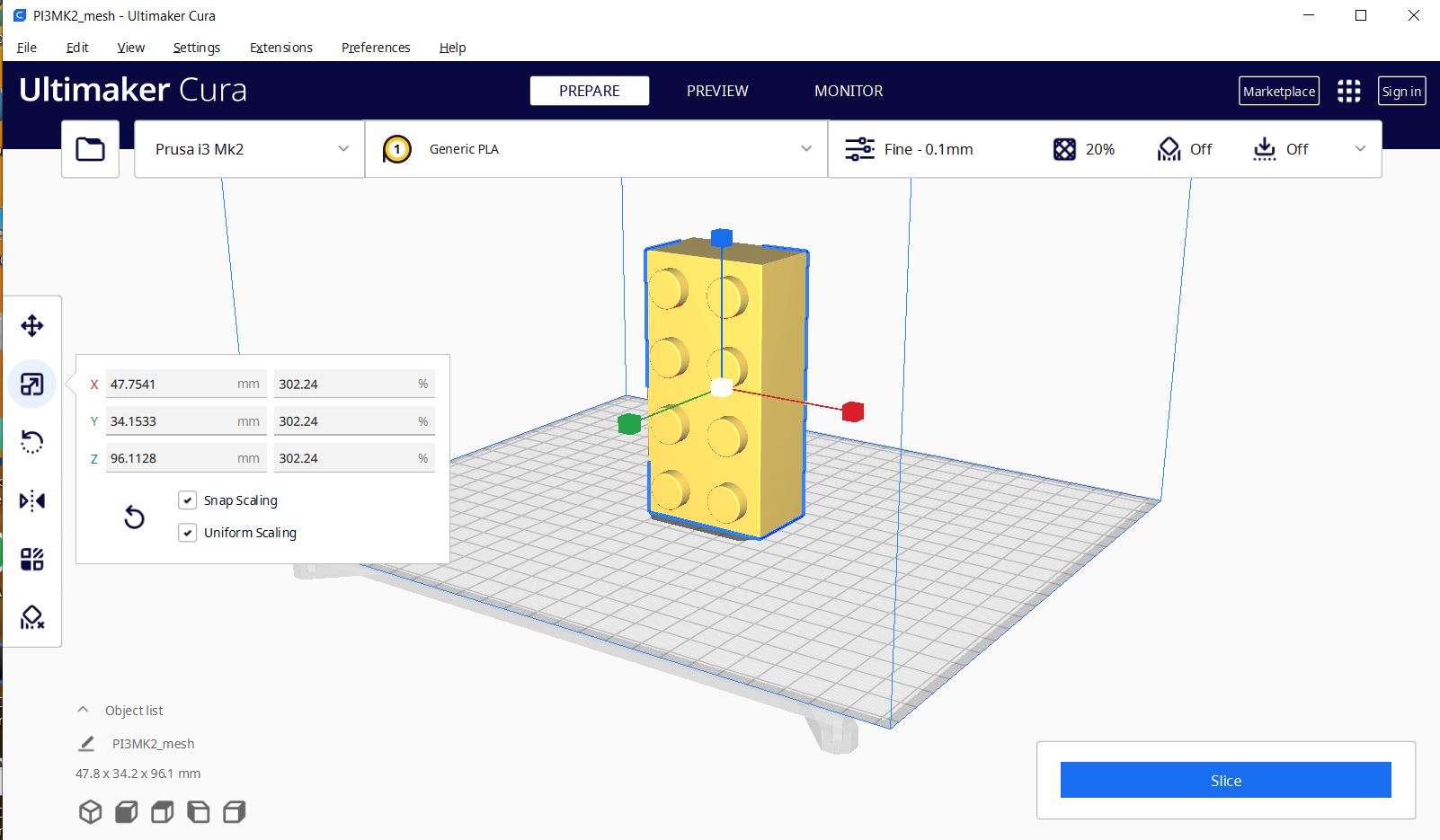

After Completing my object in fusion 360 i saved my object as mesh (stl) file and then i uploded my file on Ultimaker Cura to modify 3D ojbect and its Dimensions According to 3D printers which i am goning to use for 3D printing.

3D Printer.¶

3D printers are additive manufacturing machines that specialize in making custom parts with accuracy. As the name suggests, 3D printers add material, layer-by-layer, to form a 3D object.

