Week 3¶

In this week I designed and cut slotted weight samples.

Slotted weight measurements¶

Slotted available in Fab Lab weight 100 g. That’s a lot and will cause high margin of error while testing maximum tensile strength. So, I design a lighter acrylic samples (approximately 10 g).

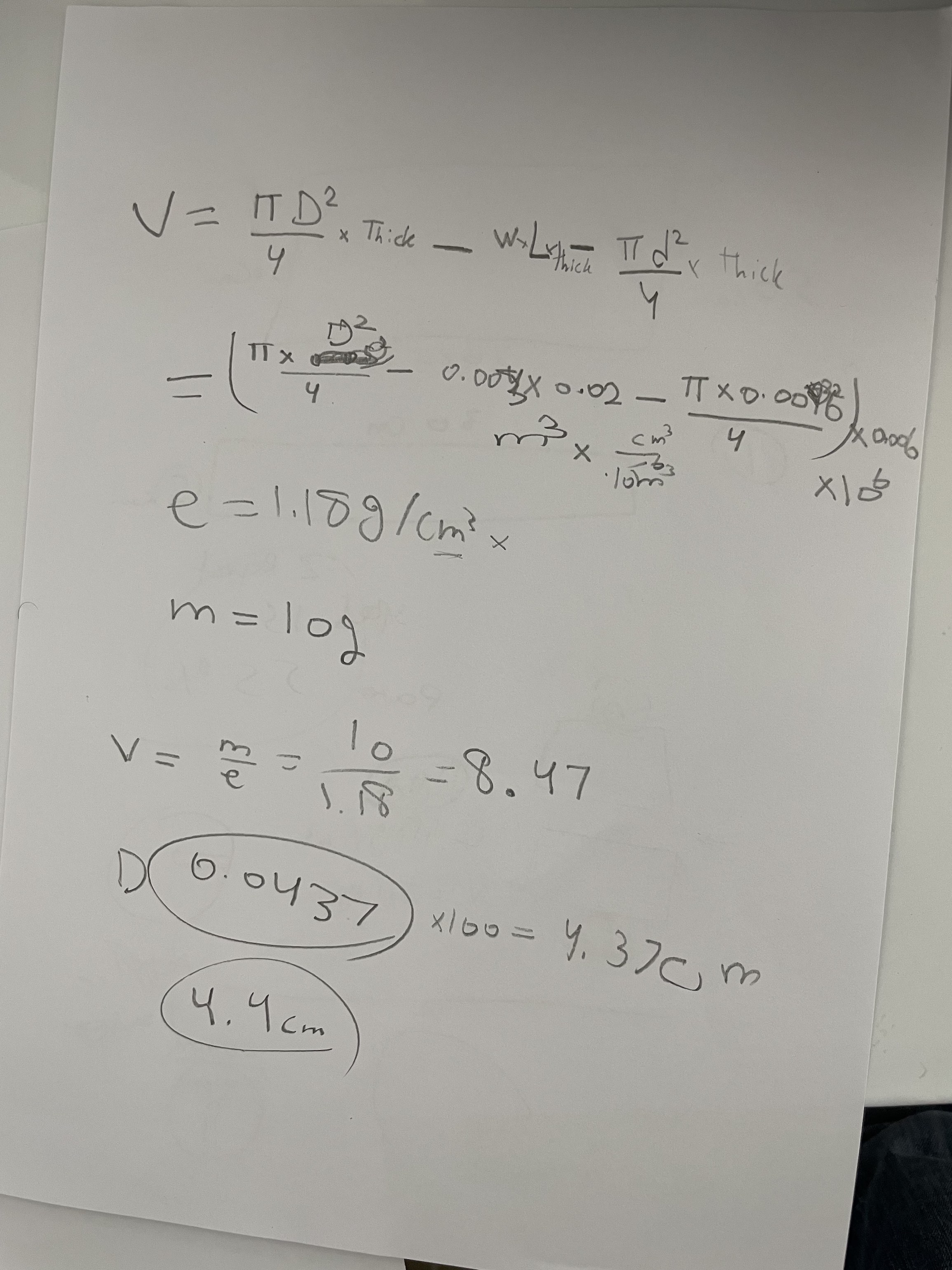

To design sample with specific weight. First I calculated volume required from density relationship e=m/v. Then, I wrote volume equation which consists of big circle minus small circle and rectangle. Small circle is not exactly a circle there is a small part removed from the circle but, I assumed it is a circle to simplify calculation. Then, I used calculator solver to find required diameter for big circle (small circle and small rectangle changes may cause fitting issues in the hanger). All parameters for small circle and rectangle are calculated manually using a ruler.

