6. Large format CNC (computer controlled Machining)¶

This week, I learned how to use CAD to design joints, align them, and then use a CNC machine to cut my design and construct an entirely new thing.

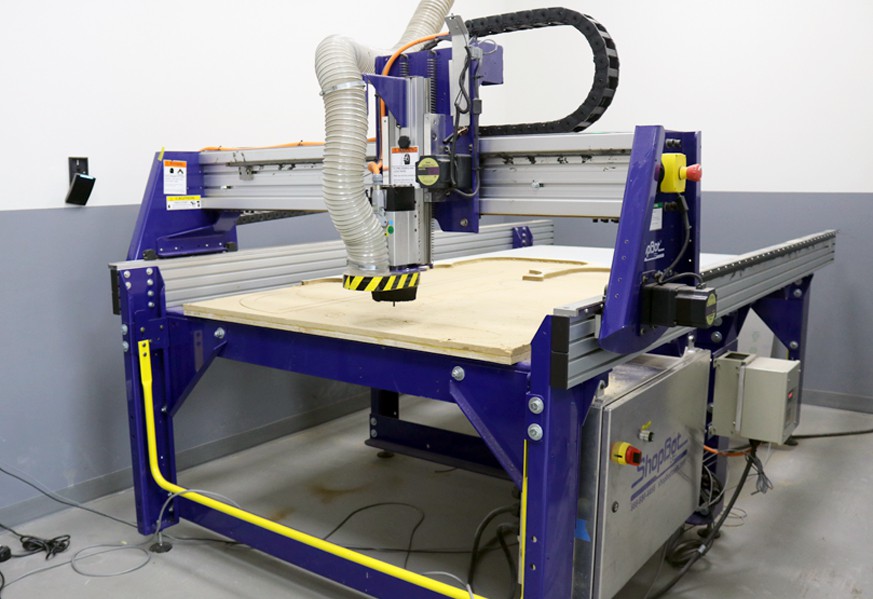

What is a CNC Machine?¶

A computer controlled control machine or simply a CNC (A subtractive manufacturing process), is the computer-controlled automated control of machining equipment (such as drills, lathes, mills, and 3D printers). A CNC machine is a machine that processes a piece of material (metal, plastic, wood, ceramic, or composite) to fit specifications by following coded programmed instructions and without the use of a manual operator.

How does a CNC machine works?

Based on 3D computer model (CAD) data, the use of several software packages to develop toolpaths and NC code to drive a CNC controlled machine When the two are utilized together, the process is known as CAD/CAM. CAM does not really run the CNC machine; rather, it generates code for it to follow. It is also not a fully automated process that imports your CAD model and generates the relevant NC code. CAM programming, like 3D modeling, necessitates knowledge and expertise in operating the software, designing machining strategies, and understanding which tools and operations to utilize in each circumstance to achieve the best results. While there are simple programs that allow untrained users to get started quickly, more advanced models are available.

What are the main features in a CNC machine

- Versatile and adaptable, CNC milling machines and machining centers can accomplish drilling, boring, reaming, milling planes, milling bevels, milling grooves, milling surfaces (cams), tapping, and other operations on a variety of workpieces with varying structures and forms.

-

High Machining Precision, CNC milling machines and machining centers have great machining precision, and the accuracy of the workpiece may be ensured under normal conditions.

-

Increased Productivity, CNC milling machines and machining centers combine the tasks of a milling machine, a boring machine, and a drilling machine, resulting in a highly focused process that enhances production efficiency and lowers workpiece clamping error.

-

It is capable of processing complex shapes, it can mill the surface of different components that regular milling machines can mill, as well as plane curve contours and spatial surface contours that ordinary milling machines cannot mill. This is due to the fact that CNC machine tools have several feed coordinates.

-

Reduce the work effort of the operator, CNC milling machine automatically completes part processing in accordance with pre-programmed processing methods.

CNC limitations

-

Cost: CNC machines are more expensive than manually operated devices. The initial expenditure for these robots is thought to be prohibitively expensive. Purchasing things like tools and machineries need substantial explanation. They also necessitate significant maintenance expenditures and might be costly to fix. The use of CNC technology does not eliminate the necessity for costly tools.

-

Errors: CNC machines are not without flaws. Operators can still press the wrong buttons, create incorrect alignments, and misplace pieces on a jig.

CNC Safety Measures

- When using a CNC machine, always wear suitable ear protection and a decent pair of safety glasses.

- When you are carefully studying the cutting instruments, keep your safety glasses firmly in place.

- Wear appropriate footwear, such as safety boots, at all times.

- If you have long hair, ensure sure it is covered when using the CNC machine.

- During machining procedures, keep your hands away from any grasping elements.

- Keep a safe distance from the machine anytime it is in use. You should also tell anybody else who is in danger of getting too close to it.

- Avoid contacting the cutting edges of instruments at all times.

- Make certain that the machine is totally turned off, and clean it whenever you have finished using it.

- It is important to have a safety device such as an emergency stop button, the emergency stop button is used to immediately shut off the machine. This button is found on the machine’s handheld part, control panel, and other locations.

Below is an image of an emergency button that wired to the machine system.

Here is an image of the second emergency button tht is placed in the right side of the machine.

Below is an image of the third emergency button that is placed on the cutting tool of the CNC machine.

A third way to stop the machine is to click anything on the keyboard to stop the machine from working.

Group Assignment¶

The group Assignment is documented in Zainab Abbas’s Website

Individual Assignment¶

CAD¶

I utilized Fusion 360 to build a pet house for the Individual assignment. I gained some inspiration after doing some quick research, however I ended up not following my first choice of design due to my limitations in using Fusion 360.

