6. Moulding and casting¶

This week’s task is about moulding and casting. Firstly, a design was done in Fusion 360. The maximum dimensions that can be designed in the milling machine is 80x40x10

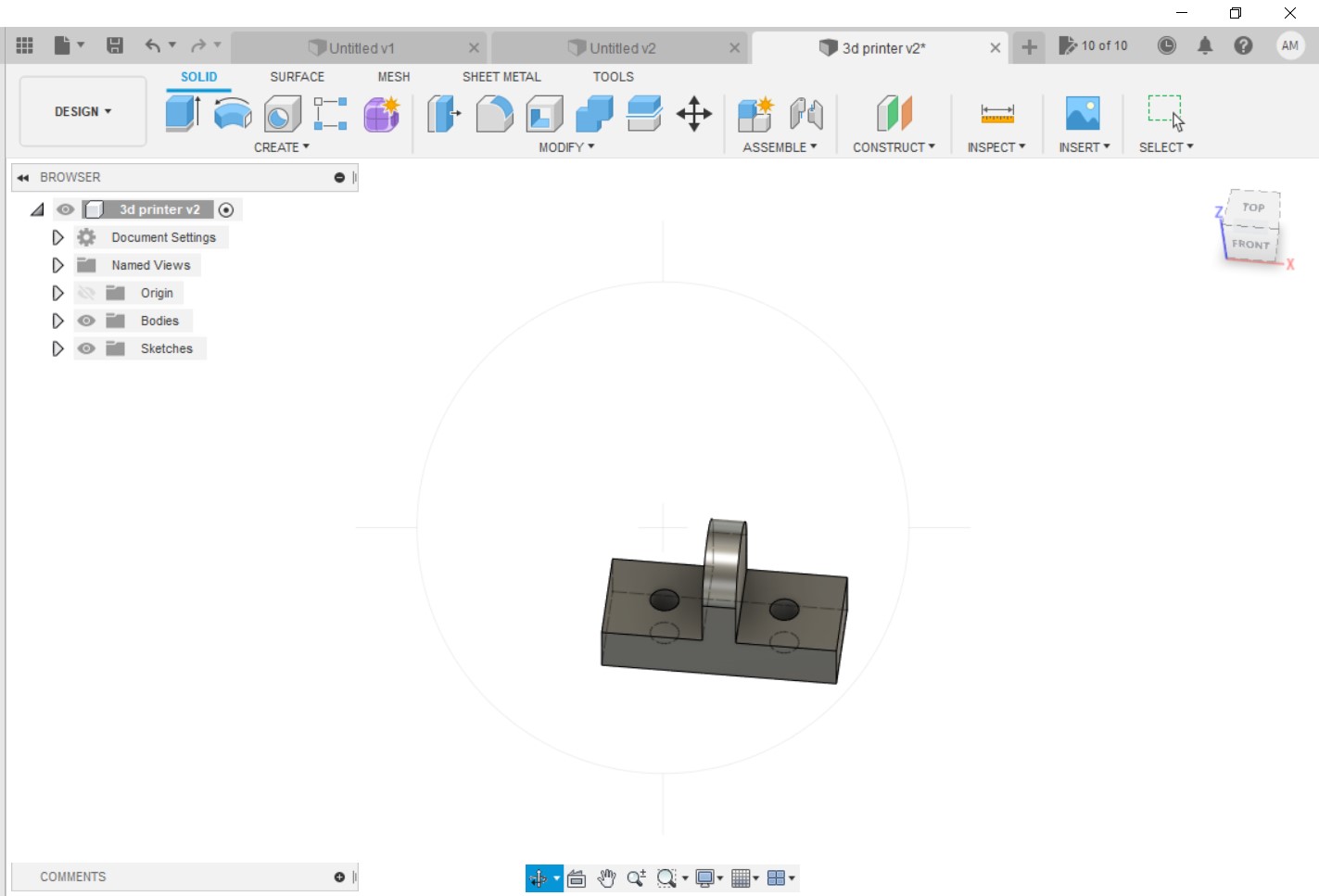

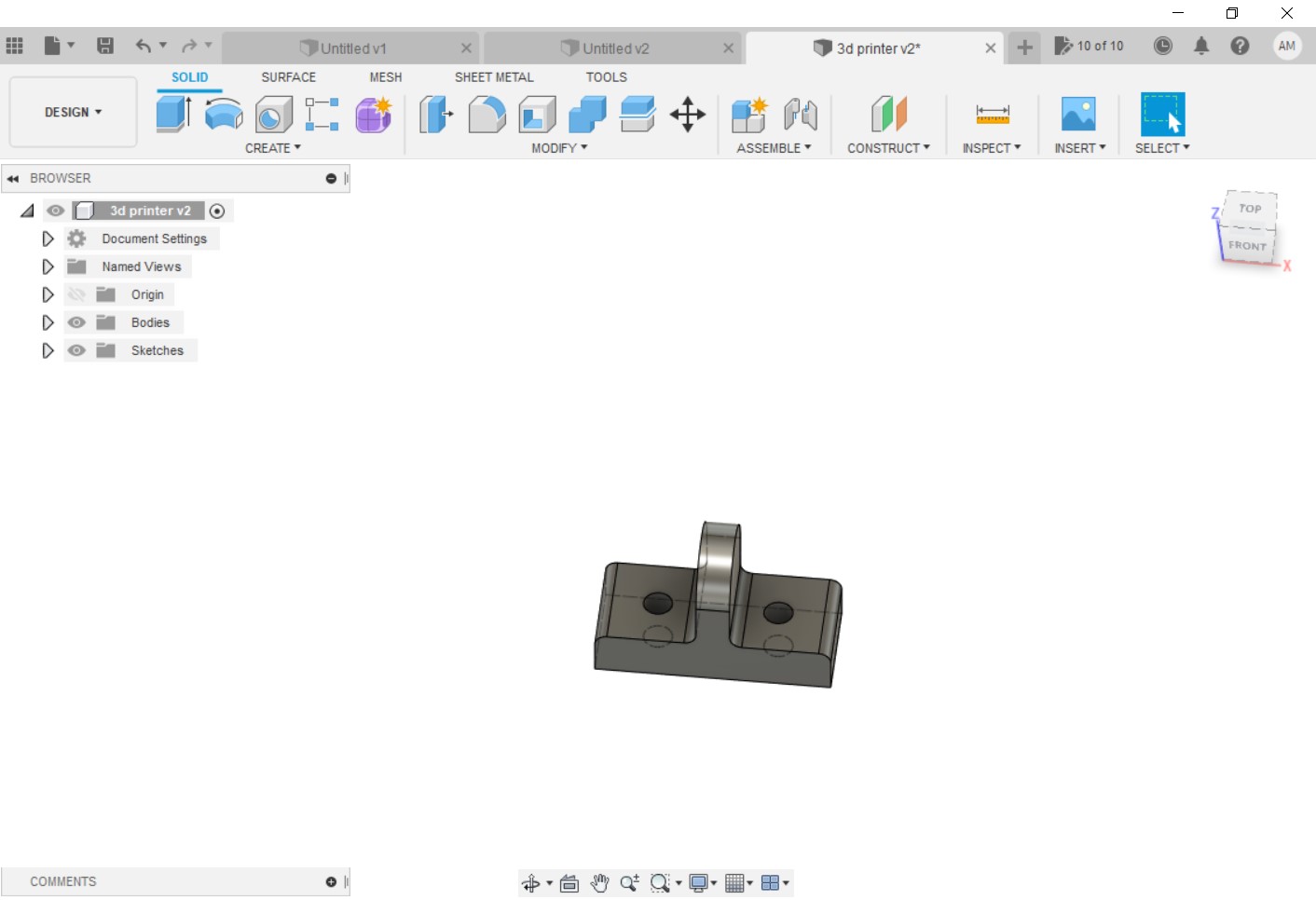

Fusion 360 Design¶

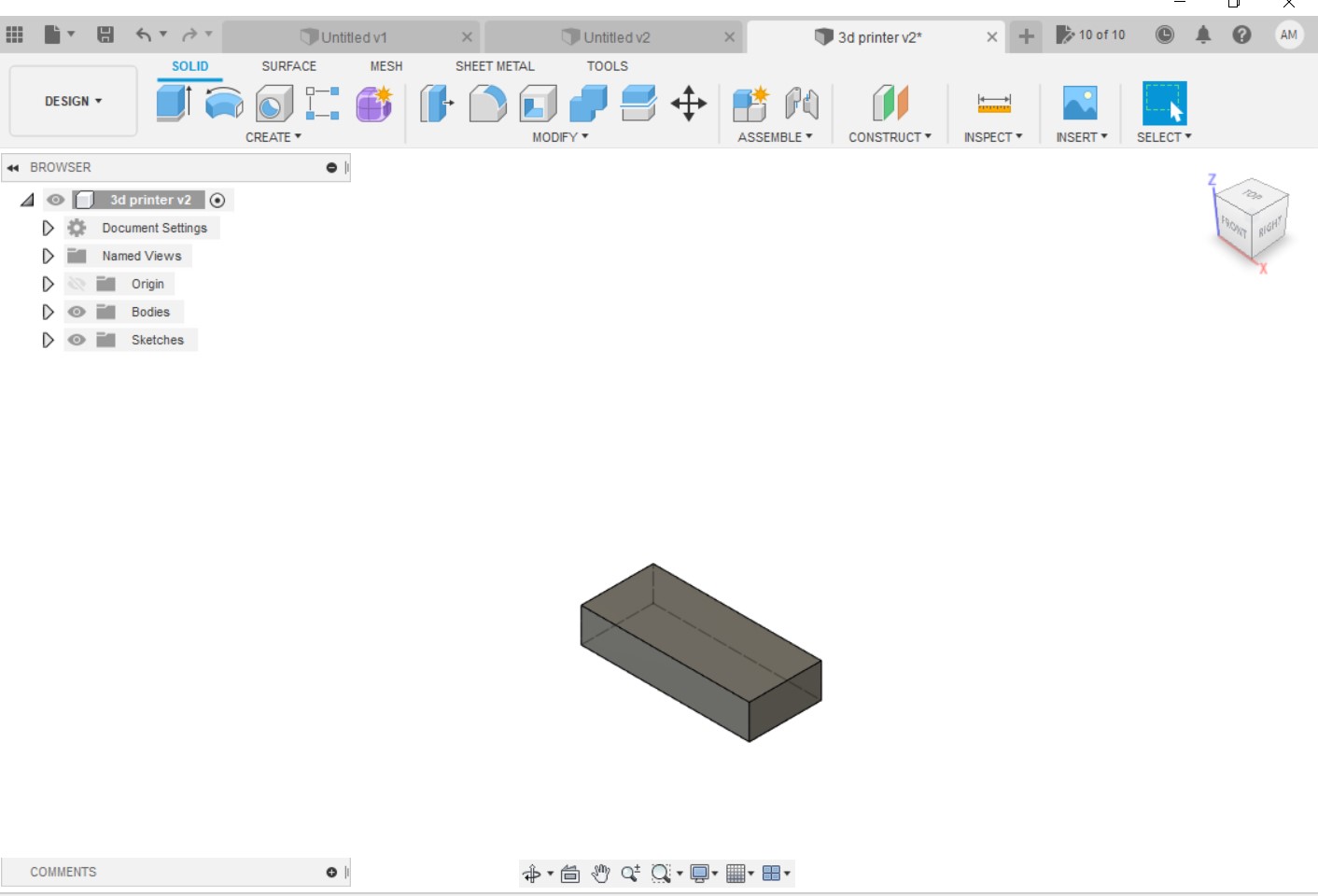

A horizontal rectangle was made and it was extruded

