6. Large format CNC (computer controlled Machining)¶

This week I have used CNC machine to cut wood.

CNC Machine¶

CNC machining can be defined as a process in which pre-programmed computer software dictates the movement of factory machinery and tools. As a result, manufacturers can produce parts in less time, reduce waste and eliminate the risk of human error.

Process of designing the object¶

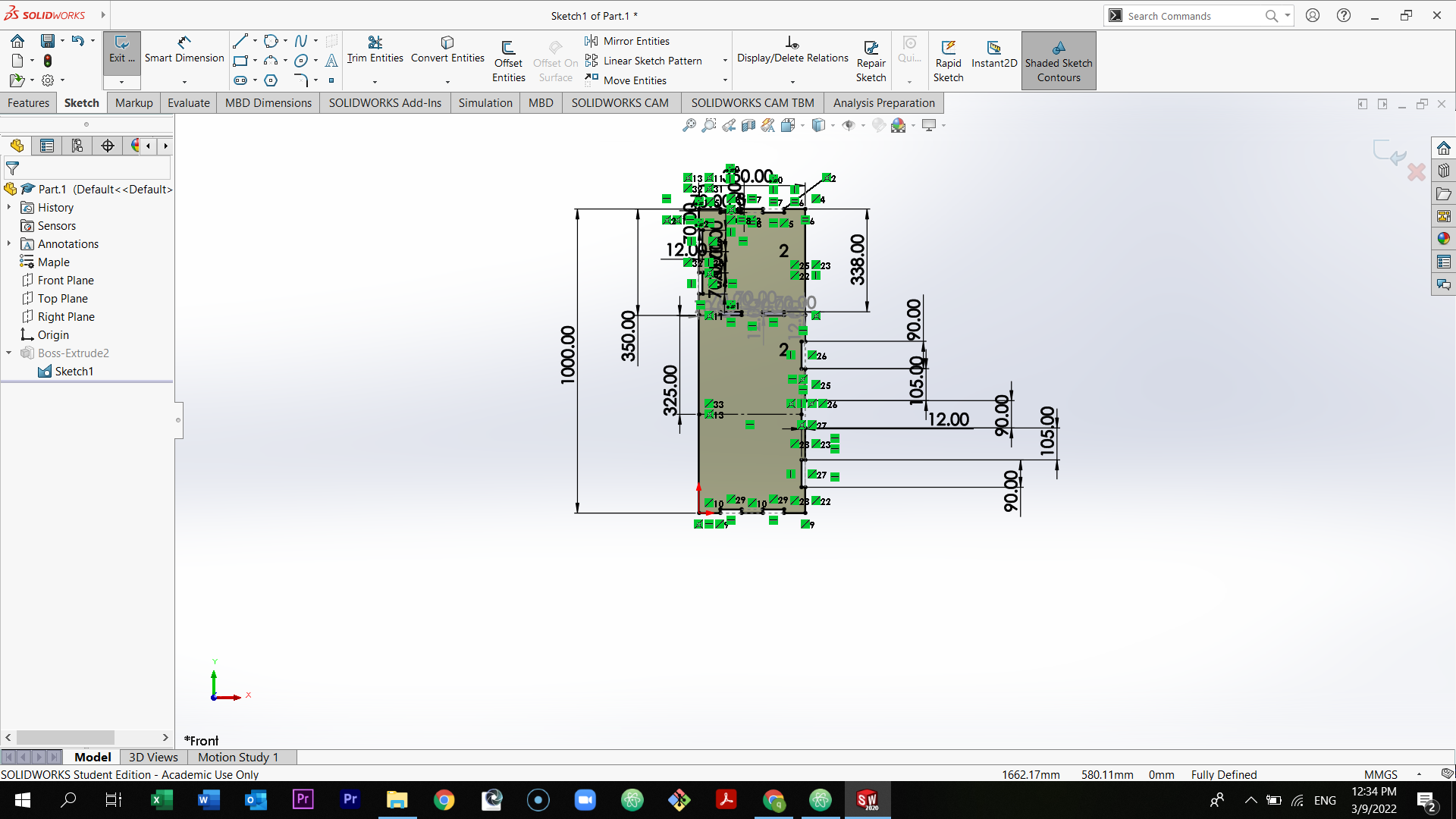

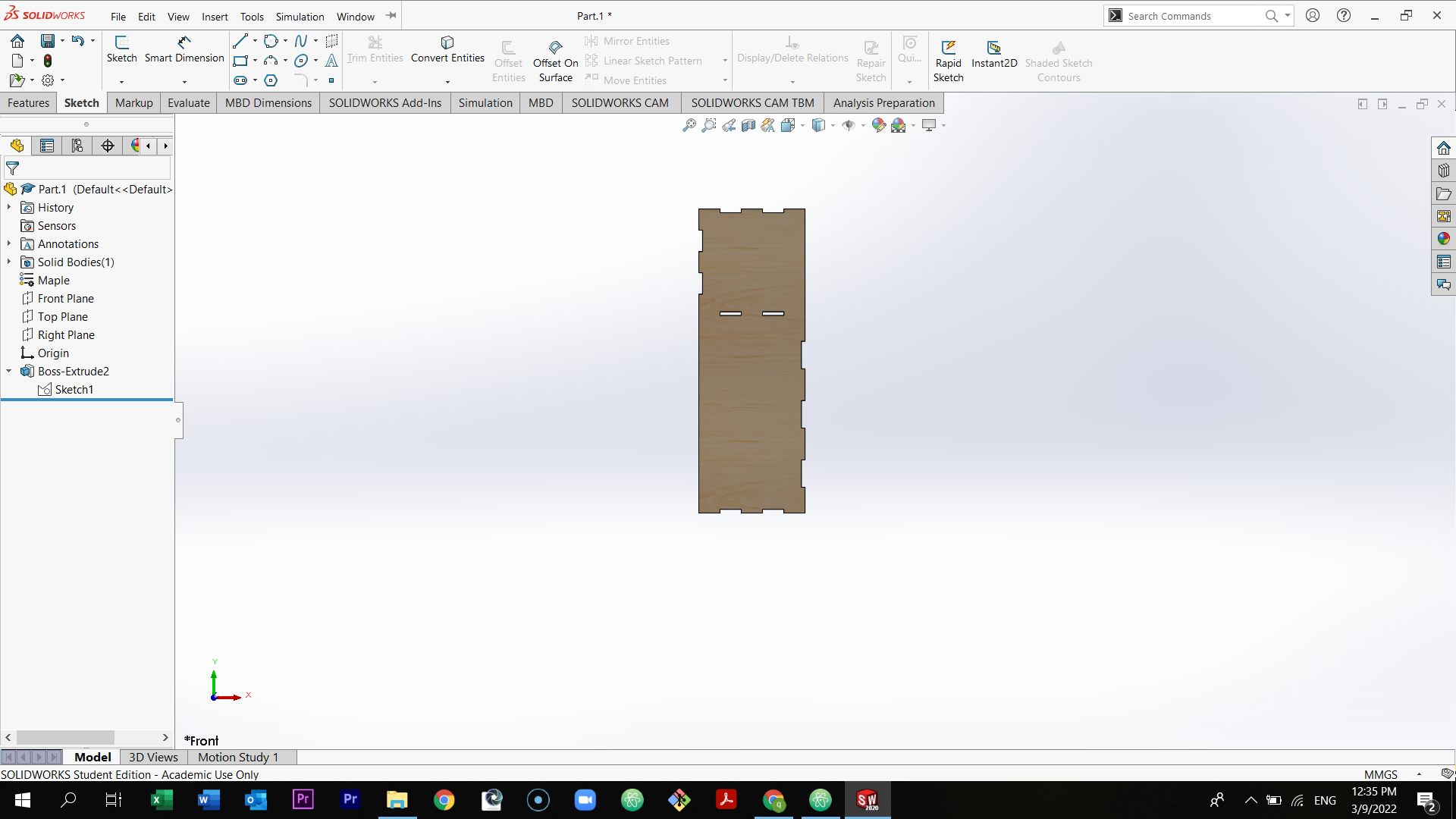