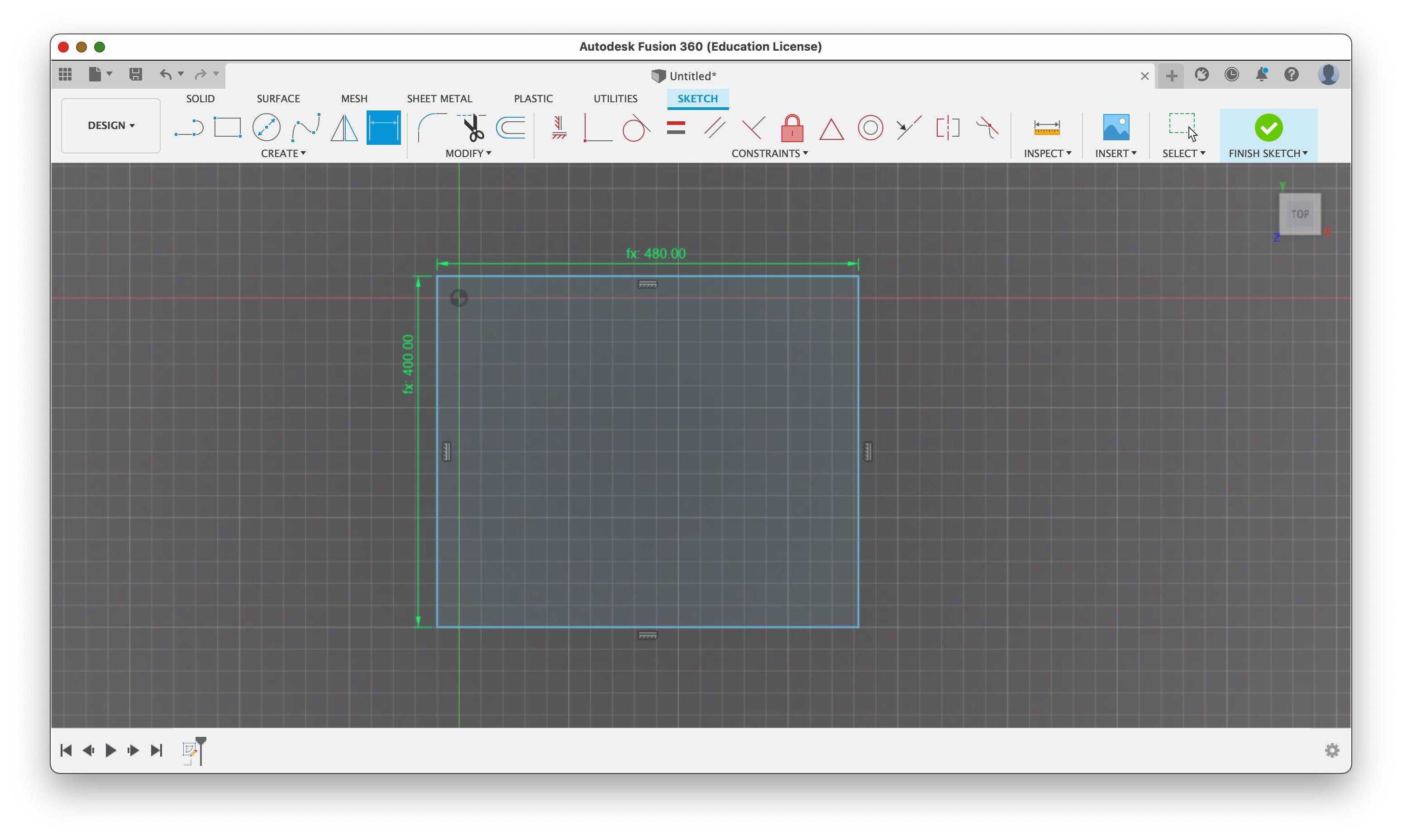

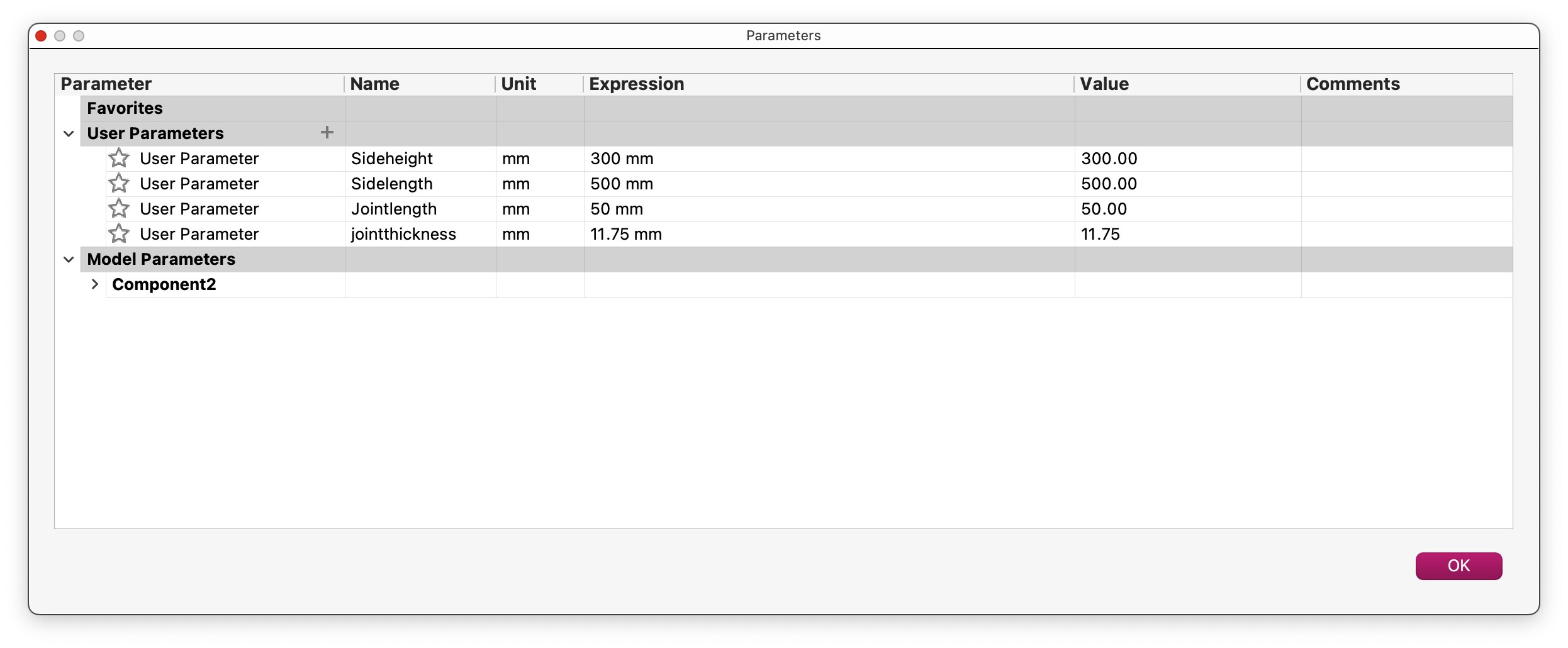

I defined parameters for the joints, height, and width of the many components that I was creating in order to construct a parametric table that would aid in the avoidance of measurement errors when designing.

Using the parameters that I set earlier, I began designing each and evey body seperately.