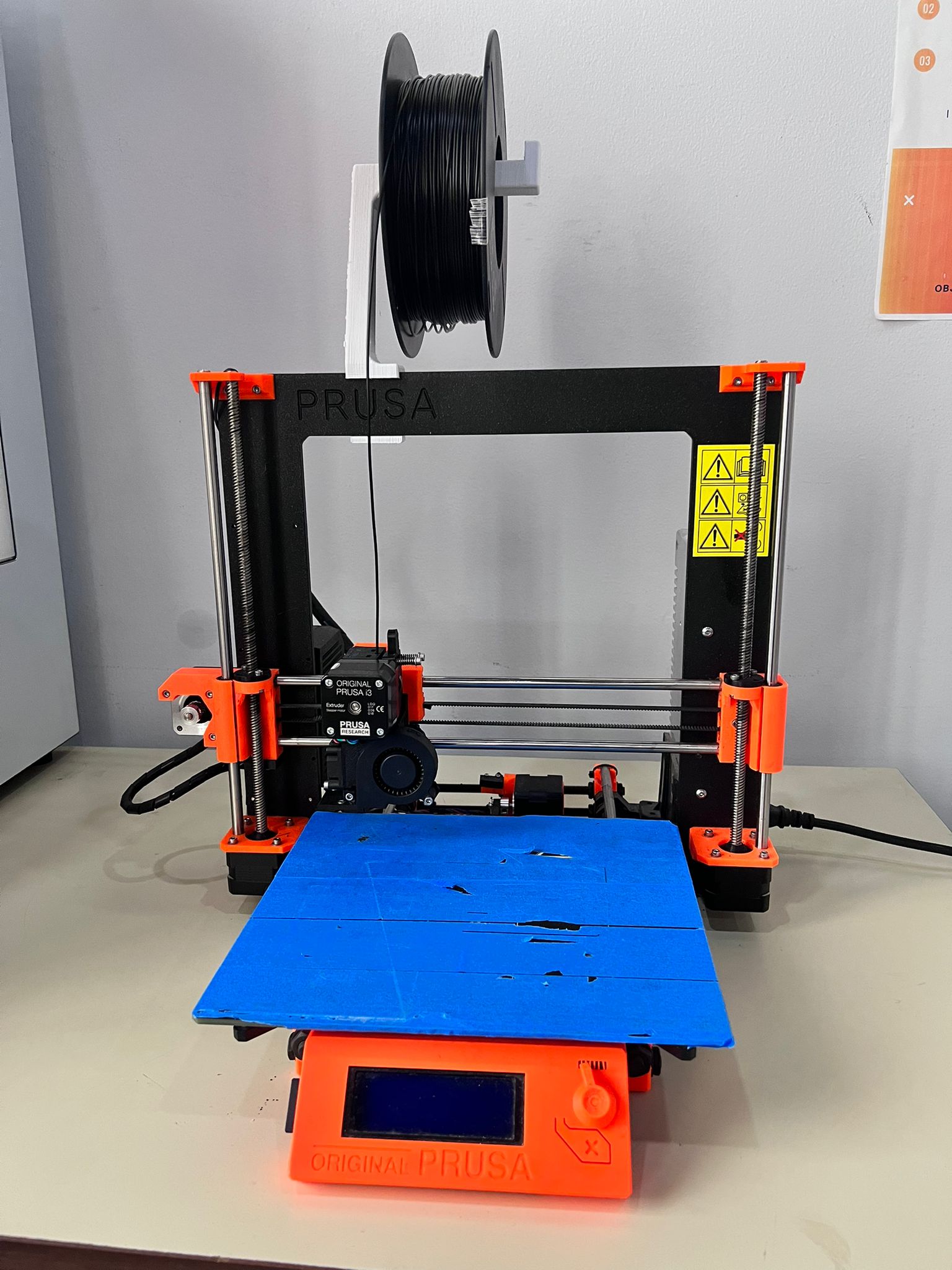

MakerBot and Prusa i3 3D printers.¶

In fab lab Bahrain we have these two kind of printers.and we started using Prusa i3 3D printer to print our 3d object.

Prusa i3 3D printer.¶

MakerBot 3D printer.¶

What is a GCODE file?¶

A GCODE file contains commands in G-Code, which is a language used to describe how a 3D printer should print a job. It stores instructions in plain text with each line representing a different command, such as how fast the printer should print, the temperature it should be set at, and where the printing parts should move. GCODE files are created by slicing programs, such as Simplify3D and Slic3r, that translate CAD drawings into G-Code, which a 3D printer can read.

Other 3 axis machine.¶

I have used also some other machines for some other designs like CNC but i cant use those machines for my current design as it has adges corners deep inside shapes.

Generating files for 3d.¶

- Saving file in Gcode. After completing on Ultimaker Cura i saved my file in gcode format.A GCODE file contains commands in G-Code, which is a language used to describe how a 3D printer should print a job.The most important thing is we cant print the file without adjustment as we need to declear the zone x y and z axis to print it succesfully with a nice result.

Sending my file to makerbot Printer.¶

After saving my file in Gcode format i sent the file to makerbot Printer where i set the setting of printer according to my object and and printer started printing the object.

