Group Assignment 1¶

The goal of the group assignment is to understand the steps to upload the design to the CNC software and edit all the necessary parameters to cut the design.

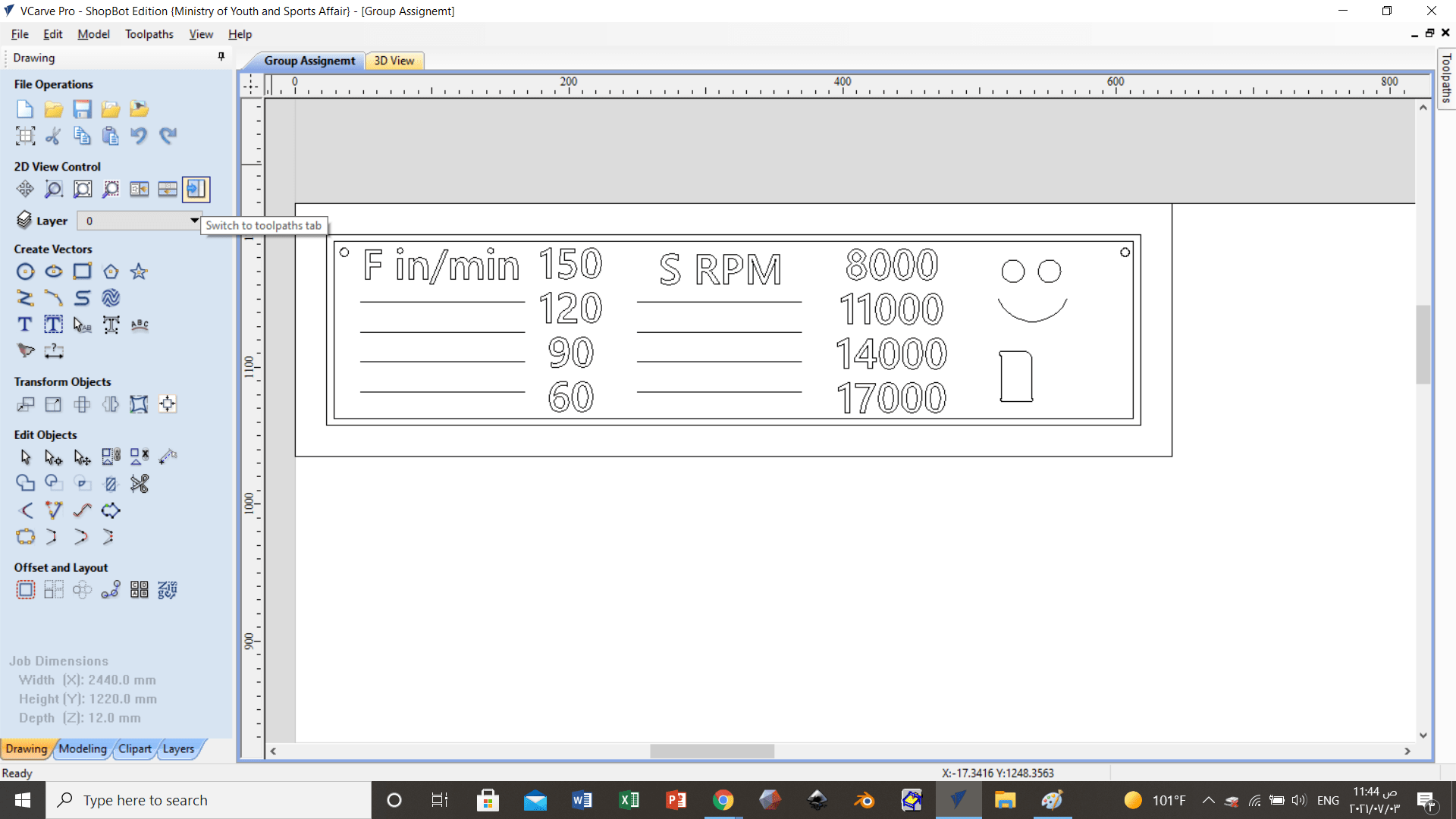