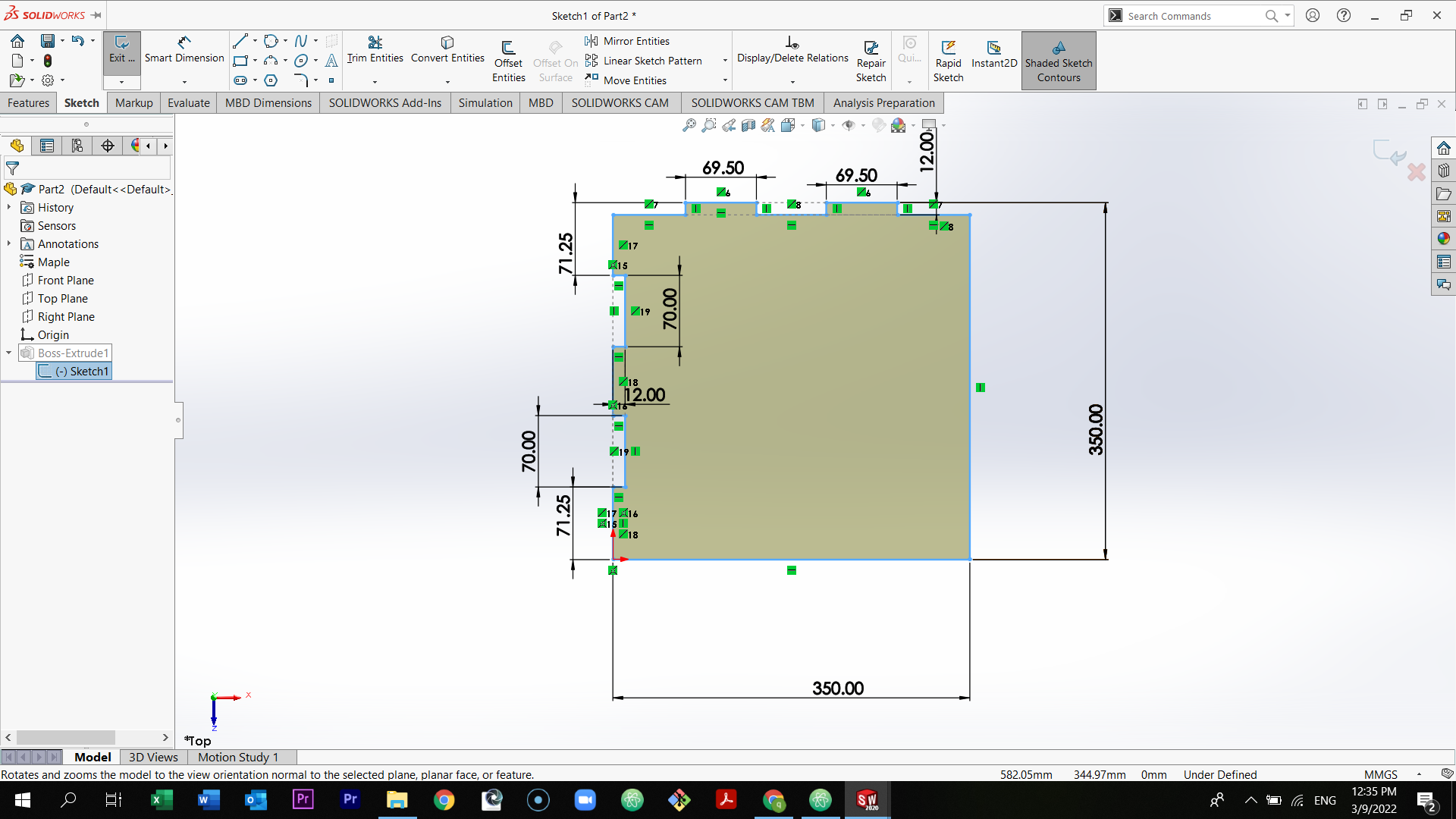

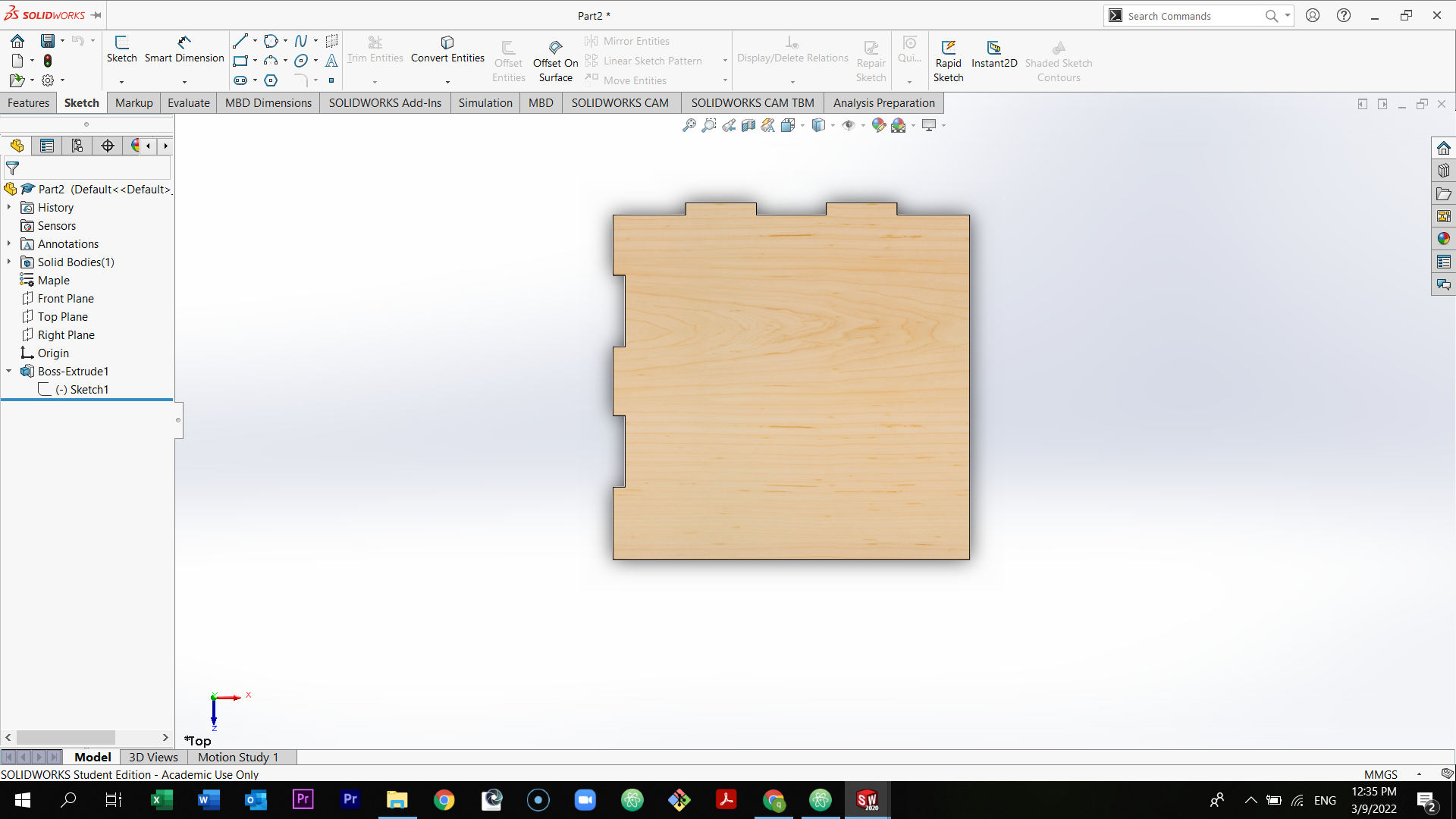

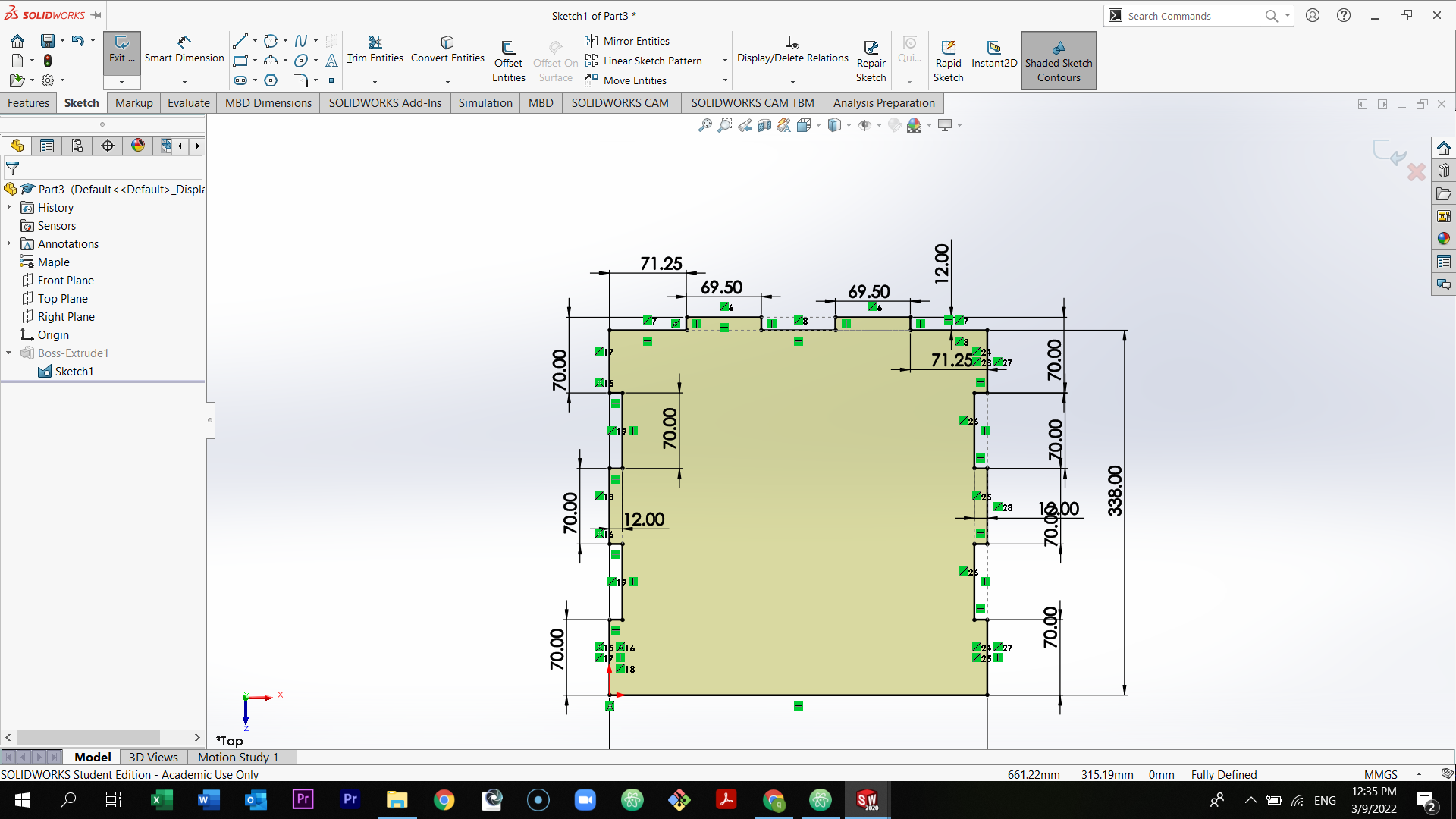

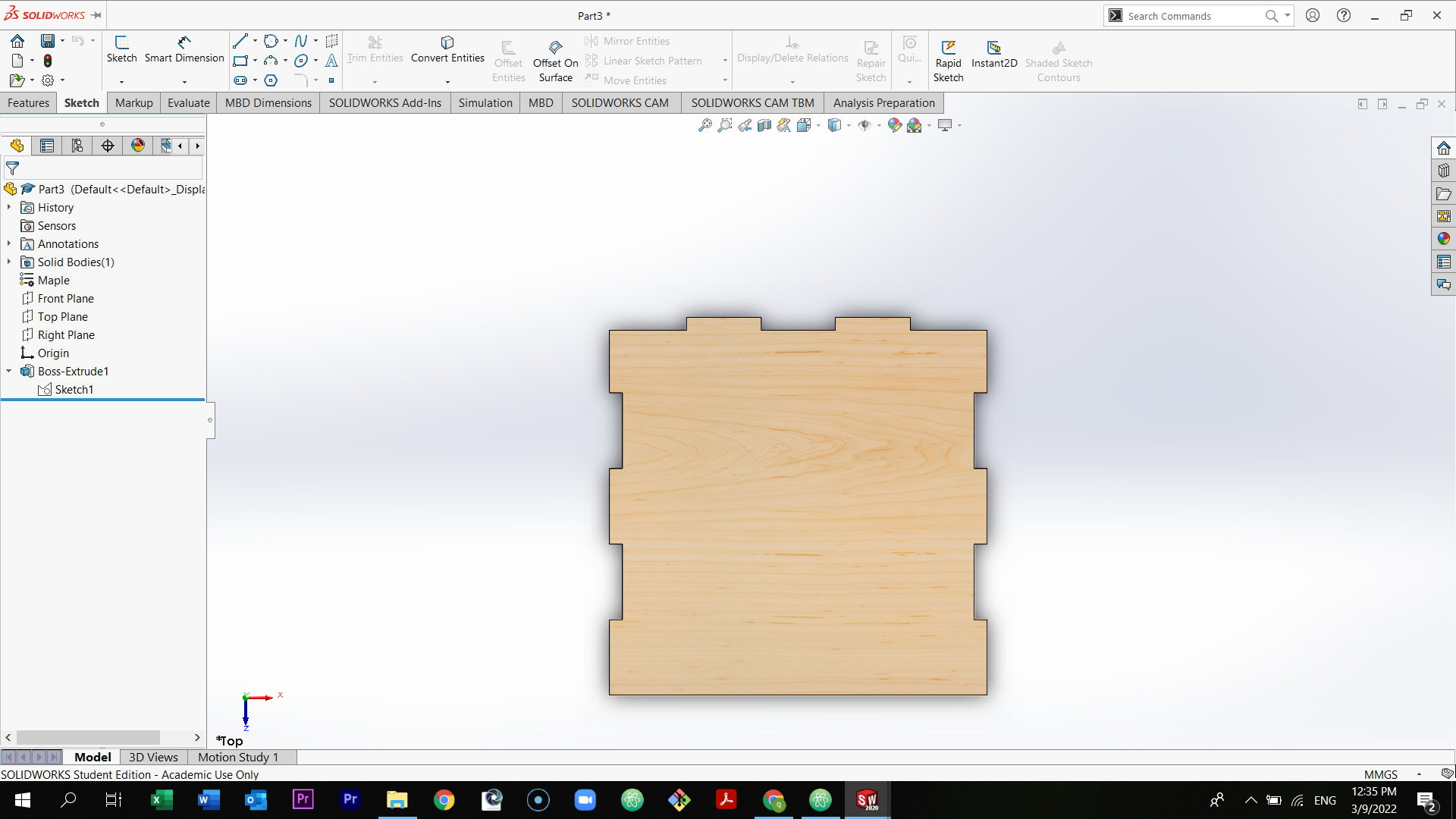

