5. CO2 laser group assignment¶

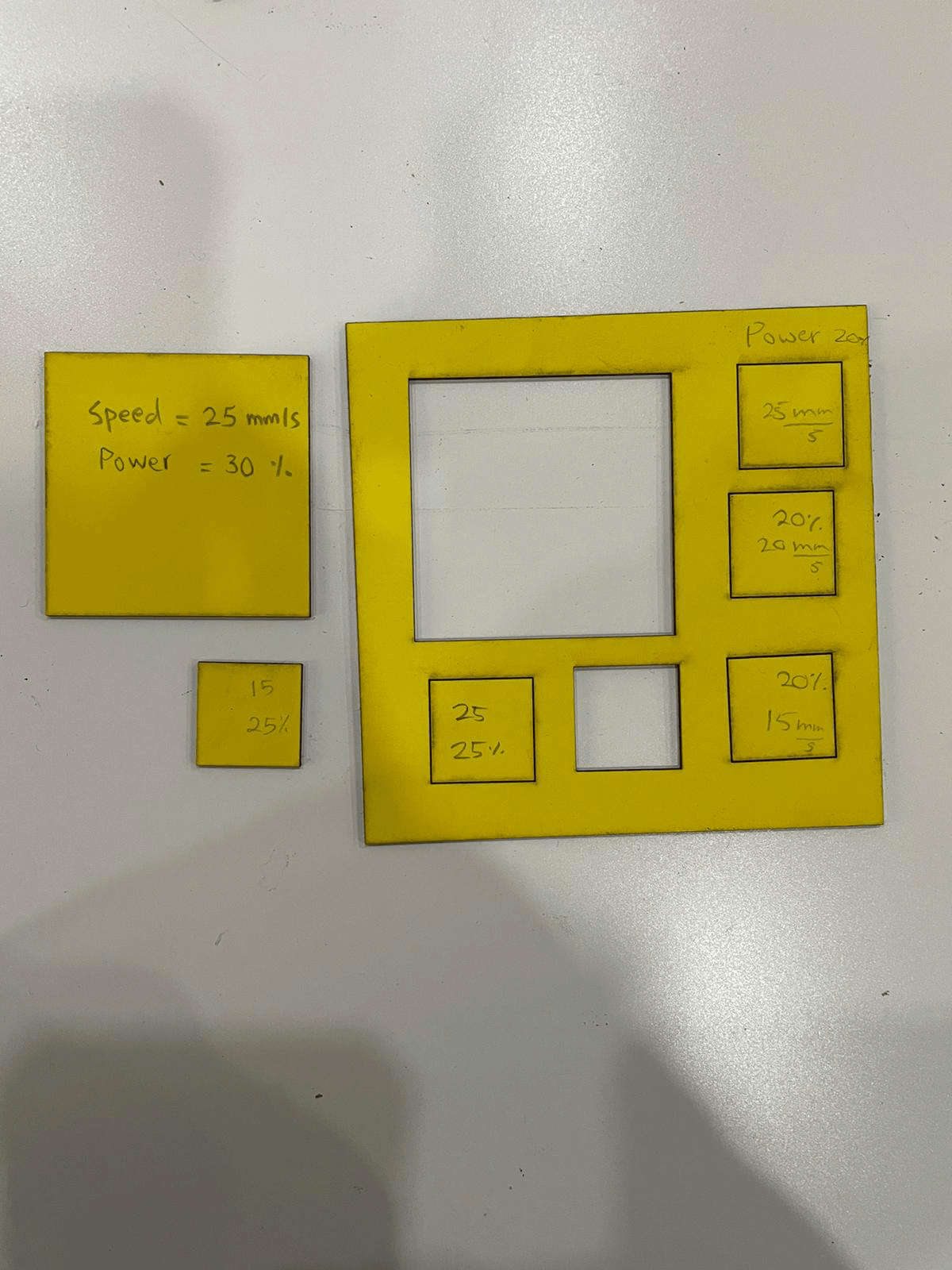

Machine Settings¶

Machine optimization for CO2 laser is very important. Thus, different speed and power values were tried to adjust the machine to the most suitable settings.

The lower the speed the longer it will stay on a certain point. The higher the power the greater the ability of the machine to engrave or cut. For very hard and thick materials, high power and low speed are required. Nevertheless the numerical values of both parameters can be manipulated to get good results in the most optimum way.