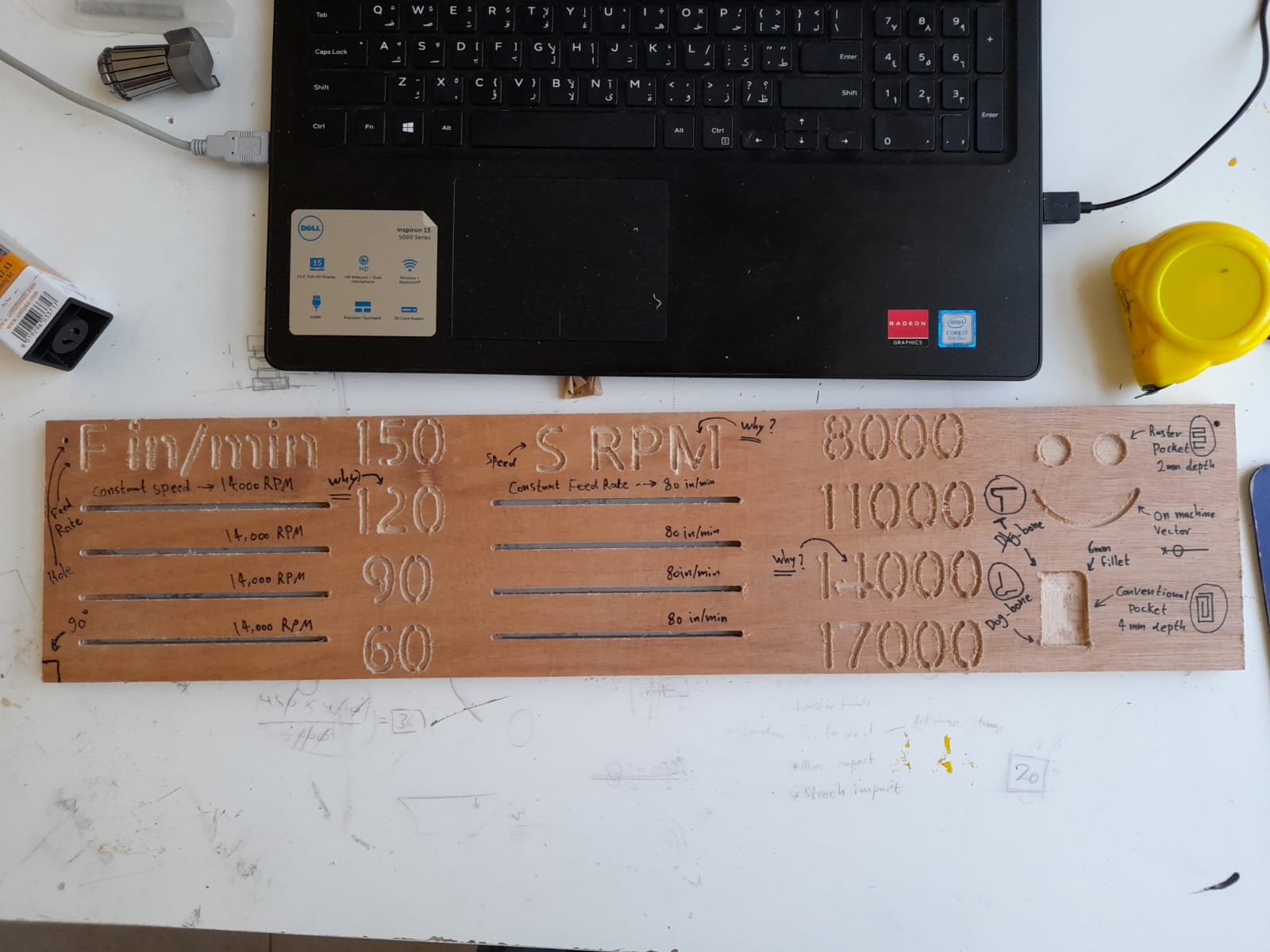

The first thing we did was creating a simple design to display the effect of changing the feed with a constant speed, and the other way around. We also add a happy face drawing to test the Pocket.