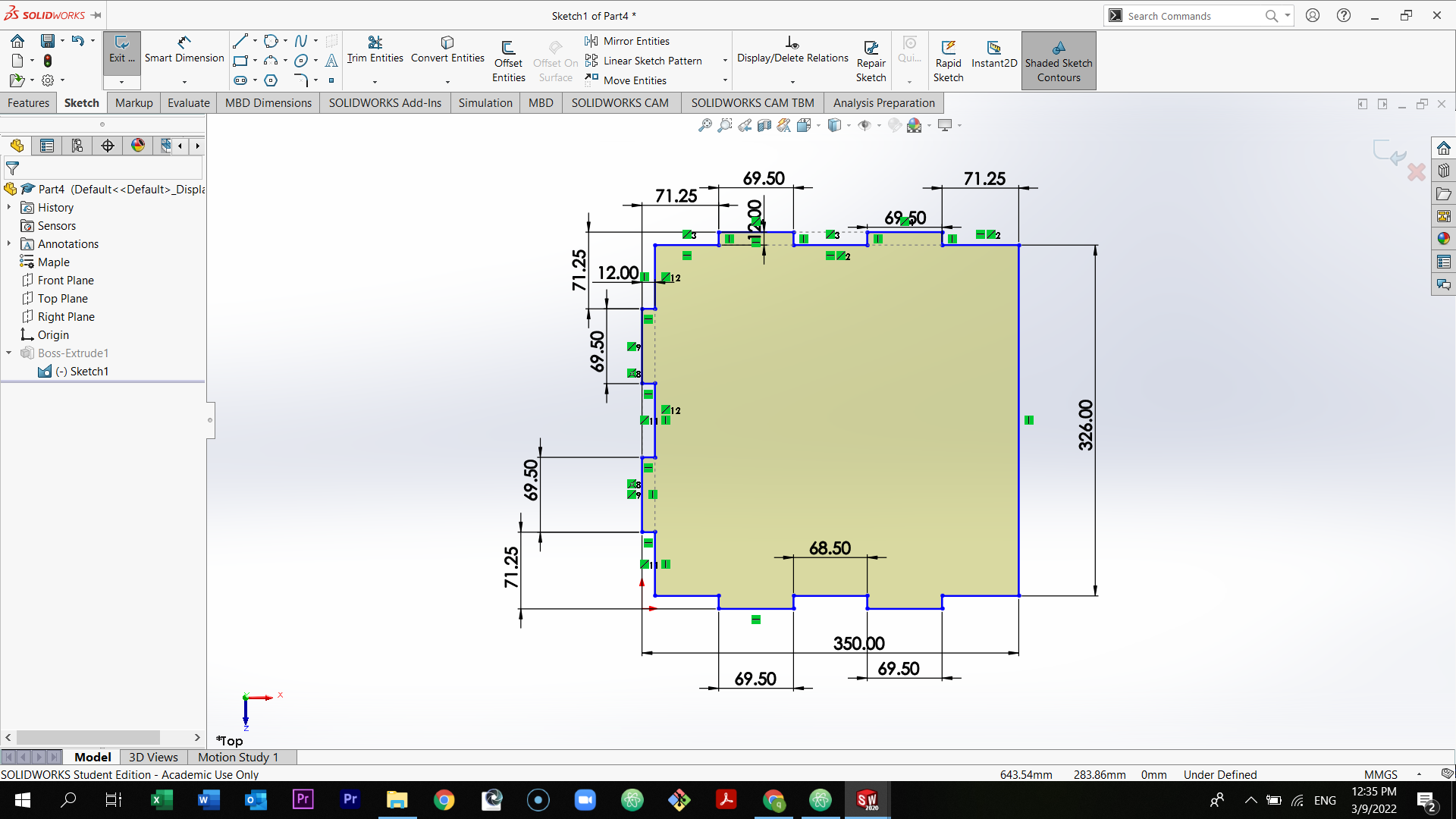

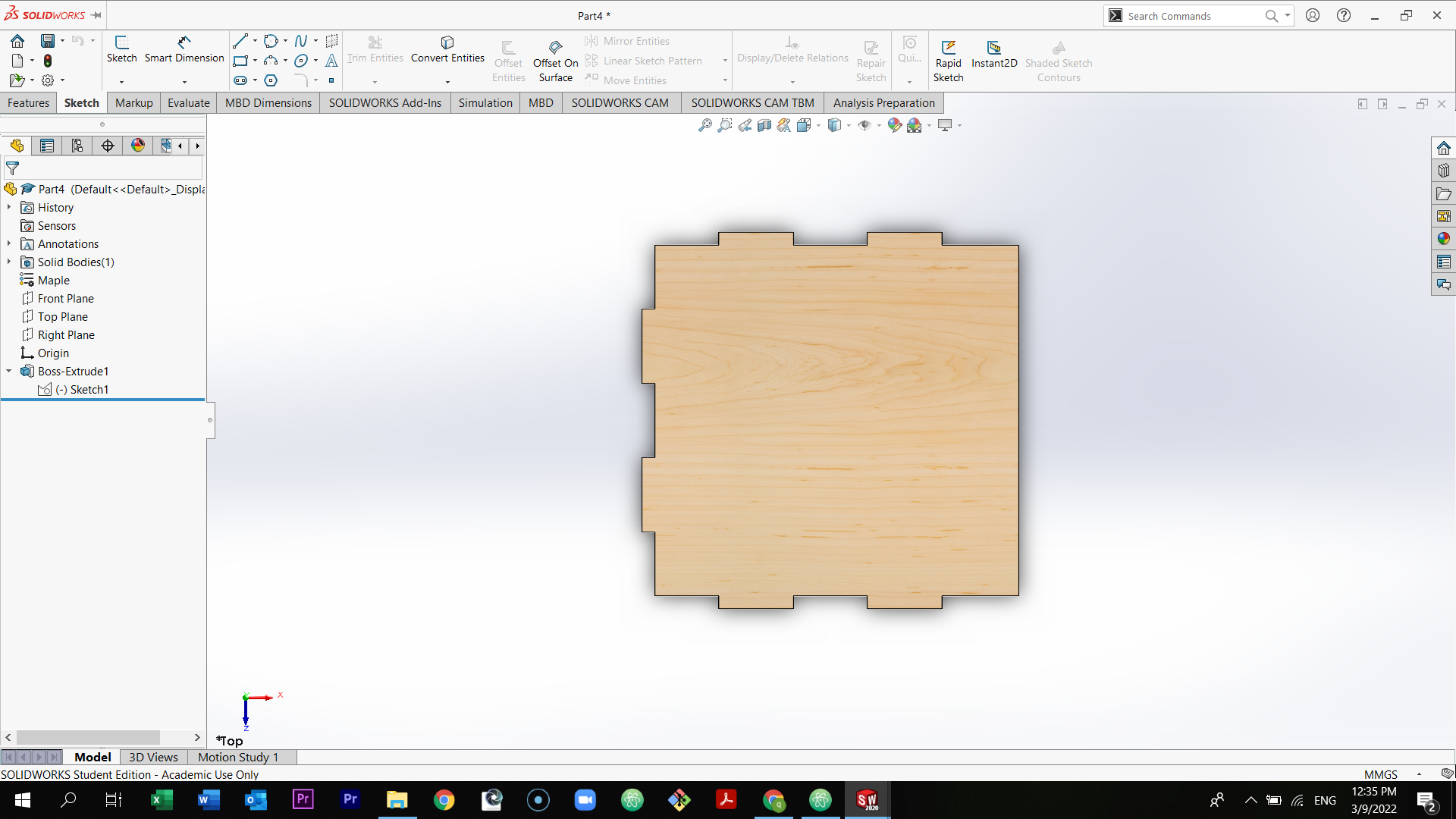

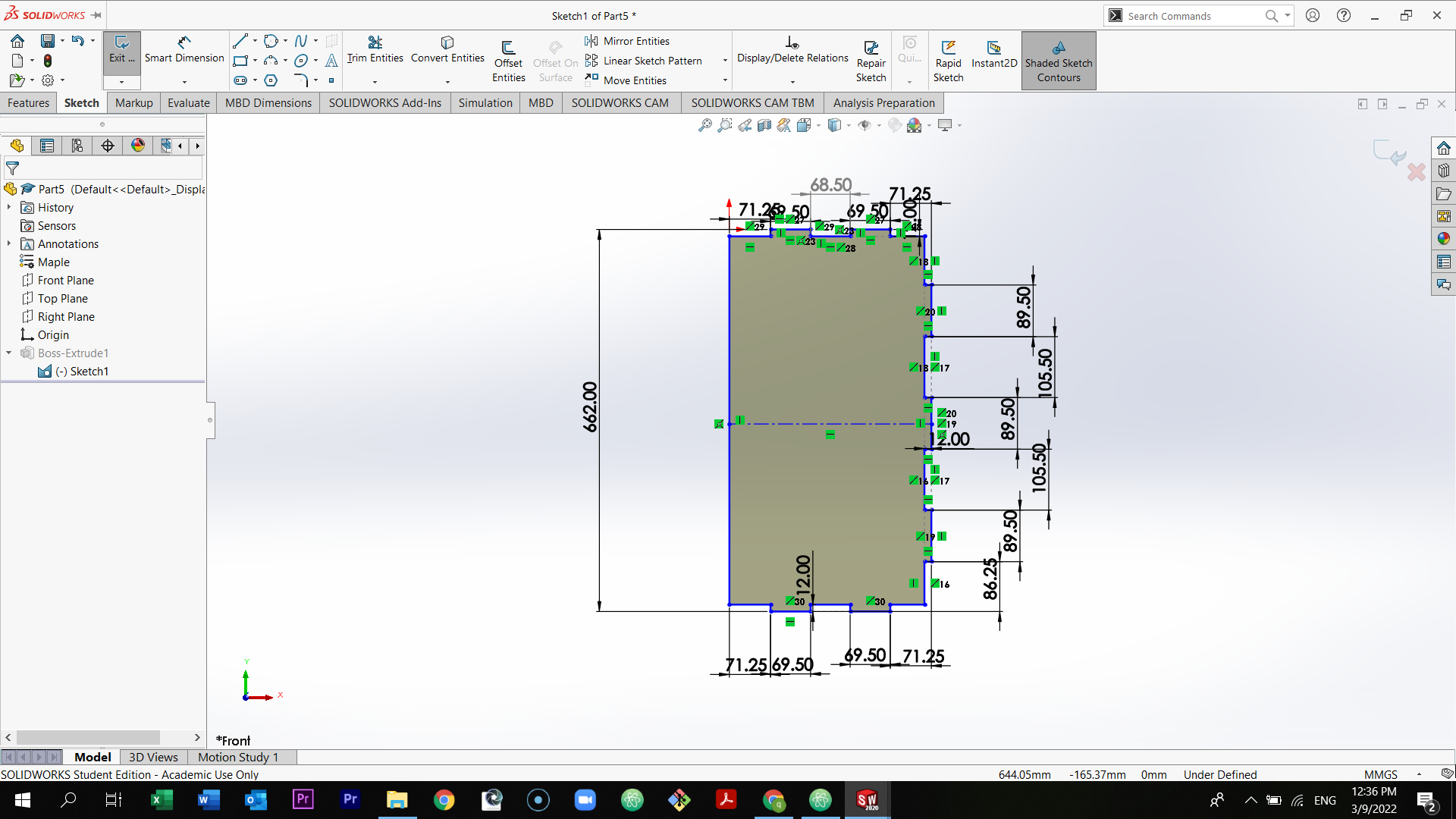

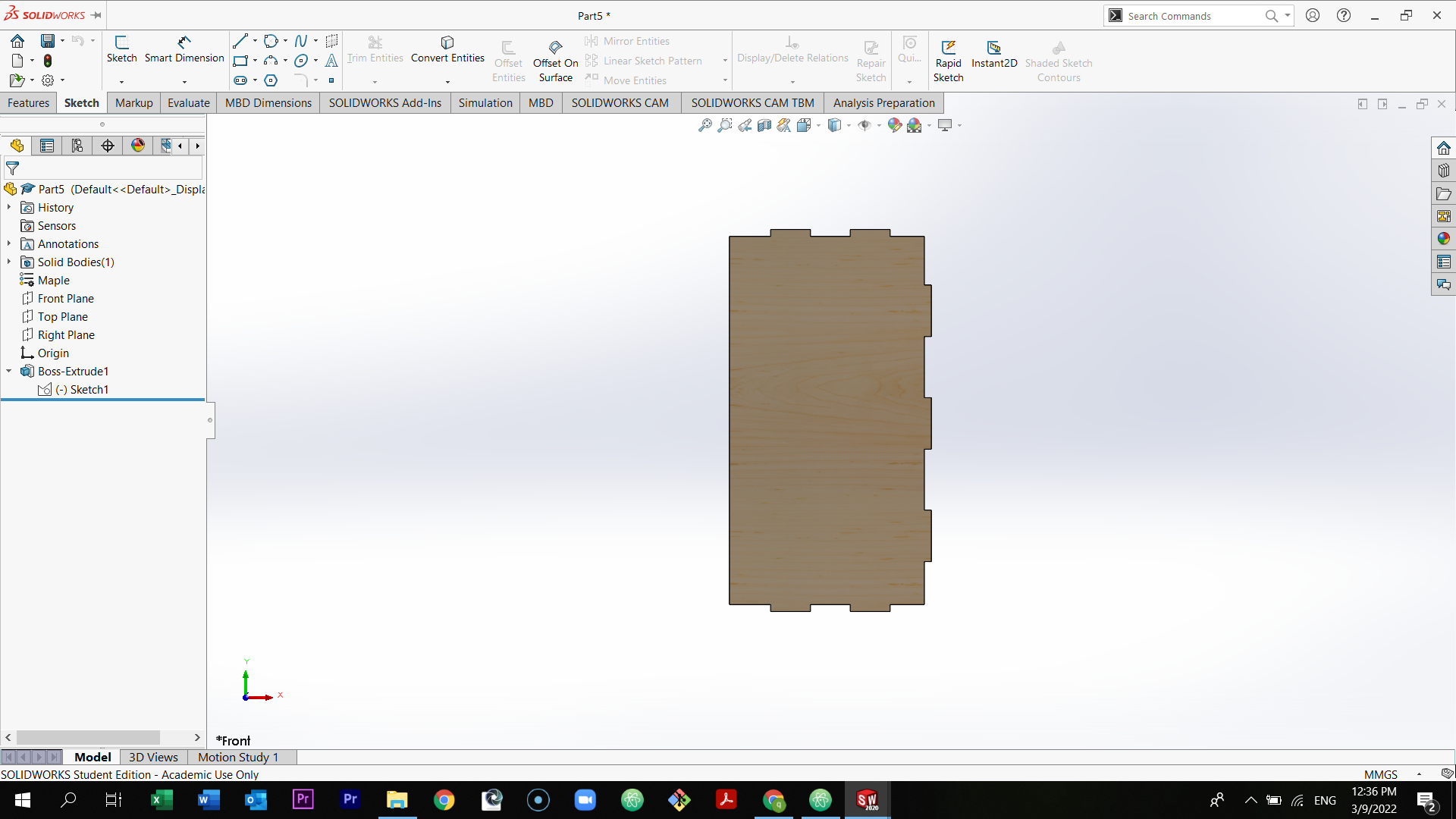

I have designed my 3d object in solidworks, and extruded everything with a thickness of 12mm. The tolerance was 0.25 from each side in every gap.