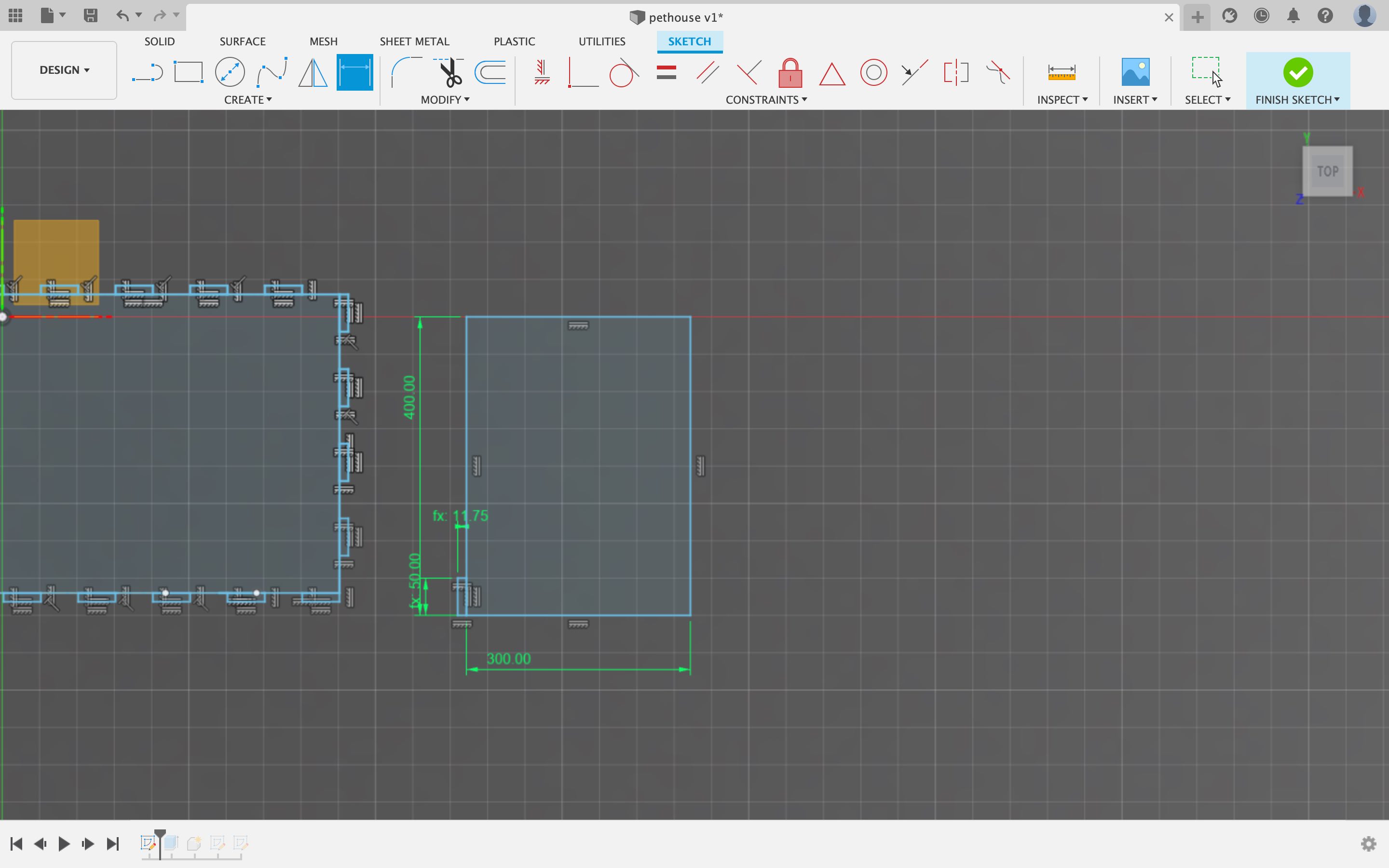

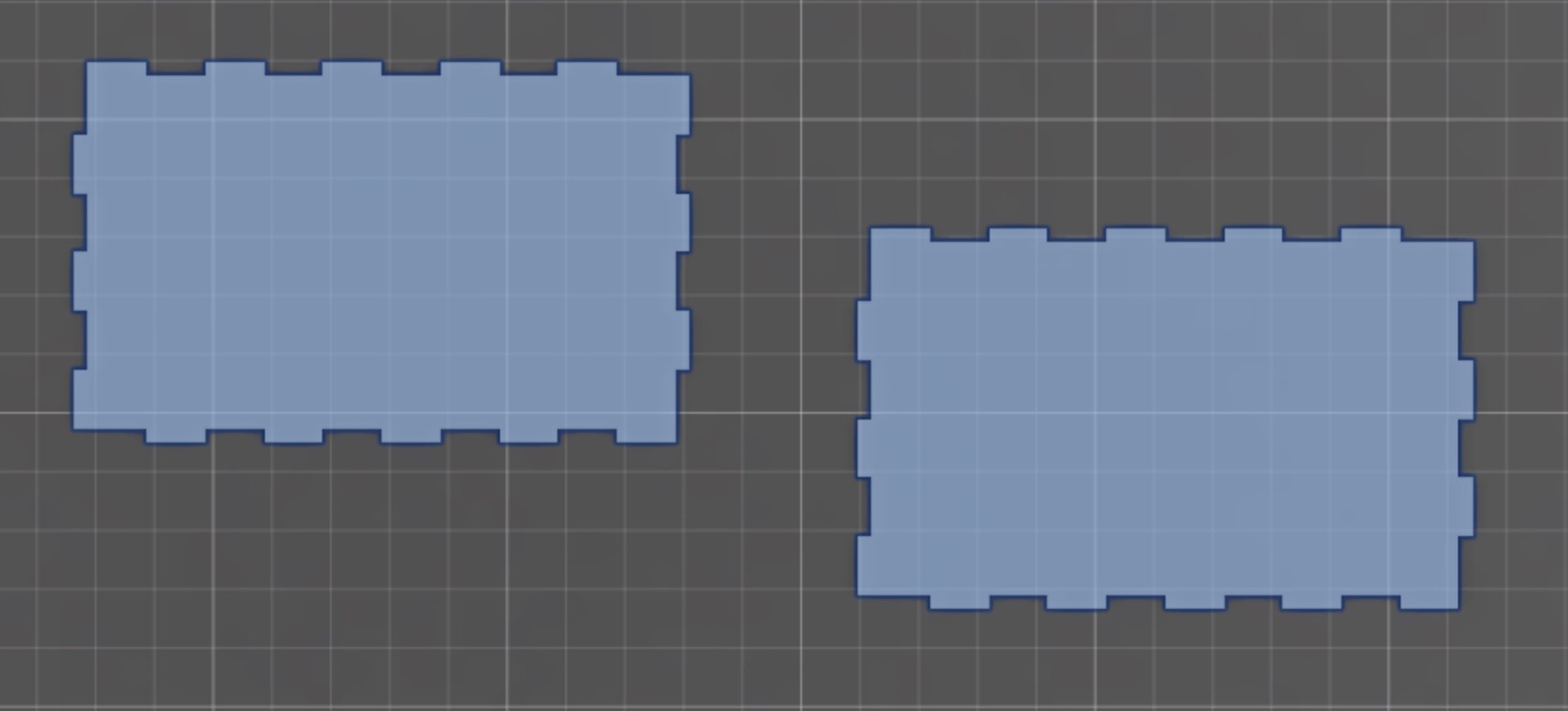

I generated joints and their surfaces for the sides of the pet house while still ensuring that I am utilizing the parameters that I have established.

I continued doing the same process for the rest of the parts.