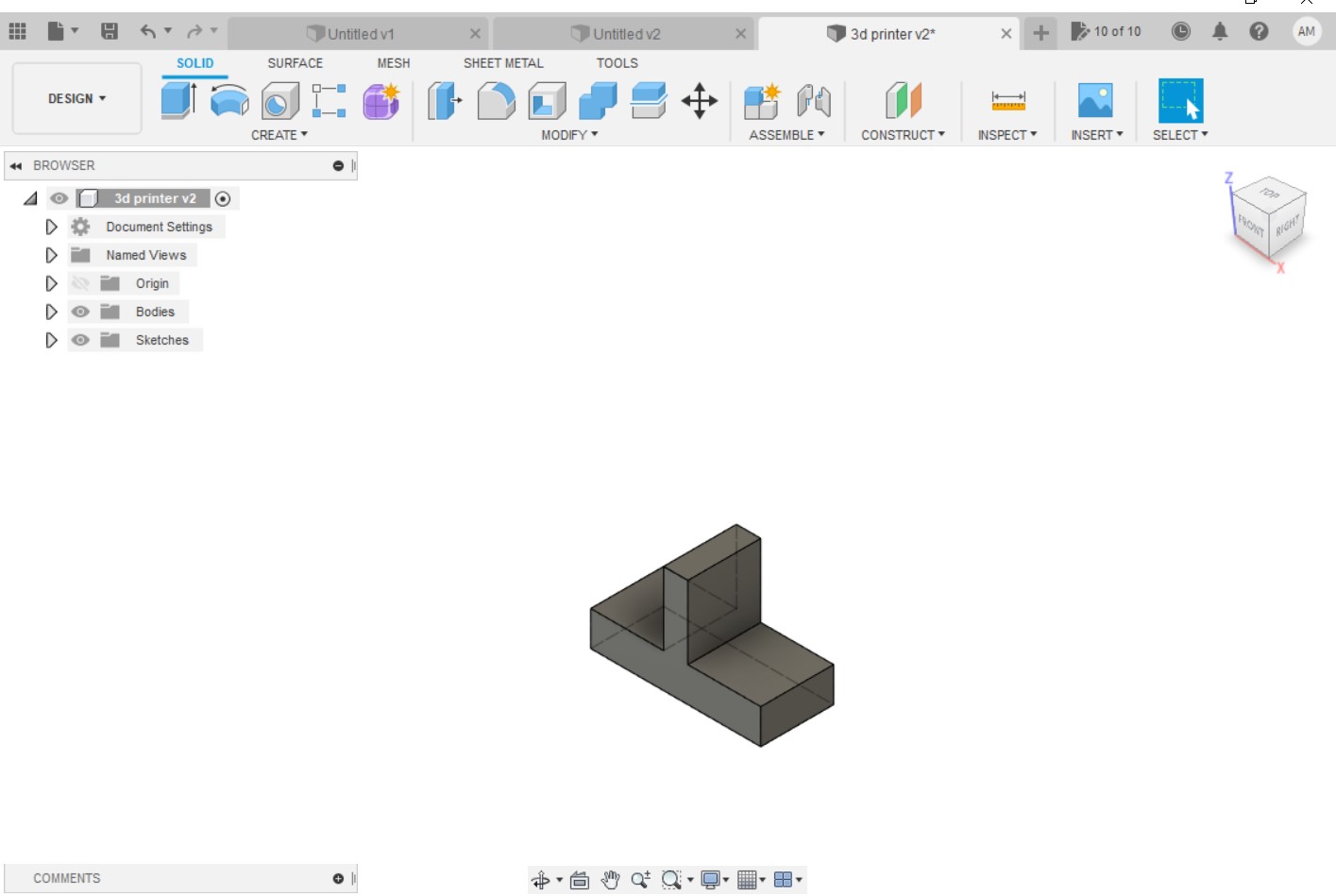

Then a vertical rectangle was added and extruded on the top of the previous rectangle

Then a vertical rectangle was added and extruded on the top of the previous rectangle

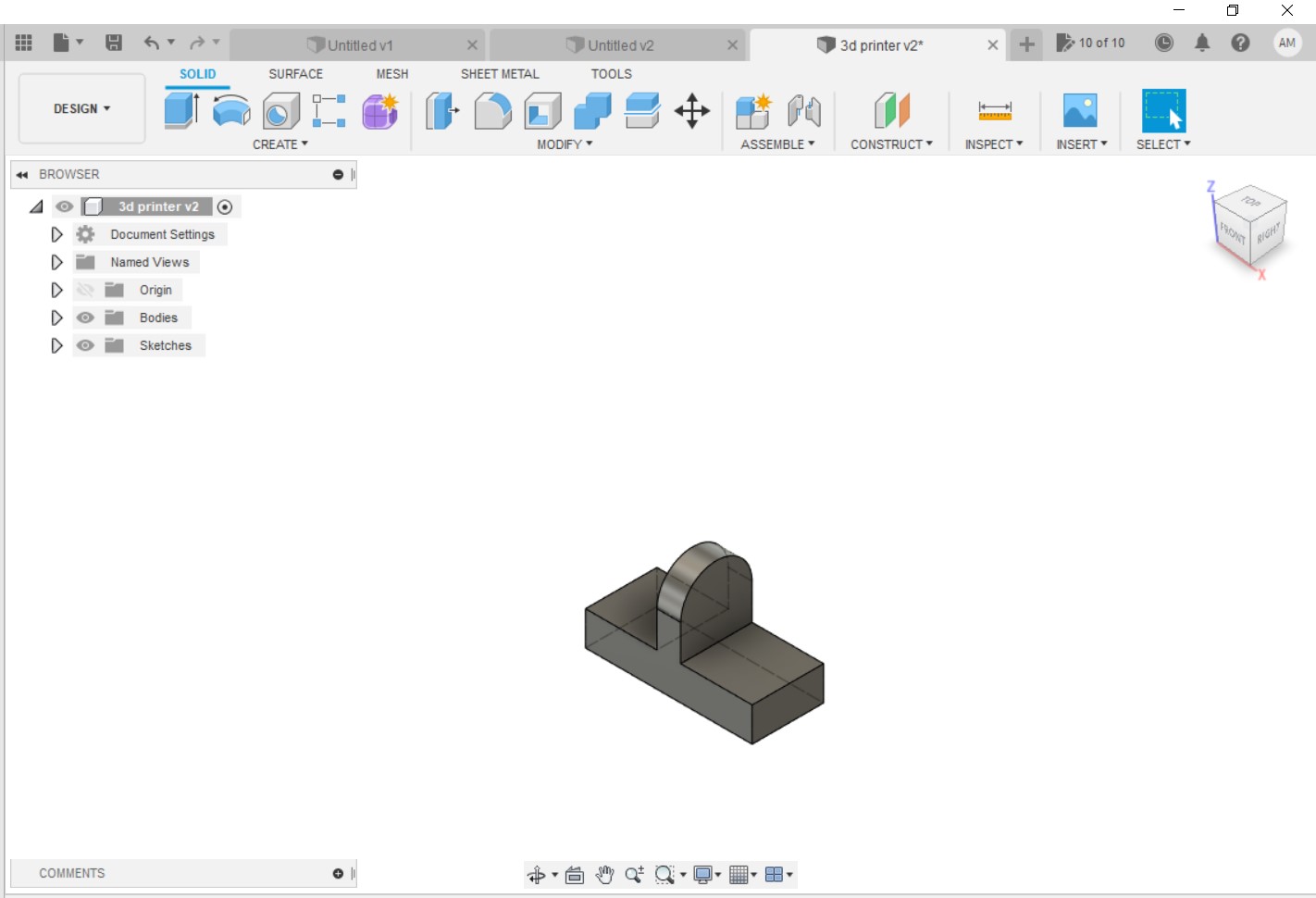

A fillet was added on the vertical rectangle edges to make them round

A fillet was added on the vertical rectangle edges to make them round

Then two circles were added and both were extruded in the opposite direction and two holes were made

Then two circles were added and both were extruded in the opposite direction and two holes were made

Finally, fillets were added on both edges of the horizontal rectangle in order to make them round

Finally, fillets were added on both edges of the horizontal rectangle in order to make them round