In other words, the following two settings did cut the material: - Speed= 25 mm/s and power= 30% - Speed= 15 mm/s and power= 25%

However, the second setting values are more efficient since less energy will be consumed.

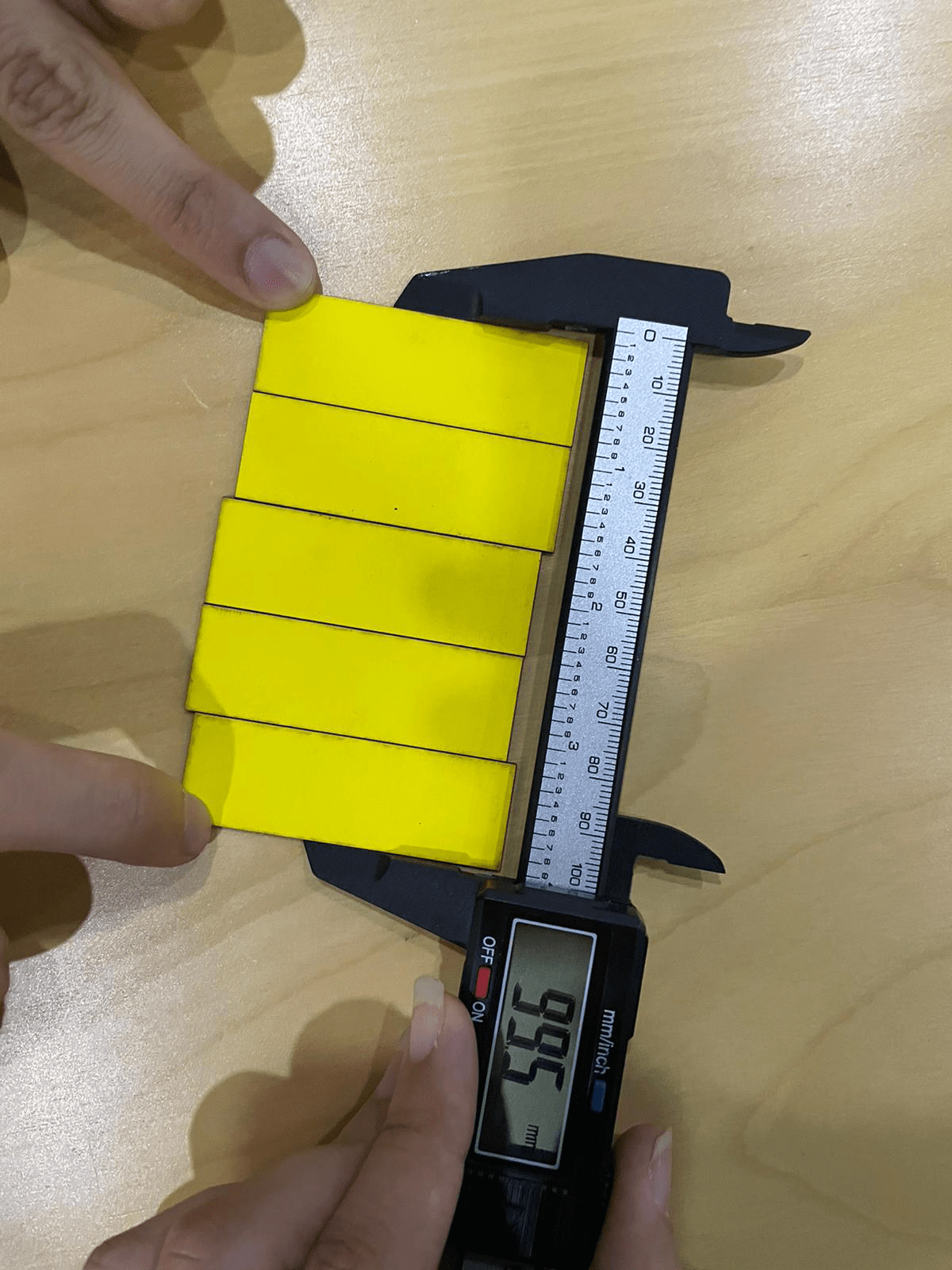

Kerf Test¶

A kerf test was constructed to measure the destructiveness of the CO2 machine for the material of 10 cm long. The length measured after cutting was 9,95 cm which means that 0.05 cm was gone of the material from 6 cuts as shown below. This means that 0.0083 cm was lost for every cut.