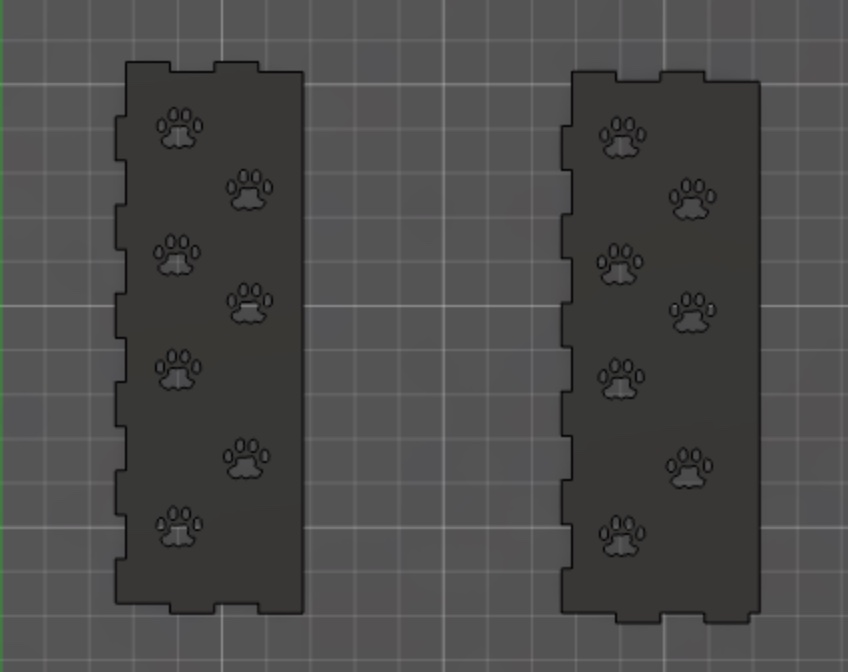

I decided to add something similar to a sky light shaped like paws to the roof of the pet house, so I downloaded an SVG file from the internet and aligned them together on the roof components.