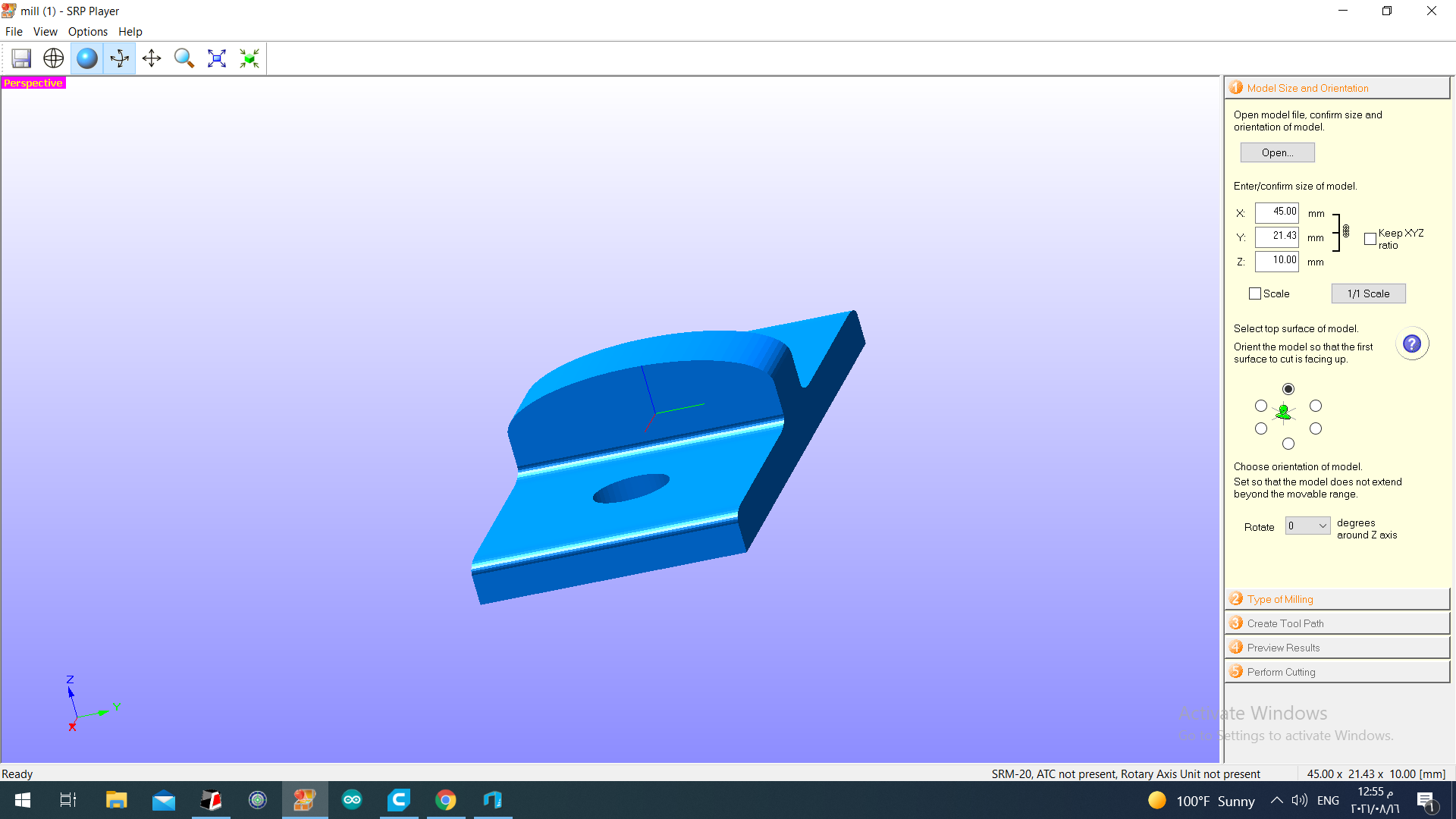

The software that was utilized for the milling machine is called SRP

Firstly, the surface was adjusted to be orthogonal on the z axis

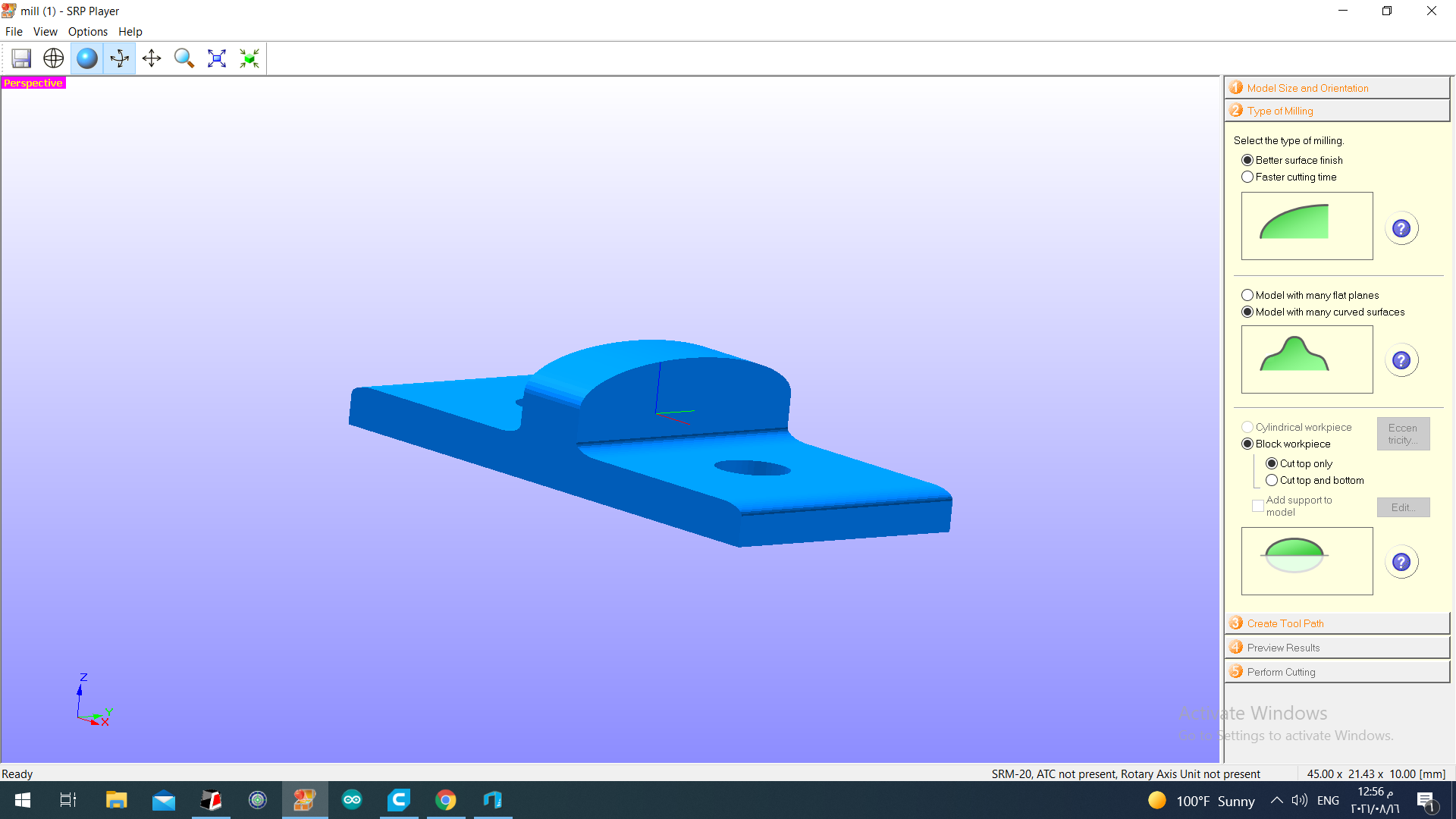

A better surface finish was chosen, even though there are not alot of details in the design

A better surface finish was chosen, even though there are not alot of details in the design