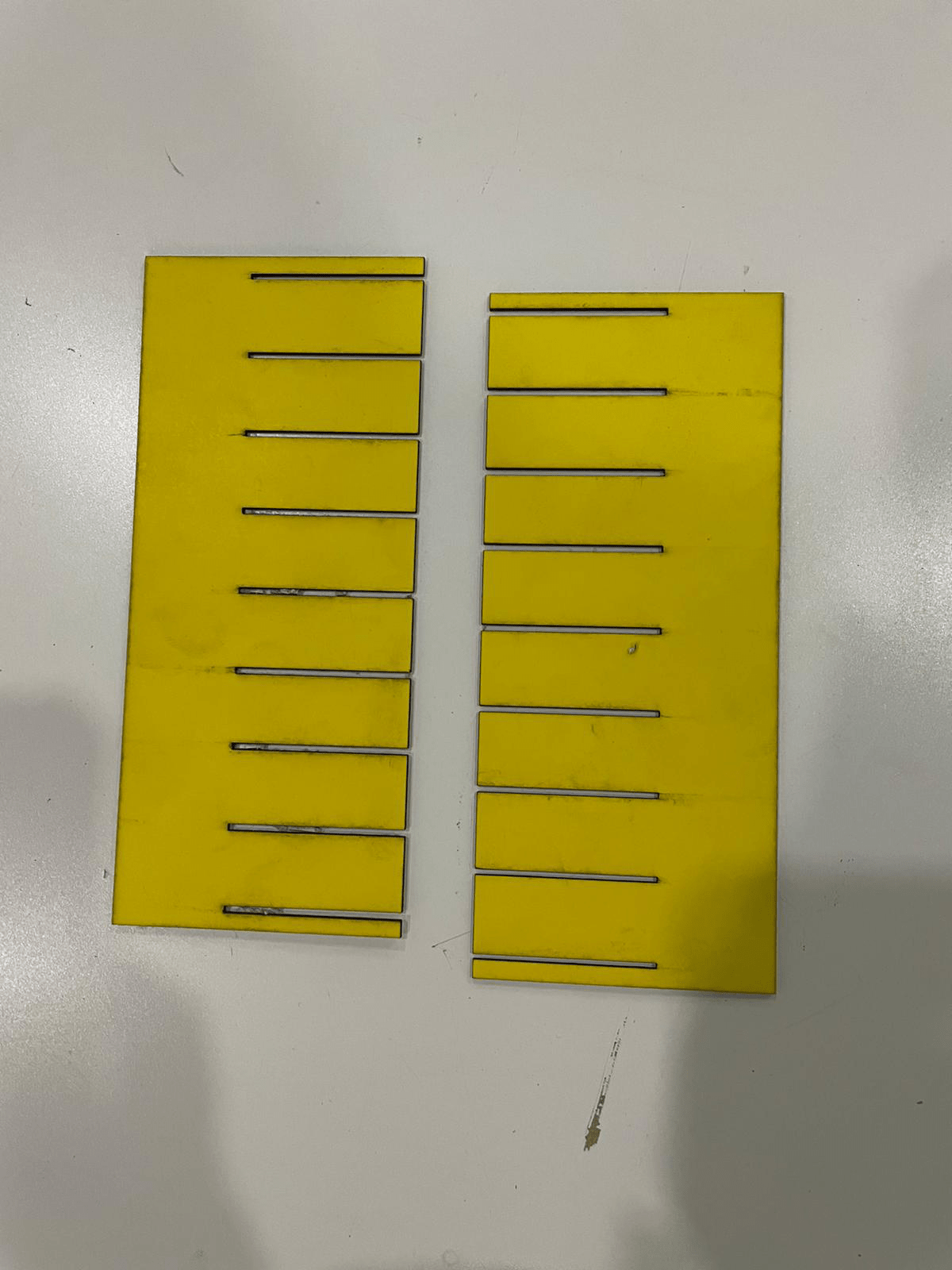

Join Test¶

For each fabrication technique join test has to be conducted for better fitting. Similar cardboard sheets were made in pairs to test the effect of adding an offset to the specified width of the joint which is 1.15 mm. The suitable width was found to be 1 mm which was then easily adjusted in our designs due to fixing some parameters during the design procedure.