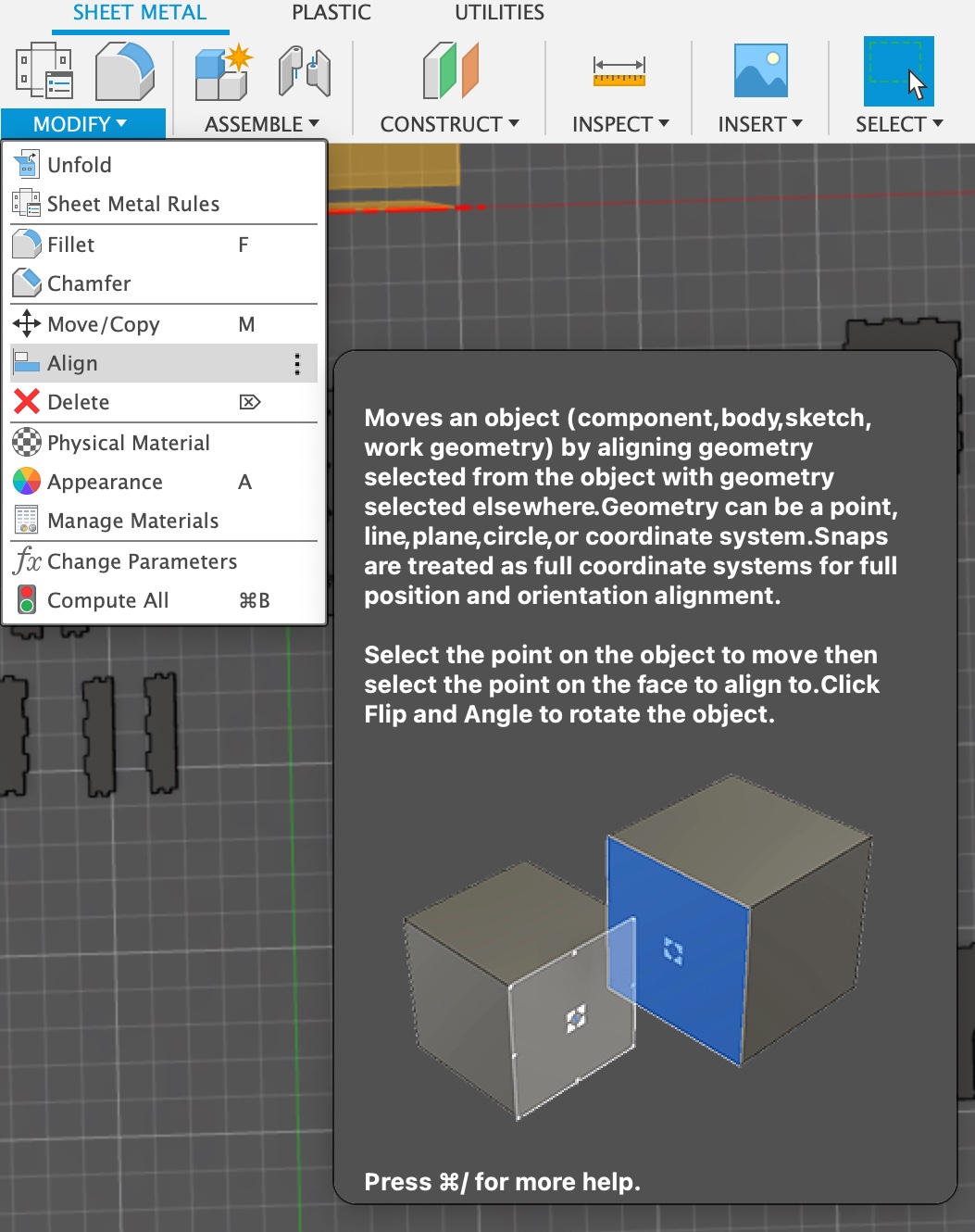

For the final steps, I extruded all parts to 12mm (the thickness of the wood I was using), and using the align option, I joined my parts together ensuring that all joints are placed correctly and in perfect size so that it would fit, this step is essential to ensure that your joints will fit together rather than having a larger than the other parts, or joints that are loose or too tight that it won’t fit, so using the align option is an essential step unless you want to waste time and effort.

CNC cutting¶

VCarve¶

What is VCarve?