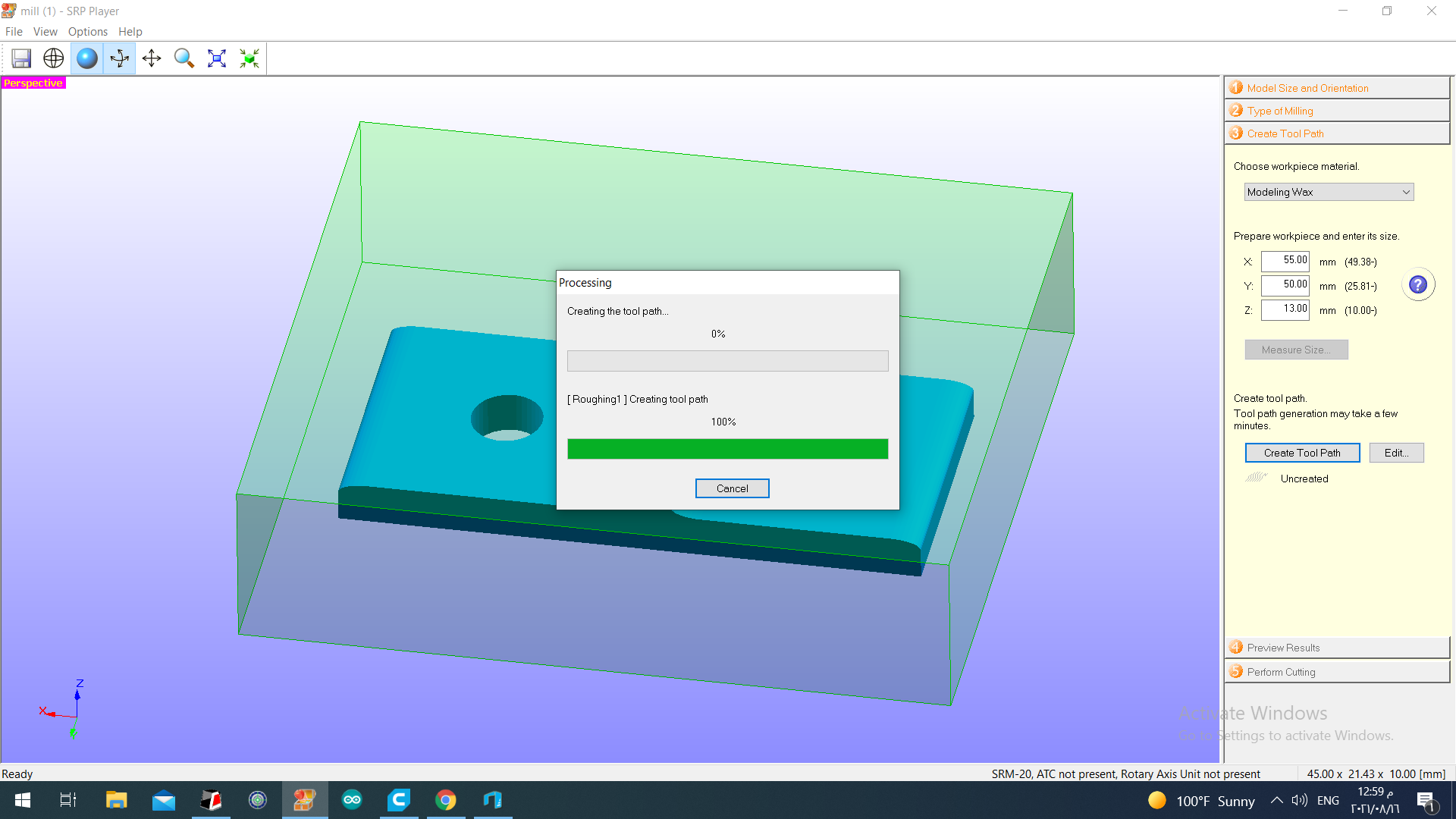

Creating tool path for roughing

Creating tool path for roughing

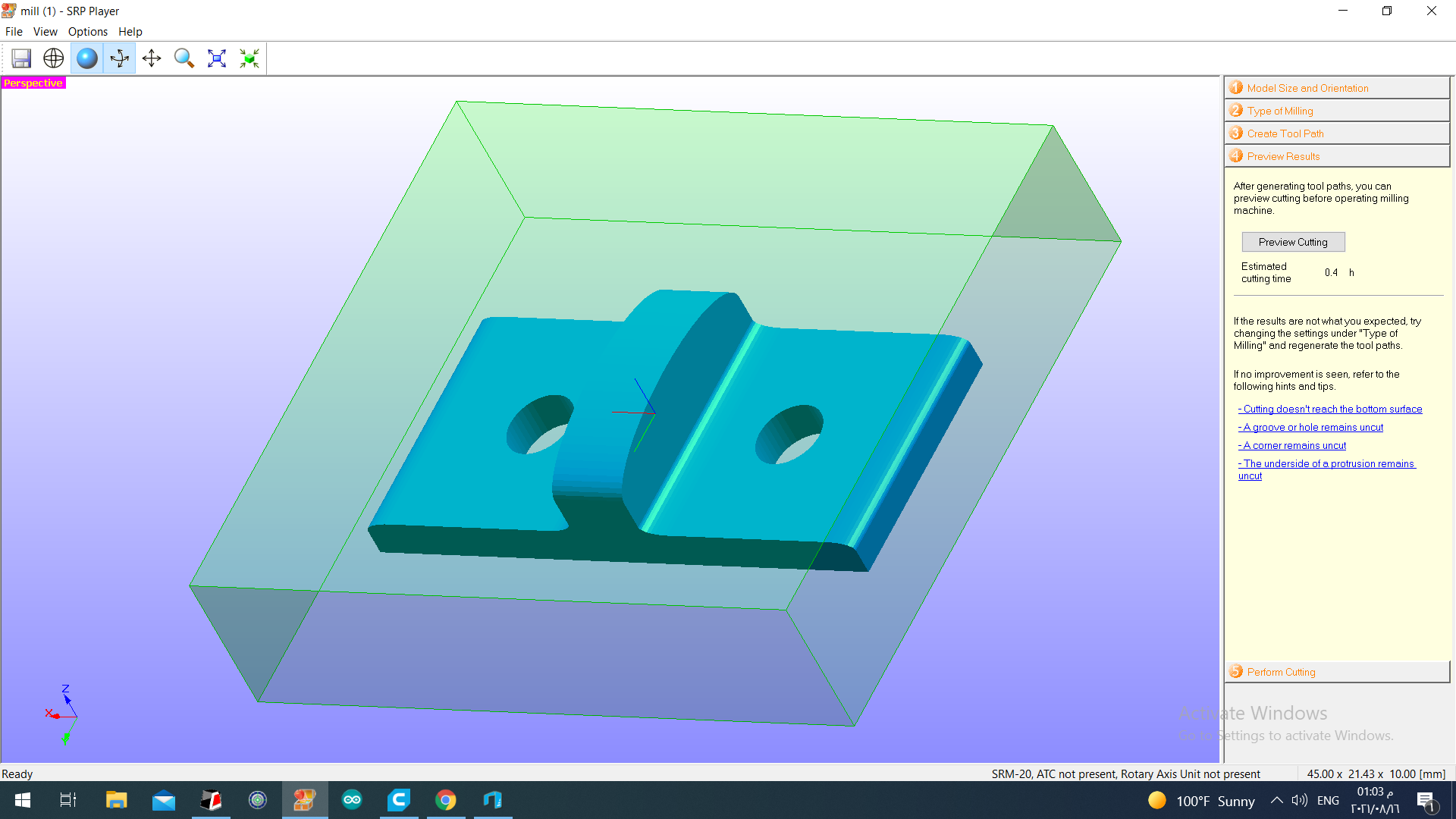

The time needed to finish the design is 0.4 hours.