I increased diameter a little bit to compensate small circle assumption and laser cutter kerf losses.

Slotted weight fusion 360 design¶

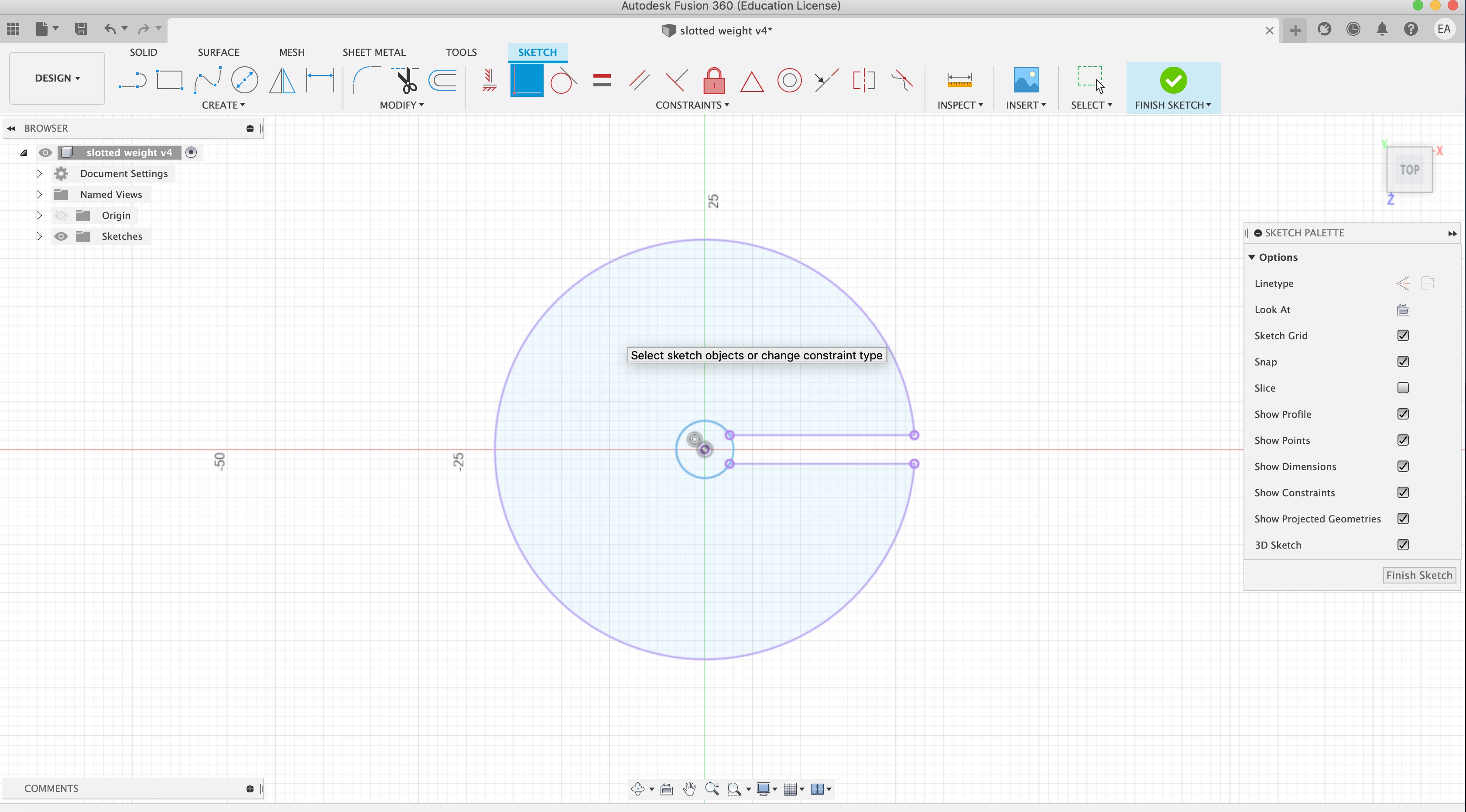

Coincident must be used to be able to use trim tool to remove unwanted parts in our design.