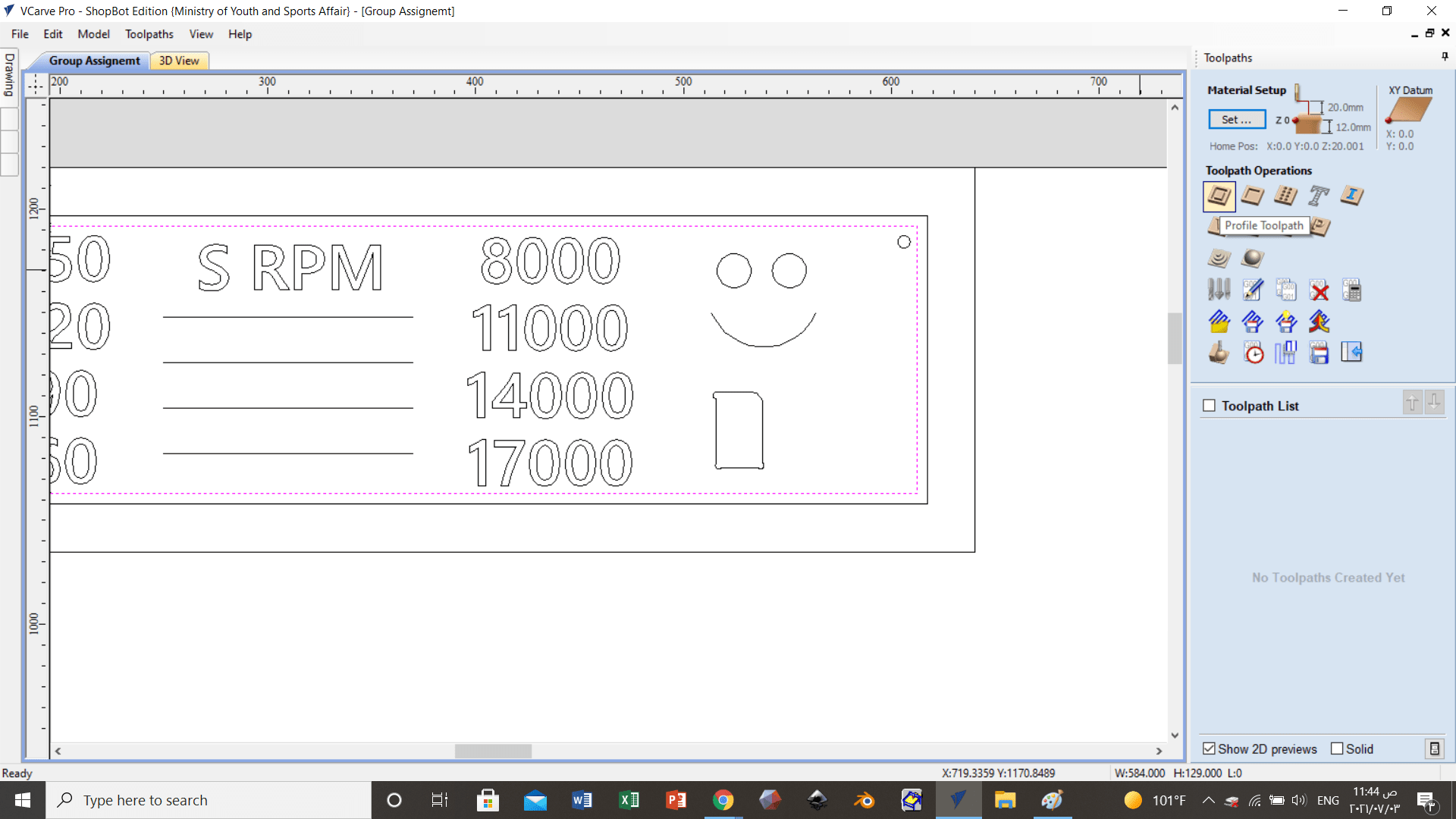

Toolpaths is the feature where you setup the material that will be cut and the method of cutting.

The dashed rectangle present where the cutting will be the toolpath edit tool is used to add the required parameter for the cut. As shown, in the figure it is possible to customize the depth of the cut, tool diameter, speed of cutting, feed rate and the number of passes.