The time needed to finish the design is 0.4 hours.

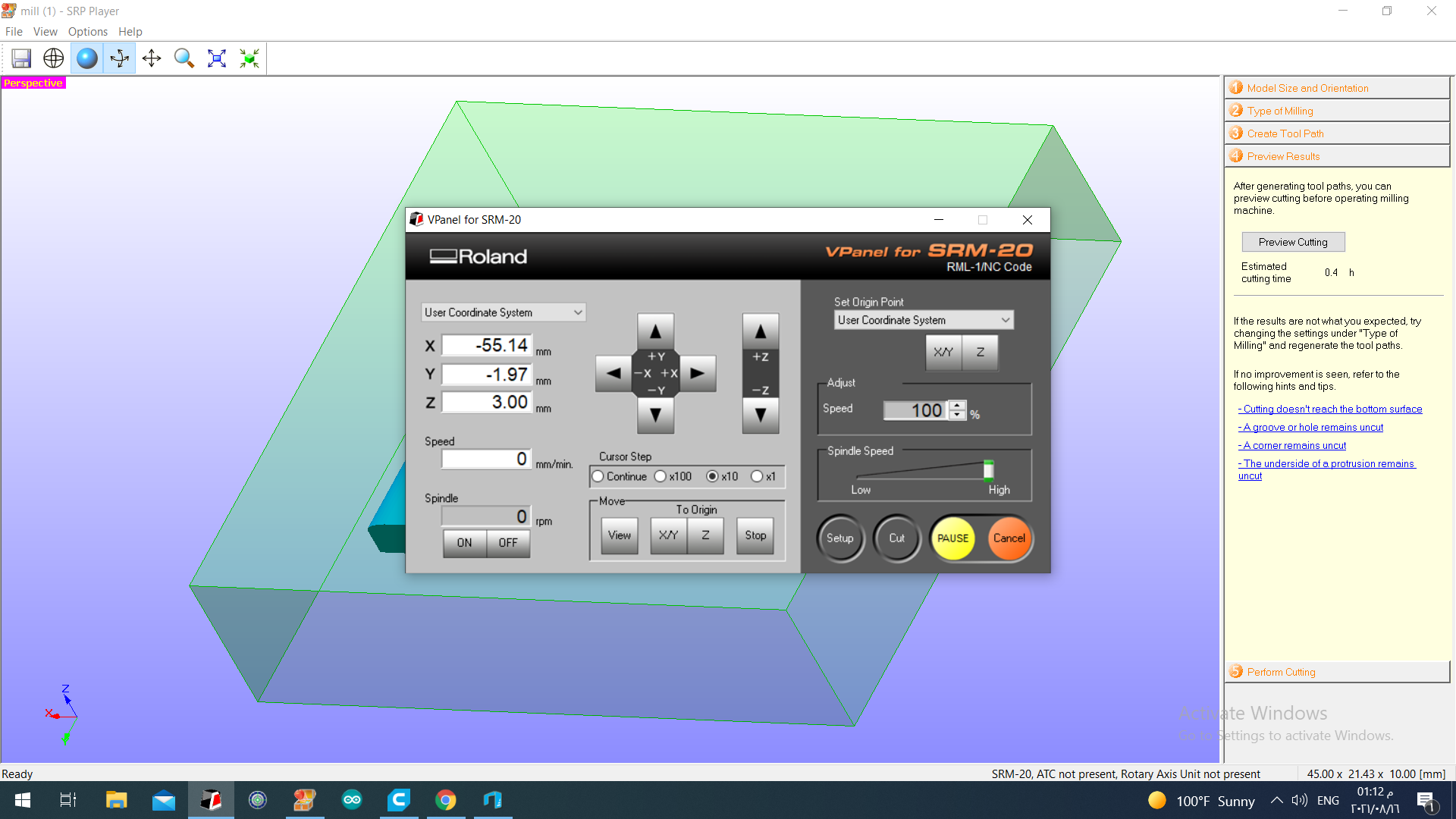

The vpanel is used to move the device bit in the desired x, y and z axis

The vpanel is used to move the device bit in the desired x, y and z axis

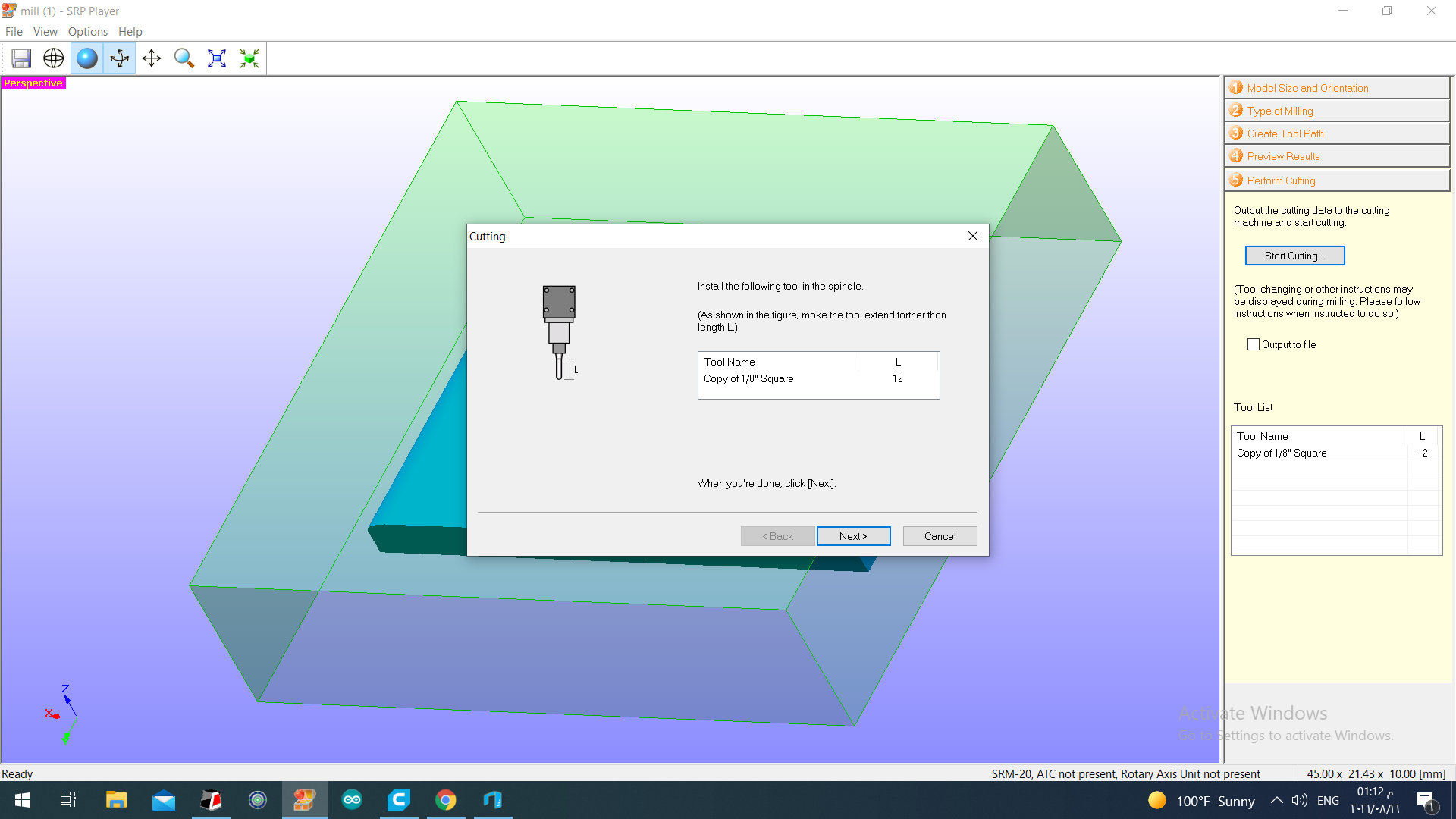

This is the type of drill bit that was used and its 1/8 bit, since there is not much details in my design

This is the type of drill bit that was used and its 1/8 bit, since there is not much details in my design