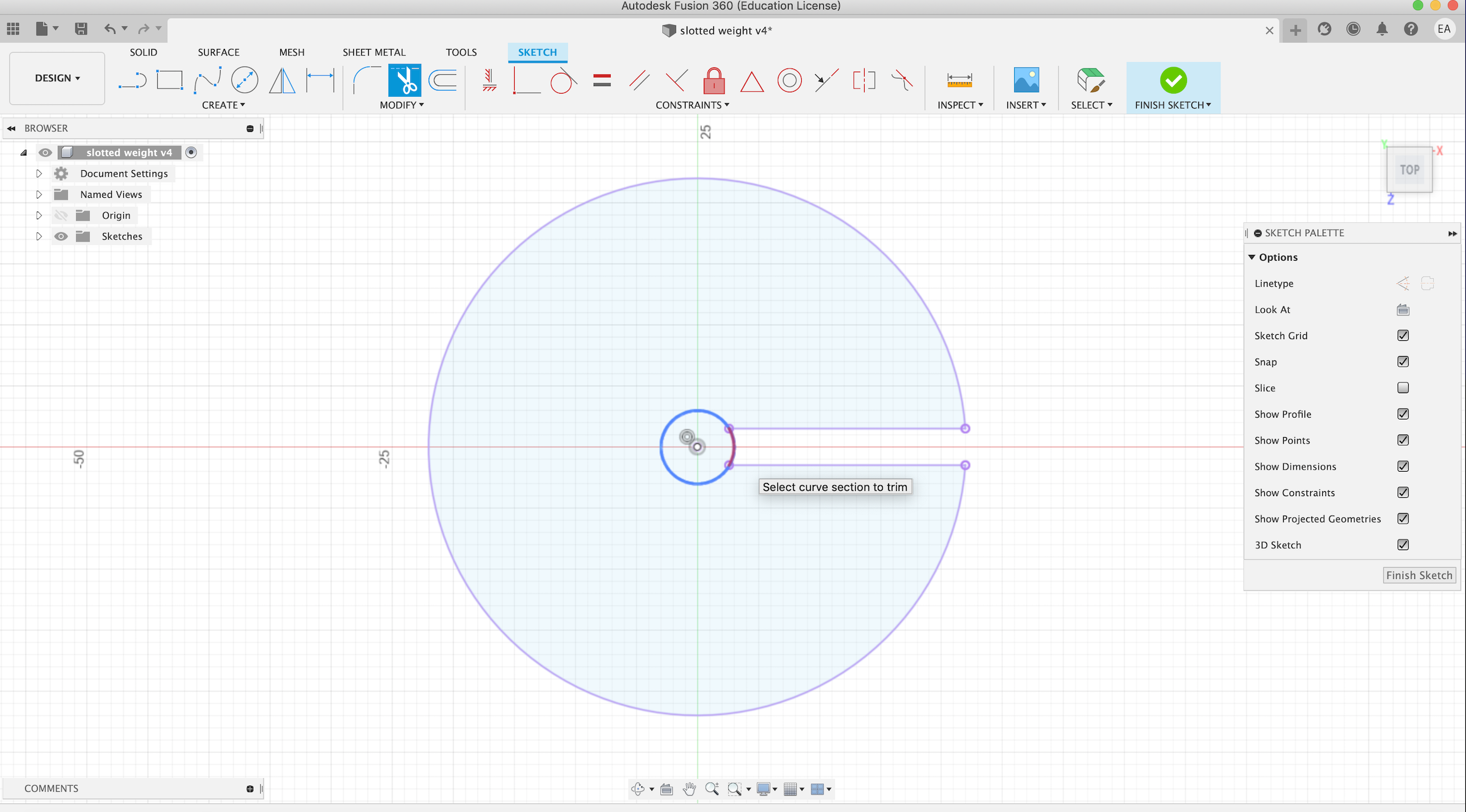

Trim tool is used to remove parts from small and big circles.