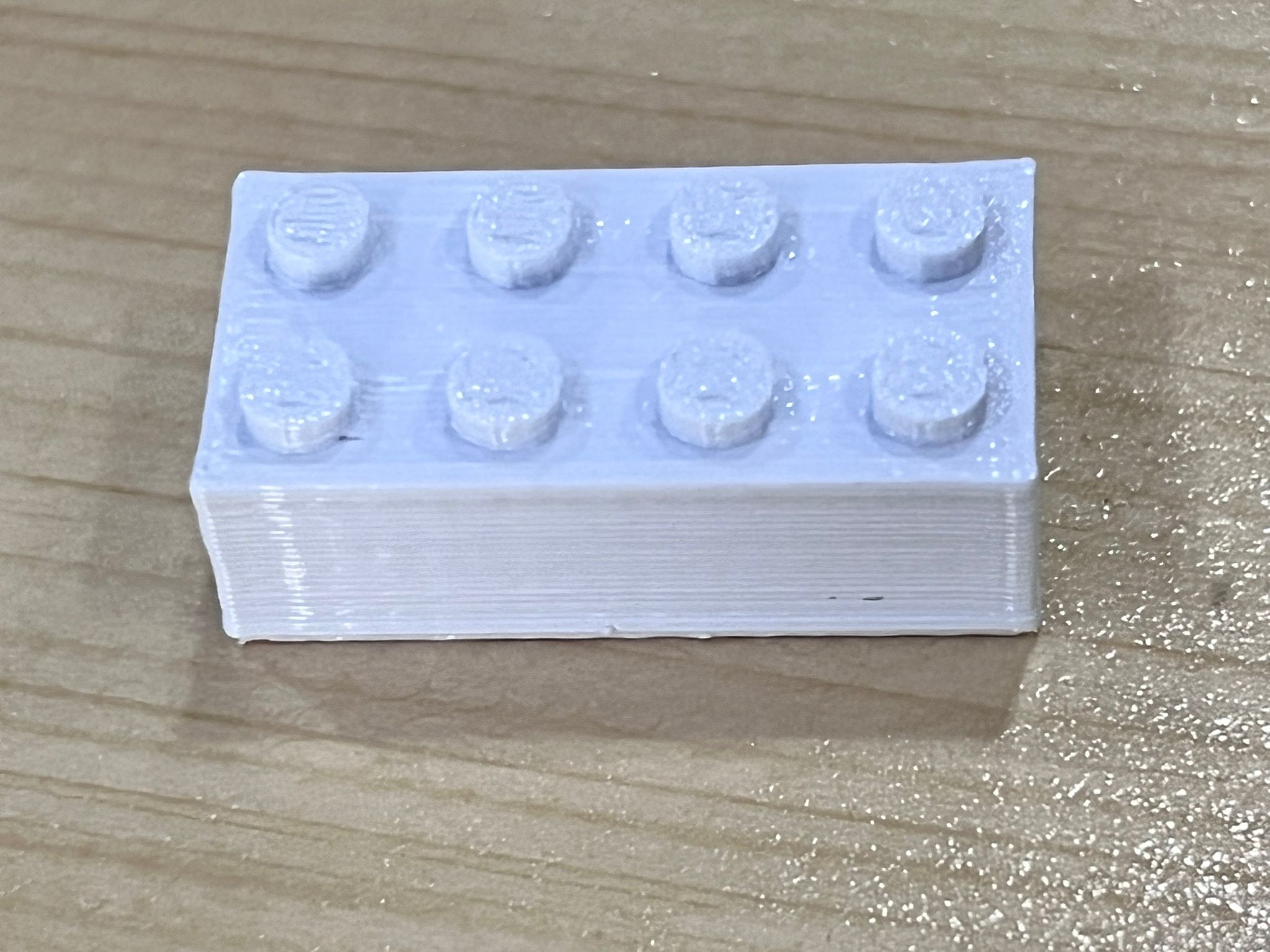

Final result.¶

Remarks.¶

I had no idea about 3D printers and printing befor i start working on this assignment after working and compleating this assignment i got new skilss with 3D printing and according to my experiance MakerBot 3D printer is better then Prusa i3 3D printer because its easy to setuo and use. - Note 3D cannot be printed without any adjustments as it needs a spasific area to print.

3D Scanning.¶

This week we also started working on 3D Scanning.

What is 3D Scanning?¶

3D scanning is the process of analyzing a real-world object or environment to collect data on its shape and possibly its appearance. The collected data can then be used to construct digital 3D models. A 3D scanner can be based on many different technologies, each with its own limitations, advantages and costs.

3D scanning softwares.¶

There are many 3D scanning softwares and online tools.I started working on two different 3D Scanning Softwares. The first one i satrted working on it was Qlone and trnio plus.

Qlone¶

Qlone is an all-in-one 3D scanner app.This is free and easily availible on app store. It easy and fast to create 3D models from real objects, edit them with built-in editing tools and seamlessly export the result to popular platforms, 3D file formats and 3D printers.

Trnio plus¶

TRNIO [turn-knee-o] converts photos on your Phone into 3D models! Trnio makes your Phone to into a high-quality 3D scanner and convert your images into high-quality scans and its easily availible on app store.