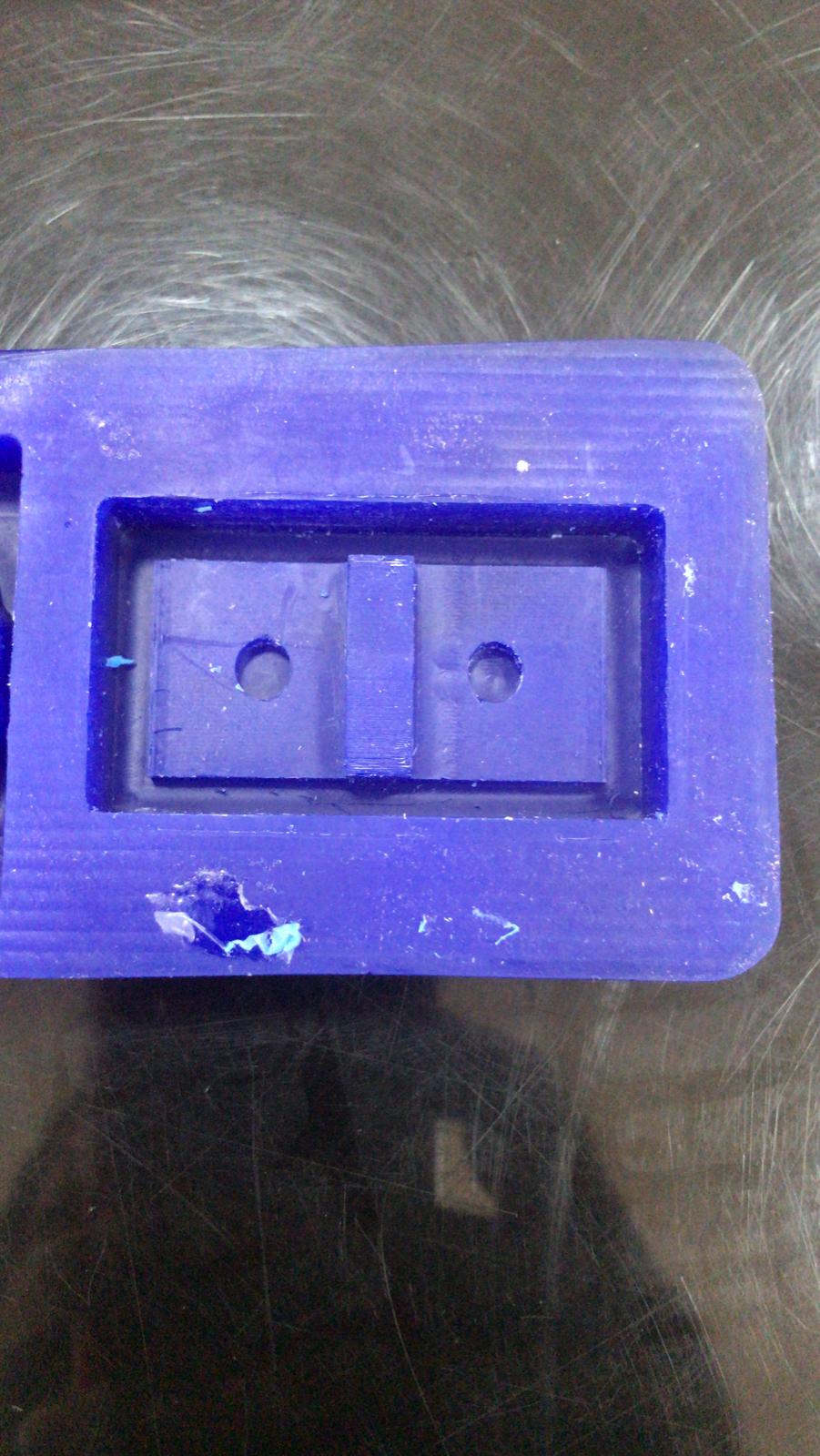

This is how my design looks in the mould

This is how my design looks in the mould

Then 10 grams of white and blue clay were mixed together and added to the mould

Then 10 grams of white and blue clay were mixed together and added to the mould

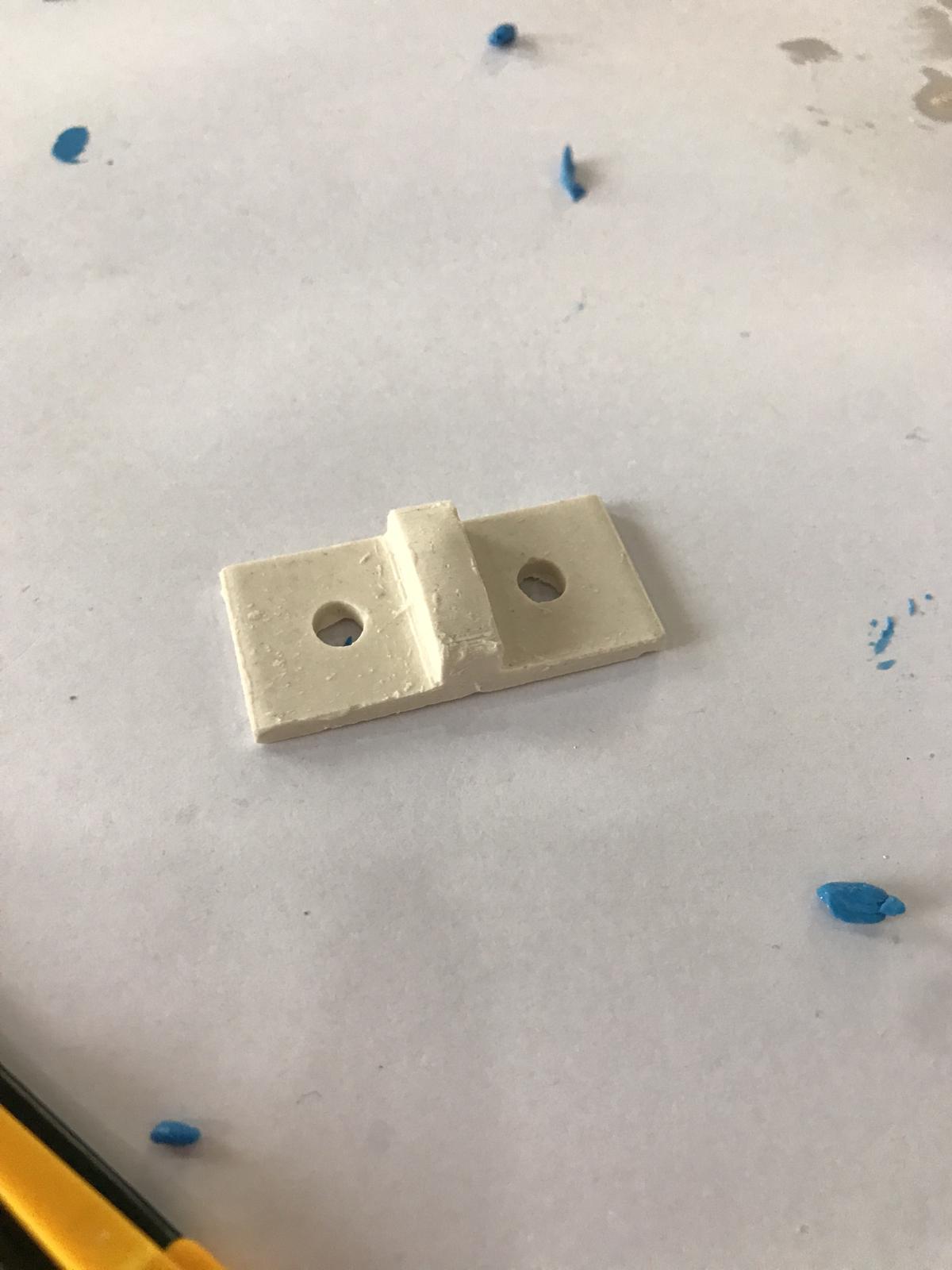

This is the shape after removing the clay from the mould