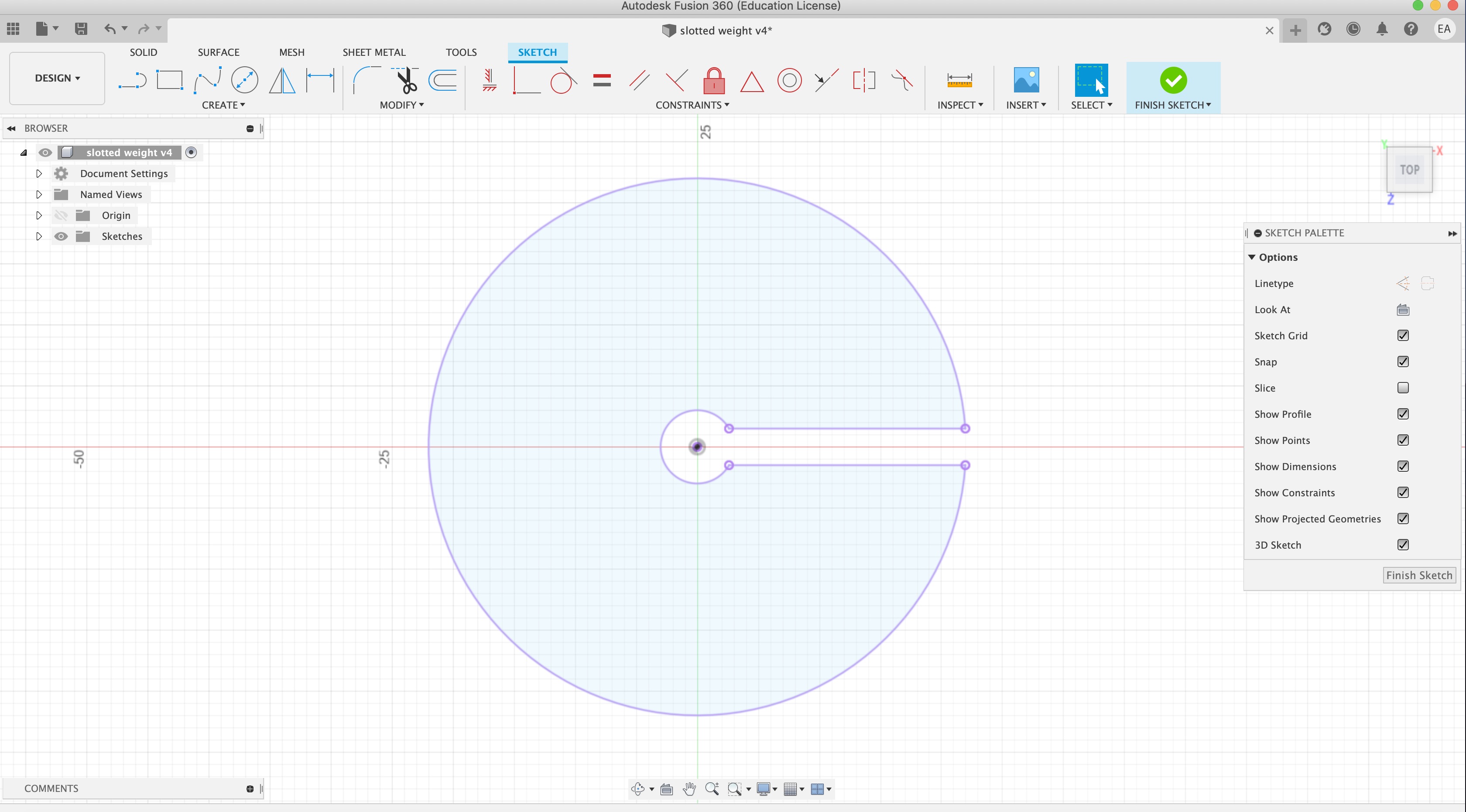

Final slotted weight design.

click here to download dxf file

click here to download f3d file

Sample cutting and measurements¶

I cut 11 samples using laser cutting machine for 6 mm acrylic at following settings (speed 15 power 55% and 2 repeat times). Settings are based on previous experiments. Weight varies between 9.6 g and 9.8 g because to different acrylic sheets were used and it seems there is slight different between them. Ten samples weight 9.6 g while one weight 9.8 g.