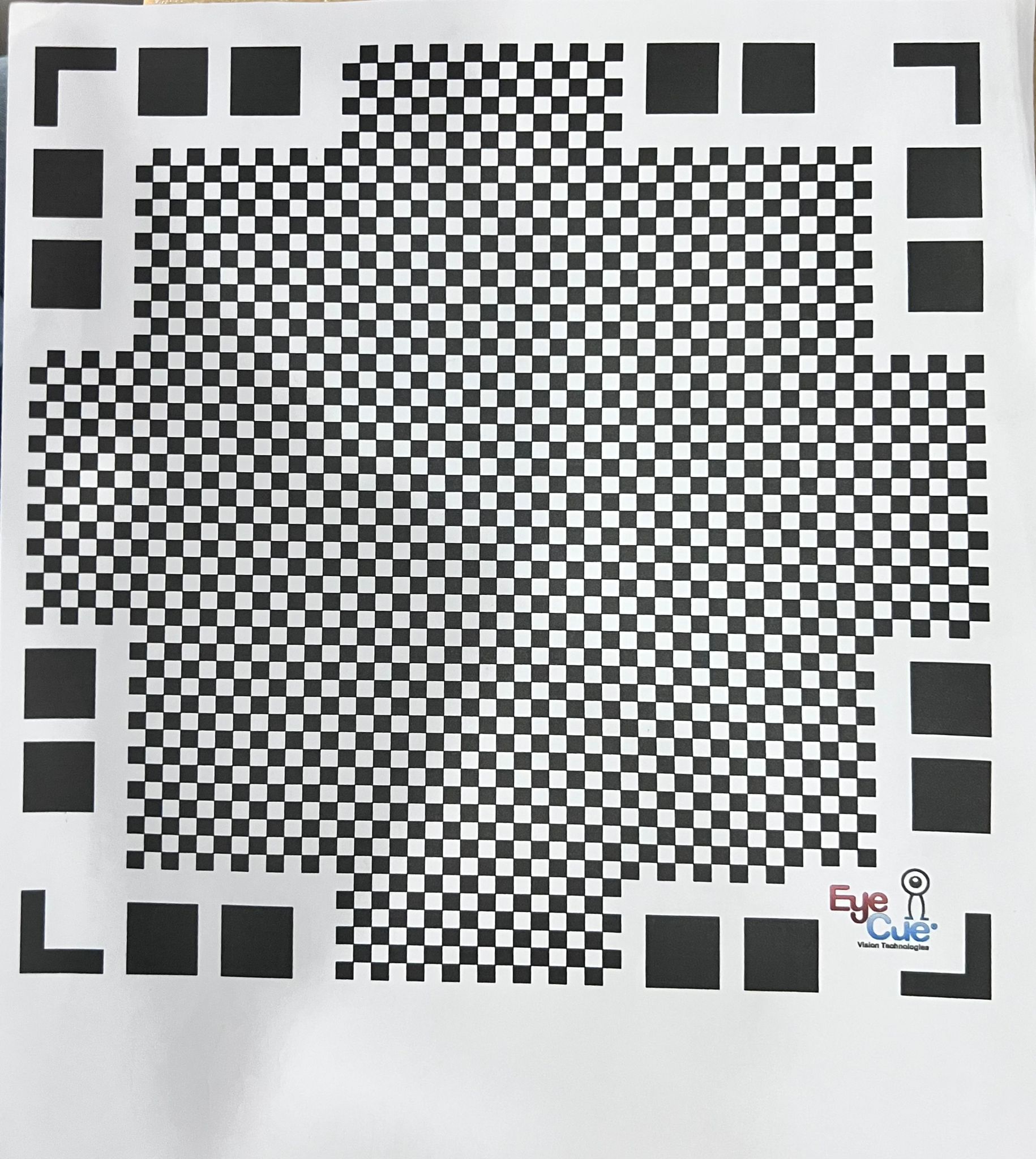

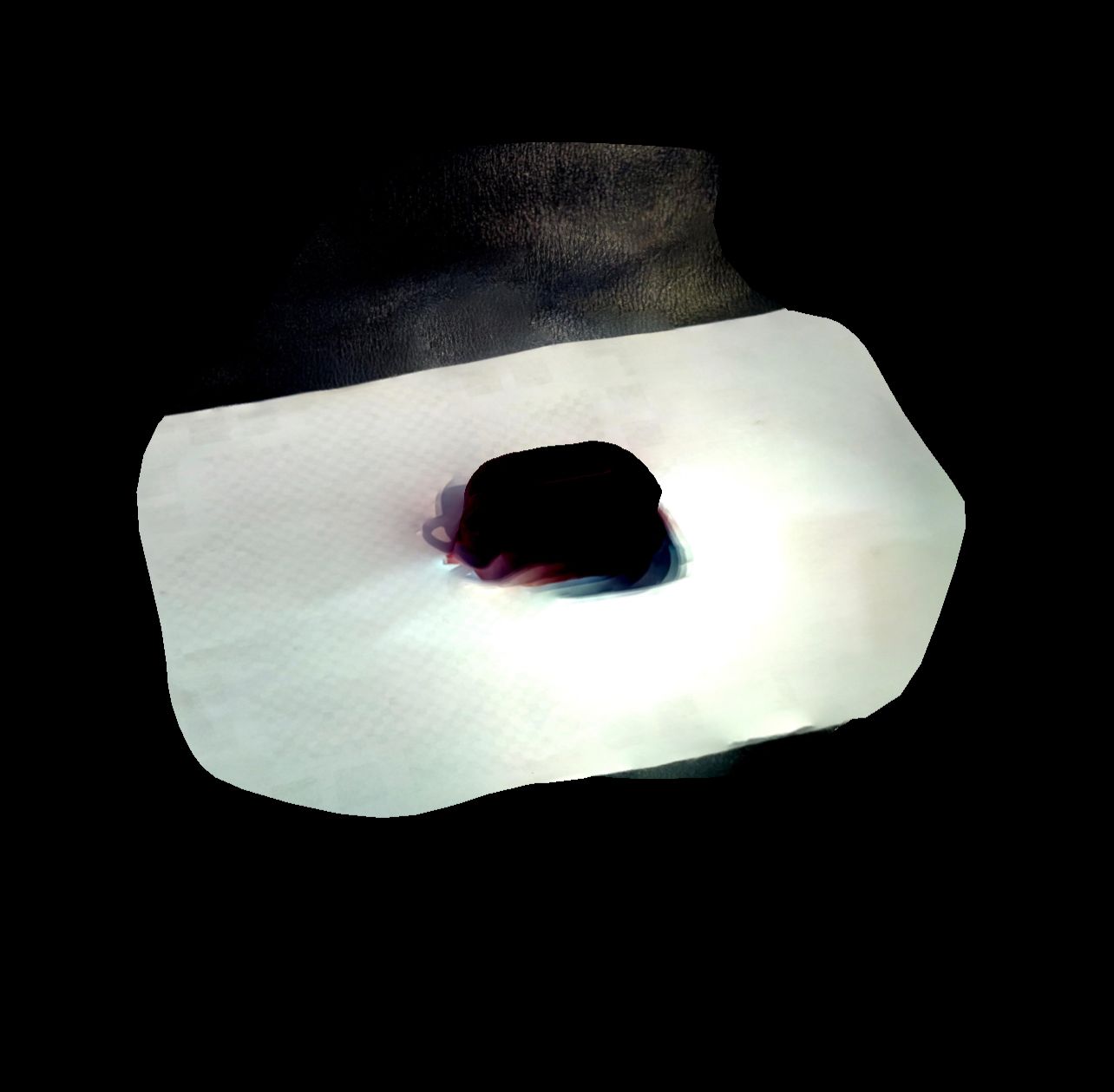

Scanning with Qlone app.¶

I chose my airpod box to scane using the Qlone app. Note. Before we start Scanning any object we need a Qlone mat to complete and get clear result. Qlone mat is easily availible on google and also on Qlone app.