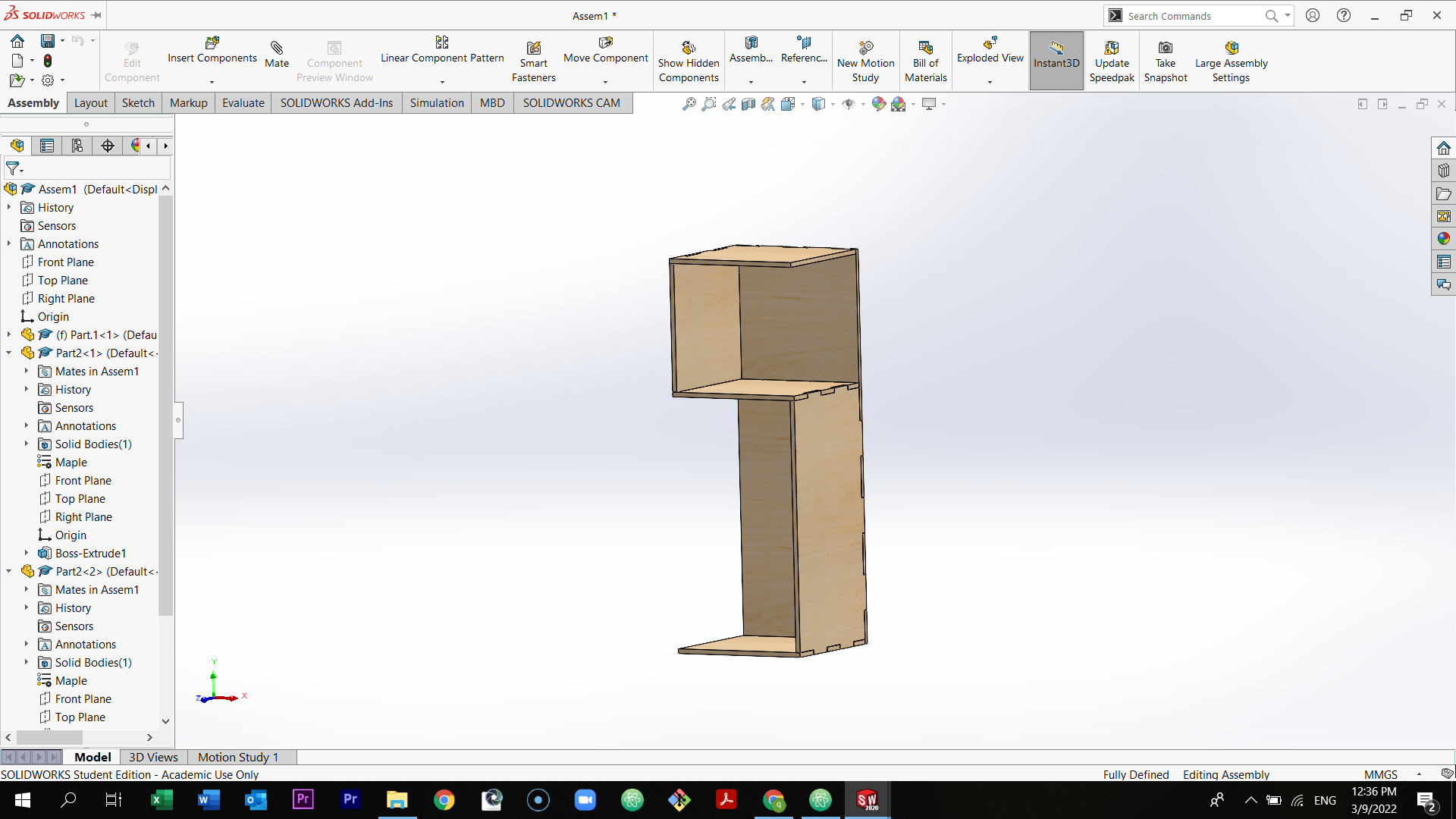

After that, I have assembled all the parts together to make sure if this will work.

## Safety

- The green button is to start the cutting process, the blue button is to pause the machine, and the red button is used in emergency cases.

- Wear safety glasses and remove all of your accessories.

Cam toolpath and making something big¶

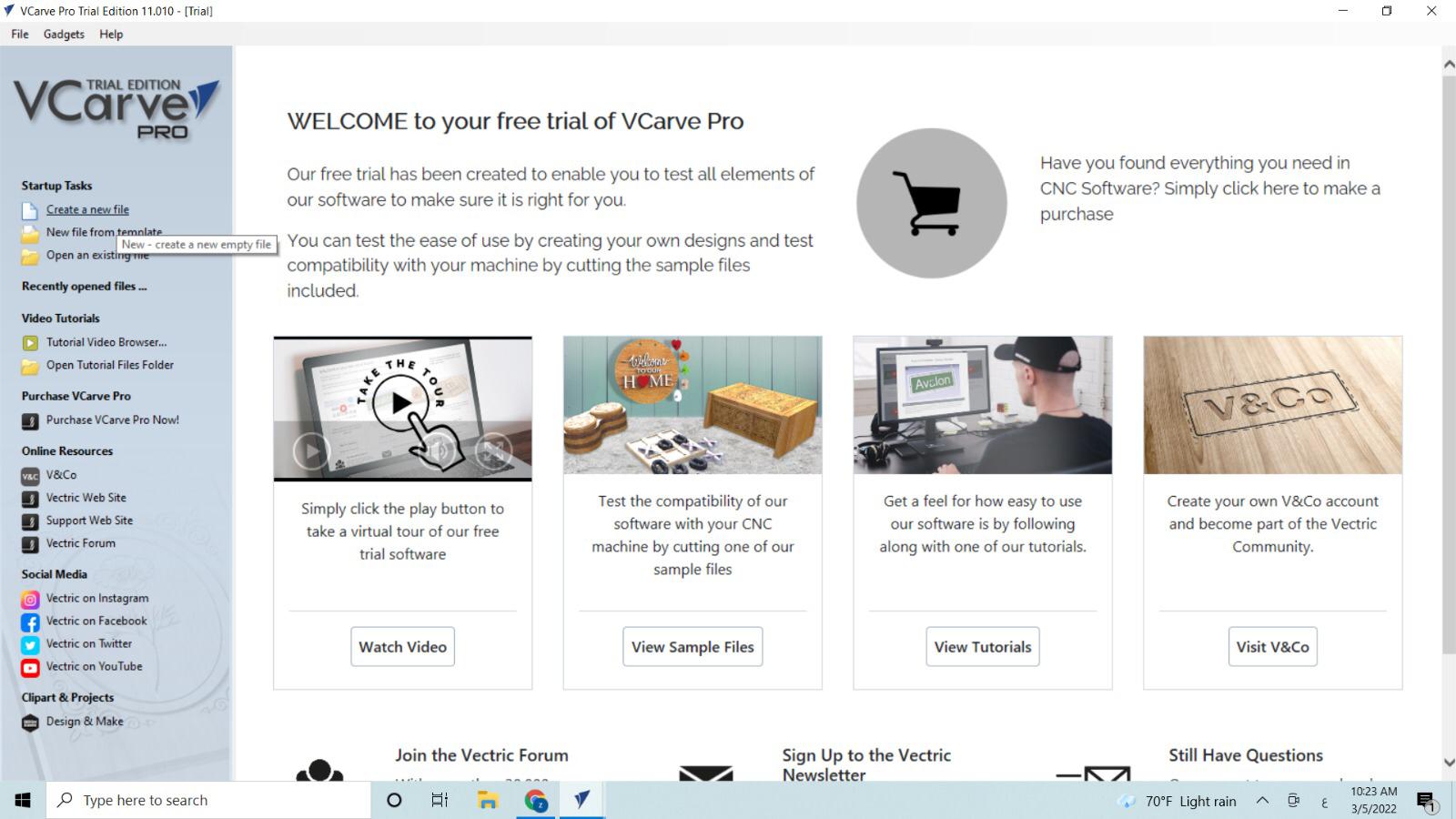

After drawing all of the parts, I have saved each part as Dxf file. Then import the dxf files in VCarve, this software allows the user to cut a 3D carving from a simple 2D image.

To download Vcarve trial version click here

Open Vcarve and click on create a new file.

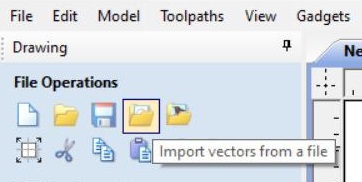

Import the dxf files.

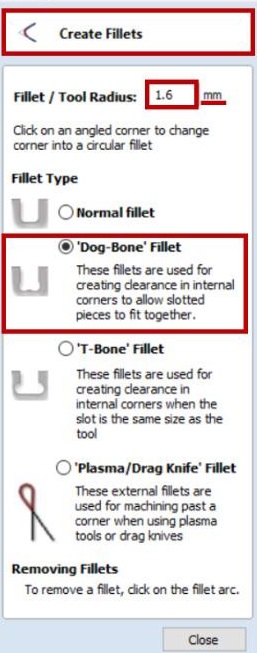

Arrange your parts in the sheet, and select create fillet - Dog Bone fillet and choose the corners inside the gaps.