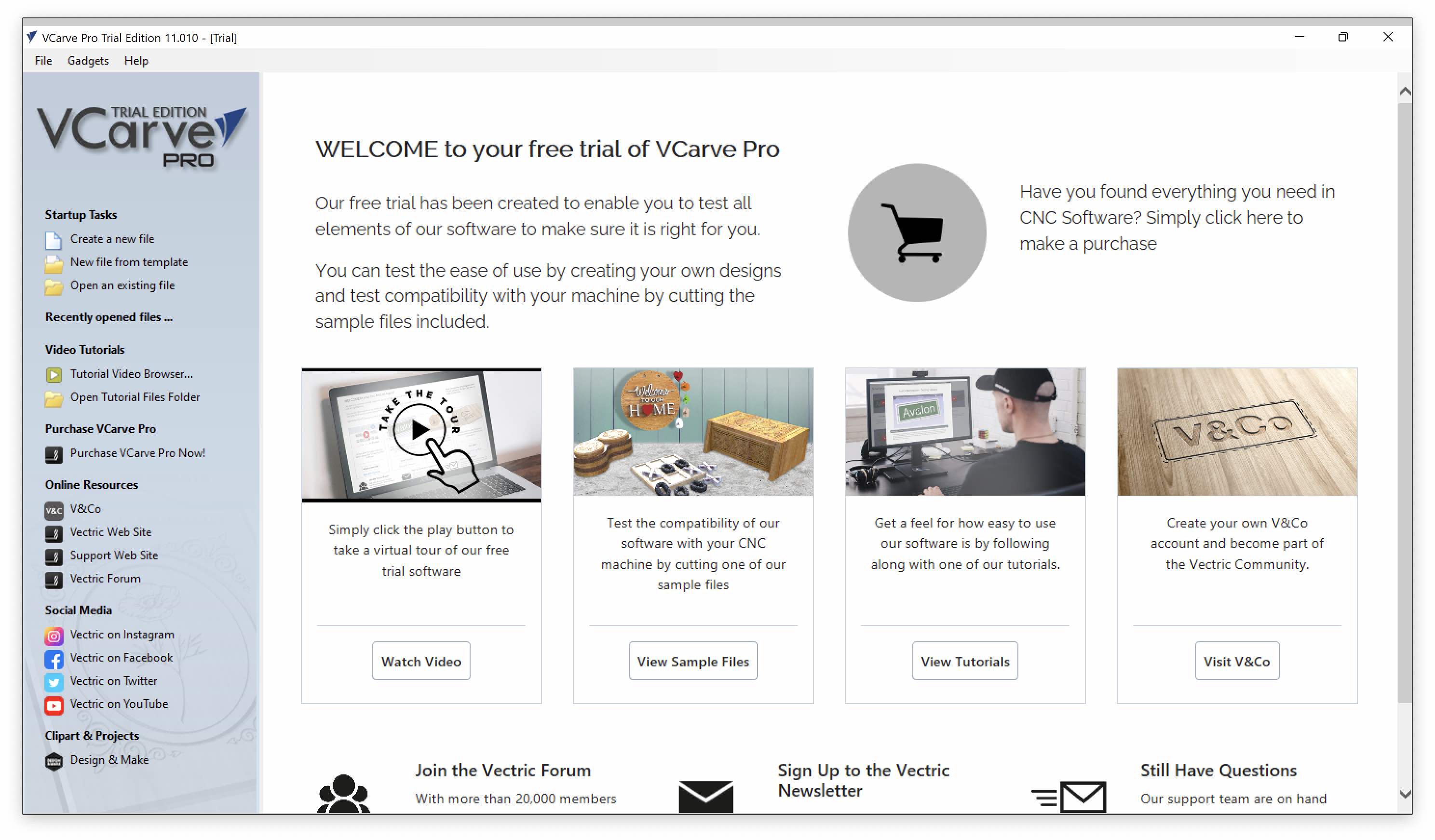

VCarve allows you to turn a basic 2D image into an intriguing 3D carving. Routing or engraving using conventional tools results in square-edged cuts of a predetermined depth.

Even though it wasn’t essential, I downloaded on my laptop since it was crucial to learn how to use it, before I use the software, familiarize myself with it.

I saved each part separately as a DXF file so that I could email them to the computer that was used to run the cnc and set my drawings on the virtual board using VCarve.

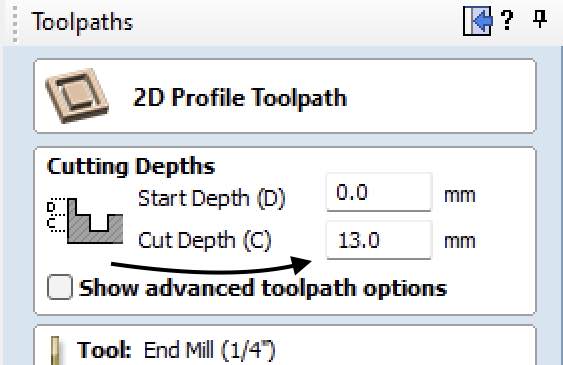

In the Tool Path section, I set the cutting depth to 13mm, which is 1mm deeper than the thickness, of course the CNC machine, wont be affected as there is a be where the wood piece is placed on.