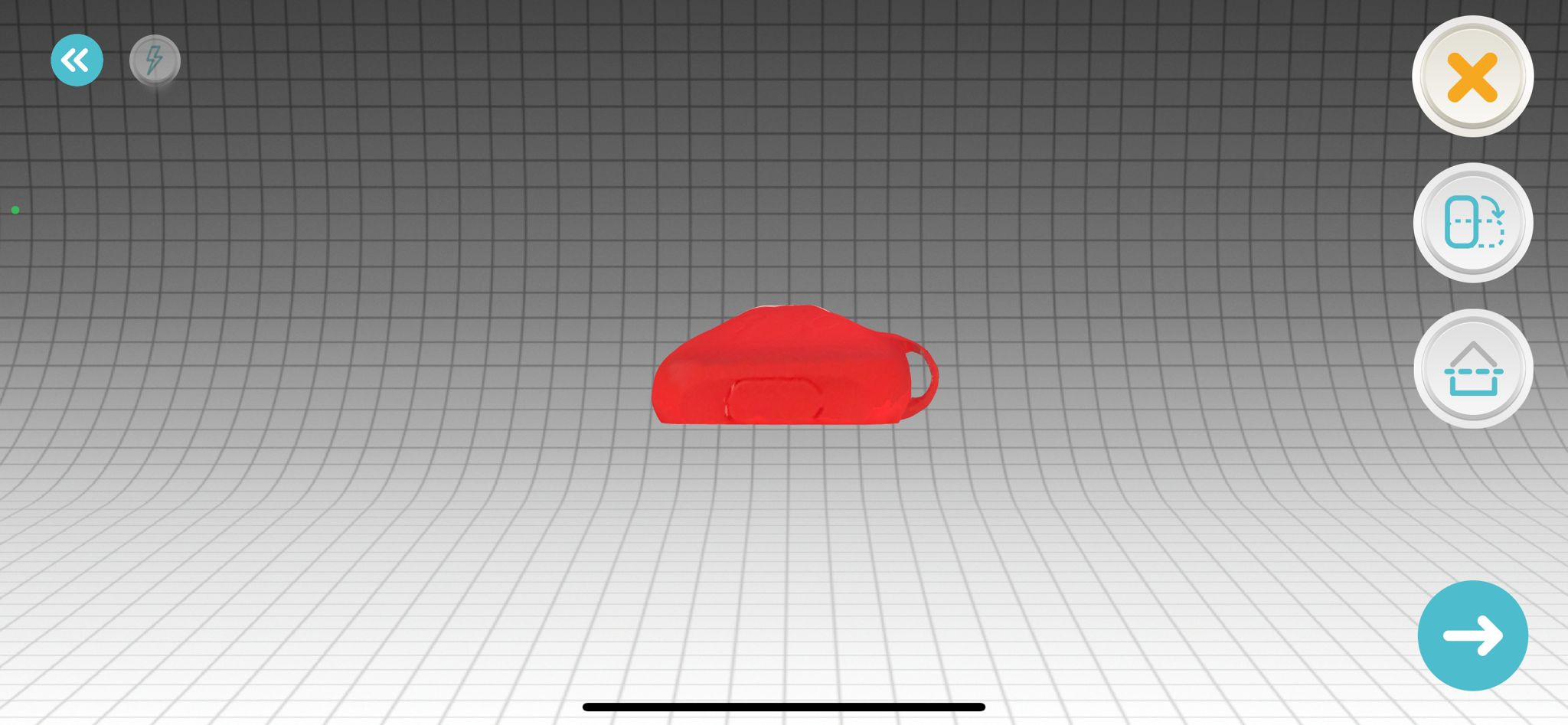

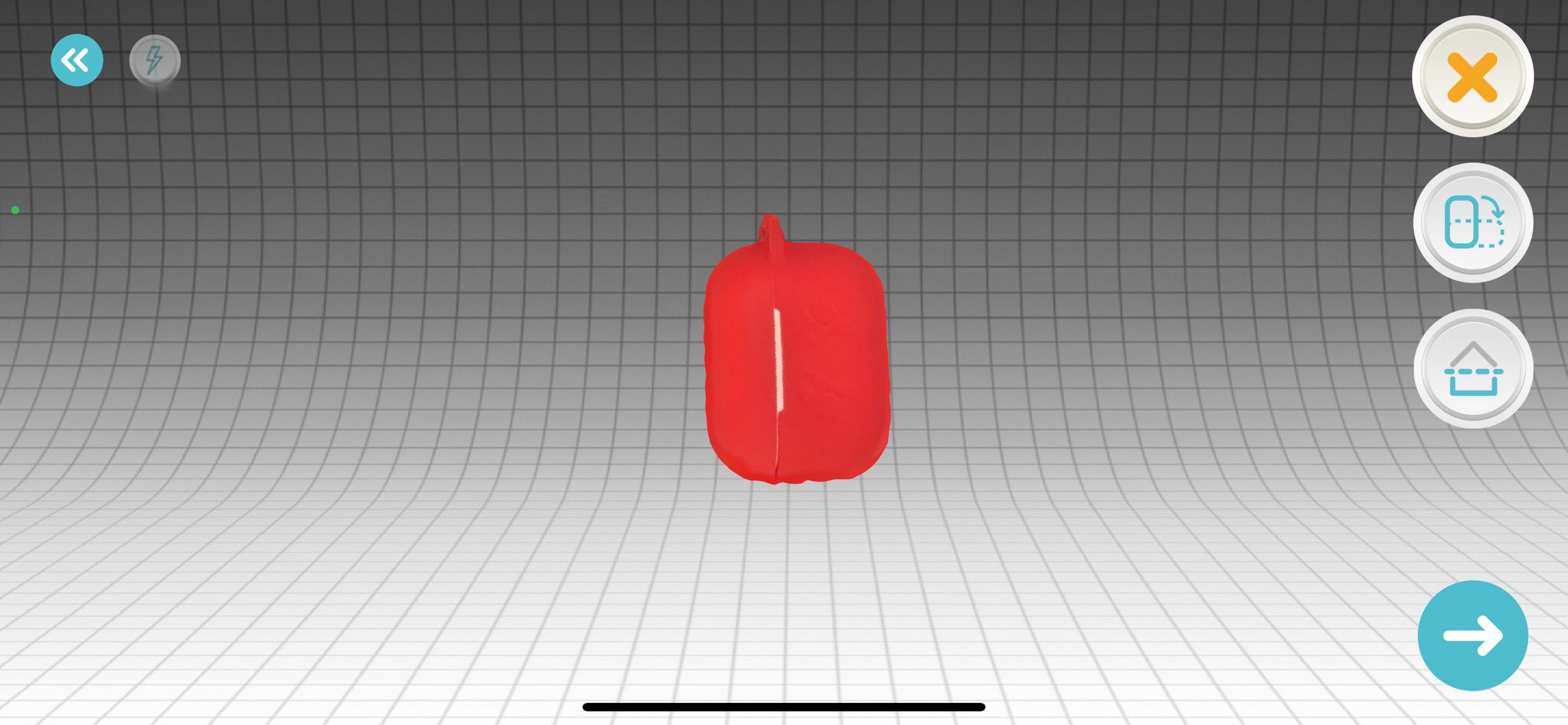

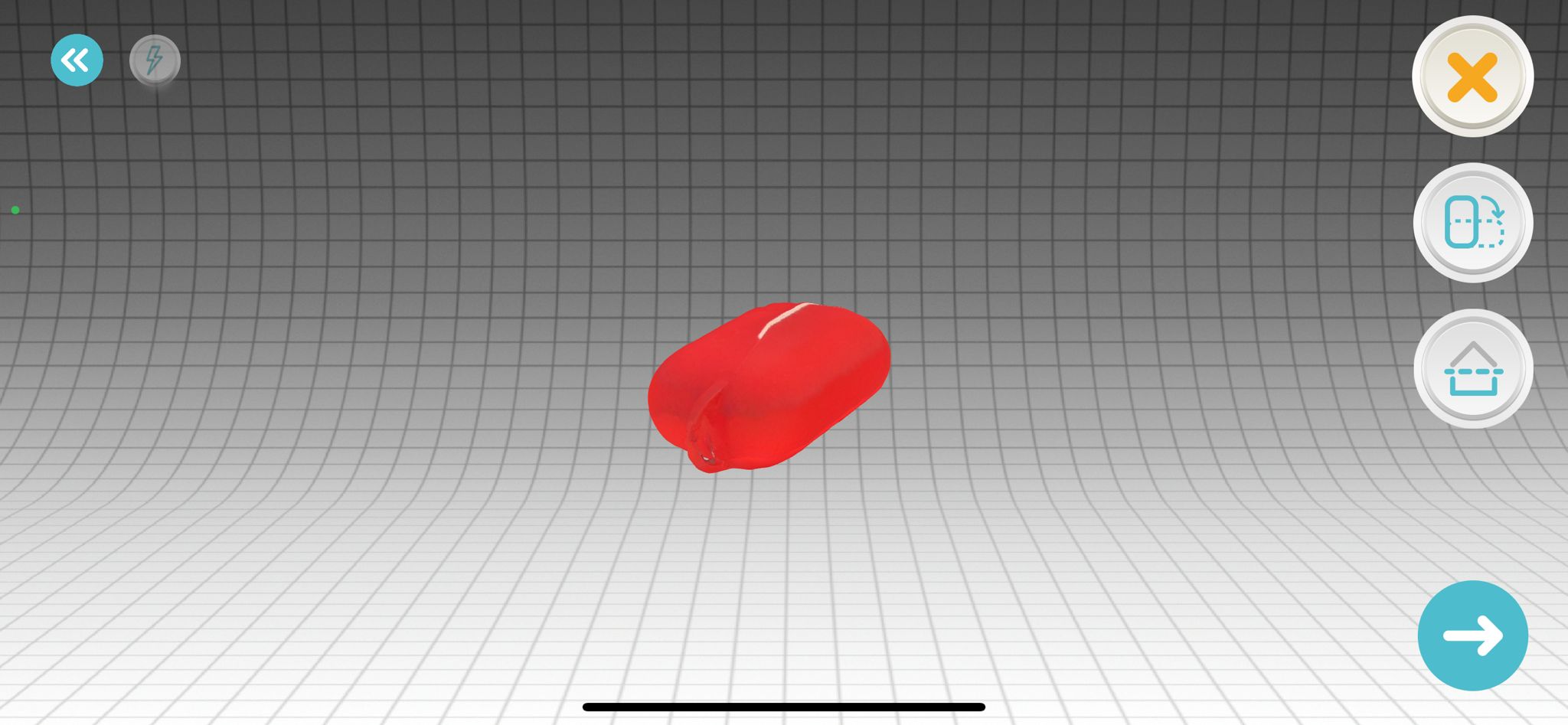

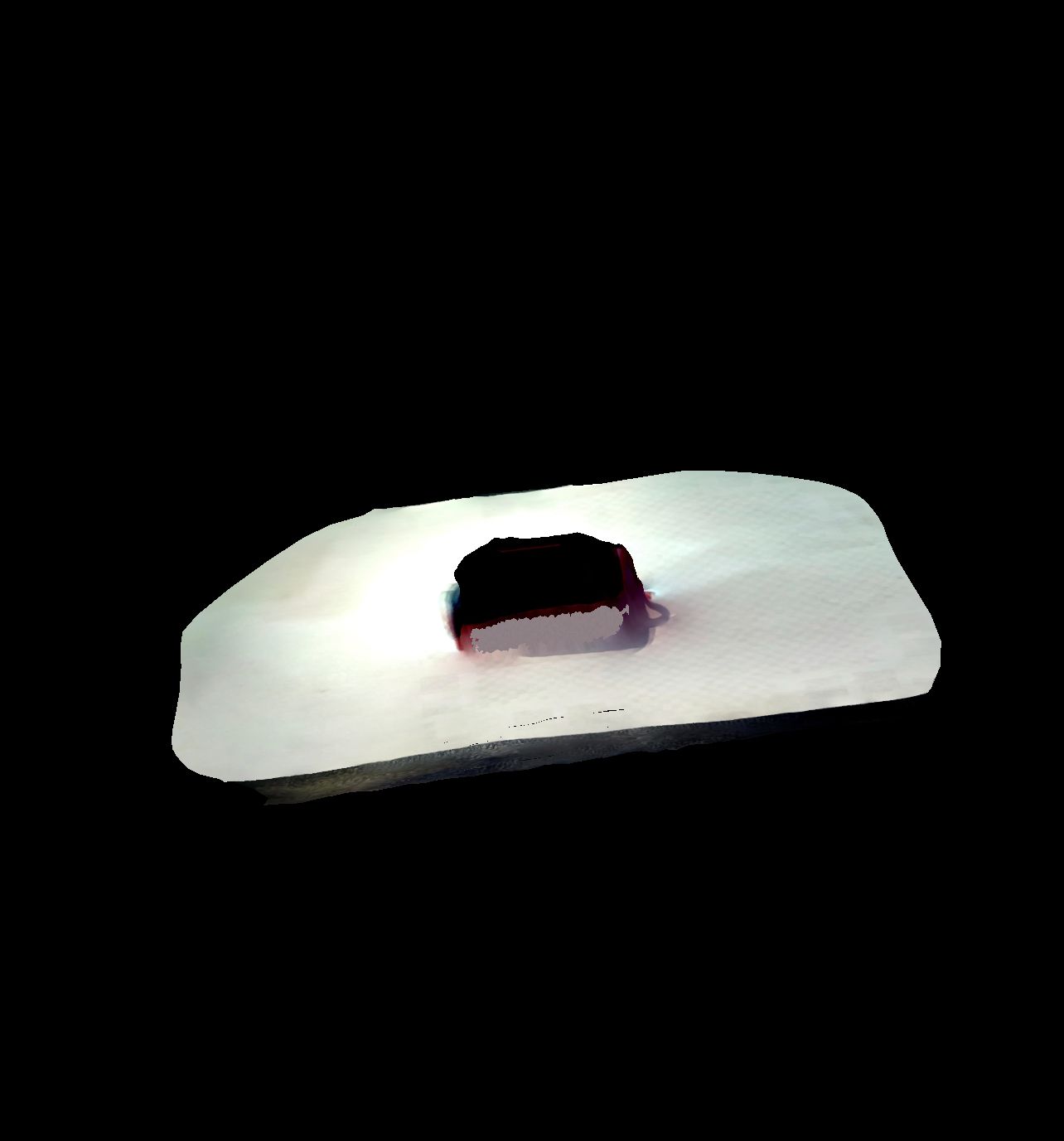

Results of Qlone App.¶

As i chose my airpod box to scan it using Qlone app so we can see the reasults are shown below in pictures

Scanning with Trnio plus app.¶

After Completing from Qlone app i started using Trnio plus app scaning same object (which is my airpod box).This app doesn’t need any mat for scanning simply i place the airpod box and i started Scanning.