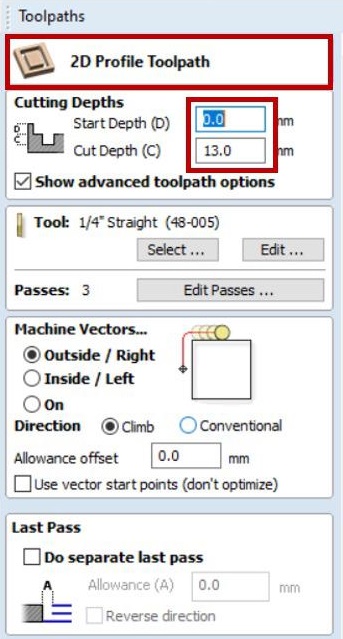

After that, select the toolpath. Edit the 2d profile toolpath. In the start depth type zero, and in the cut depth type 13. The cut depth is 1mm greater than the original thickness of the wood. We do this to make sure that all of the parts are 100% cut.

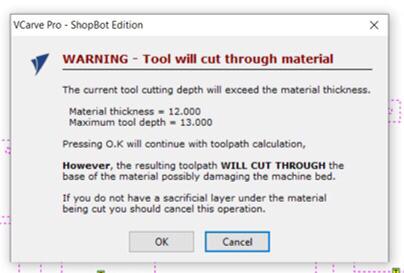

You will get a warning, but ignore it, because there is an extra sheet below the wood.

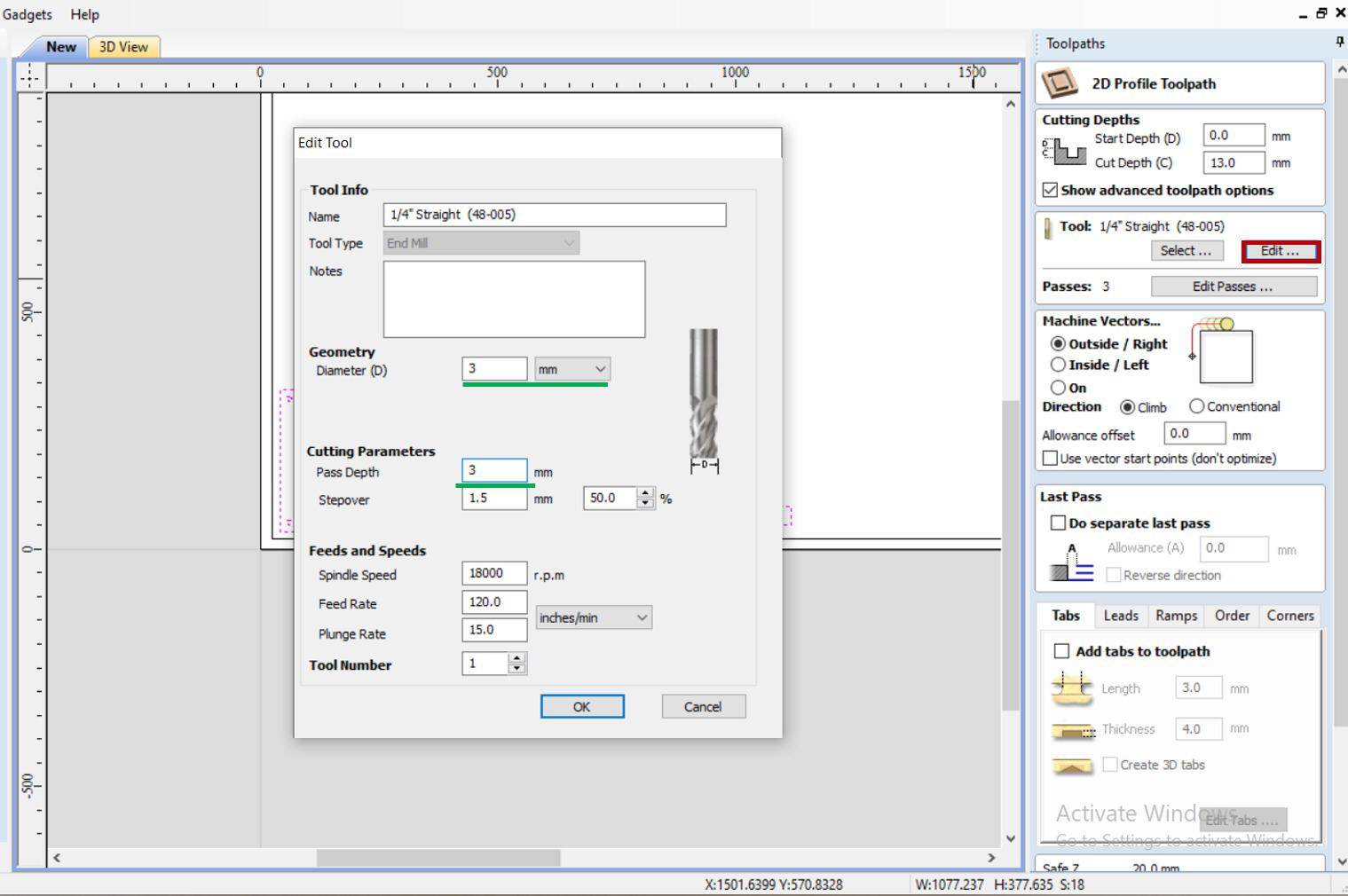

Edit tool and type these options.

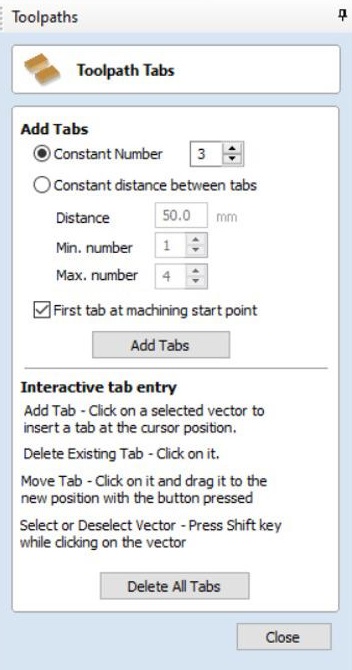

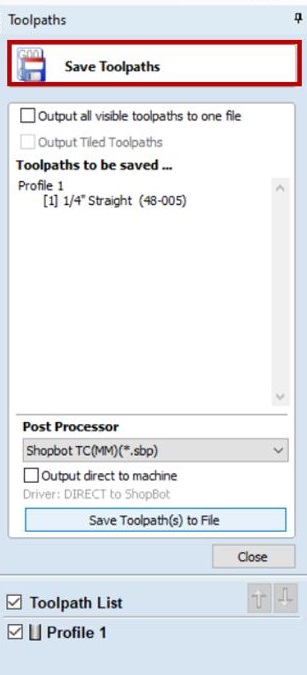

Toolpath

Then save toolpath, and proceed to the cutting part.

Cut, cut, cut.

After cutting, and removing the parts from the machine, I started sanding all of the parts. Sanding plays an important role in making the wood smooth.

After sanding, I colored the parts.

Before

Hero Shot¶

After

Final

Problems and solutions¶

The main problems that I faced were:

-

After completing my design in solidworks, and I was ready to print them. I have realized that the tolerance was wrong. So I have done them again.

-

After cutting the parts using the cnc machine. Some of the parts were not stable when attaching them together so I have used wood glue to fix this issue.

Design Files¶

Original files:

Dxf files:

Group Work¶

Click here to view the group work