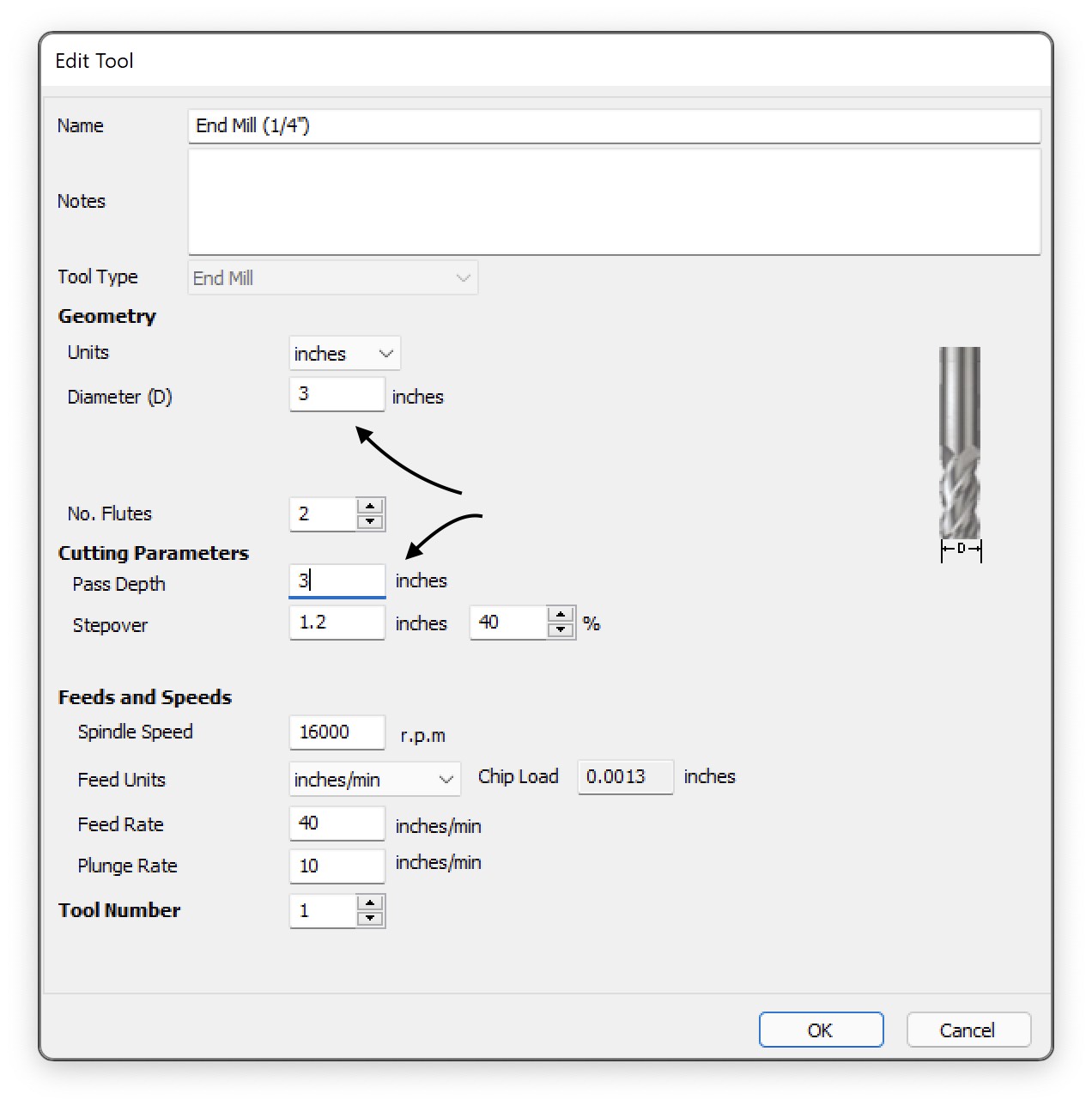

In the Edit Tool menu, I changed a few settings, to fit the CNC requirements.

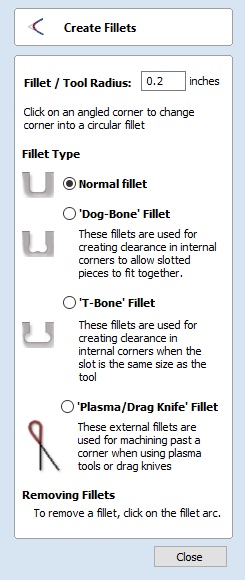

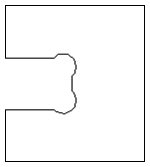

I utilized the dog bone and clicked on every female joint corner with the create fillet; this is a critical step for the CNC to cut joints. I arranged my pieces on the sheet, which serves as a guide for arranging the parts.

It should look something like this.

Cutting/ Assembling¶

Here is a video while the CNC was cutting the parts.