To make sure that the machine cuts through the sheet we add 1 mm extra to the depth of the cut from. The extra cut will go through the sacrifice sheet. This figure shows the error that will pop out to notify you that the thickness of the sheet is not equal to the depth of the cut.

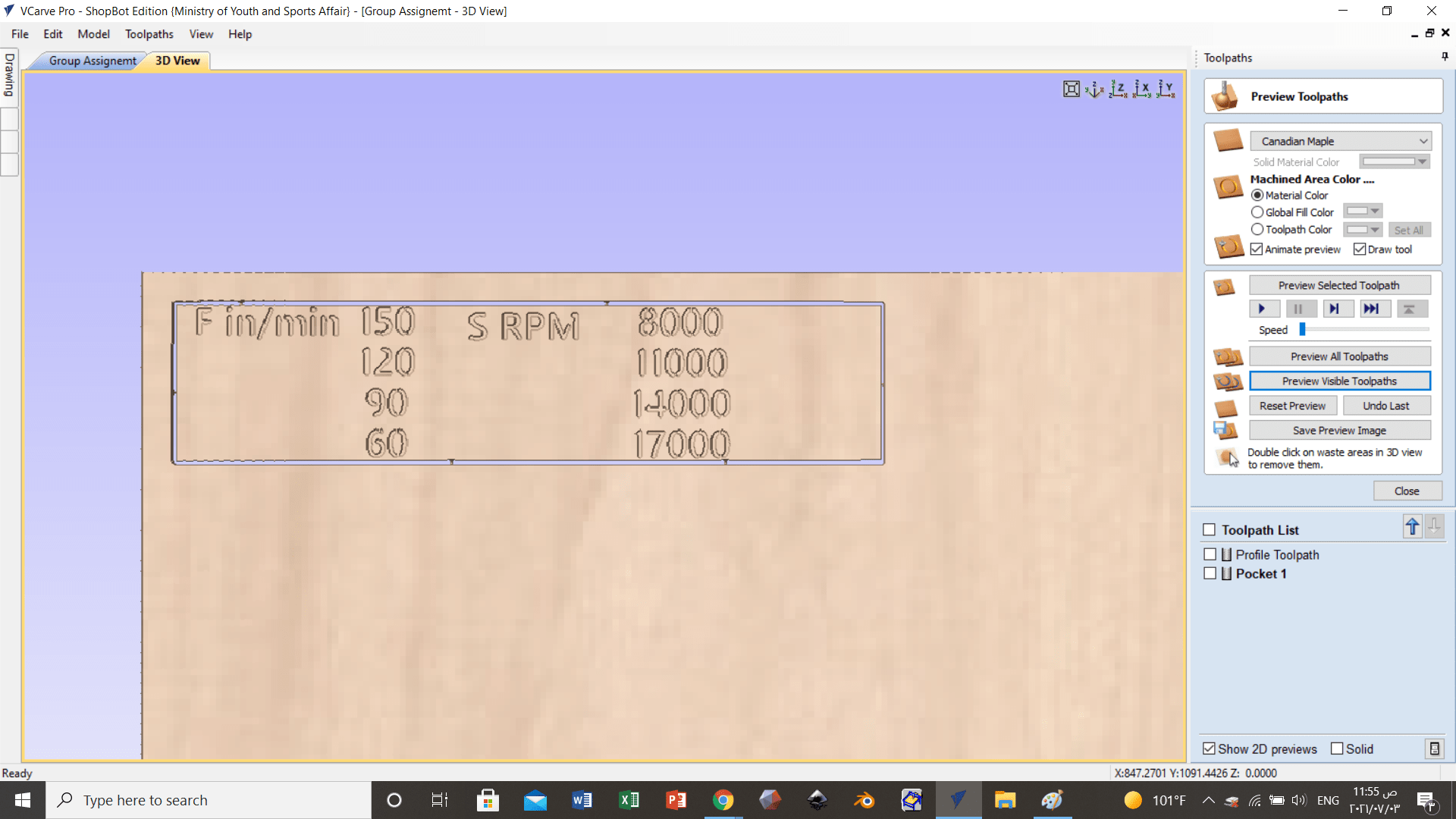

This is a preview of the toolpath operation.