This is the shape after removing the clay from the mould

After that 10 grams of water and 10 grams of Gypsum were mixed and added to the clay

After that 10 grams of water and 10 grams of Gypsum were mixed and added to the clay

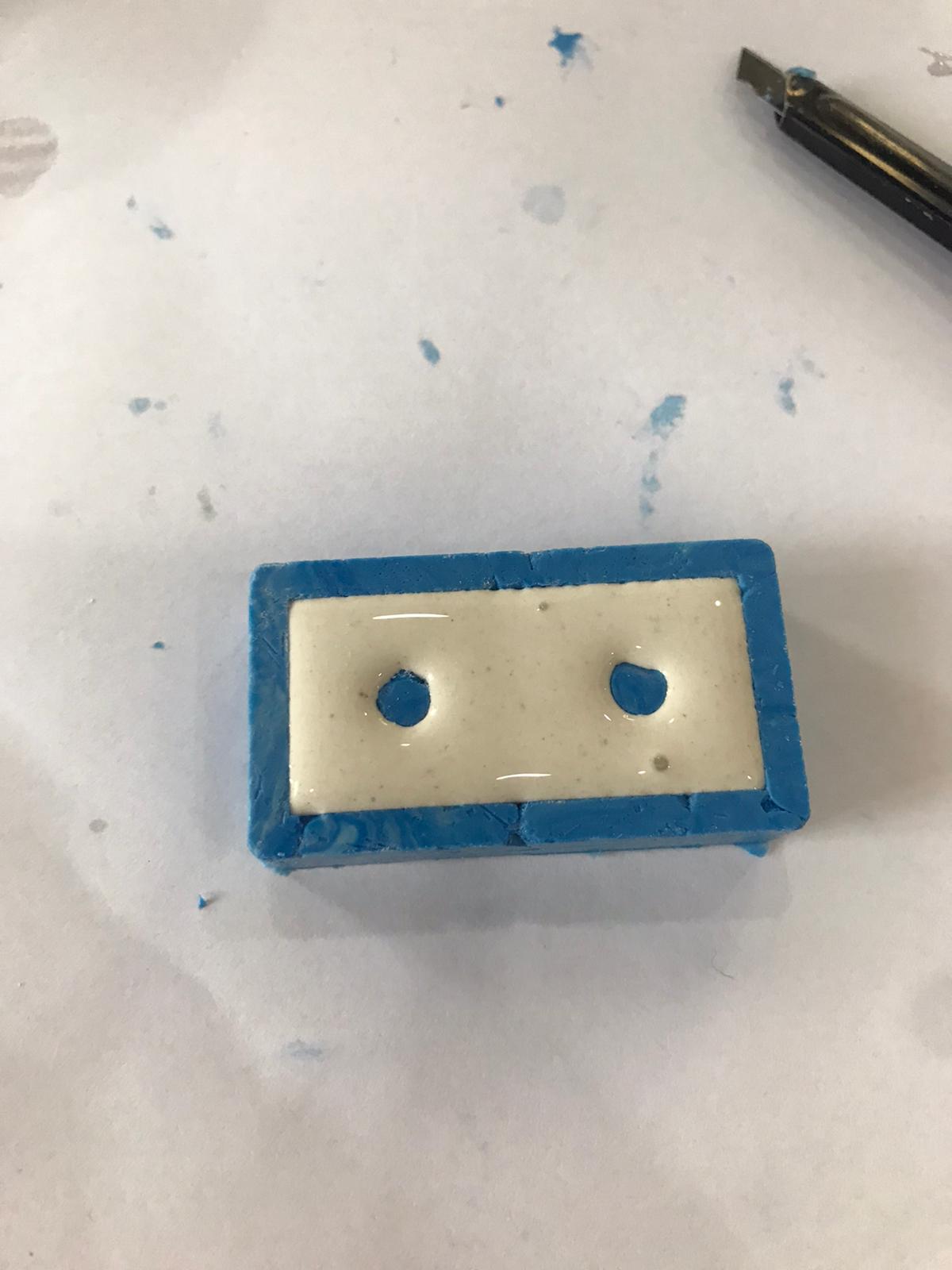

After the mixture has solidified this is how the design looks

After the mixture has solidified this is how the design looks