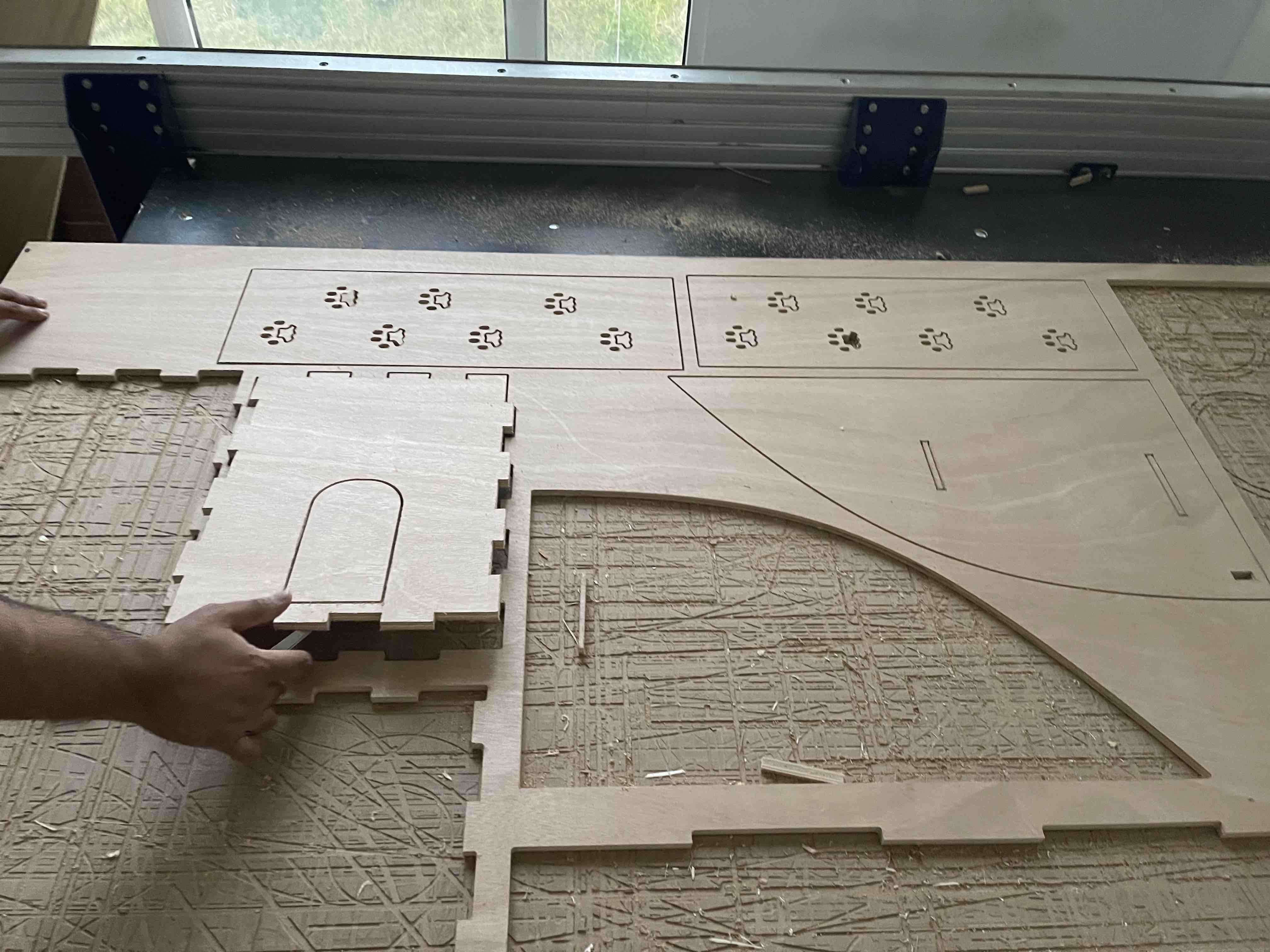

After the parts were cut, using a sharp tool, I lifted the partsfrom the main board.

I popped out the bits that were meant to be completely clipped off. Next, I smoothed down the parts that weren’t smooth and had scratches with sanding paper and a sanding tool so that it wouldn’t injure cats and fit in joints.

Here are the parts before Assembling

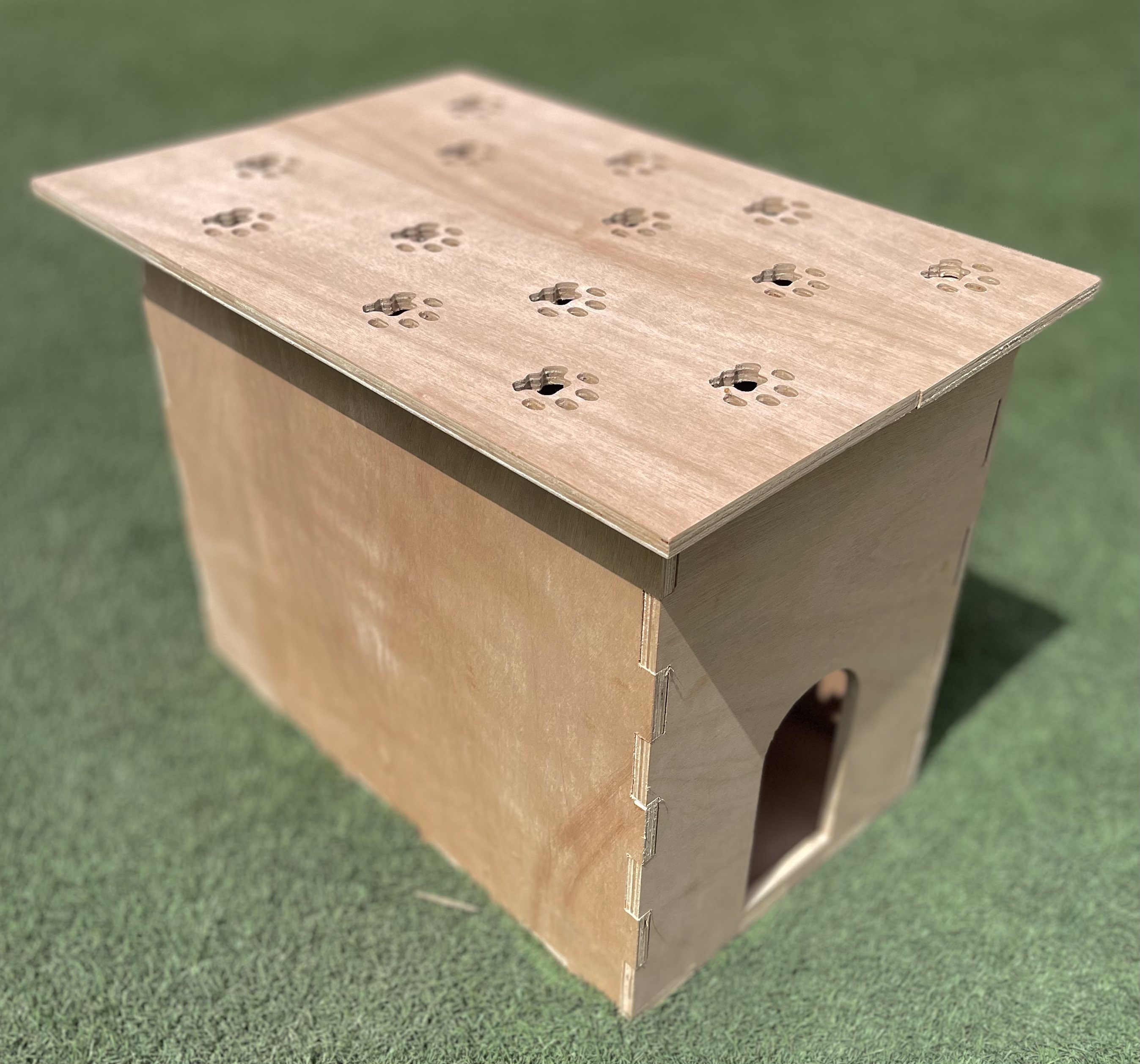

Final Results¶

Here’s a close-up showing how tightly the finger joints fit together.

Click here to download the file.

Feedback¶

I had some difficulties using the align function in Fusion360, and figuring out how joints should be aligned and was a long and a difficult process, as this was my first time ever using a CAD to create such a thing employing finger joints on a huge scale. However, with the assistance of my instructor, I was able to find out how to employ a feature to help with my design process. Furthermore, considering the pet house’s doorway and the real size of the cat, it turns out that it is somewhat small, but average-sized cats can still fit.