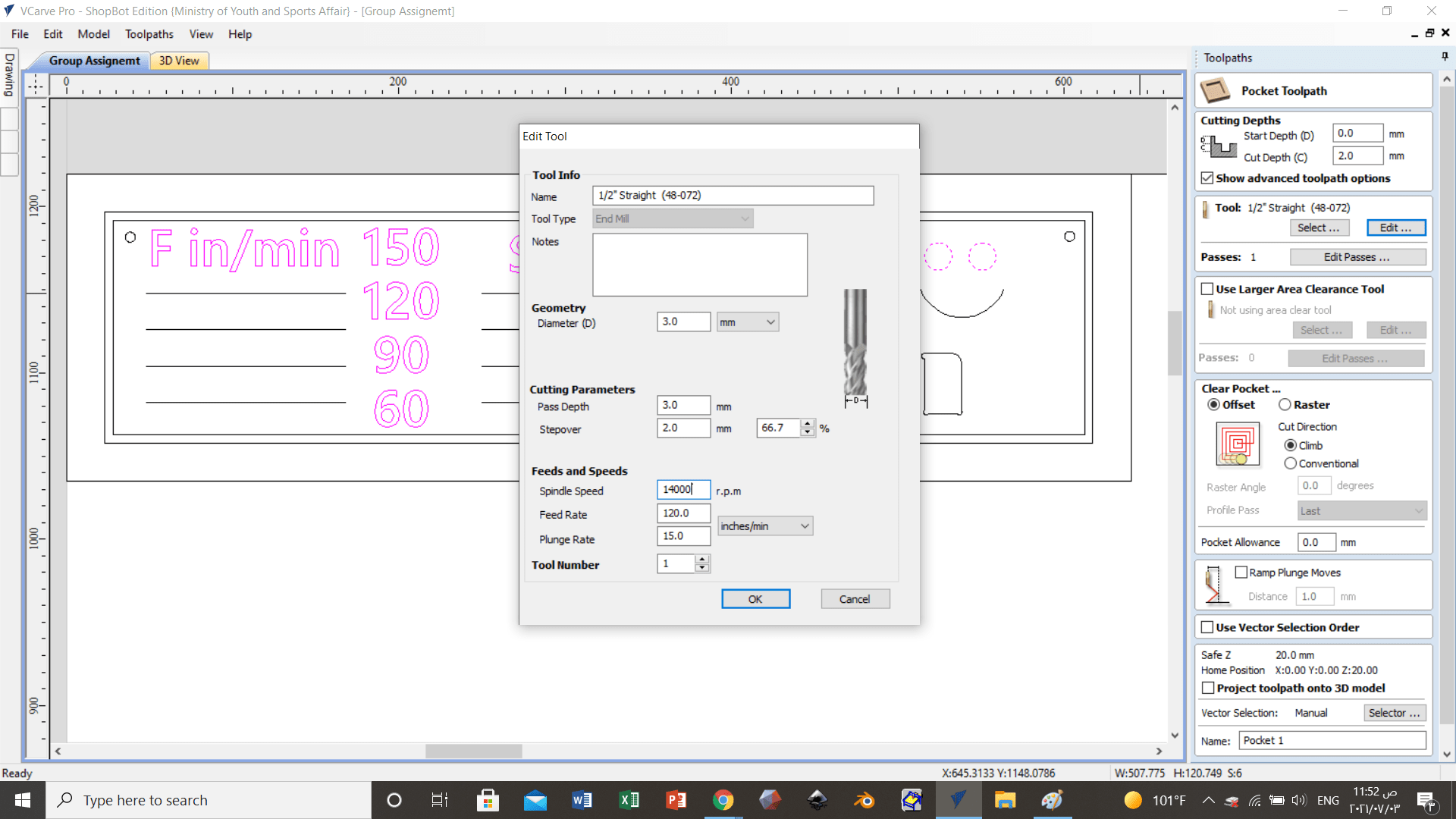

To add pockets we use the pocket toolpath this tool is useful to make engraving, the only change that we made is the depth of the cut all the other parameters are kept the same.

This is a preview after adding the pocket toolpath.

