This week’s group assignment encompasses testing the design rules for the 3D printers and checking the printers limitations There are several tests that were implemented to check the 3D printer performance

Infill test¶

This test was utilized to see how much material is filled inside the design that is to be printed.

A good fill value is around 20% but if you want a stronger design you’re going to choose a higher percentage

Shell Thickness Test¶

This test determines the thickness of the borders, as shown below, as the number of shells increases the thickness of the outer border will increase and vice versa.

On the contrary if one wishes to have a strong design but doesn’t want to add a lot of infill, he can increase the number of shells and reduce the infill and increase the robustness of the design.

Angle test¶

This test shows how much angle we can have without adding a support, and as shown below the 3D printer produces a strong design without a support until 50 degrees and after 50 degrees it starts becoming more fragile. But the maximum angle that the printer can print without a support is almost 90 degrees.

Bridging Test¶

The following test is called the bridging test and it has been built without having a support. If we have a small line the line will be smooth and won’t have any flaws but as we go up and increase the width of line there are more flaws as you can see in the figure below.

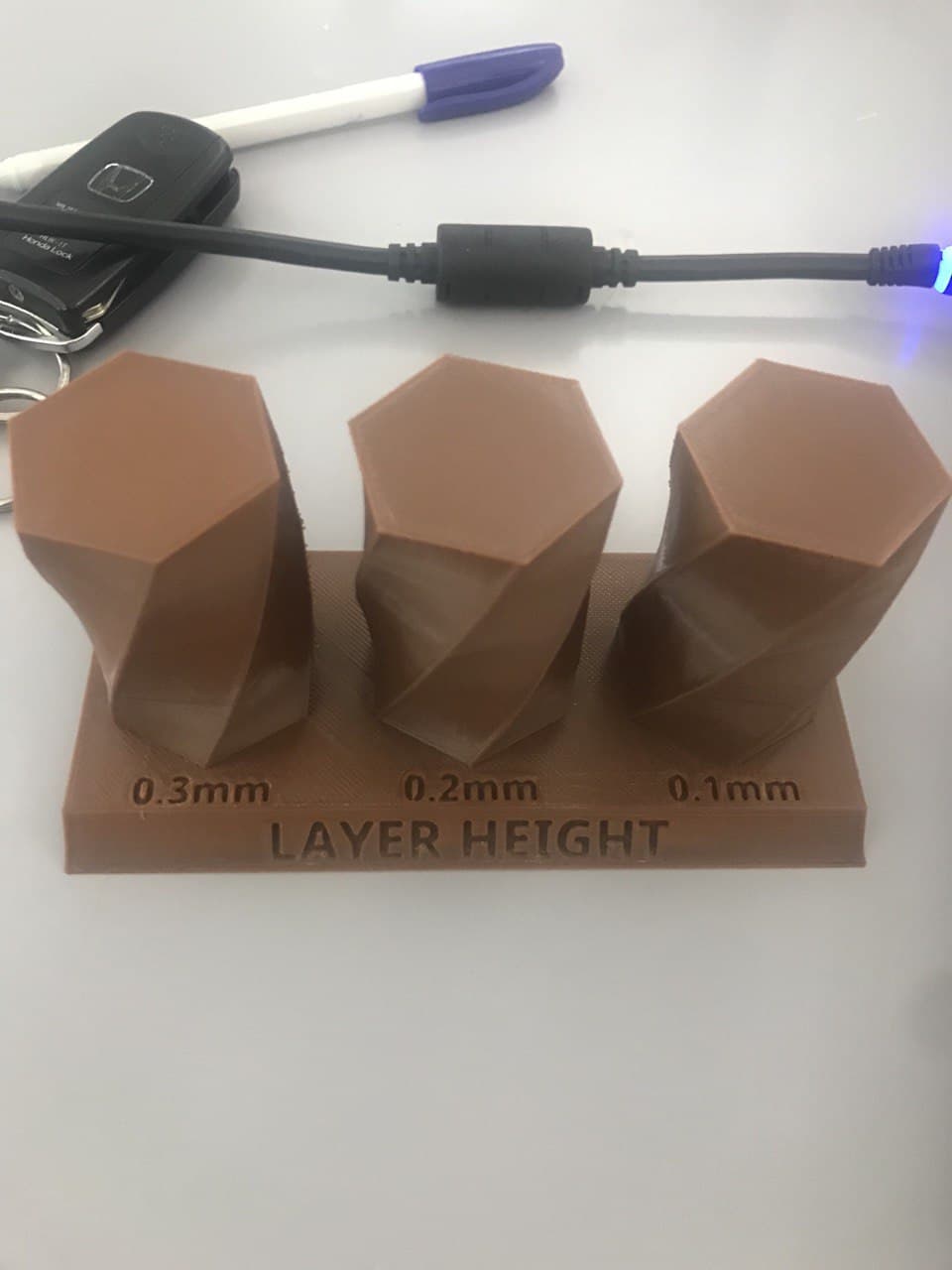

Layer Height Test¶

The following test I utilized to check the layer height effect on the design and three distinct layer heights were utilized which are 0.1, 0.2 and 0.3 mm.

As the layer height decreases more material and layers are used in the design, therefore the design will be better in quality but it might take longer periods of time to finish the design.

Support test¶

This test is used such that the 3D printer has something to print on and doesn’t add material in the air and there is something where you’re design can be printed.

The support is usually made from a fragile material and can be easily broken such that the support can be removed after the design is made.