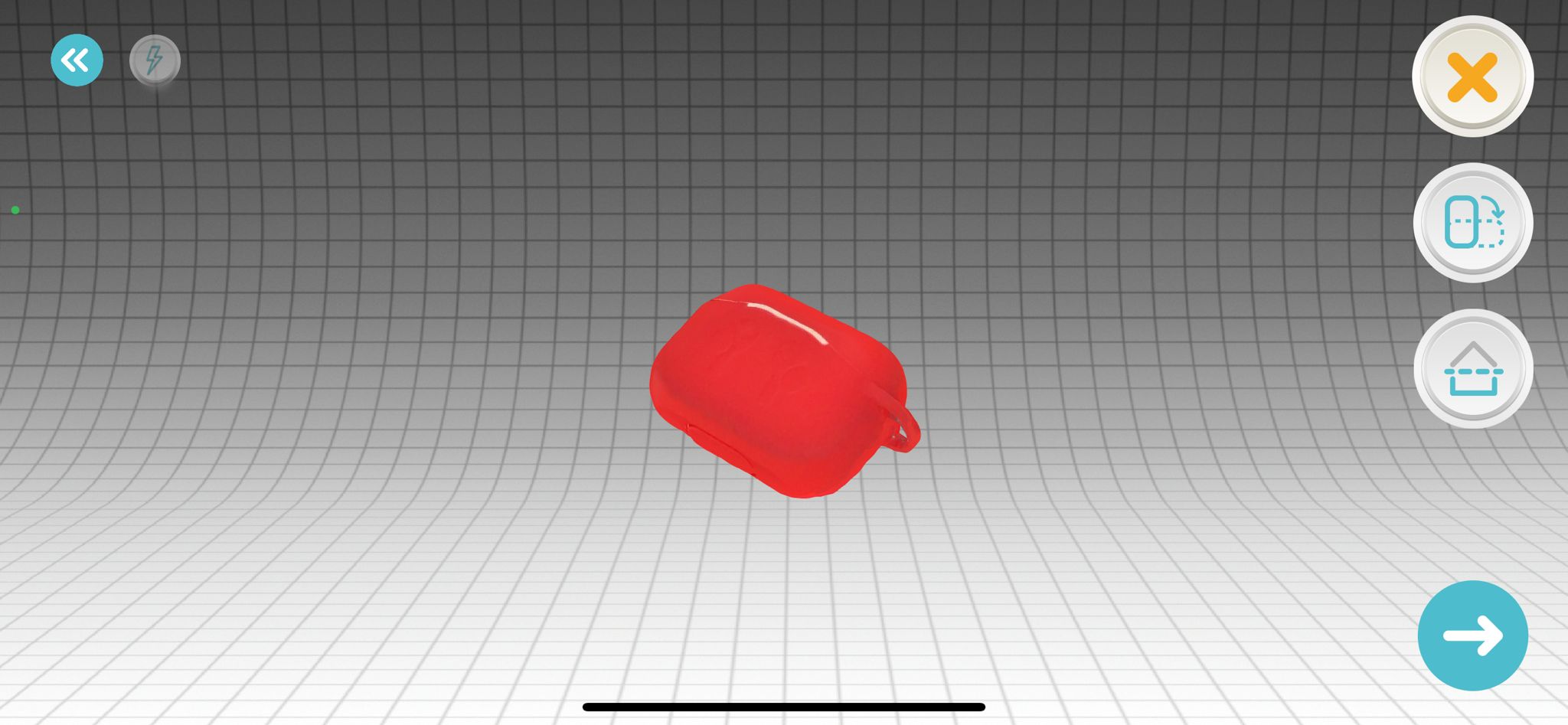

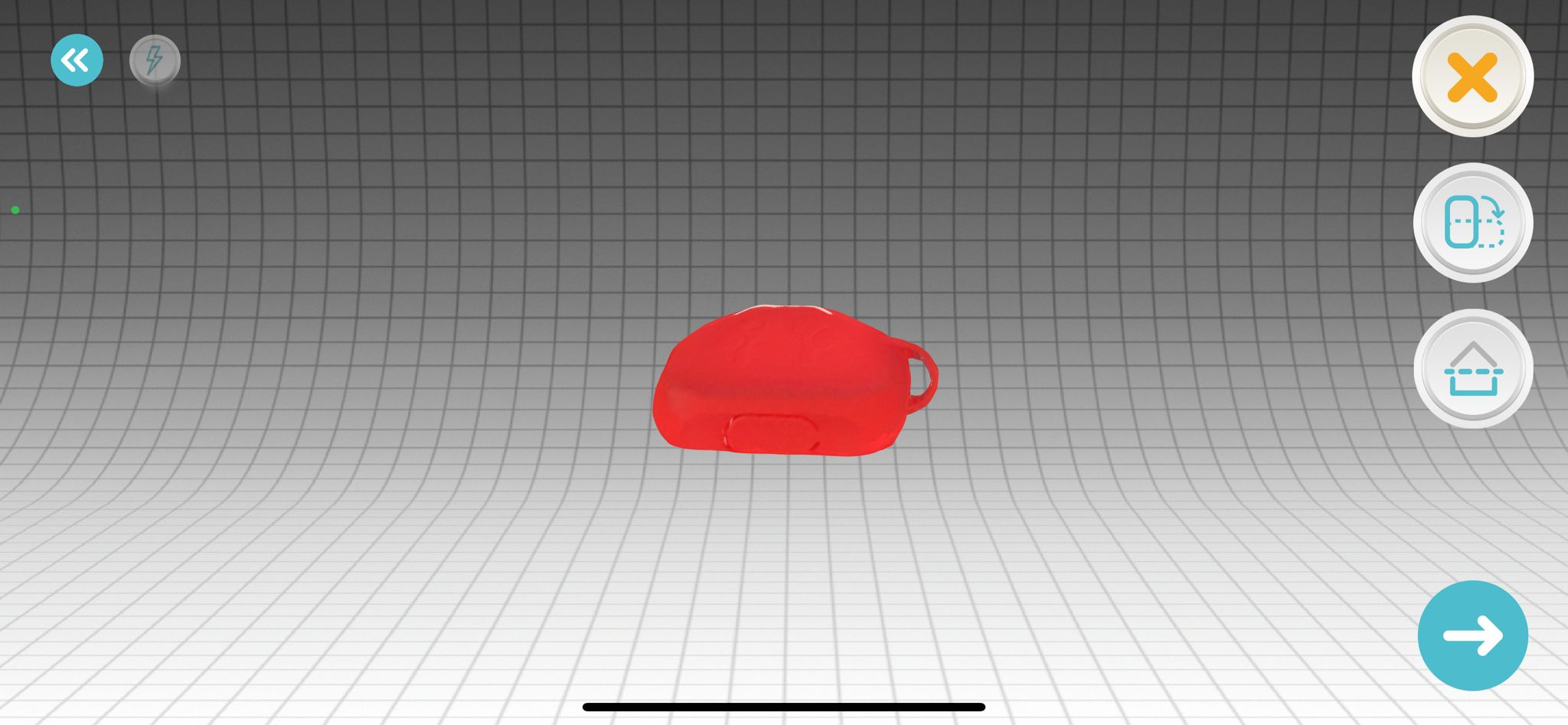

Results of Trnio plus App.¶

After completing the scane we can see the results shown below.

Remarks¶

According to my experiance with boths Application Qlone Application is a good Application for 3D scanning as its easy to use and user frinedly and with good clear results. According to my experiance Trino plus app is not that much good as its hard to use and its take time to process and the results are very bad and also i cant print the results.