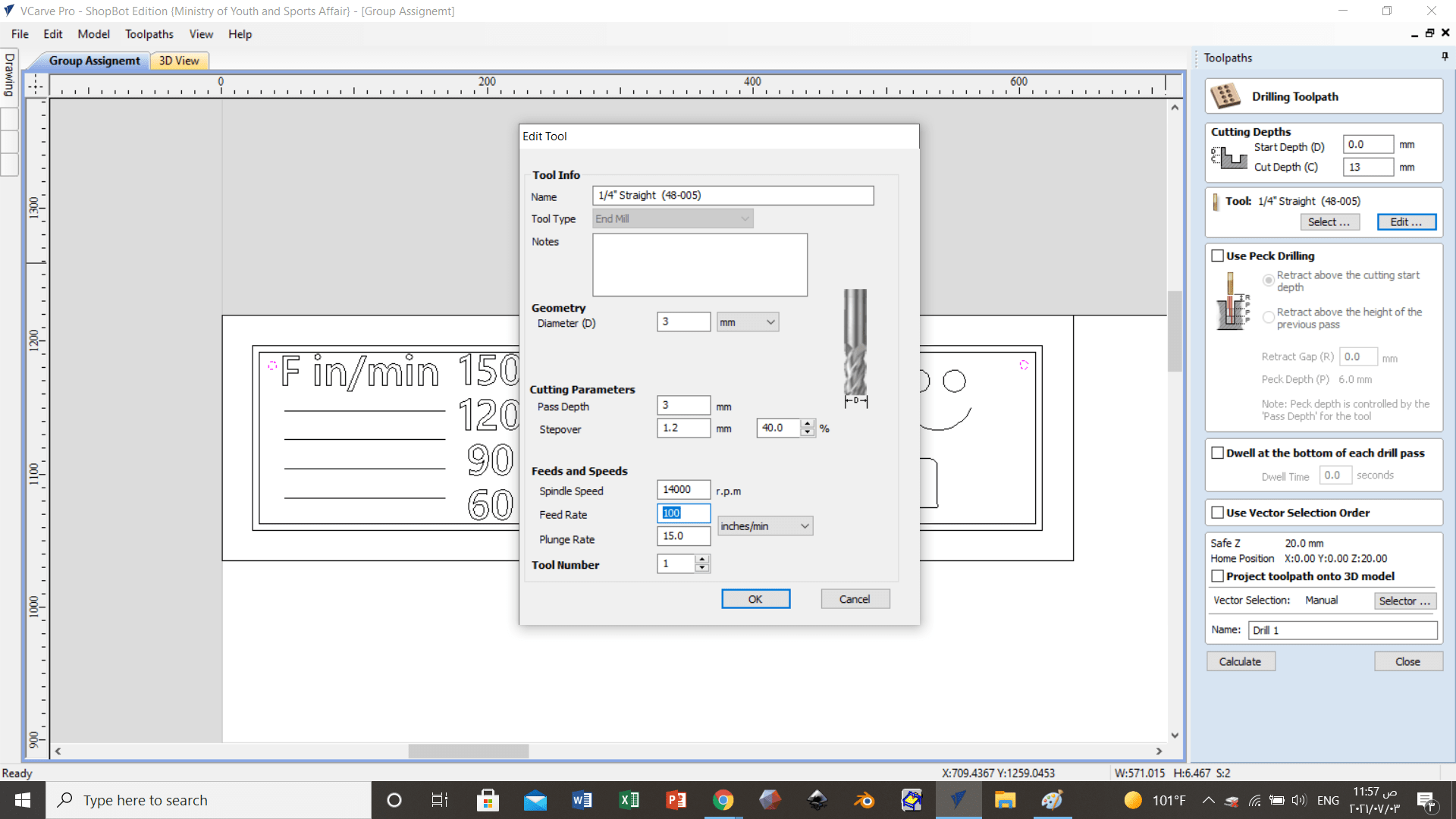

To add holes to the design we use the drilling toolpath. The depth parameter is kept at 13mm. However, the feed parameter is changed to be 100 inches/min.

