Safety datasheet for molding and casting materials¶

Prior to use of any material, the safety data sheet must be read thoroughly, and safety precautions must be followed.

The materials used to do the molding and casting were, machinable wax, silicone, epoxy resin, gypsum, and oatmeal (base for soap).

Machinable wax¶

A block of purple machinable wax was used in the milling process. It is solid at room temperature. It is non hazardous, non toxic, and it does not pose any risks to the environment. However, at elevated temperatures, it must be handled with heat-resistant gloves. It can catch fire when heated above flash point (240 degrees Celsius). It is chemically stable, but must be kept afar from strong oxidizing agents, to avoid the production of carbon dioxide and carbon monoxide. More information is given in the link below.

Purple machinable wax safety datasheet

Silicone¶

Silicone was poured into the milled wax. A 2 part silicone system was used, it consists of two viscous fluids that must be mixed together (equal parts by weight) within 15 minutes, one part is a rubber base (part A) and the other is a curing agent (part B). Once mixed together, it solidifies. Both parts are non hazardous, and non reactive and chemically stable in room temperature. More information can be found in the links below.

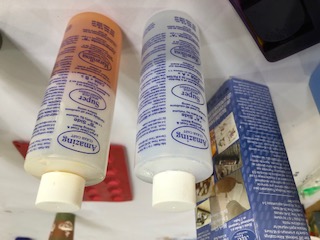

Epoxy resin¶

Epoxy resin was also used in molding and casting. Equal parts by volume of each fluid were mixed thoroughly to form a homogeneous mixture. It is a clear viscous fluid that solidifies completely within 48 hours. This material should be handled in an area with adequate ventilation, to avoid respiratory irritation. In addition, contact with eyes and skin must be avoided. In case of contact with skin, the material must be removed with waterless hand cleaner or alcohol, and then soap and water. In case of eye contact, the eyes must be flushed with water for 15 minutes. The material must be kept away from food and body, when the material is in liquid form. Additional information can be found in the link below.

Gypsum¶

Gypsum is a soft sulfate mineral, it comes in powder form. It is mixed with a water, in a 1:1 ratio, to form a solid. It takes around 15 mins to solidify. Prolonged exposure by inhalation to this material is harmful to the human body. It may cause cancer through inhalation, and may cause damage to lungs, kidneys, and autoimmune system. Also, it causes skin irritation and eye irritation. More information can be found in the link below.

Oatmeal¶

Natural soap was used for molding and casting. The base for the soap is oatmeal. Oatmeal is powdered oats which is a wholegrain. It is non hazardous, non toxic, and causes no harm to the environment. The complete safety data sheet for oatmeal is linked below.

Comparison¶

Silicon is easy and safe to use for molding. It was noticed that bubble formation might be a critical problem faced specially when mixing and pouring at high speed. Nevertheless, it is an excellent molding material when important mixing and pouring instructions are taken into consideration. Its non-reactive behavior makes it even more flexible to use for different casting applications. Epoxy resin is a simple and easy casting material to use. Yet, some safety precautions must be followed when it is in its liquid state as no direct contact with bare skin is recommended. Previously mentioned safety instructions must be followed in case any accident occurred. Gypsum has even more serious precautions to be followed due to its respective severe consequences. Oatmeal soap is the safest and has the most environmentally friendly manner among other materials. In comparison to the time required for casting to dry, soap is fastest to dry which makes it a great activity for kids to execute. In terms of results, all casting materials exhibited superb shapes by catching all the available details of all designs.