Final Project¶

Project brief¶

The objective of our project was to develop a pizza maker capable of distributing dough into any shape desired by the user. The pizza maker features two axes. Both the Y and X axes. Stepper motors, belts, and bearings are responsible for the machine’s movement mechanism.

As long as the desired shape is programmed into the software, it can be printed. This includes anything from letters to emojis to images. Once the machine has been started, the user shouldn’t have to do anything else until the process is complete.

The intended use of this device is to print pizza dough in any shape the user specifies. This is accomplished in a series of steps as detailed below:

1) the user selects the type of filament to be used and uploads the desired shape into the software.

2) the user puts the dough into the machine, turns on the air pump, and plugs in the power cord.

3) the user will choose the starting position.

4) the user clicks the “start” button.

Project demo video¶

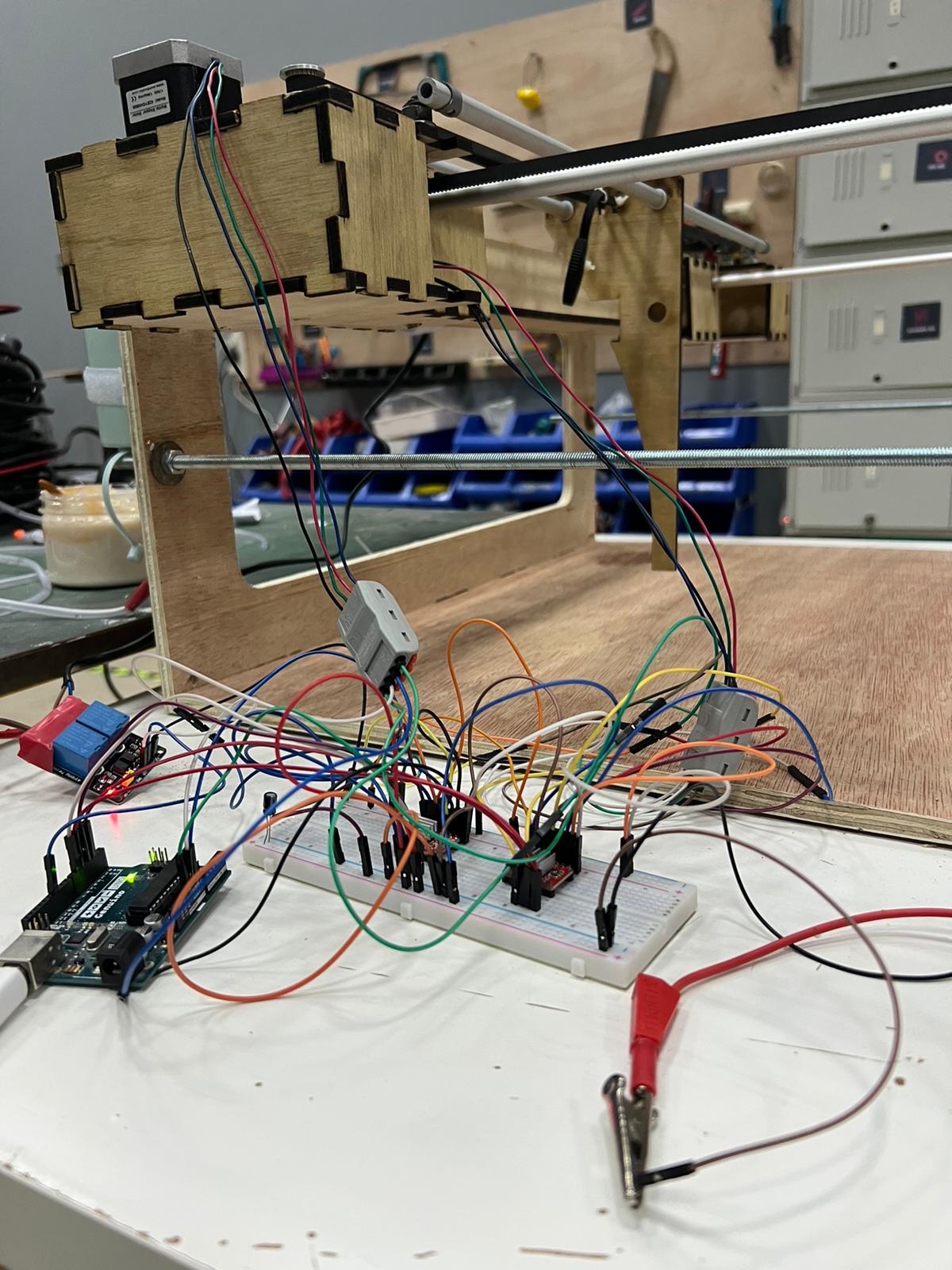

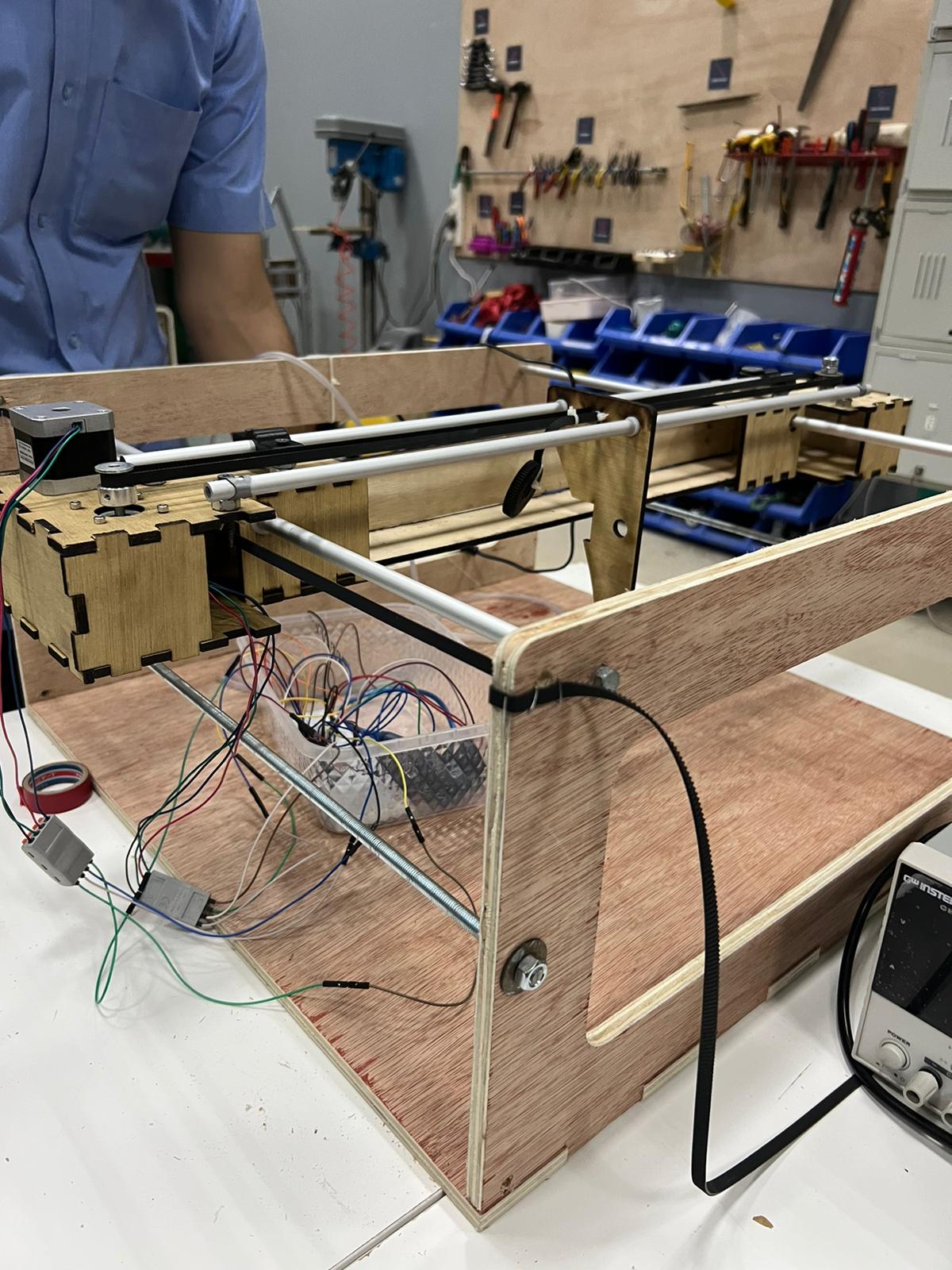

Hero Shots¶

Contribution¶

The work that Talal and I did for the project was similar. When it came to our part of the project, we focused primarily on the machine’s methods of movement. We looked into numerous potential mechanisms and analyzed their pros and cons. Then, using what we had learned in the course of our investigation, we designed the best mechanism we could for our machine using only components found in the Lab. We then set about designing the various components and determining the optimal thickness of ply to be used. There was a lot of iteration and error involved in this phase before we settled on the machine’s final design.

We also designed the inner structure of the machine and used the laser cutter machine to Cut it.The Inner Structure will be a mirrored two-part structure that will serve only to contain the CNC mechanism and the pizza dough container. It will also hold the container in the center. The electric motors that will allow the container to move in the X and Y axes will be located in the Inner Structure. The Inner Structure will be supported by shafts that connect it to the two sides of the Outer Structure. The Inner Structure, and thus the container, will be able to move on that axis using the motors. The two mirrored parts will be connected by two shafts that will hold the container, and the container will be able to move on the second axis using the power of the motors and a motor belt.

The main documentation¶

The link of the main documentation is found in Sayed Hussain’s website .