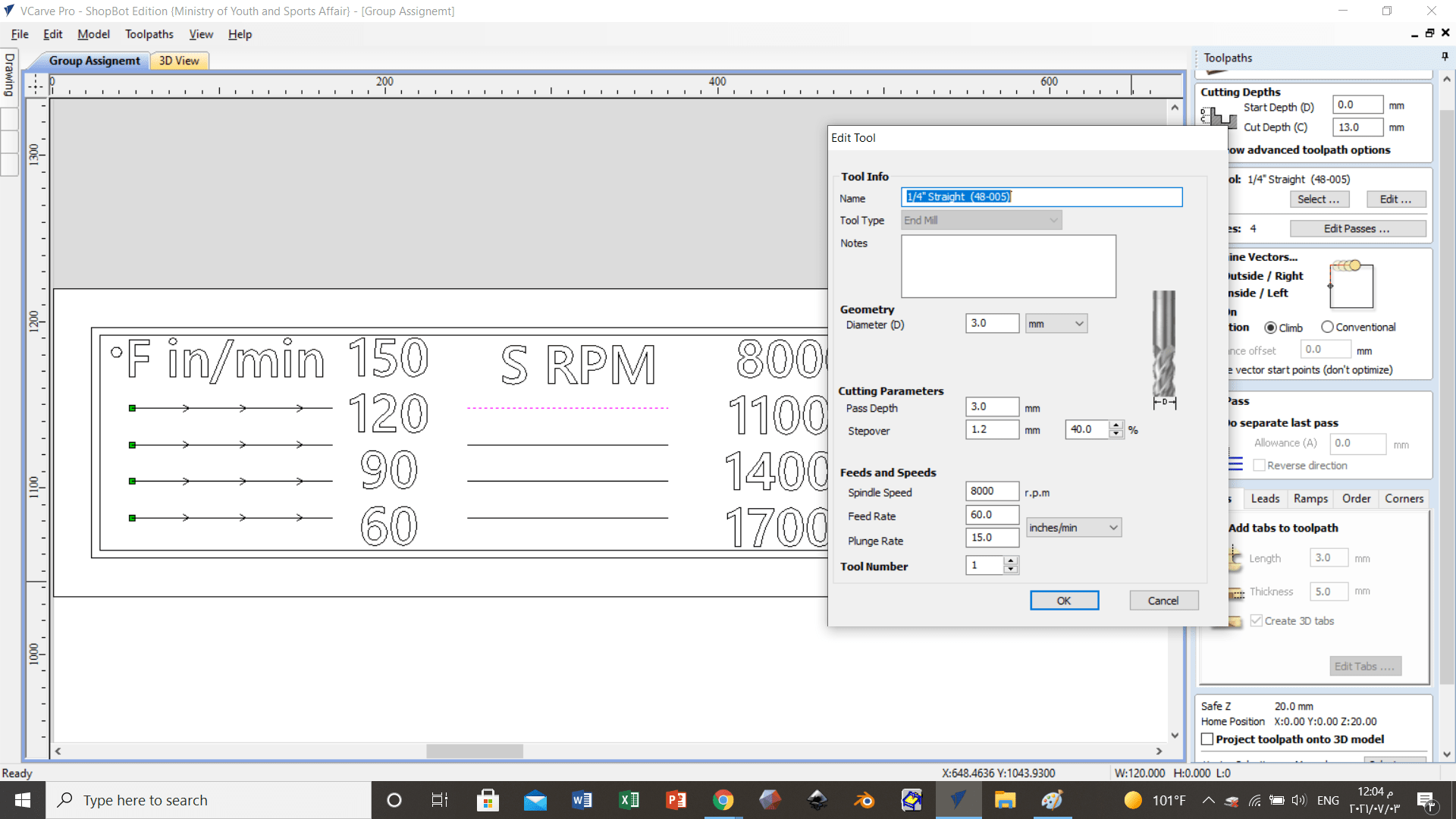

These lines are used to test how the cut changes as u manipulate the feed rate but, keeping everything constant.

The other way around this is used to manipulate the speed of the cut but keeping everything else constant.

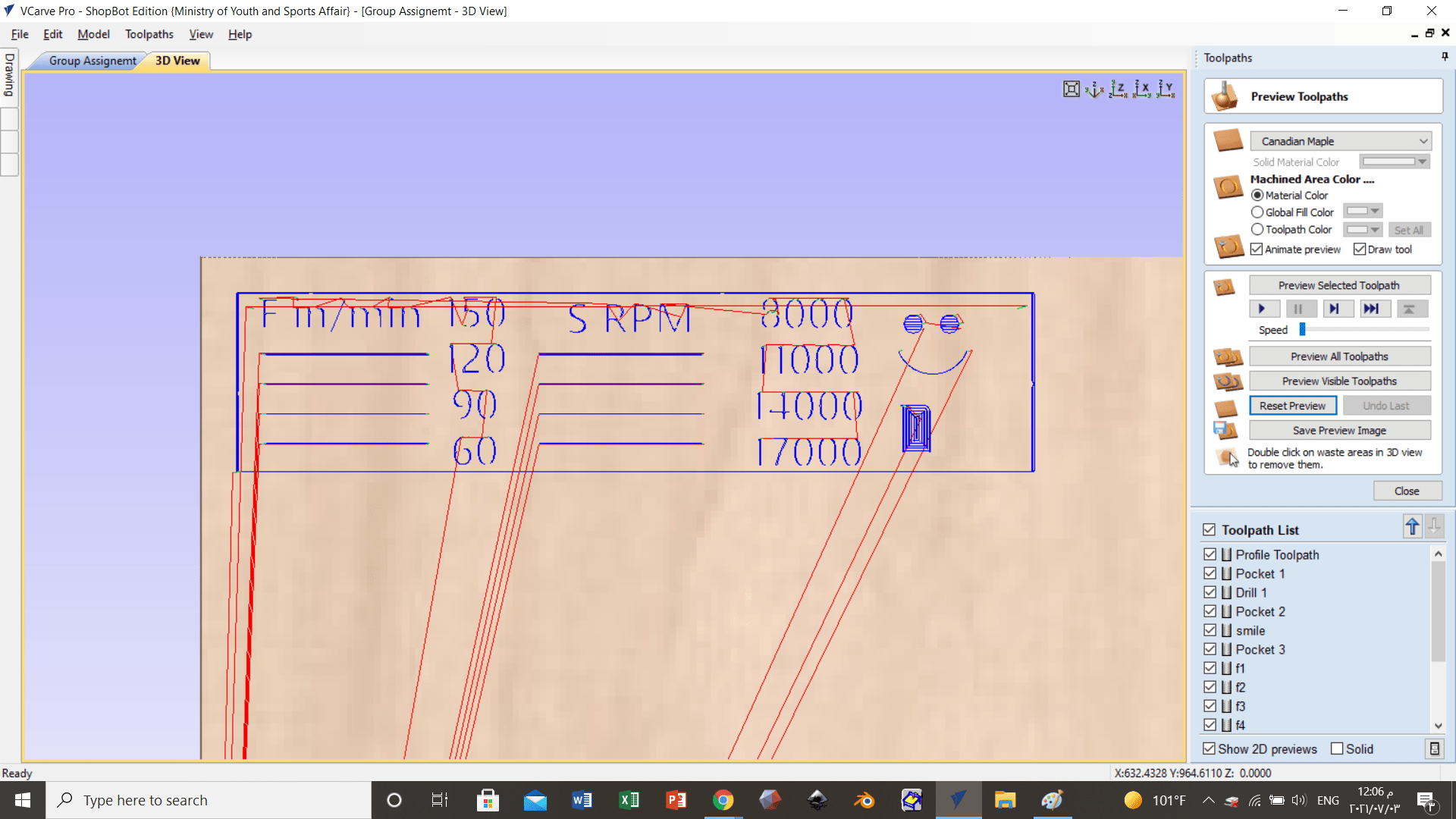

This is the toolpath preview after all the changes were implemented. On the right side we can see the orders of the cut, it is necessary to cut the inside of the rectangle first followed by the outside shape to keep everything fixed in place.

This is a preview of the design after operating the CNC machine. Moreover, Adding Dog bone to the inside edges is necessary to ensure that the device will cut the corners perfectly.

This is a joint test made by “ Abdulla Fadi ” to understand how dimension differences affect the strength of the joints and to help us choose the best dimension for our design as well.